Transcription

Career & Technical EducationMechanical Training SystemCourseware Sample36965-F0AB

CAREER & TECHNICAL EDUCATIONMECHANICAL TRAINING SYSTEMCOURSEWARE SAMPLEbythe StaffofLab-Volt Ltd.Copyright 2006 Lab-Volt Ltd.All rights reserved. No part of this publication may be reproduced,in any form or by any means, without the prior written permissionof Lab-Volt Ltd.Printed in CanadaAugust 2006

Table of ContentsCourseware OutlineAlignment and Couplings – Job Sheets . . . . . . . . . . . . . . . . . . . . . . . . . . . . VAlignment and Couplings – Work Orders . . . . . . . . . . . . . . . . . . . . . . . . . . . VISample Job Sheet Extracted from Alignment and CouplingsJob Sheet 2Reverse Indicator Method . . . . . . . . . . . . . . . . . . . . . . . . . . 3Sample Work Order Extracted from Alignment and CouplingsWork Order 2Reverse Indicator Method . . . . . . . . . . . . . . . . . . . . . . . . . 17Other Sample Extracted from Alignment and CouplingsPost-Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25III

IV

Courseware OutlineALIGNMENT AND COUPLINGS – JOB SHEETSJob Sheet 1Dial Indicator MethodJob Sheet 2Reverse Indicator MethodJob Sheet 3Flange CouplingsJob Sheet 4Flexible Sleeve CouplingsJob Sheet 5Chain CouplingsJob Sheet 6Gear CouplingsJob Sheet 7Grid CouplingsJob Sheet 8Universal JointsAppendicesABCDEquipment Utilization ChartComponents of the Alignment and Coupling SystemsUnit Conversion TablePost-TestWe Value Your Opinion!V

Courseware OutlineALIGNMENT AND COUPLINGS – WORK ORDERSWork Order 1 Dial Indicator MethodWork Order 2 Reverse Indicator MethodWork Order 3 Flange CouplingsWork Order 4 Flexible Sleeve CouplingsWork Order 5 Chain CouplingsWork Order 6 Gear CouplingsWork Order 7 Grid CouplingsWork Order 8 Universal JointsAppendicesABCDEFEquipment Utilization ChartComponents of the Alignment and Couplings SystemUnit Conversion TableSafety ProceduresLockout/Tagout ProcedureStart-up Procedure for the Constant Speed MotorWe Value Your Opinion!VI

Sample Job SheetExtracted fromAlignment and Couplings

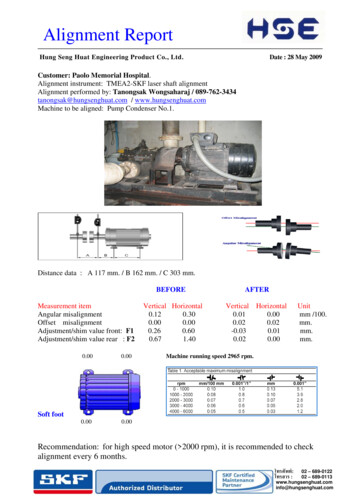

2REVERSE INDICATOR METHODThe reverse indicator method is another shaft alignment method. It uses two dialindicators, one on each shaft, to measure the parallel and angular misalignment asshown in Figure 2-1.Figure 2-1. Reverse indicator setup.All measurements are taken on the rim of the coupling hubs. The parallel andangular measurements, made in the vertical plane, are taken at the same time. Thesame is true for the measurements taken in the horizontal plane.The reverse indicator method is more accurate than the straightedge and feelergauge method and the dial indicator method. Since the measurements are takenonly on the rim of the coupling, they can be performed without disassembling thecoupling.ALIGNMENT AND COUPLINGS3

