Transcription

425 Reedie Drive, 7th FloorWheaton, MD 20902Phone: 311 in Montgomery County or (240)777-0311STATEMENT OF SPECIAL INSPECTIONSProject Name:Project Address:Permit Number: (A/P):Permit Applicant:Phone: ()Phone: ()Phone: ()Phone: ()Phone: ()Email:Applicant's Address:Owner:Email:Owner's Address:Architectural Inspector (AI):Address:License:Email:Structural Engineer of Record (SER):Address:License:Email:Mechanical Engineer of Record (MER):Address:License:Email:Page 1 of 32 Revised 10/12/2020

MONTGOMERY COUNTY STATEMENT OF SPECIAL INSPECTIONSMechanical Inspector (MI):Address:License:Phone: ()Phone: ()Phone: ()Phone: ()Phone: ()Phone: ()Phone: ()Email:Geotechnical Inspector (GI):Address:License:Email:Special Inspector (SI):Address:License:Email:Testing Agency Engineer (TA, if different from SI):Address:License:Email:Precast Concrete Engineer of Record (PER):Address:License:Email:Structural Observer (SO):Address:License:Email:General Contractor (GC):Address:License:Email:Page 2 of 32 Revised 10/12/2020

MONTGOMERY COUNTY STATEMENT OF SPECIAL INSPECTIONSSCHEDULE OF SPECIAL INSPECTIONSComplete all sections of this Schedule. Indicate N/A if not applicable.Refer to Mo.Co. Special Inspections Manual for additional clarifications.SPECIAL CASESReference: IBC Section 1705.1.1 and Section 1.2 of theSpecial Inspections Program Manual.Testing procedures used and evaluation of test results, byan engineer registered in MD, shall be submitted to theCounty for review and approval prior to thecommencement of the work.EXTENT OF SERVICE(Continuous or periodic)INSPECTION OF FABRICATED ITEMSReference: IBC Section 1705.10. Special Inspections offabricated items shall be performed in accordance withIBC Section 1704.2.5. (The requirements of IBC Section1704.2.5.1 may apply subject to County approval).Page 3 of 32 Revised 10/12/2020AGENT

MONTGOMERY COUNTY STATEMENT OF SPECIAL INSPECTIONSSTRUCTURAL STEELReference: IBC Section 1705.2.1. Inspections and non-destructive testing of structural steel elementsshall be in accordance with the quality assurance requirements of AISC 360-16, Chapter N and theMontgomery County Special Inspections Program Manual.Fabricator and Erector Quality Control ProgramReference AISC 360, Chapter N, Section N2.The fabricator’s Quality Control Inspector shall inspect the following as a minimum, as applicable:1. Shop welding, high-strength bolting, and details in accordance with AISC 360 Section N5.2. Shop cut and finished surfaces in accordance with AISC 360, Section M2.3. Shop heating for cambering, curving and straightening in accordance with AISC 360, SectionM2.1.4. Tolerances for shop fabrication in accordance with Code of Standard Practice, Section 6.4.The erector’s Quality Control Inspector shall inspect the following as a minimum, as applicable:1. Field welding, high-strength bolting, and details in accordance with AISC 360, Section N5.2. Steel deck in accordance with SDI Standard for Quality Control and Quality Assurance forInstallation of Steel Deck.3. Headed steel stud anchor placement and attachment in accordance with AISC 360, SectionN5.4.4. Field cut surfaces in accordance with AISC 360, Section M2.2.5. Field heating for straightening in accordance with AISC 360, Section M2.1.6. Tolerances for field erection in accordance with Code of Standard Practice, Section 7.13.Fabricator and Erector DocumentsReference AISC 360, Chapter N, Section N3.Submittals for Steel Construction and Available Documents for Steel Construction shall conform toAISC 360, Section N3.Inspection and Nondestructive Testing PersonnelReference AISC 360, Chapter N, Section N4Quality Control Inspector (fabricator or erector) Qualifications, Quality Assurance Inspector (specialinspector) Qualifications and Nondestructive Testing Personnel (inspection agency personnel)Qualifications shall conform to AISC 360, Section N4.Minimum Requirements for Inspection of Structural Steel BuildingsReference AISC 360, Chapter N, Section N5.Quality Control Inspections by the fabricator’s or erector’s Quality Control Inspector (QCI) andQuality Assurance Inspections by the Special Inspector (SI), shall conform to AISC 360, Section N5and tables N5.4-1, N5.4-2, N5.4-3, N5.6-1, N5.6-2 and N5.6-3. In these tables inspection tasks areas follows:O-Observe these items on a random basis. Operations need not be delayed pending theseinspections.P-Perform these tasks for each welded joint or member.Page 4 of 32 Revised 10/12/2020

