Transcription

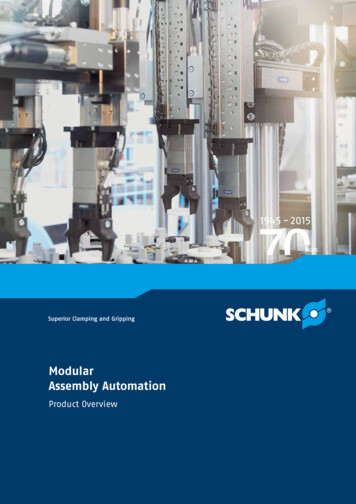

ModularAssembly AutomationProduct Overview

Superior Clamping and GrippingJens Lehmann stands for safe, precise gripping and holding.As a brand ambassador of the SCHUNK team,the No. 1 goalkeeper represents our global competenceleadership for clamping technology and gripping systems.The top performance of SCHUNK and Jens Lehmann arecharacterized by dynamics, precision, and reliability.For more information visit our website:www.gb.schunk.com/LehmannJens Lehmann

Familienseite Broschuere 2016-06 EN AUTOMATICA.pdfHenrik A. Schunk, Kristina I. Schunk, brand ambassador Jens Lehmann, and Heinz-Dieter SchunkTop Performance in the TeamSCHUNK is the world’s No. 1 for clamping technology andgripping systems – from the smallest parallel gripper tothe largest chuck jaw program.As a competence leader, we recognize and developstandards with a large potential for the future, whichwill drive the rapid progress in many industries.In order to boost efficiency, SCHUNK customers havebought more than 2,000,000 precision toolholders,1,000,000 SCHUNK grippers, and 100,000 lathe chucksand stationary workholding systems so far.Our customers profit from the expert knowledge, theexperience, and the team spirit of more than 2,500employees in our innovative family-owned company.This makes us proud and motivates us to attain new topperformances.Heinz-Dieter SchunkThe Schunk family wishes you improved end results withour quality products.Henrik A. SchunkKristina I. Schunk

SCHUNK Modular Assembly AutomationProduct OverviewComprehensive Rangesfrom the Modular System.With pneumatic and electrically driven grippers, rotary units, rotarygripping modules, and linear modules, the modular assembly systemfrom SCHUNK makes it possible to achieve custom handling solutionsin different versions and sizes. The heart of the design is the pillarassembly system that is unique in scope with numerous standardizedpillar profiles, adapter plates, centering and connection elements. Themodular system is enhanced by the SCHUNK pick & place units andstandard gantries. Take advantage of this unique range of possibilities. in your automated handling systemWhat you gain from our system advantages:· Complete range of products· Pneumatic and electric drives· High precision of all individual components· Full compatibility among all actuators· Reproducible connection technology· Extensive assembly adaptation system. in your lathe· Planning security using software toolsPage 8Page 12Page 18SCHUNK GrippersRotary ModulesLinear ModulesWith more than 2,000 possiblecombinations within themodular system, SCHUNK grippers enable a wide range ofindividual solutions.The comprehensive range ofcompact SCHUNK rotary andswivel units for every handlingtask and for a fast and easyintegration. Gripper for small components Rotary actuators Universal gripper Rotary indexing tablesThe most extensive portfolioof linear modules. Includingpneumatic, direct electricdrive or with spindle/beltdrive with short or long strokes. The perfect module forany application. Angular and radial gripper Rotary gripping moduleEGPRST-D4 Linear modules Gantry modulesELP

SCHUNK Modular Assembly AutomationProduct OverviewIt’s time to use your machine’s fullpotential!Our superior components can unlock potential you didn‘t even knowyou had. In your machine. SCHUNK SYNERGY – the perfectly harmonizedrelationship between clamping technology and gripping systems turnsour customers into productivity champions. in your automatedhandling system. in yourservice roboticsapplication. for your automated machine loading. in your machiningcenter. in your automated assembly linePage 22Page 22Page 22Pick & Place ModulePillar Assembly,Connecting ElementsAccessoriesSCHUNK pick & place units arethe fastest choice for compactand time-efficient high-speedprecision with up to 110 picksper minute. Pneumatic ElectricComprehensive modular systemof standardized pillar profiles,adapter plates, centering andconnecting elements, as wellas different standard elementswith the option of media feedthrough.With around 150 sensor variantsand a wide range of highquality accessory components,SCHUNK offers the greatest variety on the market. Measure forces exactly Sense positions Monitor workpieces Minimize energy consumptionPPU-ESAS pillar assembly systemMMS 22-PI5

