Transcription

Packaging Guidelinesfor Shipping FreightAt FedEx, we know proper packaging of your freight is the best wayto ensure that your goods arrive safely at their destination. So weoffer these guidelines for shipments weighing more than 150 lbs.

ContentsThe words skid and pallet may be used interchangeably in this document. However, a skidis defined as a handling platform without bottom deck boards, and a pallet is defined asa handling platform with bottom deck boards. Based on durability, integrity and handlingefficiency, the FedEx shipping networks recommend the use of pallets versus skids.Shipping and Handling Considerations3Pallets and Stacking4Wood Crates7Cushioning, Blocking and Bracing9Banding and Stretchwrapping9Securing Unique Freight11Marking and Labeling15Contacts and Resources17

FedEx Guidelines for Shipments Weighing More Than 150 Lbs.Start with an understanding of the FedEx Express and FedEx Freight shipping conditions and proceed to thespecific guidelines and requirements for palletizing and preparing your freight shipments.Shipping and Handling ConsiderationsWhen it comes to shipping freight, size, weight, climateand general handling issues come into play becauseoften it takes multiple vehicles to deliver your goods totheir final destination. FedEx Express Freight (Air) andFedEx Freight (LTL and Over the Road) share freightpackaging guidelines and requirements with someexceptions. For specific terms and conditions governingFedEx Express Freight and FedEx Freight shipments,go to fedex.com/us/services.FedEx Express FreightTRUCKSTATIONRAMPHUBAIRCRAFTRAMPTRUCKFedEx FreightTRUCKSERVICE CENTERTRUCKSERVICE CENTERTRUCKSize, Weight and Climate:FedEx Express FreightTake a look at our FedEx Express freight air cargocompartments and standard distribution and deliverytruck dimensions, and you’ll see why we have specific sizerecommendations for freight shipments.On board FedEx Express aircraft, temperatures varydepending on the type of aircraft, the location of eachcargo compartment and the package location withineach compartment, the length of flight and the cruisingaltitude. For general reference, temperatures aboardmost wide-body aircraft main cargo compartments varybetween 40º F (5º C) and 85º F (30º C). Packagespositioned in the bulk department, next to the aircraft’souter structure, might be exposed to temperatures aslow as 35º F (2º C) during flight, but could be subjectedto temperatures as low as 20º F (-7º C) duringinternational flights.Air pressures on FedEx Express aircraft vary from aslow as 8.3 psi at cruise altitude to as much as 14.7 psion the ground.FedEx Express Freight shipments must be on a pallet,skid or other forkliftable and pallet-jackable base witha minimum clearance of 3-1/2" for access, and shouldbe stackable. A surcharge applies to any piece, skid orpallet of a FedEx Express freight shipment that is non stackable. For details on the surcharge, please see theRates and Surcharges section of the FedEx Service Guideat fedex.com.Depending on the size and shape of product, four-waypallet or skid entry is recommended. You may shipindividual units of 151 lbs. or more. Skids exceeding2,200 lbs. require prior approval. Total shipmentweight is unlimited. Skids measuring in excess of 70"high or 119" long or 80" wide require prior approval.Individual pieces over 150 lbs. should be banded tothe pallet with either metal strapping or unbreakableplastic straps applied over the box or skid freighton all sides.Hardened containers (plywood, metal) that are notbanded should have an exterior lock or clamp. (Glue,nails and screws are not sufficient.)Back to contents70"123"Our SAA cargo carrier measures 70"H x 123"W x 88"D.85"128"115"Based on door entry, our AMJ cargo carrier measures 85"H x 128"W x 88"D.Page 3