MONTGOMERY COUNTY STATEMENT OF SPECIAL INSPECTIONSSTRUCTURAL STEEL (Continued)Nondestructive Testing of Welded jointsNondestructive testing of welded joints shall conform to AISC 360, Section N5 and shall beperformed by the Special Inspector (quality assurance inspector) in accordance with AWS D1.1.TABLE N5.4-1Inspection Tasks Prior to WeldingReference AISC 360, Chapter NInspection Tasks Prior to WeldingQCWelder qualification records and continuity recordsPWPS availablePManufacturer certifications for welding consumablesPavailableMaterial identification (type/grade)OWelder identification system*OFit-up of groove welds (including joint geometry) Joint preparations Dimensions (alignment, root opening, root face,bevel)O Cleanliness (condition of steel surfaces) Tacking (tack weld quality and location) Backing type and fit (if applicable)Fit-up of CJP groove welds of HSS T-, Y- and K-jointswithout backing (including joint geometry) Joint preparations Dimensions (alignment, root opening, root face,bevel) Cleanliness (condition of steel surfaces) Tacking (tack weld quality and location)PAGENTSIOPPAGENTOOOOFit-up of fillet welds Dimensions (alignment, gaps at root)OO Cleanliness (condition of steel surfaces) Tacking (tack weld quality and location)Check welding equipmentO* The fabricator or erector, as applicable, shall maintain a system by which a welder who has weldeda joint or member can be identified. Stamps, if used, shall be the low-stress type.Where:O-Observe these items on a random basis. Operations need not be delayed pending theseinspections.P-Perform these tasks for each welded joint or member.QC-Quality Control Inspector ((fabricator or erector).SI-Special Inspector (quality assurance inspector).(Continued)Page 5 of 32 Revised 10/12/2020

MONTGOMERY COUNTY STATEMENT OF SPECIAL INSPECTIONSSTRUCTURAL STEEL (Continued)TABLE N5.4-2Inspection Tasks During WeldingReference AISC 360, Chapter NInspection Tasks During WeldingQCControl and handling of welding consumables PackagingO Exposure controlAGENTSIOTABLE N5.4-2 (Continued)Inspection Tasks During WeldingQCAGENTSINo welding over cracked tack weldsOOEnvironmental conditions Wind speed within limitsOO Precipitation and temperatureWPS followed Settings on welding equipment Travel speed Selected welding materials Shielding gas type/flow rateOO Preheat applied Interpass temperature maintained (min./max.) Proper position (F, V, H, OH)Welding techniques Interpass and final cleaning Each pass within profile limitationsOO Each pass meets quality requirementsPlacement and installation of steel headed stud anchorsPPWhere:O-Observe these items on a random basis. Operations need not be delayed pending theseinspections.P-Perform these tasks for each welded joint or member.QC-Quality Control Inspector (fabricator or erector).SI-Special Inspector (quality assurance inspector).TABLE N5.4-3Inspection Tasks After WeldingReference AISC 360, Chapter NInspection Tasks After WeldingQCWelds cleanedOSize, length and location of weldsPWelds meet visual acceptance criteria Crack prohibition Weld/base-metal fusion Crater cross sectionP Weld profiles Weld size UndercutPage 6 of 32 Revised 10/12/2020AGENTAGENTSIOPPAGENTAGENT

