Transcription

2018SACHS ShocksSACHS Shocksfor Commercial Vehiclesfor Commercial Vehicles in U.S. and CanadaZF Services, LLC777 Hickory Hill DriveVernon Hills, IL 60061Phone: 800 321 cesNAPrinted in U.S.A.12476 EN:000 2018 ZF North American Operations, Inc. All Rights Reserved. No portion of this work may bereproduced or copied by any means without the prior approval of ZF North American Operations, Inc.2018SACHS Shocksfor Commercial Vehicles

Manufacturing & DevelopmentIn North AmericaDevelopment CenterNorthville, MI USAManufacturingEl Salto MexicoZF is centered in the heart of the automotive industry with a North American Headquarters& Technical Center in Northville, MI. Our strong market position and worldwidetechnological leadership is due in large part to a growing customer base in the NorthAmerican Region. As a leading supplier of driveline and chassis technology, it is essentialfor ZF to be close to its customers, allowing for the adaptation of new & existingtechnology to meet the needs of our local market.The SACHS division in Mexico has the largest and most modern plant in the Americas forthe manufacturing of shock absorbers with a capacity of over 20 million shocks annually.SACHS supplies to both original equipment manufacturers and the aftermarket. With morethan 64 manufacturing facilities and over 31,900 employees in the NAFTA Region, ZF isfocused on meeting and exceeding the needs of our North American customers.Customer Service & Technical Hotline1-800-321-0784Dial 1 for Customer Service 7:00 am - 6:00 pm Central Standard TimeDial 2 for Technical Support 7:00 am - 4:00 pm Central Standard Time

Performance MaximizedThe Story Behind SACHS OE ShocksSACHS - The Largest Class 8 Supplier of ShocksSince ZF was founded in 1915, it has grown tobecome the world’s leading OE supplier ofdriveline and chassis technology, as wellas active and passive safety technology to thecommercial vehicle, passenger car, off road, rail,marine and aviation industries.Worldwide, the SACHS division of ZF is thelargest manufacturer of shocks and struts. TheSACHS division in Mexico has the largest andmost modern plant in the Americas, supplyingto both original equipment manufacturers andthe aftermarket.Largest OE Producer for Medium & Heavy DutyKnowing that shocks are critical in the performance and ride of any commercialvehicle, SACHS designs quality shocks with durability, reliability andperformance to enhance the ride and give the shock a longer life.SACHS has continued to be the best kept secret for commercial vehicleshocks. We are the world’s largest OE manufacturer of shock absorbers formedium and heavy duty vehicles. SACHS is also North America’s largest OEsupplier of Class 8 shock absorbers.SACHS has a 100 year track record of technological and quality leadershipin addition to one of the largest shock and strut manufacturing bases in theworld. In the aftermarket, professionals can trust SACHS quality to maintainthe positive reputation of their business; technicians can rely on SACHS for aperfect fit, and drivers can expect preferred handling and control.

