Transcription

TEC REPORTIssue 08 · July 2010Flex-rigid technology was also employed in the re-design of an MDE device (mobile dataentry), created for inventory administration. An adapter board with two ZIF contacts enabledthe display to be updated smoothly and securely. Additionally, by laser cutting the flexibleZIF contours, precise contact tolerances were achieved and an ingenious panelisation provided a stable assembly panel. In the flexible region, the PCBs could be removed by hand,without the needs for tools or special processing.Figure 7:ZIF contact replaces wiring in a motor control unit for roller shutters and awnings.Figure 9:By laser cutting the flexible ZIF contours, precise contact tolerances were achieved and aningenious panelisation provided a stable assembly panel.For another application, a special design and implementation of contacts was created usinga semi-flexible FR4 PCB with a ZIF contact for use in standard ZIF connectors. This application was used in a module for the optical display of temperature and air quality in a sensor for measuring air quality. In order to achieve large bending radii, the single-sided PCBalready had a thickness of 0.3 mm in the contact area, which means that it could be directlyplugged into the ZIF connector without the need for additional stiffeners or extra milling.Further advantages were that cable wiring to the motherboard was no longer necessary, theassembly process was simplified and the additional benefit that a drying process beforesoldering was no longer required due to the base material used.*) Note: ZIF connector – The term ZIF (Zero Insertion Force) originates from the socket technology of components, mainly CPU’s. In a ZIF socket, contacts are opened prior to placement of the IC, e.g. by a leverage mechanism, allowing for effortless insertion of the contact pins into the socket. The mechanism is then closed, fixing the contacts to the pins inthe socket, and thus creating the electrical connection.Particular advantages of flex-rigid PCBsAbout Würth Elektronik Circuit Board Technology (CBT)Flex-rigid technology is well-proven, reliable and particularly good inovercoming space and weight issues with spatial degrees of freedom. Careful consideration of flex-rigid solutions and a proper assessment of the available options at an early stage in the designphase can return significant benefits:Würth Elektronik is the leading PCB manufacturer in Europe, producing a wide spectrumof PCBs – from standard technologies through to pioneering system solutions – at manufacturing plants in Niedernhall, Rot am See and Schopfheim. The PCB specialist deliversapplication specific solutions in all technologies and is a driving force behind new technical innovations, for example, in the field of embedded active and passive components.The extensive PCB portfolio ranges from double sided PCBs and multilayers in all conventional technologies through to technically demanding PCBs such as HDI, flex-rigid andheatsink technologies. Space requirements can be minimised by applying 3D circuitry. By removing the need for connectors and cables between theindividual rigid parts the board size could be reduced and overallsystem weight can be brought down. Less solder joints assure higher reliability. Handling during assembly is easier when compared with completeflexible boards. Otherwise difficult connections can be created, thereby simplifyingthe assembling processes. Integrated ZIF contacts provide simple modular interfaces to thesystem environment. Test conditions are simplified. A complete test prior to installationbecomes possible. Logistical and assembly costs are significantly reduced with flexrigid boards. It is possible to increase the complexity of mechanical designs,whilst also improving the degree of freedom for optimised housingsolutions.Circuit Board Technology · Tec Report · Issue 08 · July 2010About the Würth Elektronik GroupWürth Elektronik offersthe best contact betweenflex-rigid PCBs andZIF connectorsWürth Elektronik CBT is – alongside Würth Elektronik ICS (electromechanical and electronic system solutions), Würth Elektronik eiSos (passive and electromechanical components) and Würth Solar (CIS-photovoltaic modules and solar power systems) – a divisionof the Würth Elektronik Group, an internationally operating, independent subsidiary of theWürth Group. Beside their own R&D, Würth Elektronik is also involved in numerous external research communities, e.g. GloveNet or TIPS. In 2009 Würth Elektronik employedaround 5,900 personnel and generated a turnover of 374 million Euros.Further information can be found at www.we-online.com.More , July 2010 – PCB specialist Würth Elektronik once again demonstrates their competencein system solutions and customer support; now offering one-stop flex-rigid PCB solutions with ZIFcontacts and custom designed ZIF connectors. Customers from diverse fields such as industry, auto-Using flex-rigid technology to create ZIF contacts is becoming more and more widespread, as it offers a number ofbenefits:motive, medical