MONTGOMERY COUNTY STATEMENT OF SPECIAL INSPECTIONSSTRUCTURAL STEEL (Continued)TABLE N5.4-3 (Continued) PorosityArc strikesPPk-area*PPWeld access holes in rolled heavy shapes and built-upPPheavy shaped**Backing removed and weld tabs removed (if required)PPInspection Tasks After WeldingQC AGENTSIAGENTRepair activitiesPPDocument acceptance or rejection of welded joint ofPPmemberNo prohibited welds have been added without theOOapproval of the Structural engineer of Record*When welding of doubler plates, continuity plates or stiffeners has been performed in the k-area,visually inspect the web k-area for cracks within 3 in. of the weld.**After rolled heavy shapes (see AISC Specification Section A3.1c) and built-up heavy shapes (seeAISC Specification Section A3.1d) are welded, visually inspect the weld access hole for cracks.Where:O-Observe these items on a random basis. Operations need not be delayed pending theseinspections.P-Perform these tasks for each welded joint or member.QC-Quality Control Inspector (fabricator or erector).SI-Special Inspector (quality assurance inspector).TABLE N5.6-1Inspection Tasks Prior to BoltingReference AISC 360, Chapter NInspection Tasks Prior to BoltingQCManufacturer’s certifications available for fastenerOmaterialsFasteners marked in accordance with ASTMOrequirementsCorrect fasteners selected for the joint detail (grade,type, bolt length if threads are to be excluded from shearOplane)Correct bolting procedure selected for joint detailOConnecting elements, including the appropriate fayingsurface condition and hole preparation, if specified, meetOapplicable requirementsPre-installation verification testing by installationpersonnel observed and documented for fastenerPassemblies and method usedProtected storage provided for bolts, nuts, washers andOother fastener components(Continued)Page 7 of 32 Revised 10/12/2020AGENTSIPOOOOOOAGENT

MONTGOMERY COUNTY STATEMENT OF SPECIAL INSPECTIONSSTRUCTURAL STEEL (Continued)TABLE N5.6-1 (Continued)Where:O-Observe these items on a random basis. Operations need not be delayed pending theseinspections.P-Perform these tasks for each welded joint or member.QC-Quality Control Inspector (fabricator or erector).SI-Special Inspector (quality assurance inspector).TABLE N5.6-2Inspection Tasks During BoltingReference AISC 360, Chapter NInspection Tasks During BoltingQCFastener assemblies placed in all holes and washers andnuts are positioned as requiredOAGENTSIAGENTOJoint brought to the snug-tight condition prior to theOOpretensioning operationFastener component not turned by the wrench preventedOOfrom rotatingFasteners are pretensioned in accordance with RCSCSpecification, progressing systematically from the mostOOrigid point toward the free edgesWhere:O-Observe these items on a random basis. Operations need not be delayed pending theseinspections.P-Perform these tasks for each welded joint or member.QC-Quality Control Inspector (fabricator or erector).SI-Special Inspector (quality assurance inspector).TABLE N5.6-3Inspection Tasks After BoltingReference AISC 360, Chapter NInspection Tasks After BoltingQC AGENTSIDocument acceptance or rejection of bolted connectionsPPWhere:O-Observe these items on a random basis. Operations need not be delayed pending theseinspections.P-Perform these tasks for each welded joint or member.QC-Quality Control Inspector (fabricator or erector).SI-Special Inspector (quality assurance inspector).(Continued)Page 8 of 32 Revised 10/12/2020AGENT