4ALIGNMENT AND COUPLINGS

2REVERSE INDICATOR METHODOBJECTIVESIn this job, you will align two shafts using the reverse indicator method.EQUIPMENT REQUIREDCCCCCCCCCUniversal Base Assembly, model 46603Motor Package, model 46609Couplings – Shafts Panel, model 46610Pillow Block Bearings Panel, model 46611Alignment and Couplings Package, model 46615Test/Measurement Package, model 46630Test/Measurement Package 2, model 46630-10Tool Box Component Package, model 46631Tool Box Component Package 2, model 46631-10SAFETY PROCEDURESBefore proceeding with this job, complete the following check list.G You are wearing safety glasses.G You are wearing safety shoes.G You are not wearing anything that might get caught such as a tie, jewelry, orloose clothes.G If your hair is long, tie it out of the way.G The working area is clean and free of oil.G The floor is not wet.G Your sleeves are rolled up.PROCEDURELockout/Tagout ProcedureG1. Perform a lockout/tagout procedure as described in Job Sheet 1.ALIGNMENT AND COUPLINGS5

REVERSE INDICATOR METHODNote: The Universal Base should be set up from Job Sheet 1.Repeat Job Sheet 1 if necessary.Rough AlignmentG2. Align the shafts using the straightedge and feeler gauge method asdescribed in the manual titled Introduction to Mechanical Drive Systems, p/n36737-20.Coupling InstallationNote: The following steps refer to the flange coupling only.Consult the Coupling Installation procedure of the coupling youare installing.G3. Take the flange coupling from the Couplings 1 Panel.G4. Perform the following steps if the bushings are not assembled into thecoupling hubs:GCSlide a 5/8-in. bore, size H split taper bushings into both hubs. Thebushing should slide freely. If not, install it on the opposite side of thehub.CLine up the unthreaded bushing holes with the threaded holes on thehubs.CSlide and hand-tighten the capscrews to lock the bushings into thehubs.5. Install a key into each shaft keyseat.Note: The edges of the keyseats are sharp.G66. Slide hub 1 and hub 2 on the shafts as shown in Figure 2-2, leaving a 1/8-in.gap between the two hubs.ALIGNMENT AND COUPLINGS

REVERSE INDICATOR METHODFigure 2-2. Installation of the hubs on the shafts.G7. Slightly tighten the bushing hub capscrews to lock them on the shaft.G8. Tighten the pillow block bearing setscrews on the flat surface of the shaft.G9. Tighten the pillow block bearing screws to the extrusions.G 10. Tighten the mounting base screws to the extrusions.G 11. Tighten the motor screws to the mounting base.Dial Indicator SetupG 12. Mount the two dial indicators on the motor shaft as shown in Figure 2-3using the clamp attachments, swivel clamps, and rods.G 13. Make sure you can freely rotate the dial indicators around the shafts. If not,reposition the arms so that you can.ALIGNMENT AND COUPLINGS7

REVERSE INDICATOR METHODFigure 2-3. Installation of the dial indicators.Vertical AlignmentG 14. Rotate the couplings so that the dial indicator 1 is at the 12 o'clock positionand the dial indicator 2 is at the 6 o'clock position.G 15. Make sure the probe of the dial indicators touch a smooth surface on the rimof the coupling hubs.G 16. Set the indicators to zero by turning the dial.G 17. Rotate the coupling hubs so that the dial indicator 1 is at the 6 o'clockposition and the dial indicator 2 is at the 12 o'clock position.G 18. Record the dial indicator readings. This corresponds to the vertical TotalIndicator Reading (TIR).Vertical TIR indicator 1Vertical TIR indicator 2Note: Make sure you keep the sign of your readings.8ALIGNMENT AND COUPLINGS

REVERSE INDICATOR METHODG 19. Calculate the vertical misalignment (Vm) for each dial indicator using thefollowing formulas:Vm, indicator 1 -0.5 x Vertical TIR indicator 1 Note: Notice the minus sign in the calculation of the Vm, indicator 1.Vm, indicator 2 0.5 x Vertical TIR indicator 2 G 20. Measure the distances shown in Figure 2-4.Figure 2-4. Measurement of the distances.Distance 1-2:Distance 1-3:Distance 1-4:Plot of the MeasurementsG 21. Draw a horizontal line in the middle of the graph in Figure 2-6. This linerepresents the center line of the driven shaft, as shown in Figure 2-5.ALIGNMENT AND COUPLINGS9