SCHUNK Modular Assembly AutomationProduct Overview100% Flexibilityfrom the Modular System.Design an infinite number of applications for micro part handling andassembly automation with the SCHUNK modular assembly system. Anincredible variety of automation solutions can be realized with just afew standard modules from the SCHUNK modular system.Page 12Rotary ModulesHigh technology for rotary movements.Over 600 available components.Variable from 180 to infinite rotation.RM-FRST-DRM-WERDERSPage 8SCHUNK GrippersThe most extensive gripperportfolio in the world withover 2,550 pneumatic andelectric PPGN-plusPGN-plus ElectricEGP

SCHUNK Modular Assembly AutomationProduct OverviewPage 18Linear ModulesMore than 450 pneumatic and electriccomponents with up to 7,000 mm stroke.The most comprehensive program on themarket.LMCLMKLMELPHLMELBELMELSPMPBetaDeltaPage 22SCHUNK Pillar Assembly System100% flexible. Achieves a virtually infinitenumber of possibilities for combining components. Pillars up to 1,000 mm long.Media TR7

SCHUNK GrippersModular Assembly Automation2-finger parallel gripperPneumaticMPG-plusMPGKGGNumber of sizes7105Gripping force [N]25 . 3507 . 27045 . 3001.5 . 101 . 1010 . 30Weight [kg]0.022 . 0.630.01 . 0.70.09 . 0.77Recommended workpiece weight[kg]0.17 . 1.250.05 . 1.00.23 . 1.3Closing/opening time [s]0.011 . 0.08/0.011 . 0.080.01 . 0.06/0.01 . 0.060.03 . 0.17/0.03 . 0.17Max. permissible finger length [mm]20 . 8010 . 6442 . 100Repeat accuracy [mm]0.020.020.02IP protection class303040Clean-room class ISO 14644-155Comprehensive ranges Technical dataGripping moment [Nm]Stroke per jaw [mm]Opening angle per jaw [ ]Power supply [V] Options/variantsSpeed versionGripping force maintenance High temperature versionPrecision design Dust-protection versionDescription2-finger parallel gripper withsmooth roller guides of thebase jaws2-finger parallel gripper withsmooth roller guides of thebase jawsNarrow 2-finger parallelgripper with large strokeField of application Gripping and moving Gripping and moving Universal use For small to medium-sizedworkpieces For small to medium-sizedworkpieces For light to medium-sizedworkpiece weights In the areas of assembly,testing, laboratory, pharmacies In the areas of assembly,testing, laboratory, pharmacies With a large range of strokeAmbient conditionsClean Contaminated/ fine dust and liquidsHigh temperature range 90 CClean-room highly suitable/fully supported suitable in special design (on request)* Servo controlled concept for mechatronic SCHUNK components, see page 32. suitable to a limited extentThe products listed here are examples from the extensive SCHUNK product portfolio and are especiallysuitable for modular assembly automation.8

3-finger centric gripperElectric*PneumaticPGN-plusEGPNEW PGN-plus-ElectricMPZ6316123 . 3.22020 . 215110 . 57020 . 3402.5 - 133 . 881 . 50.08 . 1.850.11 . 0.511.010.01 . 1.150.62 . 11.20.2 . 1.0530.05 . 1.150.02 . 0.12/0.02 . 0.120.09 0.210.26/0.260.02 . 0.06/0.02 . 0.0654 . 18032 . 6412516 . 450.010.020.010.012424-30404040/6455 Universal 2-finger parallel gripperwith large gripping force and highmaximum moments due tomulti-tooth guidanceElectric 2-finger parallel gripperwith smooth-running base jawsguided on roller bearingsElectric 2-finger parallel gripperwith integrated motor andelectronics as well as reliablemulti-tooth guidanceSmall 3-finger centric gripperwith base jaws guided on T-slots Optimum standard solution formany fields of application Gripping and moving Optimum standard solution formany fields of application Universal use Universal use For small to medium-sizedworkpieces with flexible forceand high speed Universal use Especially suitable for grippingsmall workpieces In the areas of assembly, testing,laboratory, pharmacies