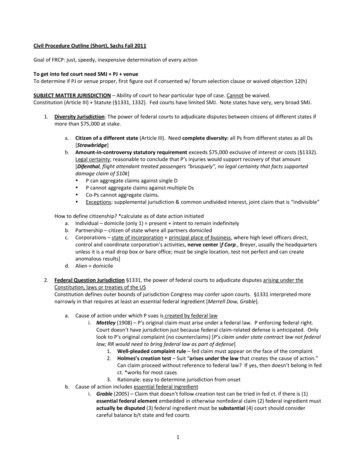

SACHS Shocks1Product Features and Benefits4Durability Micro-Polished Chrome Piston RodsSACHS micro-polished chrome piston rods are hardened for maximumstrength. The chrome fights rust and provides a low friction surface thatprevents leakage and seal damage. Our rods are manufactured to thetightest tolerance for straightness to minimize heat buildup, insuring longshock life.2Endurance Polished Cylinder, Banded Piston and Double Viton SealSACHS working cylinders are drawn to precise dimensions and arepolished smooth to prevent sintered ring wear. Our sintered piston ringeffectively seals the cylinder while preventing cylinder wear. SACHSadvanced double lip seal technology uses a special Viton syntheticrubber material which is highly wear resistant and providesexcellent performance between -40 F to 320 F. Our latest OEtechnology Viton seal keeps the oil in and the contaminants out evenin the harshest weather conditions.13 Safety & Comfort Two Different Valving TechnologiesSACHS offers two different valving technologies to provide bothdriving comfort and safety by closely matching the different needsof taper leaf and air suspension systems. For air suspensions ournew valve technology uses a pre-load element for a “digressive”setting that is specifically aligned to the spring stiffness. Thisnew valve technology provides more controlled damping at bothlow and high velocity speeds. For taper leaf suspensions our“linear” valving adds dampening force as speed increases,providing maximum damping when you need it most.4 Reliability Extra Thick Steel Eyerings andOne Piece Forged StemOur one piece stamped extra thick steel eyerings and onepiece forged stem and cap assembly provides maximumstrength and resists breaking. Combined with additionalreinforced arc welds, SACHS end mounts are built towithstand the heaviest loads.5 Protection Hydraulic StopOur state of the art hydraulic stop traps a cushion of fluidbetween the piston and rod guide by blocking the oil flowbetween the rod guide and the hydraulic stop. SACHShydraulic stop prevents the shock from topping outand the suspension from over-extending; improvingride control, comfort and system durability.532

Assembly ProcessPremium ManufacturingEvery shock we make, is outfitted with premium features to ensure utmost durability,reliability and performance. To ensure the highest quality, SACHS products areengineered to meet the highest OE manufacturing specifications.Resevoir tubes are rolled closed. By rolling the cylinder closed it eliminates the heat ofwelding and prevents internal flaking of the reserve tube,which could allow flakes into the valve and reduce shock life.Unique closing process increases internal pressureand decreases internal tolerances. Reduces component wear and maintains optimal dampingforces.Shocks are cleaned, phosphatecoated and finished with anelectrostatic painting process. This process ensures longlasting paint, which preventsrusting that could produce breakpoints and leaks.Bushings are installed afterpainting and baking. Installing bushings post paintprevents premature aging of thebushing material.Final test is performed on everyshock to ensure correctdamping forces. The final test ensures consistentquality and performance.

Table of ContentsImportant NoticeiiChassis SectionACF Brill BusAdvance MixerArvin MeritorAutocarBenson TrailerBinkleyBluebird School BusBrockway School BusBuilt Rite TrailerCarpenter BusCascade TrailerChallengecookChalmers SuspensionChance BusChevroletClark EquipmentCountry CoachCrane CarrierCrown CoachDiamond RioDodgeDuplex TruckDura SuspensionEagle BusEast Manufacturing TrailerFordFreightlinerFreightliner Custom ChassisFruehaufGeneral Trailer t Dane TrailerHardee ManufacturingHendricksonHighway ProductHinoHysterHutchens SuspensionIC BusInternationalIsuzuJohn DeereKenworthLinkLodal Refuse HaulersMackMaecoMarmon MotorMatson School BusMc Neilus Truck & 24647474747Mitsubishi – FusoMor-RydesuspensionMotor Coach Ind. (M.C.I.)Newell BusNew FlyerNorth American Bus IndustriesNova BusOle GranningOrion BusOshkoshOsterlund TruckOttawaPage SuspensionPAI CorporationPeerless TrailerPeterbiltPierce Manufacturing Inc.PrevostRex MixerReyco SuspensionRidewell CorporationSAF/HollandSpartan MotorsSterlingThomas Built BusTrailmobile Canada Corp.Tuthill TechnologiesTwin CoachUPS TruckVolvoWatson & Chalin SuspensionWestern 565858595960606364Western Unit65Cab SectionFordFreightlinerFreightliner Custom ChassisGMCInternationalKenworthLink Cabmate Air estern StarOEM InterchangeGabriel - SACHS InterchangeMeritor - SACHS InterchangeMonroe - SACHS InterchangeSpecification ChartCustomer Service & Technical Hotline666667676868707071727272727385888991Back Coveri 2018 ZF North American Operations, Inc. All Rights Reserved. No portion of this work may be reproduced or copied by any means without the prior approval of ZF North American Operations, Inc.

