Transcription

quick & easy sheet metalProjectsWorking with sheet metal isn’tdifficult — if you have the righttools. All it takes to make the itemsshown here are some basic tools,a pair of tin snips, and the metalbrake featured in ShopNotes No.108. You’ll also need the patternson the following pages for layingout the cuts and bends.I think you’ll discover that afterfabricating these few simple projects, you’ll be ready to design andbuild your own. And to me, that’shalf the fun of being in the shop— applying what I’ve learned tobuild something that’s practicaland long-lasting.Sheet Metal. The first thing Iwant to talk about is sheet metal.You’ll find it in a variety of thicknesses, or gauges. The higher thegauge number, the thinner thesheet metal. For shop projects likethese, 22-gauge steel is about right.It’s easy to cut and bend but stillhas plenty of strength.Layout. With the patterns onthe following pages and yoursheet metal in hand, it’s time to layout the project. Then all you needto do is cut out the pattern, makethe bends, and spray on a coat ofpaint. The end result is a set ofhandy projects for your shop.Simple Shelf. Page 2Storage Tray. Page 3} Drawer Case & Drawers.Starting on page 6.Tool Rack. Page 4Bit Rack. Page 5ShopNotes No. 108Page 1 of 7 2009 August Home Publishing.All rights reserved.

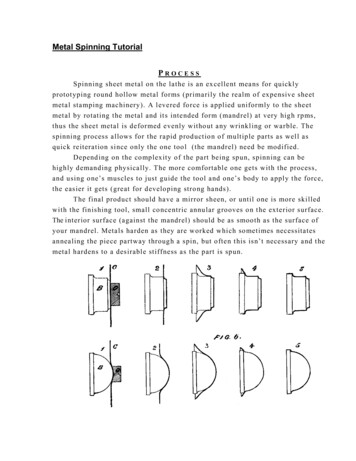

simpleShelf{ Strong and Sturdy. By following the pattern below, you’llcreate a strong shelf complete with braces. A few simple bendswith a sheet metal brake make it easy.4#/44END VIEWNOTE: SHELF MADEFROM 22-ga. SHEET 45#/42#/41#/81!/810NOTE: CIRCLED NUMBERSREPRESENT SEQUENCE OF BENDSShopNotes No. 108Page 2 of 7 2009 August Home Publishing.All rights reserved.

enclosedStorage Tray{ Storage Tray. After drilling the mounting holes in the sheetmetal blank, cut out the shape shown in the pattern. Then youcan make the bends to form the flanges and sides.END VIEW3!/2NOTE: SHELF MADEFROM 22-ga. SHEET METAL%/8319!/4%/167!/2#/16PATTERNNOTE:CIRCLED NUMBERSREPRESENT SEQUENCEOF BENDS2%/841!/2356371%/83ShopNotes No. 10812Page 3 of 7 2009 August Home Publishing.#/83%/8All rights reserved.

wall-mountedTool Rack{ Drill & Bend. To create this wall-mounted tool rack, you startby drilling the holes. To complete it, you then make the fourbends, as shown in the drawings and pattern below.END VIEW221!/41NOTE: RACK MADEFROM 22-ga. SHEET METAL12!/4#/4#/16PATTERN!/2#/423!%/163!/2" DIA.1!!/1628!/441!/4221!!/161#/42!%/161!/2NOTE: CIRCLED NUMBERSREPRESENT SEQUENCE OF BENDSShopNotes No. 108Page 4 of 7 2009 August Home Publishing.All rights reserved.

easy accessBit Rack{ Safe Router Bit Storage. Rubber grommets help protectthe delicate cutting edges and shafts of your router bits. Thedrawings below show you how the rack is made.!/4"-I.D. GROMMET(McMaster-Carr #9307K64)END VIEW22!/2#/4" DIA.GROMMETNOTE: RACK MADEFROM 22-ga. SHEET METAL2!/21!/2"-I.D. GROMMET(McMaster-Carr 2#/4"-DIA.2!/21!!/16!%/161!!/1613!/42#/4NOTE: CIRCLED NUMBERSREPRESENT SEQUENCE OF BENDS#/4ShopNotes No. 108Page 5 of 7 2009 August Home Publishing.!/4!/4All rights reserved.1!/4

sstacked drawerCaseFRONT VIEW7!/4#/8{ Simple Plywood Case. This easy-to-build case holds the!/4four drawers shown on the next page. Simple saw kerfsserve as the drawer slides.!/4!/88(/167%/88!/165!!/16TOP3#/4(9#/4" x 7!/4")1!#/16!/2"-WIDE x !/4"-DEEPRABBET(THREE SIDES)!/8"-RAD.ROUNDOVERSIDEBACK(9#/4" x 8!/16")(6#/4" x 8!/16")NOTE: ALL PARTSMADE FROM !/2" PLYWOODSIDE(9#/4" x 8!/16")BOTTOM(9#/4" x 7!/4")!/2"-WIDE x !/4"-DEEPRABBET(THREE SIDES)ShopNotes No. 108Page 6 of 7 2009 August Home Publishing.All rights reserved.

sheet metalDrawer{ Fast & Easy Storage. With four of these drawers and the caseshown on the previous page, you can create handy storage forsmall items. And it doesn’t take up much space on a shelf.NOTE: FOURDRAWERS REQUIREDDRAWER BOXSIDE VIEW(22-ga. SHEET METAL)NOTE:ATTACH DRAWER FRONTUSING FINISH NAILSBLINDRIVETS1&/89!/8"-RAD.ROUNDOVERDRAWER FRONT(%/8" x 1&/8" - 6!%/16")91!/2#/83!/4#/81!/2!/2!/441(/16!/8!/4 #/86!%/16PATTERN562%/81&/81NOTE: CIRCLED NUMBERSREPRESENT SEQUENCE OF BENDSShopNotes No. 108Page 7 of 7 2009 August Home Publishing.All rights reserved.

sheet metal. For shop projects like these, 22-gauge steel is about right. It’s easy to cut and bend but still has plenty of strength. Layout. With the patterns on the following pages and your sheet metal in hand, it’s time to lay out the project. Then all you need to do is cut out t