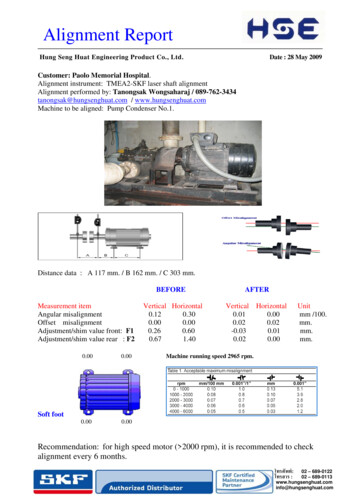

Transcription

HawkEye Alignment Systems Greater profit and productivity through innovation

Alignment as easy as 1-2-3!HawkEye Alignment Systems featuring WinAlign software fully integrate the functionsof the console, sensors and lift into one highly efficient alignment system. A series of automated features and intuitive software tools save time and simplifyprocedures to make alignment as easy as.step1stepSelect the vehicle% Scan the VINor.% Recall specs manually2Measure angles% Install targets% Capture measurements in 40 seconds% Review "before" resultsstep3Make adjustments% Follow the adjustment instructions% Print before-and-after resultsPresent your results!% Sell more alignments% Generate greater profits

Hunter's latest productivity features!PATENTEDHigh-resolution cameras!Four high-resolution camerasprovide alignment measurementswith pinpoint accuracy.Recall specs in a snap!Recall OE specs and vehiclespecific alignment proceduresinstantly.*STANDARDPatented integratedsteering system reset!Reset computerized steeringsystems on a wide variety ofvehicles with one simple tool.Simplified adjustments!Intuitive software features guide every adjustment.EXCLUSIVEInflation and no gauges!Set and record tire pressureautomatically without cumbersomehoses and gauges.EXCLUSIVEEasy access targets!Store targets within arm’s reachof each wheel for maximumproductivity.* Standard with WA600 consoles, optional with WA500 consoles.PATENTEDNo more lock-pin hassles!Forget pulling and replacing lockpins by hand.

Previous setups used valuable shop time Conventional electronic-sensor system – 10-minute-plus procedure01234567891010:00 % Chock wheelsand lift vehicle% Jack up front and rear of vehicle% Check air pressure and recall specs% Mount all 4 sensors, compensate eachsensor, and remove pins% Lower rear and front of vehicleand jounceACTIVITY TRACKER% Steer caster4% Print results10:05 Total6246Older technology requires long set-up times Camera-sensor systems speed up the process012344:00%%%%%%%Chock wheels and lift vehicleCheck air pressure and recall specsMount targetsRoll backward, then forward to compensateRemove pinsACTIVITY TRACKERSteer caster3Print results4:00 Total6l83Early camera technology improved efficiency

Today, present your results in just 2 minutes!0122:03Hunter's HawkEye System andPremium RX Lift capture all readings andproduce measurements in 2 minutes! Hunter's 2-minute procedureChock wheels and lift vehicle to work heightMount targets and set air pressureRoll forward and back to compensate sensorsScan VIN to recall specs and performenhanced caster steer% Vehicle results print automatically%%%%2:03 TotalACTIVITY TRACKERltrip around the vehicle0trips to the console72total walking stepsFast printoutsin 2 minutes!Use detailed printoutsfeaturing your company’slogo to sell more work.

When it comes to award-winning software,WinAlign is unmatched! The importance of software The most extensive vehicleinformation database for NorthAmerica's 220 million vehicles. Vehicle-specific proceduresguide your technicians withstep-by-step instructions.Over 30 years of experience and the largest R&Ddepartment in the undercar industry bring you themost profitable and productive software on the market. Patented and awardwinning power toolscomplete the work accuratelythe first time, every time. WinAlign maximizes profitand productivity in youralignment bay.Ordinary systemssimply presentalignment readingsOrdinary camerasystems simply speedup these readingsWinAlign maximizesprofit and productivityin your alignment bayPATENTEDExpressAlignPATENTED Perform every alignment with a streamlined procedure.ExpressAlign analyzes each job and presents the optimalaction sequence with the minimum steps required.WinToe Ensure a straight steering wheel every time withoutrepeated adjustments or using a steering wheel holder.A timesaver on nearly every alignment

