Transcription

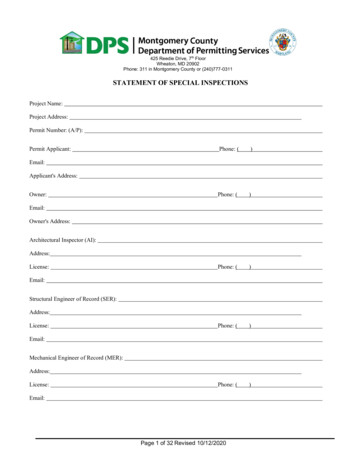

Statement ofSpecial InspectionsGuideAccording to IBC 2015Froehling & Robertson, Inc. 3015 Dumbarton Road Richmond, VA 23228Engineering Stability Since 1881

2

Table of Contents4The Fine Print5General Special Inspection Definitions6-15Structural Steel, Cold-Formed Steel, BoltedConnections and Metal Decking16-17Structural Concrete18Masonry Construction20-22Geotechnical/Soils23-24Sprayed Fire-Resistant Materials (SFRM)25Architectural Components26Mechanical, Electrical and Plumbing3

This “Statement of Special Inspections Guide” contains the interpretationsand opinions of the author and is intended to be a general guide forindividuals who are responsible for preparing the STATEMENT OF SPECALINSPECTIONS required by the International Building Code (IBC), section1704. This document is simply a guide and should not be consideredcomplete or be used as a stand-alone document that is incorporated into thecontract documents. A thorough review of the code requirements set forthby IBC and IBC reference codes and standards should be performed by theRegistered Design Professional in Responsible Charge prior to developinga project specific STATEMENT OF SPECIAL INSPECTIONS. The author of thisdocument is not liable or responsible for any errors or omissions that maybe found within this document.4Statement of Special Inspections Guide

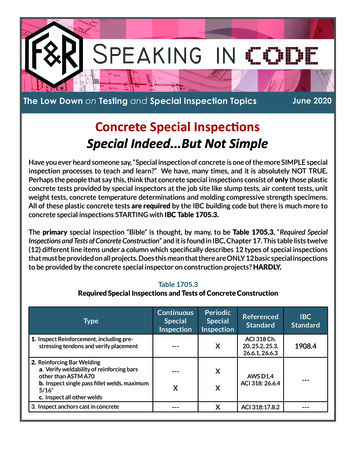

General Special Inspection DefinitionsEssential FacilityThese are buildings that are considered to be essential in that their continuous useis needed, particularly in response to disasters. The phrase “designated as essentialfacilities” refers to designation by the building official that certain facilities arerequired for emergency response or disaster recovery. IBC Chapter 16, Table 1604.5“Risk Category of Buildings and Other Structures”, category IV lists some buildingtypes deemed essential facilities.Structural ObservationsThe visual observation of the structural system by a registered design professionalfor general conformance to the approved construction documents. Structuralobservations are not special inspections. (Definition is located in chapter 2 of the IBCcode book)Special InspectionsInspection and testing of construction requiring the expertise of an approved specialinspector in order to ensure compliance with this code (IBC) and the approvedconstruction documents. (Definition is located in chapter 2 of the IBC code book)Continuous Special InspectionSpecial inspection by the special inspector who is present when and where the workto be inspected is being performed or installed. (Definition is located in chapter 2 ofthe IBC code book)Periodic Special InspectionSpecial inspection by the special inspector who is intermittently present where thework to be inspected has been or is being performed or installed. (Definition is locatedin chapter 2 of the IBC code book)ObserveObserve these items on a random basis. Operations need not be delayed pendingthese inspections. (Definition is located in AISC 360, Chapter N, Section N5, #4)PerformPerform these tasks for each welded joint or member. (Definition is located in AISC360, Chapter N, and Section N5, #4)5