care and digital image processing benefit from Würth Elektronik’s particular problemsolving approach. Most notably in the two key points: quality and cost. This makes flex-rigid and savings in joints/componentsflexible PCBs an affordable and effective choice for maximum use of complex circuit technologies in improved reliabilitythe minimum space, in particular with respect to system costs. cost savings in procurement and logistics reduced installation size less complexity and expense in design and developmentFigure 8:Semi-flexible PCB with ZIF contact serving as connection with an optical module in a sensor for measuring air quality.05Flex-rigid PCBsand ZIF connectorsCircuit Board Technology · Tec Report · Issue 08 · July 2010DIE NECKARPRINZEN 07 10. Errors and omissions excepted.Flex-rigid multilayer boards are already proving their value in daily applications. For example, as sensors for controlling motors in roller shutters, awnings and Venetian blinds. In thiscase, internal resistors and heaters were also used. Here all the typical demands are met:high operational reliability and durability; simple assembly; resistance against oil, grease,humidity and aggressive environmental conditions as well as simple, reliable electrical connections using a flexible limb with a ZIF contact. Wiring and solder joints were replaced,high quality connections applied, and an assembly process for the heating resistors wasavoided.Würth Elektronik GmbH & Co. KGCircuit Board TechnologySalzstr. 21 · 74676 Niedernhall · GermanyTel. 49 (0) 7940 946-0Fax 49 (0) 7940 946-55 00 com06www.we-online.com

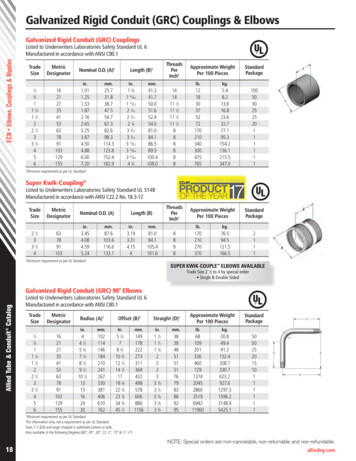

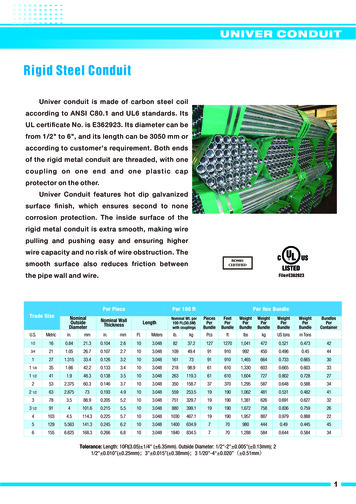

Flex-rigid PCBsand ZIF connectorsFlexible and flex-rigid PCBs are being designed more and more with the prevalent ZIF interface, possessing a so-called ZIF contact (ZIF Zero Insertion Force) for connection with a ZIFconnector. Hence, appropriate one-stop system solutions make sense. For that reason, WürthElektronik eiSos’ designers of the new ZIF connector WR-FPC paid particular attention toclosely attuning system relevant areas. The ZIF connector WR-FPC has been specificallydesigned for the best connection to flexible and flex-rigid PCBs by respecting the tight tolerances and parameters applicable in PCB manufacturing in the connector design. Customerstherefore get comprehensive and systematic design support, as well as seamlessly tailoredsystem components. Würth Elektronik is offering a ZIF connector design-kit, particularly created for designers and offering a range of options for design test. The ZIF connector WR-FPCis available in different variants and for any kind of construction, either upright, horizontal,contacts on TOP or BOTTOM.Various options for ZIF connectionsTolerances in productionThere are many ways to set connecting tabs in flex-rigid boardsFurther options with a stable intermediate tabDetachable connections between displays and PCBs, or between two PCBs are often created by using flexible printed circuit boards or by flexible flat cables and ZIF connectors.Fine pitch ZIF connectors are available, for example, on a 1.0 mm and 0.5 mm pitch. Thecontact arrangement is created between the ZIF connector, which is soldered onto the PCBand the ZIF contact, which must fit exactly into the ZIF connector. This ZIF contact can besimply a flexible flat cable, a complex flexible PCB or a flex tail from a flex-rigid PCB.There are various ways of creating ZIF contacts. Flex-rigid PCBs and the generally thinnerflex PCBs are handled in different ways to attain the required 0.3 mm PCB thickness at thecontact position: For flexible PCBs, a stiffener is affixed to the contact area; which meansrelatively high costs due to the necessary handling required at the adhesive bonding process. In contrast, for flex-rigid PCBs, Würth Elektronik utilises the simple and cost effectivemethod of high-precision depth milling to obtain the required thickness.Very small geometrical tolerances must be maintained in manufacture, so that the ZIF contact fits optimally in the ZIF connector. Due to this reason, only flat solderable surfaces arepossible. For increased reliability and a longer lifespan, the solderable surface finish electroless nickel/immersion gold has proved itself favourably in practice.The profile of a simple ZIF contact, with the technical requirements of a PCB profile with a tolerance range of 0.1 mm, is created through routing. However, enhanced tolerances suchas 50µm can only be realised through the use of camera controlled routing or laser cutting.In order to allow the insertion of the contact into the ZIF connector, the specified contact areain its length must not have any tabs at its side edges. Connection tabs must be placed beyondthe connection area. There are a number of options here:1) If the customer agrees to extend the contact stiffener into the flexible area, stable tabs canbe set in the stiffened area (FR 4 depth milling).2) If an extension of the stiffened area is not suitable, the tabs in the