REVERSE INDICATOR METHODFigure 2-5. Graphic elements.G 22. Choose a scale for the horizontal line and plot accurately the distances 1-2,1-3 and 1-4 you measured previously. Point 1 represents the position of thedial indicator 1, point 2 the dial indicator 2, point 3 the front of the motor, andpoint 4 the rear of the motor.G 23. Choose a vertical scale and record it. For example, one square is equal to0.05 in.Vertical scale:G 24. Plot the measurement of the dial indicator 1 in line with point 1. If the valueis positive, plot it below the horizontal line. If it is negative, plot it above thehorizontal line.G 25. Plot the measurement of the dial indicator 2 in line with point 2. If the valueis positive, plot it above the horizontal line. If it is negative, plot it below thehorizontal line.G 26. Draw a line that connects the two previous measurements and extend itabove point 3 and 4. The height (H3) above the horizontal line at point 3represents the amount by which the front of the motor must be shimmedand the height (H4) above point 4 represents the amount by which the rearof the motor must be shimmed.Note: If the line is below the horizontal, shims must be removed.10ALIGNMENT AND COUPLINGS

REVERSE INDICATOR METHODFigure 2-6. Plot of the measurements.ALIGNMENT AND COUPLINGS11

REVERSE INDICATOR METHODG 27. Measure the heights (H3) and (H4) and convert them in shim thicknessusing the vertical scale you determined previously.Shim thickness H3:Shim thickness H4:G 28. Add shims as required under the motor base plate.Note: The vertical misalignment should be below 0.002 in.G 29. Tighten the motor screws.Horizontal AlignmentG 30. Rotate the coupling so that the dial indicator 1 is at the 9 o'clock positionand the dial indicator 2 is at the 3 o'clock position as shown in Figure 2-7.Figure 2-7. Dial indicator positions.G 31. Make sure the probe of the dial indicators touches a smooth surface on therim of the coupling hubs.G 32. Set the indicators to zero by turning the dial.G 33. Rotate the coupling hubs so that the dial indicator 1 is at the 3 o'clockposition and the dial indicator 2 is at the 9 o'clock position.12ALIGNMENT AND COUPLINGS

REVERSE INDICATOR METHODG 34. Record the dial indicator readings. This corresponds to the horizontal TotalIndicator Reading (TIR).Horizontal TIRindicator 1Horizontal TIRindicator 2Note: Make sure to note the sign of your readings.G 35. Calculate the horizontal misalignment (Hm) for each dial indicator using thefollowing formulas:Hm, indicator 1 -0.5 x Horizontal TIRindicator 1 Note: Notice the minus sign in the calculation of the Vm, indicator 1.Hm, indicator 2 0.5 x Horizontal TIRindicator 2 G 36. Loosen the motor bolts and move the motor as follows:CIf Hm, indicator 1 is positive and Hm, indicator 2 is negative, move the motor to theleft as you stand behind it.CIf Hm, indicator 2 is positive and Hm, indicator 1 is negative, move the motor to theright as you stand behind itCAlso, if Hm, indicator 2 is greater than Hm, indicator 1, the rear of the motor mustbe moved more than the front.Note: The horizontal misalignment should be below 0.002 inch.G 37. Tighten the motor screws.G 38. Dismount the dial indicators and rod assemblies from the shafts.G 39. Slide the coupling hubs away from each other.G 40. Slide hub 1 until it is flush with the end of the motor shaft.ALIGNMENT AND COUPLINGS13