SCHUNK GrippersModular Assembly Automation2-finger angular gripper2-finger radial gripperPZN-plusSWGPWG-plusGAP58540.01 . 2.83.3 . 114151530 . 900.13 . 1.950.0025 . 0.2130.13 . 1.850.16 . 1.331.3 . 200.007 . 0.460.4 . 2.780.25 . 1.250.02 . 0.2/0.02 . 0.20.015 . 0.03/0.02 . 0.060.06 . 0.14/0.01 . 0.20.09 . 0.35/0.09 . 0.3554 . 14510 . 4264 . 16032 . 650.01 . 0.050.050.020.0540 / 64303040 255 . 5.90050 . 4302.5 . 101 . 25 Universal centric gripper withhigh gripping force andmaximum moments thanks tomulti-tooth guidanceNarrow double-acting 2-fingerangular gripperRobust 2-finger angular gripperwith oval piston and bone drive2-finger angular parallel gripperwith gripper finger actuation ofup to 90 degrees per jaw Universal use due to numerousproduct variants; also inareas where there are specialdemands on the gripper (temperature, chemical durability,contamination, and muchmore) Universal use Universal use Gripping and moving Suitable for applicationswhich require a stacked,space-optimized gripperarrangement For small to medium-sizedworkpieces 10

Modular Assembly AutomationThe NEW PGN-plusThe NEW PGN-plus ElectricThe world-proven gripper on the market –now with NEW permanent lubrication in themulti-tooth guidance. Lifelong maintenance-free.* Guaranteed!The first simple electric gripper with reliablemulti-tooth guidance.Multi-tooth guidance, digital actuation and24 V drive with permanent lubrication.Your benefits:Your benefits: Up to 50% longer gripper fingers due Up to 50% longer gripper fingersthe drive piston Maximum life span due to lubricationpockets in the robust multi-tooth guidance Maximum process reliability due tolimited surface pressure Variety in accessories* More than 50 million cycles under normal, clean operatingconditions.** Size 64: Available starting August 2016, sizes 50, 80 - 175:Available starting September/October 2016 Easy gripping force adjustmentThe gripping force can be adjusted quickly,safely, and manually in four stages Maximum life span due to lubricationpockets in the robust multi-tooth guidance Maximum process reliability due tolimited surface pressureLinear Modules More power due to the increased surface ofdue to higher maximum moments Integrated sensor systemPick & Place Modulesto higher maximum momentsRotary ModulesThe NEW SCHUNK Grippers**SCHUNK GrippersSCHUNK GrippersAlternativeAdaptableIntelligent** Available starting September 2016Patented precision!Patentierte Präzision!AccessoriesPillar Assembly Connecting ElementsMulti-tooth guidanceVielzahnführung11

Rotary ModulesModular Assembly AutomationRotary ActuatorsRotary indexing rive typeDouble piston rack andpinion drive Rotor drive Torque motor Technical dataNumber of sizes5433Torque [Nm]0.05 . 1.90.7 . 220.4 . 1.23.1 . 29.3Angle of rotation [ ]10 . 19090 . 1800 . 36022.5 . 90End positionadjustability [ ]90500Weight [kg]0.046 . 1.160.65 . 8.31.2 . 1.81 . 8.3Max. permissible mass0.023moment of inertia [kgm²]0.270.00120.6Repeat accuracy [ ]0.082 . 0.150.036 . 0.0460.010.04IP protection class404040 . 5450Options / variantsCenter position Rotary feed-through DescriptionLight and fast flat rotaryactuatorRotor with high torque for Powerful torque motorfast swiveling taskswith absolute-valuetransducer and electricand pneumatic rotaryfeed-throughsRing indexing unit forendless turning with arotation angle up to 90 per cycleField of applicationThe optimum solution foreasy to moderatelydifficult swiveling tasksFor use in clean to slightly Use as highly dynamicdirty environments.electrical turning andpositioning unit with aflexible angle of rotationUse as a stationaryindexing table for fastmovement and cycletimesAmbient conditionsClean Slightly dirty Extremely dirty highly suitable/fully supported* Servo controlled concept for mechatronic SCHUNK components, see page 32.The products listed here are examples from the extensive SCHUNK product portfolio and are especiallysuitable for modular assembly automation.12