Pallets and StackingOur AMS cargo carrier measures 108"H x 125"W x 96"D.Recommended: Column StackDoor opening is approx. 93"–96" widebased on swing or retractable door.Approx.100" basedon theswing orretractabledoor.The orientation of cartons in your palletized freightshipments can have a big impact on the integrity ofyour shipments. The FedEx Packaging Lab suggeststhat you adhere to the following guidelines. You’ll findexamples of appropriate options for palletized freightshipping and some common — but not advisable —practices. Plus you’ll get practical suggestions formanufacturing pallets and crating materials.53FedEx FreightFedEx Freight shipments may be palletized ornonpalletized, weigh up to 20,000 lbs. (no individualpiece or pallet greater than 3,150 pounds) and measureup to 20 feet in length. The use of a pallet or handlingbase in LTL shipments is preferred for handlingefficiency and safety, to reduce product damage andto maintain package orientation.Column-stack loads for palletized freight. In almost allcases it increases the top-to-bottom compressionstrength for most palletized shipments.Recommended: Interlocking StackIf the carton contents are rigid, interlocking cartons willresult in increased stability. Stack boxes corner-tocorner and edge-to-edge, for better stacking strength.The cargo areas of our trucks are not temperaturecontrolled, and temperature will vary depending ontime of year, location, exposure to sunlight and othervariables. In summer months, the temperature in thecargo area can be as much as 30 degrees higher thanthe ambient temperature outside the vehicle.Compression, Shock and Vibration:FedEx Express Freight and FedEx FreightYour freight shipment will likely face forklifts, conveyorbelts, double stacking and multiple transport vehiclesalong its way to its final destination, so in addition tosize, weight and climate recommendations, properpackaging also helps cushion goods to withstandordinary care in handling.Back to contentsNOT RECOMMENDED: Overhanging StackDon’t overhang the pallet edges with packagedproducts, because it can reduce package compressionstrength by as much as 32 percent. Plus it subjectspackages to tears, punctures and other impacts duringnormal handling and sorting.Freight overhanging or extending beyond the palletperimeter may be damaged during handling ordamaged by adjacent freight. Claims resulting fromimproper stacking or load shifting may not be honored.Page 4

Durability — Select a pallet durable enough towithstand the rigors of the shipping and handlingenvironments, specifically designed with adequate topboard spacing so forklift blades will not impact theproduct. Functionality — Utilize only pallets that will functionproperly with various packaging and material handlingequipment.NOT RECOMMENDED: Pyramid StackingSpace is at a premium, particularly in FedEx Expressaircraft, so package stacking will likely occur, and pyramidstacking is not recommended. More important, pyramidstacks don’t provide a level surface, so the top cartons areexposed to potential damage from other shipments. Unitswith a level top surface provide better strength andstability for even load and weight distribution whendouble-stacked. Price — Balance the price of the pallet with the value ofthe product, while properly supporting the load so itcan be delivered without damage to the customer.Recommended: Standard Wood PalletsThe FedEx Packaging Lab prefers the standard woodpallet developed by the Grocery ManufacturersAssociation (GMA) now referred to as the ConsumerBrands Association (CBA). It typically measures 40" by48" and features four-way entry capabilities. The pallet isdesigned with adequate top board spacing so forkliftblades will not impact the freight being shipped. It canbe designed to carry heavy or light loads. If you areshipping your goods internationally, some countriesrequire the wood used in pallets or crating to be treatedwith chemicals or heat to avoid possible pest infestation.For the latest regulations and information on shippingwith wood packaging materials, go to www.usda.gov andenter the search words “wood packaging materials.”Pallet Design ConsiderationsOne of the key benefits of a four-way entry pallet is theease with which it can be moved into trailers and air cargocontainers. Keep these basic design parameters in mind: Strength — Make sure your pallet is strong enough tosupport the load-carrying weight throughout theshipping and storage environment.A new pallet is recommended versus a damaged orrepaired pallet. The pallet should be designed to supportthe packaged product load and withstand the rigors ofthe shipping environment. A damaged or repaired pallet,though cost-effective, has an unknown integrity, and itsquality and strength is only as good as the repair. Reusedpallets and crates should be monitored for use andexcessive degradation over time. Stiffness — Choose a pallet stiff enough to resistdeforming under the load.Back to contentsPage 5