flexible area must be setdirectly beside the stiffener.3) Intermediate tabs: Here, the entire PCB’s material thickness remains unchanged, offeringvarious advantages.4) Laser-cut micro tabs in the flexible area: Micro tabs can be applied for laser-cut flexible outlines. Rigid material underneath the flexible limb enhances the delivery panel’s stability andallows for easy manual de-panelisation.5) Ease of handling with “ears”: An idea originating from PCB technology; highly efficient andcost saving.Usually, for flex-rigid boards with an internal flexible layer, the ZIF contact is also located onthe flexible core. That would require some complex special operation steps during the production process. For flex-rigid with the flexible layer located as external layer, a change ofthe contact side could become necessary. Such a change is made possible by via holes inthe rigid area in between.Figure 5:An idea originating from PCB technology: “Ears” behind the ZIF contact improves handling:The contact can be easily inserted into the connector by holding it at these “ears”.Figure 6:For flex-rigid boards with a flexible internal layer, the ZIF contact is usually also located onthe flexible core. For flex-rigid boards with a flexible external layer, a change of the contactface can be necessary sometimes. Such change of sides is realised by via holes in the rigidarea in between.Figure 3:A combination of precise laser cutting and depth milling leaves a stable assembly support atthe underside of the PCB. Conventional milling (see PCB in the background) removes thisextra support, and the assembly panel becomes less stable.Figure 1:Würth Elektronik eiSos’ ZIF connectors are ideally suited for connecting flex-rigid PCBs.Flex-rigid boards in practiceDrawing specifications in the manufacturing documentsFaithful to Würth Elektronik’s tradition of close customer ties and proximity, difficult and complex customised solutions can be worked out as well. “We are not only service providers, butalso consultants and trouble-shooters in the entire range of flexible and flex-rigid matters,”emphasises Andreas Schilpp, product manager “3D” at Würth Elektronik, “no single job willbe released into production without full optimisation – even if in some cases that could onlybe a double-check of the production panelisation for cost reduction purposes. For example,a well-thought-out use of base materials can help reduce costs whilst, at the same time,improving quality. At present, we are able to build about 80% of incoming jobs with WürthElektronik’s specifically qualified and standardised range of base materials, a selection of themany materials available in the market for rigid-flex PCB technologies. For the remaining20%, we find specifically tailored solutions together with our customers.”02Circuit Board Technology · Tec Report · Issue 08 · July 2010Figure 2:For flexible PCBs, a stiffener is affixed to the contact area, resulting in a higher operatingexpense. For flex-rigid boards, Würth Elektronik utilises cost-effective precision depth millingto meet the required thickness.Without the corresponding specifications on the drawing and/or without dimensioning in thegerber data, a flexible tail is not recognisable as a ZIF contact. Therefore, the following detailsshould be contained in the manufacturing drawing according to the data sheets of the connector manufacturer: length and width of the contact area thickness of the contact (stiffening material flex material copper) including thetolerance. Standard is 0.3 mm 0.05 mm lenght of the stiffener. The stiffener must overlap with the flexible solder mask/coverlay toleranced distance of the first contact to the profile ideally an indication of the possible areas for connecting tabs in the delivery panelFigure 4:Tabs can be set in various ways: The upper variant has tabs in the flexible area directly besidethe stiffeners (see option two). The method shown at the bottom leaves material in the originalPCB thickness offering many advantages (see option three).“Making quality manufacturable and cost effective is Würth Elektronik’s top priority”, highlights the flex-rigid PCB specialist Andreas Schilpp, “an essential prerequisite is as muchstandardisation as possible. Through our internal, cross-departmental coordination of system solutions, we are in a position to almost standardise innovative technologies such asflex-rigid and open up more and more areas of application. We have been able to prove thisin many projects”.Furthermore, Schilpp points out: “As it’s also the case in many other areas: the earlier customers involve their suppliers in the design and development stages, the higher thechances of benefiting from system solutions become. Namely, this is because we are ableto introduce our PCB production know-how at the right time. A fact that often proves advantageous and cannot necessarily be recognised by customers at the early stage of design”.www.we-online.com04