MONTGOMERY COUNTY STATEMENT OF SPECIAL INSPECTIONSSTRUCTURAL STEEL (Continued)Inspection of Fabricators and Fabrication ProceduresReference IBC Section 1704.2.5Inspection of fabricators and fabrication procedures shall be performed by the Quality AssuranceInspector (special inspector) and shall conform to IBC Sections 1704.2.5. (The requirements of IBCSection 1704.2.5.1 may apply subject to County approval).Nonconforming Materials and WorkmanshipReference AISC 360, Chapter N, Section N7Identification and rejection of materials or workmanship that is not in conformance with theconstruction documents shall be permitted at any time during the progress of the work.Nonconforming material and workmanship shall be brought to the immediate attention of theGeneral Contractor and the fabricator or erector, as applicable.Nonconforming material or workmanship shall be brought into conformance, or made suitable for itsintended purpose as determined by the Structural Engineer of Record.Structural repairs shall be reviewed and approved by the County.Page 9 of 32 Revised 10/12/2020

MONTGOMERY COUNTY STATEMENT OF SPECIAL INSPECTIONSCOLD-FORMED STEEL DECKReference: IBC Section 1705.2.2. Inspections and qualification of welding special inspectors forcold-formed steel floor and roof deck shall be in accordance with the quality assurance inspectionrequirements of SDI QA/QC-2017 Standard for Quality Control and Quality Assurance forInstallation of Steel Deck.Required SubmittalsReference: SDI QA/QC-2017, Section 2.Documents to be submitted to the SER and the Owner/General Contractor for approval prior to theinstallation of the steel deck shall conform to SDI QA/QC-2017, Section 2.Inspection and Testing PersonnelReference SDI QA/QC-2017, Section 3The Quality Control Inspector (installer) Qualifications and the Quality Assurance Inspector (specialinspector) Qualifications shall conform to SDI QA/QC-2017, Section 3 as modified in MontgomeryCounty Executive Regulation.Requirements for Inspection of Steel Deck InstallationReference SDI QA/QC-2017, Section 4.The requirements for inspection for steel deck installation shall conform to SDI QA/QC-2017,Section 4 as modified in Montgomery County Executive Regulation.Installer’s Quality Control ProgramReference SDI QA/QC-2017, Section 5.The installer’s quality control program shall conform to SDI QA/QC-2017, Section 5. All materialcontrol and installation procedures shall be monitored by the installer’s Quality Control Inspector(QCI).Quality Assurance TasksReference SDI QA/QC-2017, Section 6.The quality assurance tasks shall conform to SDI QA/QC-2017, Section 6 and shall be performed bythe Quality Assurance Inspector (QAI).Nonconforming material and workmanshipReference SDI QA/QC-2017, Section 7.Identification and rejection of materials and workmanship not in conformance with the constructiondocuments shall be as per SDI QA/QC-2017, Section 7. Nonconforming material or workmanshipshall be brought into conformance, or made suitable for its intended purpose as determined by thestructural engineer of record (SER).(Continued)Page 10 of 32 Revised 10/12/2020

MONTGOMERY COUNTY STATEMENT OF SPECIAL INSPECTIONSCOLD-FORMED STEEL DECK (Continued)TABLE 1.1Inspection or Execution Tasks Prior to Deck PlacementReference SDI QA/QC-2017, Appendix 1.TaskQCIAGENT QAIAGENTA Verify compliance of materials (deck and all deckPPaccessories) with construction documents, includingprofiles, material properties, and base metalthicknessB Document acceptance or rejection of deck andPPdeck accessoriesWhere:O-Inspect these items on an intermittent basis. Operations need not be delayed pending these inspectionP-Perform these tasks prior to final acceptance for each item or element.QCI-Quality Control Inspector (Installer).QAI-Quality Assurance Inspector (Special Inspector).TABLE 1.2Inspection or Execution Tasks After Deck PlacementReference SDI QA/QC-2017, Appendix1.TaskQCIAGENT QAIA Verify compliance of deck and all deck accessoriesinstallation with construction documentsB Verify deck materials are represented by the millcertifications that comply with the constructiondocumentsPPN/APAGENTC Document acceptance or rejection of installation ofPPdeck and deck accessories.Where:O-Inspect these items on an intermittent basis. Operations need not be delayed pending these inspectionP-Perform these tasks prior to final acceptance for each item or element.QCI-Quality Control Inspector (Installer).QAI-Quality Assurance Inspector (Special Inspector).(Continued)Page 11 of 32 Revised 10/12/2020