Recommended: Plastic PalletsA viable alternative to wood pallets, plastic pallets aretypically more expensive, but they are also reusable. Thesolid deck often protects the package bottom from forklifttine damage and helps support the load of the productsstacked on it. However, the plastic surface is often slippery,which makes fastening or blocking products to preventmovement more difficult. Some plastic pallets can weighmore than wood pallets, and they may not be the bestoption if weight is a consideration.NOT RECOMMENDED: Corrugated PalletsBecause corrugated pallets are lightweight, easily recycledand preferred by some countries that restrict wood pallets,some shippers opt to use them. However, paper-basedpallets are easily damaged, and moisture often causes thecorrugate to degrade. They simply do not withstand therigors of the transportation environment, so corrugatedpallets are not recommended.NOT RECOMMENDED: Pressed Block-Style Pallets andMolded Pulp PalletsPressed Block-style and molded pulp pallets are popularin Europe and Asia, and their popularity is growing inthe United States. Most pallets manufactured in Asia aremade from processed wood, which lacks the sturdinessand strength of a natural-wood pallet. These palletstyles do not hold up to the rigors of the transportationenvironment and are not recommended. If you dochoose to use these pallet designs, make sure they arebuilt to hold the weight of the product, from materialsthat will make them sturdy and resistant to many touchpoints in the transportation environment.NOT RECOMMENDED: Wood Pallets WithoutBottom Boards (“Skids”)Because wood pallets without bottom boards (commonlyknown as “skids”) don’t distribute weight evenly, theycan be challenging to lift and the stringers are easilycompromised or damaged. This style of pallet simplydoes not stand up to the rigors of the transportationenvironment, and we do not recommend them.Back to contentsPage 6

Wood CratesCrating, if constructed properly from quality lumber, canhelp protect your product. The FedEx Packaging Labrecommends plywood, not oriented strand board (OSB),medium-density fiberboard (MDF) or particleboard.Knots should be limited, and fasteners should not beanchored in knots or other defective areas of theplywood. Diagonal braces should be used on each panelto increase the strength and integrity of the crate.NOT RECOMMENDED: Inadequate Three-WayCorner ConstructionIn these examples of weak and improper construction,the corners have low nail-holding strength because thenails are driven into the end grain.FastenersOK—Rectangular Wire StapleCrate Corners and Diagonal BracingIt’s true that diagonal braces can have a dramaticeffect on the strength of your crate. But more oftenthan not, the way the wood is assembled is moreimportant than how much wood is used. When buildingcorners and diagonal braces, avoid weak designs andaim for the stronger constructions shown here.Good—Helically Threaded NailBetter—Annularly Threaded NailRecommended: Proper Three-WayCorner ConstructionIn these examples, the corner construction is strongand rigid because the nails are driven into the sidegrain, which increases the nail-holding strength.Best—Wood ScrewsUse the appropriate fastener and wood material sizesto resist splitting or fracturing the wood componentsduring assembly.Back to contentsPage 7