Flex-rigid PCBsand ZIF connectorsFlexible and flex-rigid PCBs are being designed more and more with the prevalent ZIF interface, possessing a so-called ZIF contact (ZIF Zero Insertion Force) for connection with a ZIFconnector. Hence, appropriate one-stop system solutions make sense. For that reason, WürthElektronik eiSos’ designers of the new ZIF connector WR-FPC paid particular attention toclosely attuning system relevant areas. The ZIF connector WR-FPC has been specificallydesigned for the best connection to flexible and flex-rigid PCBs by respecting the tight tolerances and parameters applicable in PCB manufacturing in the connector design. Customerstherefore get comprehensive and systematic design support, as well as seamlessly tailoredsystem components. Würth Elektronik is offering a ZIF connector design-kit, particularly created for designers and offering a range of options for design test. The ZIF connector WR-FPCis available in different variants and for any kind of construction, either upright, horizontal,contacts on TOP or BOTTOM.Various options for ZIF connectionsTolerances in productionThere are many ways to set connecting tabs in flex-rigid boardsFurther options with a stable intermediate tabDetachable connections between displays and PCBs, or between two PCBs are often created by using flexible printed circuit boards or by flexible flat cables and ZIF connectors.Fine pitch ZIF connectors are available, for example, on a 1.0 mm and 0.5 mm pitch. Thecontact arrangement is created between the ZIF connector, which is soldered onto the PCBand the ZIF contact, which must fit exactly into the ZIF connector. This ZIF contact can besimply a flexible flat cable, a complex flexible PCB or a flex tail from a flex-rigid PCB.There are various ways of creating ZIF contacts. Flex-rigid PCBs and the generally thinnerflex PCBs are handled in different ways to attain the required 0.3 mm PCB thickness at thecontact position: For flexible PCBs, a stiffener is affixed to the contact area; which meansrelatively high costs due to the necessary handling required at the adhesive bonding process. In contrast, for flex-rigid PCBs, Würth Elektronik utilises the simple and cost effectivemethod of high-precision depth milling to obtain the required thickness.Very small geometrical tolerances must be maintained in manufacture, so that the ZIF contact fits optimally in the ZIF connector. Due to this reason, only flat solderable surfaces arepossible. For increased reliability and a longer lifespan, the solderable surface finish electroless nickel/immersion gold has proved itself favourably in practice.The profile of a simple ZIF contact, with the technical requirements of a PCB profile with a tolerance range of 0.1 mm, is created through routing. However, enhanced tolerances suchas 50µm can only be realised through the use of camera controlled routing or laser cutting.In order to allow the insertion of the contact into the ZIF connector, the specified contact areain its length must not have any tabs at its side edges. Connection tabs must be placed beyondthe connection area. There are a number of options here:1) If the customer agrees to extend the contact stiffener into the flexible area, stable tabs canbe set in the stiffened area (FR 4 depth milling).2) If an extension of the stiffened area is not suitable, the tabs in the flexible area must be setdirectly beside the stiffener.3) Intermediate tabs: Here, the entire PCB’s material thickness remains unchanged, offeringvarious advantages.4) Laser-cut micro tabs in the flexible area: Micro tabs can be applied for laser-cut flexible outlines. Rigid material underneath the flexible limb enhances the delivery panel’s stability andallows for easy manual de-panelisation.5) Ease of handling with “ears”: An idea originating from PCB technology; highly efficient andcost saving.Usually, for flex-rigid boards with an internal flexible layer, the ZIF contact is also located onthe flexible core. That would require some complex special operation steps during the production process. For flex-rigid with the flexible layer located as external layer, a change ofthe contact side could become necessary. Such a change is made possible by via holes inthe rigid area in between.Figure 5:An idea originating from PCB technology: “Ears” behind the ZIF contact improves handling:The contact can be easily inserted into the connector by holding it at these “ears”.Figure 6:For flex-rigid boards with a flexible internal layer, the ZIF contact is usually also located onthe flexible core. For flex-rigid boards with a flexible external layer, a change of the contactface can be necessary sometimes. Such change of sides is realised by via holes in the rigidarea in between.Figure 3:A combination of precise laser cutting and depth milling leaves a stable assembly support atthe underside of t

This makes flex-rigid and flexible PCBs an affordable and effective choice for maximum use of complex circuit technologies in the minimum space, in particular with respect to system costs. Flex-rigid PCBs and ZIF connectors www.we-online.com Würth Elektronik offers the best contact between