MONTGOMERY COUNTY STATEMENT OF SPECIAL INSPECTIONSCOLD-FORMED STEEL DECK (Continued)TABLE 1.3Inspection or Execution Tasks Prior to WeldingReference SDI QA/QC-2017, Appendix1TaskQCIAGENT QAIAWelding procedure specifications (WPS) availableOOBOOCManufacturer certifications for welding consumablesavailableMaterial identification (type/grade)OODCheck welding equipmentOOAGENTWhere:O-Inspect these items on an intermittent basis. Operations need not be delayed pending these inspectionP-Perform these tasks prior to final acceptance for each item or element.QCI-Quality Control Inspector (Installer).QAI-Quality Assurance Inspector (Special Inspector).TABLE 1.4Inspection or Execution Tasks During WeldingReference SDI QA/QC-2017, Appendix1.TaskQCIAGENT QAIAUse of qualified weldersOOBControl and handling of welding consumablesOOCEnvironmental conditions (wind speed, moisture,temperature)WPS followedOOOODAGENTWhere:O-Inspect these items on an intermittent basis. Operations need not be delayed pending these inspectionP-Perform these tasks prior to final acceptance for each item or element.QCI-Quality Control Inspector (Installer).QAI-Quality Assurance Inspector (Special Inspector).TABLE 1.5Inspection or Execution Tasks After WeldingReference SDI QA/QC-2017, Appendix 1.TaskQCIAGENT QAIAPPBVerify size and location of welds, includingsupport, side lap, and perimeter weldsWelds meet visual acceptance criteriaPPCVerify repair activitiesPPAGENTD Document acceptance or rejection of weldsPPWhere:O-Inspect these items on an intermittent basis. Operations need not be delayed pending these inspectionP-Perform these tasks prior to final acceptance for each item or element.Page 12 of 32 Revised 10/12/2020

MONTGOMERY COUNTY STATEMENT OF SPECIAL INSPECTIONSCOLD-FORMED STEEL DECK (Continued)TABLE 1.5 (Continued)QCI-Quality Control Inspector (Installer). QAI-Quality Assurance Inspector (Special Inspector).COLD-FORMED STEEL DECK (Continued)TABLE 1.6Inspection or Execution Tasks Prior to Mechanical FasteningReference SDI QA/QC-2017, Appendix 1.TaskQCIAGENT QAI AGENTA Manufacturer installation instructions availableOOfor mechanical fastenersB Proper tools available for fastener installationOOC Proper storage for mechanical fastenersOOWhere:O-Inspect these items on an intermittent basis. Operations need not be delayed pending these inspectionP-Perform these tasks prior to final acceptance for each item or element.QCI-Quality Control Inspector (Installer).QAI-Quality Assurance Inspector (Special Inspector).ATABLE 1.7Inspection or Execution Tasks During Mechanical FasteningReference SDI QA/QC-2017, Appendix 1.TaskQCIAGENT QAIFasteners are positioned as requiredOOAGENTBFasteners are installed in accordance withOOmanufacturer’s instructionsWhere:O-Inspect these items on an intermittent basis. Operations need not be delayed pending these inspectionP-Perform these tasks prior to final acceptance for each item or element.QCI-Quality Control Inspector (Installer).QAI-Quality Assurance Inspector (Special Inspector).TABLE 1.8Inspection or Execution Tasks After Mechanical FasteningReference SDI QA/QC-2017, Appendix 1TaskQCIAGENT QAIABCDCheck spacing, type, and installation of supportfastenersCheck spacing, type, and installation of side lapfastenersCheck spacing, type, and installation of perimeterfastenersVerify repair activitiesPPPPPPPPEAGENTPDocument acceptance or rejection of mechanicalPfastenersWhere:O-Inspect these items on an intermittent basis. Operations need not be delayed pending these inspectionPage 13 of 32 Revised 10/12/2020