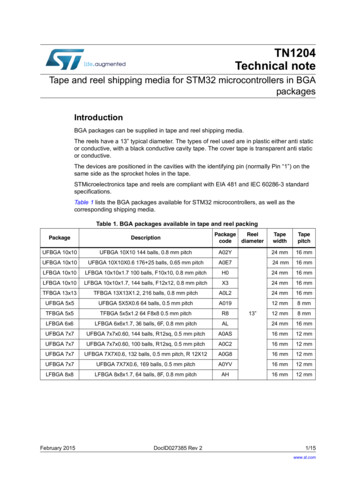

Cleated Crate RecommendationsIn addition to plywood thickness and cleat stock sizes,fasteners play an important role in maintaining cratestrength. From staples to screws, using the properfastener rated for the weight of the product and crateis key. This chart offers recommendations for appropriatematerials based on the weight of your shipment.NETWEIGHTPART1THICKNESS 2 REQ.1/422 REQ.32 REQ.(L 2) x D(L 2) x(W 2 )0–5005/16500–8003/8(L 2-1/8) x DWxD(L 2-1/4) x D800–1,000WHENSPECIFIEDCLEATSTOCKPANEL SIZE1/2(L 2-1/2) x DCLEAT LENGTHS454 REQ. 4 REQ.1x2(L 2-1/8) x(W 2-1/8)74 REQ.84 REQ.W 2L–1L 2W–31x3D94 REQ.W–5L – 7/8W – 7/8D–5D–5D–7D–7(L 2-1/2) x(W 2-1/2)W–7W 2-1/2 L – 4-1/2 L 2-1/2L – Container Length (inside dimension)W – Container Width (inside dimension)D – Container Depth (inside dimension)Note: Chart measurements are in inches.W – 2-3/4L 2-1/4L – 4-3/41x4PANEL CONSTRUCTIONCONTAINER ASSEMBLYNAILS STAPLES OTHERS NAILS SPACINGSTRAPD–3L 2-1/8L – 2-3/4W 2-1/49A10AS REQ.W–1D–3W 2-1/8(L 2-1/4) x(W 2-1/4)Notes:1. Plywood will conform to exteriorgrade plywood.64 REQ.FASTENERS4D1/2 x 1-1/41-1/4xx16 GAGE16 GAGE1/8 x 1-3/81 3/87D43/4 x .023W – 4-3/4W – 4-1/21037682. Lumber will conform to Class 2 structural.Structural lumber is 2 or more inches inthickness and width for use where workingstresses are required.929A24 MAX.419A5Grades of PlywoodGradeAppearanceCommon UseAFree of knots; smooth, solid surfaceConstruction (cabinets)BFew knots; sanded, smooth surfaceConstruction, visibleCTight, open knot holes; face splitsWood cratesD*Lowest quality; not weather-resistantIndoor-use construction* Not recommended for crate construction.Back to contentsPage 8

Cushioning, Blocking and BracingShock and vibration forces naturally occur duringcarriage of your goods throughout the shipping process;consequently, most products require some form ofcushioning to protect them. Blocking and bracing are alsoimportant for larger commodities that cannot be boxed orcrated. To effectively stabilize your shipment, rememberto choose the type and size of lumber that’s appropriatefor the weight of your shipment.shipping single heavy goods. For goods that are over1,500 lbs., we recommend that the pallet and blockingmaterial be made from hardwood. The blocking shouldbe placed tightly against the object with a goal ofkeeping it in a fixed position during all transportationand handling. As a general rule, blocking requires aminimum of two fasteners in each end to preventpivoting and maintain adequate strength.Foam CushioningWhen developing crates or packaging for your palletizedshipments, foam is a natural option for cushioning. Aspart of the end design, cushioning should be engineeredto provide the foam density required to protect thefragility level of the product. It should also be validatedthrough testing that simulates the shipping environment.For FedEx shipments, we can help by testing yourpackaging and making recommendations.BracingFoam corner cushionsTop and bottomload-protector padsFoam corner cushionsOuter cartonWood BlockingThe FedEx Packaging Lab suggests a blocking materialsuch as wood be used to prevent any movement whenBack to contentsItems that can roll or shift during transportation dueto their shape or size should be braced on a forkliftablepallet base for shipping. Your selection of lumbershould be based on the product that you are bracingand its weight. As the shipping weight increases, thegrade and thickness of the bracing lumber shouldincrease. As an example, No. 3 (utility-grade) lumberis often used to construct pallets and for bracingmaterials. However, if the product you are shipping isvery heavy, you should choose a better grade of wood,like a No. 1 or No. 2 grade (construction grade), forproper protection.Banding and StretchwrappingTypically, any damage during transit occurs because theshipment was improperly unitized, bundled or securedfor transport. This is a particular issue with retail goodsand boxed products. If there is cosmetic carton damage,the customer is likely to assume the contents are alsodamaged. As discussed earlier, pallet strength andstacking play an important role in freight shipmentintegrity. So do load protection, stretchwrapping andbanding, which we will cover here.Page 9