PATENTEDPATENTEDTools and Kits DatabaseVirtual ViewSave trips back and forth to the tool box. Hunterpresents all of the tools and aftermarket correction kitsneeded for each alignment.Online ordering supportedSee your alignment job in 3-D using real-time 3-Dgraphics. Used by experts and novices alike.Every alignment can be shown in 3-DPATENTEDPATENTEDControl Arm Movement Monitor Shim-Select II Cut adjustment times in half for front-shim, dual-camor dual-slot vehicles. Step-by-step graphics let you getit right on the first try.Over 60 million vehicles benefitEliminate confusing shim charts and tables. Shim SelectII quickly calculates and displays the template you needfor proper shim installation.Over 30 million vehicles benefitPATENTEDPATENTEDWheel-Off AdjustmentAutomatic Bushing CalculatorSpeed the alignment process by making adjustmentswith the wheel removed.*Available when you need itCalculate the proper bushing size and positionadjustment without wasting time with a zero bushing.Over 10 million light trucks and vans benefit* Requires Wheel-Off Adjustment Kit 20-1978-1.

Take your alignment business to the next level!Perform body shop alignments Perform specialty alignments PATENTEDPATENTEDSuspension Body Dimension AuditQuickly screen vehicles to determine alignabilityand collision repair needs.Live Ride Height Adjustment *Measure and adjust ride height in real-time.Symmetry Angle MeasurementsInstantly access symmetry angles and setbackfor your body shop customers.PATENTEDOver 20 million vehicles require ride heightmeasurement to complete alignment serviceWinAlign Tuner*Perform alignments on tuned suspensions and other modifiedvehicles with tools to monitor tire wear and handling.Drive-on cameraSafely and easilyposition a vehicle on alift with one technician.WinAlign softwaresupports the use of adrive-on camera, whichuses the aligner screenas a guide. (Drive-oncamera sold separately.) TPMSpecsOver 100 TPMS procedures in a simple, yetcomprehensive, user-friendly format for the technician. * Standard with WA600 consoles, optional with WA500 consoles.

Help your customers make informed decisions!PATENTEDPATENTEDWinAlign Video Library*400 videos cover all aspects of wheel alignment today.% Educate your customers% Find answers to unusual problems% Extend your service and profit opportunities% Strengthen technician competency Point & Click Inspection Photos*5,000 vehicle-specific photos and illustrationsto assist your shop.% Show your customers their hidden repair needs% Guide your technicians to the proper inspectionpoints% Extend your service and profit opportunitiesPATENTEDThe latest specs available onlineDownload, access and communicate alignment serviceinformation through the Internet.% WebSpecs .NET specification database **% ShopResults.NET online service **% UnderCarInfo.NET subscription ** WinAlign printouts help sell workExplain needed parts and repairs and show completedwork to customers using detailed, color-coded printouts. Clear and detailed printouts help youcommunicate and build rapport with yourcustomers and sell more alignments* Standard with WA600 consoles, optional with WA500 consoles.** Two-year free subscription for WebSpecs.NET, one-year free subscription for ShopResults.NET and UnderCarInfo.NET.

FIA streamlines the entire alignment process.Communication links automate tasks once performed by thetechnician manually, eliminating time-consuming trips aroundthe vehicle and to-and-from the console.2134

1PATENTEDRX Scissor Lift console% Raising the vehicle triggers the sensorsto look for wheel targets% Control PowerSlide and Inflation Stationsettings on the lift console% Store bar-code scanner and CodeLinktool near the vehicle to save steps 2AlignLights turn onautomatically atalignment heightPATENTEDWinAlign console % Centralized control of entire system% Communicate directly with lift to settire pressure and automatically operateturnplates and slipplates% Guide the technician through thealignment process3Measurements are takenautomatically once thefourth target is installedPATENTEDPowerSlide system % Slipplates and turnplates automaticallylock and unlock at appropriate times% No more struggles with lock pinsAuto-locking turnplatesand slipplates save tripsaround the vehicle4PATENTEDInflation Station% Automatically inflate all four tiressimultaneously% Record starting and final pressure% Hose recoils to keep work area clearRequires FIA lift. See RX or Four-Post lift brochures for details.Software tracks beforeand after tire pressures forthe customer's printout

CodeLink – The new last step in alignment service STANDARDCodeLink directly "links" the vehicle OBD-II tothe aligner to reset steering system sensors, asrequired by the manufacturer. Simple and efficientAutomatically identifies candidate vehiclesIncorporates reset steps into the alignmentUses aligner screen to display instructionsUpdates automatically with system softwareupgrades% Dedicated alignment tool%%%%PATENTEDOne tool replacesmultiple OEM scan tools123Simplified reset instructionsreplace confusing OEMproceduresFinishes the job right% No other reset tool matches CodeLink's patented integration withthe alignment procedure% Guarantees precision with exact steering system sensor thresholds% Reduces errors that result in customer comebacksPrinted documentation confirms that steeringsystem reset was completed properlySome of the more popular OEMs that currently require reset:Audi BMW Chevy Ford Hyundai Infiniti Lexus Mazda Mercury MINI Nissan Pontiac Saturn Scion Toyota Volkswagen

