Transcription

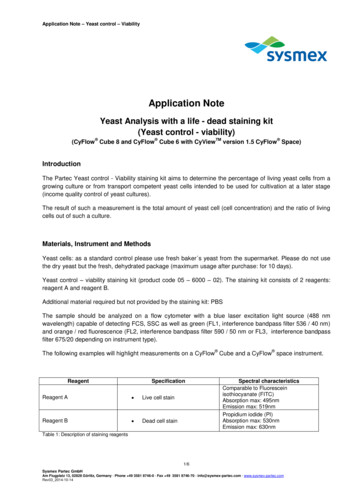

Application Note – Yeast control – ViabilityApplication NoteYeast Analysis with a life - dead staining kit(Yeast control - viability) (CyFlow Cube 8 and CyFlow Cube 6 with CyViewTM version 1.5 CyFlow Space)IntroductionThe Partec Yeast control - Viability staining kit aims to determine the percentage of living yeast cells from agrowing culture or from transport competent yeast cells intended to be used for cultivation at a later stage(income quality control of yeast cultures).The result of such a measurement is the total amount of yeast cell (cell concentration) and the ratio of livingcells out of such a culture.Materials, Instrument and MethodsYeast cells: as a standard control please use fresh baker s yeast from the supermarket. Please do not usethe dry yeast but the fresh, dehydrated package (maximum usage after purchase: for 10 days).Yeast control – viability staining kit (product code 05 – 6000 – 02). The staining kit consists of 2 reagents:reagent A and reagent B.Additional material required but not provided by the staining kit: PBSThe sample should be analyzed on a flow cytometer with a blue laser excitation light source (488 nmwavelength) capable of detecting FCS, SSC as well as green (FL1, interference bandpass filter 536 / 40 nm)and orange / red fluorescence (FL2, interference bandpass filter 590 / 50 nm or FL3, interference bandpassfilter 675/20 depending on instrument type). The following examples will highlight measurements on a CyFlow Cube and a CyFlow space instrument.ReagentSpecificationReagent A Live cell stainReagent B Dead cell stainSpectral characteristicsComparable to Fluoresceinisothiocyanate (FITC)Absorption max: 495nmEmission max: 519nmPropidium iodide (PI)Absorption max: 530nmEmission max: 630nmTable 1: Description of staining reagents1/6Sysmex Partec GmbHAm Flugplatz 13, 02828 Görlitz, Germany · Phone 49 3581 8746-0 · Fax 49 3581 8746-70 · info@sysmex-partec.com · www.sysmex-partec.comRev03 2014-10-14

Application Note – Yeast control – ViabilitySample preparation Cell suspensionStarting with commercial dehydrated yeast: resuspend 0,01 g (10 mg) of yeast material in 10 mlPBSStarting with a yeast cell culture: take 10 µl of cells from a growing culture in mid-log phase anddilute with 990 µl PBS (dilution factor: 100) Staining reagentsTake 1 ml of yeast suspension (either from the commercialdehydrated yeast or the growing yeast culture) and add 10 µl ofreagent A. Incubate for 5 min at room temperature protected fromlight.Add 10 µl of reagent B and incubate for another 5 min at roomtemperature protected from light.The solution B containspropidiumiodideandmethanol and should behandled with care. Pleasefollow the instructions givenwithin the product leaflet.The sample is ready for analysis. Prepared samples should be analyzed within 15 min afterpreparation. Optional sample preparation: as a dead cell control prepare one lot of cells as described above andincubate the cells in an appropriate, heat-proof sample container at 70 C in a water bath for 10min. In such way obtained cells can be mixed with fresh cells to generate a control sampleconsisting of living and dead cells. Analysis on a FCMSet-up of the instrument:1. Select a layout with three or more plots (histogram and dotplots) showing at least FSC – SSCand FL1 – FL2 or FL3 (depends on the filter set-up)2. Select FSC as trigger parameterlog3 on FSC and SSClog4 on fluorescence parametersSet the analysis speed to 1 µl / sLL 100gain approximately 200gain approximately 330-3803. Attach a negative control – sample without stain – to fine adjust GAIN values and LL-valueObserve the analysis rate (events / sec). If the value exceeds 1000 dilute the sample by afactor of 5 with PBS (and repeat again if the analysis speed is still too high). For later countinganalysis keep rate / s below 1000!2/6Sysmex Partec GmbHAm Flugplatz 13, 02828 Görlitz, Germany · Phone 49 3581 8746-0 · Fax 49 3581 8746-70 · info@sysmex-partec.com · www.sysmex-partec.comRev03 2014-10-14