REVERSE INDICATOR METHODCoupling AssemblyNote: The following steps refer to the flange coupling only.Consult the Coupling Assembly procedure of the coupling you areinstalling.G 41. Tighten the hub 1 bushing capscrews up to 95 lbfAin. using a torque wrenchto lock the assembly on the motor shaft.G 42. Slide hub 2 until it mates with hub 1 and lock the hubs together with thecoupling screws.G 43. Tighten the hub 2 bushing capscrews up to 95 lbfAin. using a torque wrenchto lock the assembly on the driven shaft.G 44. Ask the instructor to check your work.Name:Instructor's approval:14ALIGNMENT AND COUPLINGSDate:

Sample Work OrderExtracted fromAlignment and Couplings

2REVERSE INDICATOR METHODTask: Align two shafts using the reverse indicator method.PROCEDUREG1. Perform the Safety Procedures listed in Appendix D.G2. Perform the Lockout/Tagout Procedure described in Appendix E.G3. Should the probe of the dial indicator be placed on the rim or face of thecoupling hub when taking the measurements with the reverse indicatormethod?Position of the probe:G4. Take the flange coupling from the Couplings 1 panel, and install it as shownin Figure 2-1.Figure 2-1. Installation of the flange coupling.G5. Perform a rough alignment using the straightedge and feeler gauge method.ALIGNMENT AND COUPLINGS17

REVERSE INDICATOR METHODG6. Assemble the dial indicator on the motor shaft as shown in Figure 2-2 usingthe clamp attachments, swivel clamps, and rods.Figure 2-2. Installation of the dial indicators.Vertical AlignmentG7. Record the following parameters:Vertical TIR indicator 1:Vertical TIR indicator 2:Note: Make sure you keep the sign of your readings.Vm, indicator 1:Note: Notice the minus sign in the calculation of the Vm, indicator 1.Vm, indicator 2:G188. Measure the lengths shown in Figure 2-3.ALIGNMENT AND COUPLINGS

REVERSE INDICATOR METHODFigure 2-3. Measurement of the lengths.Length 1-2:Length 1-3:Length 1-4:Plot of the MeasurementsG9. Plot your measurements on Figure 2-5. Refer to Figure 2-4 for the detailsof the elements to plot.ALIGNMENT AND COUPLINGS19

REVERSE INDICATOR METHODFigure 2-4. Graphic elements.20ALIGNMENT AND COUPLINGS

REVERSE INDICATOR METHODFigure 2-5. Plot of the measurements.ALIGNMENT AND COUPLINGS21

REVERSE INDICATOR METHODG 10. Measure the heights H3 and H4, and convert them in shim thickness.Shim thickness H3:Shim thickness H4:G 11. Install the shims.G 12. Repeat the procedure until the vertical parallel misalignment is less than0.002 in.Horizontal AlignmentG 13. Record the following parameters:Horizontal TIRindicator 1Horizontal TIRindicator 2Note: Make sure you keep the sign of your readings.Hm, indicator 1:Note: Notice the minus sign in the calculation of the Hm, indicator 1.Hm, indicator 2 :G 14. Adjust the motor position.G 15. Repeat the procedure until the horizontal misalignment is less than 0.002 in.G 16. Complete the coupling assembly.G 17. Ask the instructor to check your work.Name:Instructor's approval:22ALIGNMENT AND COUPLINGSDate:

Other SampleExtracted fromAlignment and Couplings

Post-Test1. What is the most precise shaft alignment method?a.b.c.d.Dial indicator methodReverse indicator methodStraightedge and feeler gauge methodCoupling method2. Which of the following couplings does not require lubrication?a.b.c.d.Chain couplingGrid couplingGear coupling with a steel sleeveFlange coupling3. Which of the following alignment procedures involves the installation of shims?a.b.c.d.Horizontal angular alignmentHorizontal

REVERSE INDICATOR METHOD ALIGNMENT AND COUPLINGS 3 The reverse indicator method is another shaft alignment method. It uses two dial indicators, one on each shaft, to measure the parallel and angular misalignment as shown in Figure 2-1. Figure 2-1. Reverse indicator setup. All measurements are taken on the rim of the coupling hubs. The parallel andFile Size: 2MBPage Count: 34