Choose the right alignment console for your shop!WinAlign WA500Premium consolesIndustry-leading hardwareProcessorMemoryHard drive Monitor class240 GB Solid State Drive (or greater)Standard24" widescreen LCDWireless network moduleOperating systemThree-dimensional target (TD Target ) support 4 GB of DDR4 RAMDVD-RW/CD-RW combo driveVehicle specifications (30 plus years)Award-winning productivity tools3.70 GHz Intel Core i3 (or greater)OptionalWindows 10 IoT EnterpriseOptional (requires premium feature key)Standard (2 years free updates)PATENTEDAward-winning WinAlign softwareStandardPATENTEDReal-time specs delivered by webWebSpecs (2 years standard)PATENTEDSteering system reset (integrated)Yes (with standard CodeLink ) Bar code readerOptionalComplete TPMS reset databaseStandardPATENTEDLive Ride Height adjustmentOptionalPATENTEDFully Integrated AlignmentYes (FIA-equipped lift required)PATENTEDModified vehicle alignmentOptionalPATENTEDVehicle inspection with photosOptionalPATENTEDTools & Kits – basic catalogStandardPATENTEDTools & Kits – video and photosOptionalEquipment video help/assistanceOptionalShopResults (via ShopResults.NET )OptionalUnderCarInfo (via UnderCarInfo.NET)OptionalPATENTEDPATENTED Training and productivity aidsCompact console1,600 illustrations100 animationsFor product dimensions, weights and site requirements, please contact your local Hunter Sales Representative.Wall-mount console

Choose the right sensor package for your shop!PATENTEDFixed-column configurations fit most service bayapplications.PATENTEDLift-column configurations automatically position thecameras to any lift height during the alignment process.PATENTEDPATENTEDEXCLUSIVEEXCLUSIVEWall- and ceiling-mount configurations are perfect whenspace is at a premium.Cabinet-mounted configuration is mobile to servicemultiple alignment bays and provides a full range oftravel for additional lift height.PATENTEDPATENTEDEXCLUSIVEEXCLUSIVEManually operated vertical camera configurationprovides a full range of travel for additional lift height.Floor-mounted overhead configurations are idealfor drive-through bays or to accommodate uniqueapplications.

HawkEye alignment sensor and adaptorspecifications SpecificationsPATENTEDNo metal-to-metal contact with wheelWeight of assembly11 lbs.Profile of assembly18 inchesInstallation time per wheel10-15 secondsRolling compensation styleBack/ForwardCamera resolutionWheelbase210 inchesSecondary Measurements66 - 107 inchesSuggested distance*99 inchesShort-bay distance (see site info)*66 inchesSetbackMaximum steering angleLive ride height**Wheelbase differenceTrack width differenceTread width differenceLateral offsetRear setbackAxle offsetBodyMeasurements20,000,000 (pixels total)80 inchesS.A.I. and included angleAdjustments2,608 x 1,952 (pixels per camera)Track widthDistance to wall*PATENTEDN/A%%To lock%%%%%%%PATENTEDSBDAPATENTEDBody anglePATENTEDBody wheel offset & setbackPATENTEDBody roll%%%%PATENTEDWay Up Way Out WinToe%PATENTEDWheel-Off Adjustment* Refer to site requirements for exact bay specifications.** Requires Ride Height targets. Standard with WA600 consoles, optional with WA500 consoles.Optional

Increase revenue with Hunter merchandising!Introduce your wheel alignmentcapabilities and educate yourcustomers with great Point-of-Saleoptions from Hunter.Sell morealignmentswith clear andinformativeprintoutsSTANDARDCustomizedcolumn capMake youralignment bay standout. Hunter's lightedsensor column capcan be customized withyour logo or shop name.(available for most sensorconfigurations)HawkEye, WinAlign, CodeLink, PowerSlide, TPMSpecs, ExpressAlign, WinToe,Virtual View, Control Arm Movement Monitor, Shim-Select, Automatic BushingCalculator, WebSpecs and ShopResults.NET are registered trademarks ofHunter Engineering Company.Be sure to check out other Hunterliterature for more quality productsfrom Hunter Engineering.Copyright 2017, Hunter Engineering CompanyForm 6321-T, 06/17Supersedes form 6321-T, 03/16

1 2 3 Alignment as easy as 1-2-3! HawkEye Alignment Systems featuring WinAlign software fully integrate the functions of the console, sensors and lift into one highly efficient alignment system. A series of automated fea