Application Note – Yeast control – ViabilitySet the gain values of FSC and SSC in such a way that the cell population shows up in thecenter of the FSC – SSC dotplot (fig. 1).Surround the yeast cells by a polygon and apply this polygon to the dot-plot FL1 vs. FL2/3.Set the gain values of FL detectors to display cells in the first of 4 log decades (fig. 1b)Yeast cellsBackgroundda)b)Fig. 1 FSC – SSC plot allows identification of the yeast cells (a) which can be surrounded by a polygon anddisplayed in the fluorescence dot-plot (b)4.Attach sample stained with FDA only (control), analyse and stop. Set compensation for FL1vsFL2/3Fig. 2 FDA vs PI plot (live vs dead) uncompensated without (a) and with compensation line for FDA vs FL3 (b)5.Attach sample stained with PI only (control), analyse and stop. Set compensation for FL2/3vs FL1. If required correct GAIN and LL values.3/6Sysmex Partec GmbHAm Flugplatz 13, 02828 Görlitz, Germany · Phone 49 3581 8746-0 · Fax 49 3581 8746-70 · info@sysmex-partec.com · www.sysmex-partec.comRev03 2014-10-14

Application Note – Yeast control – ViabilityFig. 3 FDA vs PI plot (live vs dead) uncompensated with compensation line for PI vs FL1 (a) and compensated (b)Sample analysis and counting:Analyse double stained samples. Use True Volumetric Counting to enumerate number ofvital and dead cells (instructions below).Within the dotplot FL1 – FL2/3 the fluorescence signals of vital and dead cells can be clearlyidentified (fig. 4) as vital cells are mainly green fluorescent whereas dead cells are mainly redfluorescent.Fig. 4 FDA vs PI plot (live vs dead) compensated without absolute counting results4/6Sysmex Partec GmbHAm Flugplatz 13, 02828 Görlitz, Germany · Phone 49 3581 8746-0 · Fax 49 3581 8746-70 · info@sysmex-partec.com · www.sysmex-partec.comRev03 2014-10-14

Application Note – Yeast control – ViabilityCounting with Electrode Sensors (True Volumetric Absolute Counting, TVAC)In order to quantify the concentration of yeast cells (and vital cells) the measure mode “Volumetric countingwith electrodes” should be used. Fill 850µl of sample in a standard sample tube. Mix well and attach it tothe sample port.An analysis cycle according the below sequence is started automatically and a true absolute volumetriccounting begins when the liquid level in the tube reaches the first, shorter sensor.1. The system starts with an initialization sequence of “Pre-run” phase followed by2. “Stabilization” switching into3.“Run” phase (a pre-counting phase).When the liquid level in the sample tube reaches the start electrode the counting procedure initiatesand the system switches from “Run” to4. “Count” phaseleading to the end of counting when the liquid level reached the second sensor5. During “Repositioning” sample pump is moving into start position followed by6. “Clean” which washes the sample port and flow cell7. “Ready” is displayed when the system is ready to analyse the next sampleThe current phase is indicated always in the Instrument Settings Box next to the flow counter.With sample speed of 3 µl/s this procedure takes about 100 seconds. In order to minimize effects ofparticle sedimentation during the process it is recommended to use high speed values of 3-5 µl/s! Themeasured volume is fixed to 200 µl by the position of the electrodes.StartCountStop5/6Sysmex Partec GmbHAm Flugplatz 13, 02828 Görlitz, Germany · Phone 49 3581 8746-0 · Fax 49 3581 8746-70 · info@sysmex-partec.com · www.sysmex-partec.comRev03 2014-10-14

Application Note – Yeast control – ViabilityCleaning and Shutdown processset speed 4 µl/soConnect a sample tube filled with 1.5ml 0.5 % Hypochloride (Order No. 04-4012) to disinfect thetubing – run until system stopsoConnect a sample tube filled with 1.5ml Cleaning Solution (green solution, Order No. 04-4009) – rununtil system stopsoConnect a sample tube filled with 1.5ml Decontamination Solution (violet solution, Order No. 04-4010)– run until system stopsoConnect a sample tube filled with 1.5ml Sheath fluid (Order No. 04-4007) – – run 2 minutes and STOP-Shut down FloMax-Switch off CyFlow Space instrument-Shut off the computer6/6Sysmex Partec GmbHAm Flugplatz 13, 02828 Görlitz, Germany · Phone 49 3581 8746-0 · Fax 49 3581 8746-70 · info@sysmex-partec.com · www.sysmex-partec.comRev03 2014-10-14

Application Note – Yeast control – Viability 3/6 Sysmex Partec GmbH Am Flugplatz 13, 02828 Görlitz, Germany · Phone 49 3581 8746-0 · Fax 49 3581 8746-70 · info@sysmex-partec.com