MONTGOMERY COUNTY STATEMENT OF SPECIAL INSPECTIONSCOLD-FORMED STEEL DECK (Continued)TABLE 1.8 (Continued)P-Perform these tasks prior to final acceptance for each item or element.QCI-Quality Control Inspector (Installer).QAI-Quality Assurance Inspector (Special Inspector).OPEN-WEB STEEL JOISTS AND JOIST GIRDERSReference: IBC Section 1705.2.3, IBC Table 1705.2.3 and the Special Inspections Program Manual.Required Special Inspections of Open Web Steel Joists and EXTENT OF SERVICE AGENTJoist Girders(Continuous or periodic)Reference: IBC Table 1705.2.31. Installation of open-web steel joists and joist girders.a. End connections – welding or bolted.b. Bridging – horizontal or diagonal1. Standard bridging2. Bridging that differs from the Steel Joist InstituteSJI specifications listed in IBC Section 2207.1COLD-FORMED STEEL TRUSSES SPANNING 60FEET OR GREATERReference: IBC Section 1705.2.4Page 14 of 32 Revised 10/12/2020

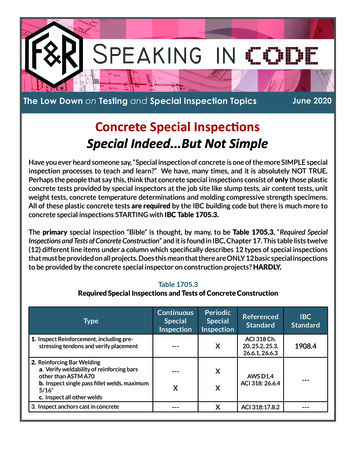

MONTGOMERY COUNTY STATEMENT OF SPECIAL INSPECTIONSCONCRETE CONSTRUCTIONReference: IBC Section 1705.3 Special inspections and tests of concrete construction shall beperformed in accordance with IBC Section 1705.3, IBC Table 1705.3 and the Montgomery CountySpecial Inspections Program Manual.CONCRETEEXTENT OF SERVICE AGENTReference: IBC Table 1705.3(Continuous or periodic)1. Inspect reinforcement, including prestressingtendons, and verify placement.2. Reinforcing bar welding:a. Verify weldability of reinforcing bars other thanASTM A706;b. Inspect single-pass fillet welds, maximum 5/16; andc. Inspect all other welds.3. Inspect anchors cast in concrete.4. Inspect anchors post-installed in hardened concretemembers. See note below.a. Adhesive anchors installed in horizontally orupwardly inclined orientations to resist sustainedtension loads. Installation shall be performed by anACI or CRSI certified adhesive anchor installer.b. Mechanical anchors and adhesive anchors notdefined in 4.a.5. Verify use of required design mix.6. Prior to concrete placement, fabricate specimens forstrength tests, perform slump and air content tests, anddetermine the temperature of the concrete.7. Inspect concrete and shotcrete placement for properapplication techniques.8. Verify maintenance of specified curingtemperature and techniques.9. Inspect prestressed concrete for:a. Application of prestressing forces; andb. Grouting of bonded prestressing tendons.10. Inspect erection of precast concrete members.11. Verify of in-situ concrete strength, prior tostressing of tendons in post-tensioned concrete andprior to removal of shores and forms from beams andstructural slabs. The strength evaluation shall bedemonstrated by field cured cylinders only.12. Inspect formwork for shape, location and dimensionsof the concrete member being formed.Continuous. (Countyamendment).Continuous. (Countyamendment).Note: Specific requirements for special inspection shall be included in the research report for the anchorissued by an approved source in accordance with 17.8.2 in ACI 318, or other qualification procedures.Where specific requirements are not provided, special inspection requirements shall be specified by theregistered design professional and shall be approved by the County prior to the commencement of the work.Page 15 of 32 Revised 10/12/2020