Rotary gripping modules with 2-finger parallel gripperElectric*PneumaticERSGSM-PRPNumber of sizes45Gripping force [N]/opening angle[Nm]33 . 16250 . 420Stroke/opening angle per jaw[mm]/[ ]1.5 . 102.5 . 83Weight [kg]0.37 . 1.510.5 . 1.942.5 . 10Torque [Nm]0.35 . 2.70.38 . 1.90 . 360Angle of rotation [ ]0 . 1800 . 1900Recommended workpiece weight[kg]0.2 . 0.610.25 . 1.42.7 . 10.9Closing/opening time [s]0.01 . 0.05/0.01 . 0.050.015 . 0.06/0.015 . 0.060.6Max. permissible finger length [mm]32 . 6440 . 75Repeat accuracy [mm]0.020.023040Technical data 0.01 . 0.04Power supply [V]40 . 54IP protection classOptions / variantsGripping force maintenance Electric rotary actuatorwith torque motor andangle of rotation 360 in optional protectionclass IP 54 plus optionalrotary feed-through andholding brakeStationary use as anindexing table orpositioning system withflexible rotation angles Intermediate position Rotation adapter DescriptionCompact rotary gripper combination,consisting of a powerful rotor driveand a 2-finger parallel gripperCompact 2-finger parallel rotarygripper module with double pistonrack and pinion swivel driveField of applicationFor gripping and swiveling small tomedium-sized workpieces in cleanenvironmentsFor gripping and swiveling workpiecesin clean environmentsAmbient conditionsClean Slightly dirtyExtremely dirty highly suitable/fully supported* Servo controlled concept for mechatronic SCHUNK components, see page 32.

Rotary ModulesModular Assembly AutomationGripping modules with 3-fingercentric grippersGripping modules with 2-fingerangular grippersElectric*PneumaticRMPGEGSRCRW515510 . 283050 . 4200.6 . 6.01.2 . 2.232.5 . 83 . 160.1 . 0.2230.550.54 . 2.250.5 . 1.840.38 . 1.90.38 . 1.90.05 . 0.2240 . 1850 . 2700 . 1900 . 1900.05 . 0.140.150.25 . 1.40.25 . 1.40.01 . 0.030.05/0.050.015 . 0.06/0.015 . 0.060.015 . 0.0612 . 203240 . 10025 . 400.020.020.020.02 . 0.0530304040 Compact 2-finger parallelminiature rotary gripper modulewith junction roller guide for highaccuracy when grippingCompact electrical 2-fingerparallel rotary gripper modulewith smooth-running rollerbearing guideCompact 3-finger centric rotarygripper module with doublepiston rack and pinion swiveldriveCompact 2-finger angular rotarygripper module with doublepiston rack and pinion swiveldriveFor gripping and swiveling smallworkpieces in clean environmentsFor the electrical gripping andswiveling of small to mediumsized workpieces up to 270 For the centric gripping andswiveling of small workpieces inclean environmentsFor gripping and swiveling smallworkpieces in clean environments 14

Modular Assembly AutomationThe world's most compact electric rotarygripping unitERS Electric Rotary Module with DDFRotary Feed-throughCompact, dynamic and uniquely versatileThe SCHUNK ERS electric rotary module offers theoption of a pneumatic and electrical rotaryfeed-through. This module is driven by a torquemotor with a hollow shaft and features a rotaryfeed-through, making it one of the most compactelectric rotary modules with an integratedpneumatic and electrical feed-through on themarket. As standard, the rotary feed-through hasmore than eight signal feed-throughs and apneumatic air duct.Your benefits:Your benefits:Small dimensions58 mm x 45 mm x 89 mm Backlash-free pre-loaded junctionroller guides for high-precisiongripping and virtually constant grippingforce over the entire finger lengthSwiveling time 0.18 s/180 Gripping time 0.05 s/strokeGripping force is 30 NFreely definable rotating angle between40 and 320 Torque from 0.04 NmBrushless 24 V-DC motors4 digital inputs (open gripper, close Extremely low-profile design Pneumatic and electrical feed-throughs Endless turning at up to 250 rpm Great process versatility due to free choiceof intermediate positions Easy system integration High acceleration and short cycletimes due to high torquegripper, turn left, turn right)www.gb.schunk.com/EGSAccessories Pillar Assembly Connecting ElementsPick & Place ModulesLinear ModulesFor the first time, the SCHUNK EGS electric grippingand swiveling unit successfully combines electricgripping and swiveling in confined spaces in onesingle housing. The affordable and low-maintenance standard component paves the way forhighly efficient pneumatic-free systems. Couplingof the gripping and rotation gear, patented bySCHUNK, allows endless turning without anelectric feed-through.Rotary ModulesEGS Electric Rotary Gripping UnitSCHUNK GrippersRotary Moduleswww.gb.schunk.com/ERS with DDF15