ii 2018 ZF North American Operations, Inc. All Rights Reserved. No portion of this work may be reproduced or copied by any means without the prior approval of ZF North American Operations, Inc.

CHASSIS SECTIONZOEM Number: ;ACF BRILL BUSAll w/ OEM Number659129661732316 841316 839316 841316 839ADVANCE MIXERAll w/ OEM Number12111 ADV317 530A-3280-M-9711316 488A-7805L-1000671020671507316 488317 944317 944ARVIN MERITORAll RHP11 w/ Air Suspension RideSentry Trailer SuspensionAll Trailer Air Suspension FS230TAll w/ OEM Number21227751317 944A-7805L-1026671507317 944317 94435901-32018026658807152460680-003316 311316 818317 783316 83390044089315 544689816965315 554315 554AUTOCARAll ACM & ACL ModelsAll w/ Air Suspension & OEM NumberBENSON TRAILERAll Models w/ Neway Air Suspension & OE NumberBINKLEYAll w/ OEM NumberBLUEBIRD SCHOOL BUSALL AMERICAN SERIES (FE & RE MODELS)All Front w/ Hendrickson Parasteer SuspensionAll Front w/ Hendrickson AirtekSuspensionAll Front w/ Parabolic Leaf SpringAll Rear w/ Hendrickson Comfort Air Suspension00040015316 488001108081658525315 544317 94200085991315 61160998-003315 611TC 2000 BUS, TC/2000 FE SERIESAll Front w/ Leaf SpringAll Front w/ Parabolic Leaf Spring131776716678311658525315 594315 594317 942All Rear w/ Neway Air Suspension90045050317 954008803547 1700 000 4640008599160998-003315 389315 389315 611315 611VISION SERIES10-05w/ Rear Leaf Spring SuspensionRear w/ Hendrickson Comfort Air Suspension1 2018 ZF North American Operations, Inc. All Rights Reserved. No portion of this work may be reproduced or copied by any means without the prior approval of ZF North American Operations, Inc.

CHASSIS SECTIONZOEM Number: ;BLUEBIRD SCHOOL BUS (Continued)ADDITIONAL APPLICATIONSAll Buses w/ Neway Air Suspension & OEM NumberAll Buses w/ Reyco Air Suspension & OEM NumberAll w/ OEM NumberAll City Bird Buses w/ 1 " Mounting Pins & OEM numberAll School Bus w/ 1" Mounting Pins & OEM 300-08230471962430614966614966317 782317 941317 941―15241251523114QK-281P10530873317 782316 839315 392315 556317 782316 830317 964317 533410 057410 057316 308315 392317 782BROCKWAY SCHOOL BUSAll 257T, 260S, 260TAll w/ OEM NumberBUILT RITE TRAILERAll w/ Air Suspension318-06-100315 554CARPENTER BUSAll w/ OEM Number63-0001316 308316 308CASCADE TRAILERAll w/ Air Suspension120-1315 554632147632155317 955317 928800 Series 40K - 58K Tandem Truck Suspension w/ Standard Shock665174315 423800 Series 40K - 58K Tandem Truck Suspension w/High MountShock800 Series 40K - 58K Tandem Truck Suspension w/Low MountShock800670317 953800781315 556665174315 423665174315 423CHALLENGECOOKAll w/ OEM NumberCHALMERS SUSPENSION1000 Series 23K Lbs single axle Truck Suspension1030 Series 30K Lbs single axle Truck SuspensionCHANCE BUSAll w/ OEM Number6892689359039728600317 782410 056317 782410 056317 782410 056317 782410 0562 2018 ZF North American Operations, Inc. All Rights Reserved. No portion of this work may be reproduced or copied by any means without the prior approval of ZF North American Operations, Inc.