MONTGOMERY COUNTY STATEMENT OF SPECIAL INSPECTIONSMASONRY CONSTRUCTIONReference: IBC Section 1705.4Special inspections and tests of masonry construction shall be performed in accordance with the QualityAssurance Program requirements of TMS 402 and TMS 602 and the Montgomery County SpecialInspections Program Manual.QUALITY ASSURANCE PROGRAMThe Quality Assurance Program shall comply with the Level defined in Table 3.1 of TMS 402,depending on how the masonry was designed and the Risk Category, as defined in IBC 2018, Table1604.5. The Quality Assurance Program shall itemize the requirements for verifying conformance ofmaterial composition, quality, storage, handling, preparation, and placement with the requirements ofTMS 602, and shall comply with the minimum requirements of TMS 602, Tables 3 and 4 for therequired Level. The Structural Engineer of Record may increase the amount of Verification and SpecialInspections required.Designed inaccordance withPart 3 orAppendix B orAppendix C of TMS402Part 4 of TMS 402Appendix A of TMS402MINIMUM QUALITY ASSURANCE LEVELReference TMS 402, Table 3.1Risk Category I, II or IIIRisk Category IVLevel 2Level 3Level 1Level 1Level 2Not permittedMINIMUM VERIFICATION REQUIREMENTSReference TMS 602, Table 3Minimum VerificationRequired for Quality AssuranceLevel 1Level 2Level 3Prior to construction, verification of compliance ofRRRsubmittalsPrior to construction, verification of f’m and f’aac,NRRRexcept where specifically exempted by the CodeDuring construction, verification of Slump flow andNRRRVisual Stability Index (VSI) when selfconsolidating grout is delivered to the project siteDuring construction, verification of f’m and f’aacNRNRRfor every 5000 sq. ft.During construction, verification of proportions ofNRNRRmaterials as delivered to the project site forpremixed or preblended mortar , prestressing grout,and grout other than self-consolidating groutWhere: R Required, NR Not Required.Page 16 of 32 Revised 10/12/2020AGENT

MONTGOMERY COUNTY STATEMENT OF SPECIAL INSPECTIONSMASONRY CONSTRUCTION (continued)MINIMUM SPECIAL INSPECTION REQUIREMENTSReference TMS 602, Table 4INSPECTION TASKFrequency*Level 1Level 2Level 31. As masonry construction begins, verify thatthe following are in compliance:a. Proportions of site-prepared mortarNRPPb. Grade and size of prestressing tendons andanchoragesc. Grade, type and size of reinforcement,connectors, anchor bolts, and prestressingtendons and anchoragesd. Prestressing techniquee. Properties of thin-bed mortar for AACmasonryf. Sample panel construction2. Prior to grouting, verify that the following arein compliance:a. Grout spaceb. Placement of prestressing tendons andanchoragesc. Placement of reinforcement, connectors, andanchor boltsd. Proportions of site-prepared grout andprestressing grout for bonded tendons3. Verify compliance of the following duringconstruction:a. Materials and procedures with the approvedsubmittalsb. Placement of masonry units and mortar jointconstructionc. Size and location of structural membersd. Type, size, and location of anchors, includingother details of anchorage of masonry tostructural members, frames, or otherconstructione. Welding of reinforcementf. Preparation, construction, and protection ofmasonry during cold weather (temperaturebelow 40 degrees F) or hot weather(temperature above 90 degrees F)g. Application and measurement of age 17 of 32 Revised 10/12/2020AGENT