Linear ModulesModular Assembly AutomationLinear modulesPneumaticLMCLMKLMDrive typePiston rod cylinders Rodless cylinderDirect drive (linear motor)Spindle driveToothed belt driveRack and pinion driveTechnical dataNumber of sizes564Useful stroke [mm]0 . 4500 . 1500 . 300Driving force [N]50 . 75325 . 48250 . 753Repeat accuracy [mm] 0.01 0.01 0.015Weight [kg]0.44 . 15.650.07 . 5.250.5 . 12.6Max. number of intermediatestops302Adjustable end positions ActuationPneumatic valvePneumatic valvePneumatic valveIP protection class404040/64Junction roller guideJunction roller guideJunction roller guideMeasuring systemGuidance typeOptions / variantsDust-tight BellowRod lock Load compensationDescriptionUniversal linear module forchallenging positioning tasksMini-slides for universal useRobust linear module for versatilemoving tasksField of application For demanding requirementswith respect to precision, flexibility and rigidity Ideal for short stroke applications with high demands forprecision Optimal use as Z-axle in handling modulesAmbient conditionsClean Slightly dirty fully supported* Servo controlled concept for mechatronic SCHUNK components, see page 32.The products listed here are examples from the extensive SCHUNK product portfolio and are especiallysuitable for modular assembly automation.16

Electric*HLMELPELBELM 43120 . 1500 . 2000 . 1250 . 26050 . 48217 . 104150160 0.01 0.01 0.01 0.050.5 . 5.571.8 . 8.32.3 . 2.91.5 . 5.500Freely programmableFreely programmableExternal controllerExternal controller Pneumatic valve Digital signals40Junction roller guideIncremental or absoluteHall-effect sensorJunction roller guideJunction roller guideProfiled rail guideYes, via MagSpringYes, via MagSpring Compact stroke module with baseLinear module with 24 V power supply, Short-stroke axis with linear motorintegrated control unit, backlash-free drive and junction roller guidespre-loaded junction roller guidesCompact stroke module with directdrive and integrated measuringsystem For lifting workpieces Electric alternative to pneumaticlinear modules For the versatile and dynamicmovement of small loads Ideal for space-optimized applications For light moving tasks and shortstrokes with high precision For dynamic and precise shifting orfor controlled press-in operation ofworkpieces

Linear ModulesModular Assembly AutomationGantry axesELSPneumaticElectric*PMPBetaDelta 22220 . 2600 . 27000 . 77700 . 7340150100 . 25018.00010.000 0.01 0.02 0.03 0.031.2 . 4.73 . 8.8Freely programmableSeveral ntroller on external motorPneumatic valveController on external motorController on external motorHall-effect sensorMotor-dependentDouble-profiled rail guideDouble-profiled rail guide Motor-dependentProfiled rail guideProfiled rail guide Compact stroke module withspindle drivePneumatic gantry axis for broadstroke rangesGantry axis with different driveconcepts for universal useFlat height gantry axis for largeloads with different drive concepts For applications with high driving force and precision Robust and precise gantrysystems Spindle drive for high precisionand driving force Spindle drive for high precisionand driving force Toothed belt drive for dynamicmovements Toothed belt drive for dynamicmovements 18

LM Pneumatic Linear ModuleELP Electric Linear ModuleStandard solution for high-precision applicationsThe new benchmark for mechatronic linearmodules.The SCHUNK ELP is the most easily adjusted electriclinear module on the market and is put intooperation more quickly than the pneumatic linearmodule. As there is no shock absorber installed, theSCHUNK ELP is practically wear-free, making it robustand long-lasting. Actuation can be distributed usinga fieldbus distributor or directly over digital signals.Linear ModulesThe linear modules of the LM series are equipped with pre-loaded junction rollers in hardenedprismatic running rails as guides. This precisionguidance system ensures absolute freedom fromplay in the overall system and offers high loadcapacities in all directions.SCHUNK GrippersModular Assembly AutomationRotary ModulesLinear Modules Closed slide construction for high rigidityShock absorbers and proximityswitches integrated in the projectingsurfaces for vibration-free movements andend position monitoring Compact dimensions for minimal interferingcontours in the entire system Pre-loaded junction roller guides andtherefore free from play Pick & Place Modules Your benefits:Simple 1:1 replacement of pneumaticcomponents with mechatronic componentsStart-up in only 2 steps Simple speed adjustment using two rotary switches 0.01 mm repeat accuracy No shock absorber, meaning fewerwearparts and longer maintenance intervalsPillar Assembly Connecting ElementsYour benefits:High load capacity in all directionsStandardized mounting bores fornumerous combinations with othercomponents from the modular systemRod lock by means of a clampingcartridge for safety in case of emergency stopsAccessories 19