CHASSIS SECTIONZOEM Number: ;CHEVROLETC SERIES / KODIAK (C40-C70 & C4500-C8500)09-08 All Conventional Cab w/ OEM Number09-97 All w/ OEM Number07-97 All Conventional Cab w/ OEM NumberAll w/ OEM Number07-90 All C Chassis - Conventional Cab02-90 All Conventional Cab (Drive Axle) w/ 16,900 lb. Taper LeafSpring01-96All Conventional Cab (Drive Axle) w/ Hendrickson Air Suspension89-76 All C & M Chassis - 97" BBC Conventional Cab89-75 All C Chassis - Conventional Cab w/ 20,800 & 23,000 lb.Rear Axles89-73 All C Chassis - Conventional CabAll C Chassis - Conventional Cab (Exc. 20,800 & 23,000 lb.Rear Axles)All C Chassis - Conventional Cab w/ 20,800 & 23,000 lb. Rear80-79 All W Chassis - 72" BBC Steel Tilt Cab80-75 All C & M Chassis - Conventional Cab80-73 All C Chassis - Conventional CabAll C & T Chassis - Conventional & Tilt Cab w/ 5,000 & 7,000 lb.AxleAll R Chassis - Rear Engine Bus72-71 All Conventional Cab & Tilt Cab w/ 9,000 & 11,000 lb. AxlesAll TDM 4 Cycle Detroit Diesel w/ Tandem Axle (Exc. Tilt Cab)72-69 All (Exc. Tilt Cab)72-66 All 72" BBC Steel Tilt Cab w/ V6 2 Cycle Diesel 423022064489316 303316 303316 303316 303316 303316 303510 0171247491715740554220120952201209622012166410 057410 057315 542316 320315 315 542315 542316 320316 320316 320315 542315 542315 542315 542316 320316 320315 542315 542315 542315 542315 542315 542315 542315 542315 392315 392316 320315 542315 542315 542315 542316 32022012096316 320316 3203171462319289022012095315 542315 542315 5423 2018 ZF North American Operations, Inc. All Rights Reserved. No portion of this work may be reproduced or copied by any means without the prior approval of ZF North American Operations, Inc.

CHASSIS SECTIONZOEM Number: ;CHEVROLET (Continued)C SERIES / KODIAK (C40-C70 & C4500-C8500) (Continued)All 72" BBC Steel Tilt Cab w/ V6 2 Cycle Diesel Engine 17201 &17221 AxleAll 72" BBC Tilt Cab w/ V6 2 Cycle Diesel Engine 19101 & 19201Axle70-69 All D-D Forward Control w/ 9,000 & 11,000 lb. Axles (Exc. TiltCab)All D-D Forward Control w/ Tilt Cab68-67316 320316 3204940600315 43222012096316 3204940606220120953192892494060622012095315 542315 542All Cowl (Exc. School Bus)3192892316 320316 320All TDM 4 Cycle Detroit Diesel w/ Tandem Axle (Exc. Tilt Cab)22012096319289222012096―All (Exc. Tilt Cab)69-68 All w/ 9,000 & 11,000 lb. Axles (Exc. Tilt Cab)6831928922201

08.08.2019 · 1 4 2 3 5 SACHS Shocks Product Features and Benefits 1 5 3 4 2 Durability Micro-Polished Chrome Piston Rods Endurance Polished Cylinder, Banded Piston and Double Viton Seal Safety & Comfort Two Different Valving Technologies Reliability Extra Thick Steel Eyerings and One Piece Forged Stem Protection Hydraulic Stop SACHS micro-polished chrome piston rods are hardened for maximum