MONTGOMERY COUNTY STATEMENT OF SPECIAL INSPECTIONSMINIMUM SPECIAL INSPECTION REQUIREMENTSReference TMS 602, Table 4 (Continued)INSPECTION TASK (Continued)Frequency*Level 1Level 2Level 3NRCCAGENTh. Placement of grout and prestressing grout forbonded tendons is in compliancei. Placement of AAC masonry units andNRC**/P***Cconstruction of thin-bed mortar joints4. Observe preparation of grout specimens,NRPCmortar specimens, and/or prisms5. Inspect location and conformance of wallNRPPpenetrations, embedded items and wallflashing* Frequency refers to frequency of inspections, which may be Continuous during the listed task orPeriodic during the listed task, as defined in Table 4 above.Where: NR Not Required, P Periodic, C Continuous** Required for the first 5000 square feet of AAC masonry.*** Required after the first 5000 square feet of AAC masonry.Page 18 of 32 Revised 10/12/2020

MONTGOMERY COUNTY STATEMENT OF SPECIAL INSPECTIONSWOOD CONSTRUCTIONReference: IBC Section 1705.5 and the MontgomeryCounty Special Inspections Program ManualEXTENT OF SERVICE(Continuous or periodic)Special Inspections of prefabricated wood structuralelements and assemblies shall be in accordance withSection 1704.2.5. (The requirements of IBC Section1704.2.5.1 may apply subject to County approval).Special Inspection of site built assemblies shall be inaccordance with IBC Section 1705.5Inspect high-load diaphragms as per IBC 2018, Section1705.5.1Inspect metal-plate-connected trusses as per IBC Section1705.5.2Inspect Load Bearing Walls as follows, as applicable:1. Wall stud species and spacing as per projectspecifications.2. Placement of cripple stud blocking inside of floorsystem.3. Stud drillings and penetrations (not to exceed onethird of stud dimension unless otherwise isspecified by the structural engineer of record).4. Sill plate species as per project specifications.Inspect Wood Columns as follows, as applicable:1. Types and placement of wood columns as perconstruction documents.2. Column connection details to beams and trusses.3. Cripple stud project requirements within the floorsystem for load path continuity.4. Column base assemblies.Inspect Shear Wall Systems as follows, as applicable:1. Wall stud, size and spacing.2. Anchor bolt size, location on sill plates andstrappings through floor system.3. Placement of diagonal bracing and componentshear trusses.4. Placement of hold-down anchors and tension rodsas per contract documents.5. Shear wall sheathing type, fastener types andfastener spacing.6. Wall blockingsPage 19 of 32 Revised 10/12/2020AGENT

MONTGOMERY COUNTY STATEMENT OF SPECIAL INSPECTIONSWOOD CONSTRUCTION (Continued)Reference IBC Section 1705.5 and the MontgomeryCounty Special Inspections Program ManualEXTENT OF SERVICE(Continuous or Periodic)Inspect Roof Framing as follows, as applicable:1.2.3.4.Placement of hurricane hangers.Placement of parapet hold-down anchors.Placement of permanent roof bracing.Placement of gable truss bracings.Inspect Steel Framing as follows, as applicable:1. Wood to steel connections (number, size andspacing of bolts and hunger types).2. Bracing of steel beams and columns (placement ofsill plates, anchor bolt, and diagonal bracing to topof beams and blocking placement at steel beamwebs).Inspect Floor trusses as follows, as applicable:1. Placement of 2x6 band members at end of trusses.2. Truss bearing width in butting and diagonalsituations.Other Wood Inspections as determined by SER:Page 20 of 32 Revised 10/12/2020AGENT

MONTGOMERY COUNTY STATEMENT OF SPECIAL INSPECTIONSSOILSReference: IBC Section 1705.6, IBC Table 1705.6 and the Special Inspections Program ManualRequired Special Inspections and Tests of SoilsEXTENT OF SERVICEAGENTReference: IBC Table 1705.6(Continuous or periodic)1. Verify materials below shallow foundations areContinuous.adequate to achieve th

Oct 12, 2020 · Reference AISC 360, Chapter N, Section N5. Quality Control Inspections by the fabricator’s or erector’s Quality Control Inspector (QCI) and Quality Assurance Inspections by the Special Inspector (SI), shall conform to AISC 360, Section N5 and tables N5.4-1, N5.4 -2, N5.4-3, N5.6-1