Pick & Place ModulesModular Assembly AutomationLinear pick & placeLifting / rotary unitStandard PU-EDRLLPPNumber of sizes2321Horizontal stroke in Y [mm]121 . 2100 . 28030 . 450 . 150Technical data300 . 1.500Horizontal stroke in X [mm]Vertical stroke [mm]23 . 40Rotating angle [ ]25 . 22590 . 180Useful load[kg]0 . 30 . 50 . 30 . 5Repeat accuracy [mm] 0.01 0.01 0.01 0.01Weight [kg]4.5 . 15.515 . 352.7 . 5Max. cycle time/picks per minute95075ActuationPneumatic valveExternal controllerPneumatic valvePneumatic valveIP protection class40404040Guidance typeJunction roller guideProfiled rail guideGuidance/deep groove ballbearingProfiled rail/junction rollerguideNumber of possible combinations234Options / versionsRod lock Center positionIntegrated valve Additional C-axis Drive packageDescriptionCompact 2-axis unit forrunning a typical pick &place motionCompact 2-axis unit forflexible running of anycurve on one planeCompact lifting/rotary unitconsisting of a powerfulshort-stroke cylinder and arack and pinion swivelactuatorLine gantry with ahorizontal, pneumaticgantry axis, and a vertical,pneumatic linear moduleField of applicationFor rapid and precisetransfer of workpieces inhigh-speed assemblyFor rapid and precisetransfer or controlledpress-in operation ofworkpieces in high-speedassemblyFor rapid and precisetransfer and turning ofworkpieces in high-speedassemblyFor easily conducting themost common two-dimensional handling andassembly tasks for small tomedium-sized workpieces Ambient conditionsClean Slightly dirty fully supported* Servo controlled concept for mechatronic SCHUNK components, see page 32.The products listed here are examples from the extensive SCHUNK product portfolio and are especiallysuitable for modular assembly automation.20

Modular Assembly AutomationPick & Place Unitselectric*Cycle times, repeat accuracy and process reliability –these are three critical factors for the automatedassembly of small and medium-sized parts.SCHUNK pick & place units are specially designedfor these exact factors.RPERotary ModulesLPEThe modular solutions from SCHUNK cover anyindividual requirement imaginable. The compactpick & place units are especially adept withhigh-speed applications.2SCHUNK GrippersPick & Place Modules2Linear Modules500 . 1.500100 . 5000 . 200 . 20 0.01 0.01Controller on external motorController on external motor4040Profiled rail guideProfiled rail guide90150 Line gantry with a horizontal, electricbelt drive axis, and a vertical, electricspindle axisRoom gantry with two electrictoothed belt axes in a horizontaldirection, and one electric spindleaxis in a vertical directionFor easily conducting the mostcommon two-dimensional handlingand assembly tasks for medium-sizedand large workpiecesFor easily conducting the mostcommon three-dimensional handlingand assembly tasks for medium-sizedand large workpieces Your benefits: Up to 110 picks per minute possible Up to 50% shorter cycles possible with the PPU-Ppick & place unit due to forced guidance over curvedrollers 100% compatible with modules from the SCHUNKmodular assembly automation systemPillar Assembly Connecting Elements100 . 500Pick & Place Modules500 . 1.500 Up to 100% less cable breakage with the PPU-Epick & place unit, as there is no moving motor cable Repeat accuracy upprecision to 0.01 mm for maximumFive solutions for all weight classes – handling afew grams up to several kilograms21Accessories500 . 1.500