A. StructuralSteel- WeldingSection GUIDESTATEMENTOF SPECIALINSPECTIONSTHIS SECTION APPLICABLE IF BOX IS CHECKED:A.According to IBC 2015STRUCTURAL – STEEL – WELDING SECTIONTHIS SECTION APPLICABLE IF BOX IS CHECKED: STEEL INSPECTION PRIOR TO WELDING – VERIFY THE FOLLOWING ARE IN COMPLIANCEIBC 1705.2.1, AISC 360-10: Table C-N5.4-1TASK1.Verify that the welding proceduresspecification (WPS) is available2.Verify manufacturer certificationsfor welding consumables areavailable3.Verify material identification4.Welder Identification SystemINSPECTION TYPE1PERFORM5.Fit-up of groove welds (includingjoint geometry)OBSERVE6.Configuration and finish of accessholesFit-up of fillet weldsOBSERVE7.DESCRIPTIONPERFORMPERFORMPERFORMType and gradeThe fabricator or erector, as applicable, shall maintain a system bywhich a welder who has welded a joint or member can be identified.Stamps, if used, shall be the low-stress type. Joint preparation Dimensions (alignment, root opening, root face, bevel) Cleanliness (condition of steel surfaces) Tacking (tack weld quality and location) Backing type and fit (if applicable) Dimensions (alignment, gaps at root) Cleanliness (condition of steel surfaces) Tacking (tack weld quality and location)STEEL INSPECTION DURING WELDING – VERIFY THE FOLLOWING ARE IN COMPLIANCEIBC 1705.2.1, AISC 360-10: Table C-N5.4-2TASKINSPECTION TYPE1DESCRIPTION8.Use of qualified weldersPERFORMWelding by welders, welding operators, and tack welders who arequalified in accordance with code requirements.9.Control and handling of weldingOBSERVE Packagingconsumables Electrode atmospheric exposure control10. No welding over cracked tackOBSERVEwelds11. Environmental conditionsOBSERVE Wind speed within limits Precipitation and temperature12. Welding Procedure SpecificationOBSERVE Settings on welding equipmentfollowed Travel speed Selected welding materials Shielding gap type/flow rate Preheat applied Interpass temperature maintained (min./max.) Proper position (F, H, V, OH) Intermix of filler metals avoided13. Welding techniquesOBSERVE Interpass and final cleaning Each pass within profile limitations Each pass meets quality requirements1OBSERVEPERFORM: Perform these tasks for each weld, fastener or bolted connection, and required verification.OBSERVE: Observe the items on a random sampling basis daily to ensure that applicable requirements are met. Operationsneed not be delayed pending these inspections at contractor’s risk.6For more information or further enthusiastic discourse on topics of CODE, please contactFROEHLING & ROBERTSON, INC.Alan Tuck at atuck@fandr.com OR 540.344.79392

A. StructuralSteelWeldingSection (continued)STATEMENTOF -SPECIALINSPECTIONSGUIDE According to IBC 2015THIS SECTION APPLICABLE IF BOX IS CHECKED:A.STRUCTURAL – STEEL – WELDING SECTION (CONTINUED)THIS SECTION APPLICABLE IF BOX IS CHECKED: STEEL INSPECTION AFTER WELDING – VERIFY THE FOLLOWING ARE IN COMPLIANCEIBC 1705.2.1, AISC 360-10: Table C-N5.4-1TASK14.15.16.17.18.19.20.21.Welds cleanedSize, length, and location of allweldsWelds meet visual acceptancecriteriaINSPECTION TYPE1OBSERVEPERFORMPERFORM ANDDOCUMENTArc strikes, removed and groundflushk-areaPERFORMBacking removed, weld tabsremoved and finished, and filletwelds added where requiredRepair activitiesDocument acceptance or rejectionof welded joint or memberPERFORMPERFORMDESCRIPTIONSize, length, and location of all welds conform to therequirements of the detail drawings. Crack prohibition Weld/base-metal fusion Crater cross-section Weld profiles Weld size Undercut PorosityWhen welding of doubler plates, continuity plates or stiffenershas been performed in the k-area, visually inspect the web karea for cracksPERFORMPERFORMEND SECTION1PERFORM: Perform these tasks for each weld, fastener or bolted connection, and required verification.OBSERVE: Observe the items on a random sampling basis daily to ensure that applicable requirements are met. Operationsneed not be delayed pending these inspections at contractor’s risk.7For more information or further enthusiastic discourse on topics of CODE, please contactFROEHLING & ROBERTSON, INC.Alan Tuck at atuck@fandr.com OR 540.344.79393