Top and bottomload-protector padsCartons stackedsquarelyAngleboardLooped aroundthe deck board orstringer, not throughthe notched portionof the stringerNo overlap of baseStretchwrap27" minimum width,3-1/2" minimum heightfor pallet-jack entryLoad Protectors and Edge BoardsTop and bottom load-protector pads (corrugated pad/tray) help reduce damage to top and bottom layers ofyour shipment. They also help distribute the weight of toploaded freight. Bottom load protectors provide a levelsurface, offer protection from pallet nail heads, and helpkeep boxes from slipping into the gap between the boardson the pallet. A corrugated pad between stacked layers(tier sheet) will also help stabilize packages and distributeweight. Angleboards along the unit edges should run thefull length or depth of the stack to help unitize the load,increase vertical stacking strength and reduce damage tobox edges that make up the load corners.BandsBanding is typically used to secure the bundled load tothe pallet. You should band corrugated stacks on eachside as shown. As a general rule, keep the banding closeto the load to avoid exposure, damage or breakage.Loads significantly smaller than the pallet should becentered and banded to the closest pallet deck boardsvs. the pallet exterior. The more perpendicular thebanding is, the greater its holding force. All palletizedloads being shipped via FedEx Express Freight requirebanding with heavy-duty steel, rayon, polypropylene,nylon or polyester strapping.Back to contentsStretchwrap film is critical for bundling loads and alsofor securing and protecting large individual pieces offreight. Wrap freight tightly to prevent load shifting.Use 70-gauge stretchwrap that sticks to itself so it canbe wipe-sealed as it is applied to the stack. Whenmachine wrapping, spiral-wrap the cartons with aminimum 50 percent overlap. Proper applicationincludes a secure wrapping along the pallet perimeterand a 3" overlap at the top of the stack.To manually apply stretchwrap, tuck the lead wrapbetween the pallet and the bottom box. Spiral aroundthe boxes in an upward direction, overlapping the filmby 50 percent. When you reach the top, stretch the filmdiagonally over the top corners with a 3" overlap toanchor the stack vertically before spiraling back to thebottom to finish the load with a secure wrapping alongthe pallet perimeter.3" overlap at thetop of the stack3" overlap ontothe palletBased on the weight and stability of your shipment, theFedEx Packaging Lab recommends the following wrapstandards. Achieving the minimum containment forceis critical for properly securing freight to the pallet. ForPage 10

unstable and mixed loads, “roping” the stretchwrapcan help contain freight and prevent the stretchwrapfrom fraying and tearing.Stretchwrap GuidelinesWeight ofPallet LoadContainmentForceBottom Wrap*(Includes Pallet)Top Wrap*0–500 lbs.2–5 lbs.32501–750 lbs.5–7 lbs.43751–1,000 lbs.7–12 lbs.541,001–1,500 lbs.12–20 lbs.66Over 1,501 lbs.20 lbs.88Truck and Auto Tires* Wrap indicates layers of stretchwrap film.* Any shipment over 1,000 lbs. should also have bands along with stretchwrap.Securing Unique FreightSome uniquely shaped items such as tires, bags, drums,spools, transit cases, engines, pipes, and medical orelectronic equipment require special packaging. FedExhighly recommends that all packaging systems betested to validate the performance of your design.Improper packaging of these freight shipments candisrupt service, causing product damage or shippingdelays. We’ll explore ways to palletize/

Pallet Design Considerations One of the key benefits of a four-way entry pallet is the ease with which it can be moved into trailers and air cargo containers. Keep these basic design parameters in mind: Strength — Make sure your pallet is strong enough to support the load-carryin