Pillar Assembly SystemComponent OverviewSCHUNK SAS Pillar Assembly System.Over 10,000 possible Combinations.With more than 10,000 possible combinations, SCHUNK offers the world‘s most extensive modular range of pillar assembly applications. The SCHUNK pillar assembly systemallows for a combination of diverse handling modules without mechanical adaptationby means of mounting and centering holes, for an exact fit and angular precision aswell as the safe, stable, and reproducible mounting of components.323122

1Rotary ModulesComponent OverviewSCHUNK GrippersPillar Assembly SystemVEH Adjustment UnitFor easy fine adjustments to the finished assembly· For linear and rotary compensation· Adjustable with hexagon socket wrench2Pick & Place ModulesLinear Modules· Suitable for single and double socketsPillar Assembly SystemFlexible. Quick. Precise.· 3 different pillar diameters· 17 elements, combined as desiredMedia Feed-throughFast and easily combined from the modular system· Exact hose guide and cable feed-through possible· Either through the hollow pillars or attached with clips along thepillars· The media hose for actuator supply can be directly attachedAccessories3Pillar Assembly Connecting Elements· Direct screw connection for SCHUNK components23

Pillar AssemblyConnecting Elements1 Adjustmentunit2 Pillar assembly systemAdjustment unitBase supportBase supportHollow pillarsVEHSOESODSLHAPEH/APDH horizontal mountingplatesVertical mountingplatesAPEV/APDVAMEH/AMDH horizontal mountingplatesApplication withPillars Ø 20 mm Pillars Ø 35 mm Pillars Ø 55 mm MaterialAluminum, hardanodizedAluminum, hardanodizedAluminum, hardanodizedSteel, hard-chromium platedAluminum, hardanodizedAluminum, hardanodizedAluminum, hardanodizedDescriptionThe adjustmentunit simplifiesmechanical adjustment of completehandling systemsThe base support isthe base used forthe pillar assemblysystem and can bedirectly mountedonto a firm surfaceThe base support isthe base used forthe pillar assemblysystem and can bedirectly mountedonto a firm surfaceA 2-pillar assemblycan be mountedwith the SODVersatile steel pillars can be insertedat various lengthsand provide highrigidityThe mountingplates connect thevarious SCHUNKmodules of themodular system tothe pillar systemThe mountingplates connect thevarious SCHUNKmodules of themodular system tothe pillar systemThe mountingplates withfunctional screwconnection diagramconnect variousSCHUNK modules orcustomer-specificstructures to thepillar systemField of applicationFor universal useThe base used forwith structures that all pillar assembliesmust be readjusted with a single pillarduring assembly.The base used forall pillar assemblies with a doublepillarsFor all assemblysystems and framesand as a mountingoption for automation componentsFor attachingSCHUNK linearmodules with horizontal movementFor attachingSCHUNK linearmodules with horizontal and verticalmovementFor attachingcustomer-specificstructures or otherautomation components verticallyAdvantages Mechanical adjustment Robust and high- Robust and high- Robust and high- Robust and high- Robust and high- Robust and highly precisely precisely precisely precisely precisely precise High degree offlexibility Weight-reduceddue to hollowprofile Can be used as ahose and cablechannel highly suitable/fully supported24 suitable to a limited extent Standardized in- Standardized in- Flexible mounterface for manyterface for manyting optionsSCHUNK productsSCHUNK products

Connecting Elements3 Media routingAdjustment ringCross connectorMounting plateMounting clipHose routingHose routingSTG/STRKVBMPLMFCSPL/MFB/MFSMFS/MFV/MFK Aluminum, hardanodizedAluminum, hardanodizedAluminum, hardanodizedAluminum, hardanodizedAluminum, hardanodizedPOMPOMPOMThe mountingplates withfunctional screwconnection diagramconnect variousSCHUNK modules orcustomer-specificstructures to thepillar systemThe mountingplates withfunctional screwconnection diagramconnect variousSCHUNK modules orcustomer-specificstructures to thepillar systemThe adjustmentring provides accurate positioningof the assemblyelements that aremounted to thepillarsCross connectorsallow for rightangle junctionsto be includedin the pillarassembly system.The mounting plateoffers the possibility of adding extrafunctionalities orstructuresMoun

SCHUNK Modular Assembly Automation Product Overview Design an infinite number of applications for micro part handling and assembly automation with the SCHUNK modular assembly system. An incredible variety of automation solutions can be realized with just a few standard modules from the SCH