STATEMENTOF ionB.According to IBC 2015THIS SECTIONAPPLICABLEIF BOX IS CHECKED:STRUCTURAL– STEEL– BOLTING SECTIONTHIS SECTION APPLICABLE IF BOX IS CHECKED: STEEL INSPECTION PRIOR TO BOLTING – VERIFY THE FOLLOWING ARE IN COMPLIANCEIBC 1705.2.1, AISC 360-10: Table C-N5.6-1B.TASKINSPECTION TYPE1DESCRIPTION1.Manufacturer’s certifications available forPERFORMfastener materials2.Fasteners marked in accordance withOBSERVEASTM requirements3.Proper fasteners selected for joint detailOBSERVE(grade, type, bolt length if threads are tobe excluded from shear plane)4.Proper bolting procedure selected for joint OBSERVEdetail5.Connecting elements, includingOBSERVEappropriate faying surface condition andhole preparation, if specified, meetapplicable requirements6.Proper storage provided for bolts, nuts,OBSERVEwashers, and other fastener componentsSTEEL INSPECTION TASKS DURING BOLTING – VERIFY THE FOLLOWING ARE IN COMPLIANCEIBC 1705.2.1, AISC 360-10: Table C-N5.6-2TASKINSPECTION TYPE1DESCRIPTION7.Fastener assemblies of suitable condition,OBSERVEplaced in all holes and washers (if required)are positioned as required8.Joint brought to the snug-tight conditionOBSERVEprior to pretensioning operation9.Fastener component not turned by theOBSERVEwrench prevented from rotating10. Bolts are pretensioned in accordance withOBSERVERCSC Specification, progressingsystematically from the most rigid pointtoward the free edges.STEEL INSPECTION TASKS AFTER BOLTING – VERIFY THE FOLLOWING ARE IN COMPLIANCEIBC 1705.2.1, AISC 360-10: Table C-N5.6-3TASKINSPECTION TYPE1DESCRIPTION11. Document acceptance or rejection of allbolted connectionsEND SECTION18PERFORM:OBSERVE:Perform these tasks for each weld, fastener or bolted connection, and required verification.Observe the items on a random sampling basis daily to ensure that applicable requirements are met. Operationsneed not be delayed pending these inspections at contractor’s risk.For more information or further enthusiastic discourse on topics of CODE, please contactFROEHLING & ROBERTSON, INC.Alan Tuck at atuck@fandr.com OR 540.344.79394

STATEMENTOF SPECIALINSPECTIONSTestingGUIDE SectionAccording to IBC 2015C. StructuralSteel- Non DestructiveTHIS SECTIONIF BOXIS CHECKED:STRUCTURAL– STEELAPPLICABLE– NON DESTRUCTIVETESTINGSECTIONTHIS SECTION APPLICABLE IF BOX IS CHECKED: NON DESTRUCTIVE TESTING OF WELDED JOINTS – VERIFY THE FOLLOWING ARE IN COMPLIANCEIBC 1705.2.1, AISC 360-10: Section N5.5C.TASK1.Use of qualified nondestructive testingpersonnelINSPECTION TYPE1PERFORMAWS D1.12.OBSERVECJP groove weldsAISC 360, Chap N,section 5b.3.Welded joints subject to fatigue4.Weld tab removal sitesOBSERVEAISC 360, Chap N,section 5d.OBSERVEAISC 360, Chap N,sections 5c, 5d, 5eand 5f.END SECTION1DESCRIPTIONVisual weld inspection and nondestructive testing (NDT) shallbe conducted by personnel qualified in accordance with AWSD1.1.[NOTE: RDP must delete this row if section D (SEISMICPROVISIONS SECTION) is checked]For structures in Risk Category III or IV of IBC Table 1604.5,UT shall be performed by QA on all (100%) CJP groove weldssubject to transversely applied tension loading in butt, T- andcorner joints, in materials 5/16” thick or greater. Forstructures in Risk Category II, UT shall be performed by QAon 10% of CJP groove welds in materials 5/16” thick orgreater.When required by Appendix 3, Table A-3.1, welded jointsrequiring weld soundness to be established by radiographicor ultrasonic inspection shall be tested by QA as prescribed.At the end of welds where weld tabs have been removed,magnetic particle testing shall be performed on the samebeam-to-column joints receiving UT. Rate of UT should be inaccordance with AISC 360, Chapter N, sections 5e and 5f. Theincrease or reduction of UT should be according to sections 5eand 5f.PERFORM: Perform these tasks for each weld, fastener or bolted connection, and required verification.OBSERVE: Observe the items on a random sampling basis daily to ensure that applicable requirements are met. Operationsneed not be delayed pending these inspections at contractor’s risk.9For more information or further enthusiastic discourse on topics of CODE, please contactFROEHLING & ROBERTSON, INC.Alan Tuck at atuck@fandr.com OR 540.344.79395

STATEMENTOF s)to IBC 2015D. StructuralSteelAISC 341RequirementsD. STRUCTURAL341 REQUIREMENTSSECTIONTHIS– AISCSECTIONAPPLICABLE(SEISMICIF BOXPROVISIONS)IS CHECKED:Section– STEELTHIS SECTION APPLICABLE IF BOX IS CHECKED: NONDESTRUCTIVE TESTING OF WELDED JOINTS – VERIFY THE FOLLOWING ARE IN COMPLIANCEIBC 1705.2.1, AISC 341-10: Section J6.2TASKINSPECTION TYPE1DESCRIPTION[NOTE: RDP may uncheck this section for projects NOT designed in accordance with AISC 341 (SEISMIC PROVISIONS) or for projectsdesigned according to AISC 341, but using an R value equal to 3]5CJP groove weldsOBSERVEUT is used to detect serious flaws in groove welds, but is notsuitable for the detection of surface or near- surface flaws. MTAISC 341,is used to detect serious flaws on or near the surface of welds.Section J6.2bBecause visual inspection is also done for all CJP groove welds,detecting the most serious surface defects invokes MT at a rateof 25%6.Beam cope and access holeOBSERVEAt welded splices and connections, thermally cut surfaces ofbeam copes and access holes shall be tested using magneticAISC 341,particle testing (MT) or dye penetrant testing (PT), when theSection J6.2dflange thickness exceeds 1 ½ in. for rolled shapes, or when theweb thickness exceeds 1 ½ in. for built-up shapes.7.K-area NDT (AISC 341)PERFORMWhere welding of doubler plates, continuity plates or stiffenershas been performed in the k-area, the web shall be tested forAISC 341,cracks using magnetic particle testing (MT). The MT inspectionSection J6.2aarea shall include the k-area base metal within 3-inches of theweld. The MT shall be performed no sooner than 48 hoursfollowing completion of the welding.END SECTION110PERFORM:OBSERVE:Perform these tasks for each weld, fastener or bolted connection, and required verification.Observe the items on a random sampling basis daily to ensure that applicable requirements are met. Operationsneed not be delayed pending these inspections at contractor’s risk.For more information or further enthusiastic discourse on topics of CODE, please contactFROEHLING & ROBERTSON, INC.Alan Tuck at atuck@fandr.com OR 540.344.79396

STATEMENTOF -SPECIALINSPECTIONSGUIDE 1 According to IBC 2015StructuralSteelCompositeConstructionSTATEMENT OF SPECIAL INSPECTIONS GUIDE According to IBC 2015E.1THIS SECTIO

IBC 1705.2.1, AISC 360-10: Table C-N5.6-1 TASK INSPECTION TYPE1 TASKDESCRIPTION INSPECTION TYPE 1. Manufacturer’s certifications available for fastener materials personnel PERFORM 1. 2. Fasteners marked in accordance with ASTM requirements OBSERVE 3. Proper fasteners selected for joint detail STATEMENT OF SPECIAL INSPECTIONS GUIDE FROEHLING & ROBERTSON, INC.