Transcription

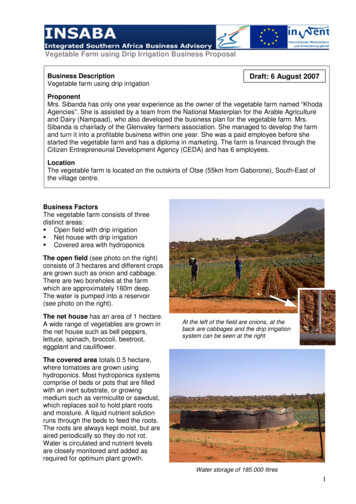

Vegetable Farm using Drip Irrigation Business ProposalBusiness DescriptionVegetable farm using drip irrigationDraft: 6 August 2007ProponentMrs. Sibanda has only one year experience as the owner of the vegetable farm named “KhodaAgencies”. She is assisted by a team from the National Masterplan for the Arable Agricultureand Dairy (Nampaad), who also developed the business plan for the vegetable farm. Mrs.Sibanda is chairlady of the Glenvaley farmers association. She managed to develop the farmand turn it into a profitable business within one year. She was a paid employee before shestarted the vegetable farm and has a diploma in marketing. The farm is financed through theCitizen Entrepreneurial Development Agency (CEDA) and has 6 employees.LocationThe vegetable farm is located on the outskirts of Otse (55km from Gaborone), South-East ofthe village centre.Business FactorsThe vegetable farm consists of threedistinct areas: Open field with drip irrigation Net house with drip irrigation Covered area with hydroponicsThe open field (see photo on the right)consists of 3 hectares and different cropsare grown such as onion and cabbage.There are two boreholes at the farmwhich are approximately 160m deep.The water is pumped into a reservoir(see photo on the right).The net house has an area of 1 hectare.A wide range of vegetables are grown inthe net house such as bell peppers,lettuce, spinach, broccoli, beetroot,eggplant and cauliflower.At the left of the field are onions, at theback are cabbages and the drip irrigationsystem can be seen at the rightThe covered area totals 0.5 hectare,where tomatoes are grown usinghydroponics. Most hydroponics systemscomprise of beds or pots that are filledwith an inert substrate, or growingmedium such as vermiculite or sawdust,which replaces soil to hold plant rootsand moisture. A liquid nutrient solutionruns through the beds to feed the roots.The roots are always kept moist, but areaired periodically so they do not rot.Water is circulated and nutrient levelsare closely monitored and added asrequired for optimum plant growth.Water storage of 185.000 litres1

Mrs. Sibanda, the owner of the vegetable farm inside the net houseThe farm is connected to the mains electric grid and uses electricity for pumping water into astorage tank, operating booster pumps for drip irrigation and pressure pumps for the hydroponicssystem and for lighting. This case study compares the use of grid electricity with solar PVelectricity for pumping water using drip irrigation to grow cabbage in the open field. Calculationsfor other vegetables are similar. Growing of vegetables in the net house and hydroponically werenot considered due to lack of information regarding some of the parameters that are required forthe calculations. These farming techniques are also not as easy to replicate due to the largercapital investment and complexity of operation, such as in the case of hydroponics.Pre-AssessmentThe vegetable farm is an existing and operating business. It has proven to be feasible. Thisexercise serves as an assessment to determine if similar vegetable farms may be feasible usingsolar PV for water pumping and to determine the most important success and failure factors.Only growing cabbage in open field using drip irrigation is considered for the case study. Thegrowing season for cabbage is 3 months and 4 crops can be harvested during the year. For easeof comparison, calculations are carried out for one hectare. From working experience andrecords that were kept, the following parameters are known:Cost of equipping the borehole and irrigation system per hectare:P88,714Cold room, office and office equipment:P14,250Drilling of the borehole and pump:P49,120Storage tank (370.000 litres). This is double the size compared topumping with grid electricity to cover for cloudy days:P42,5003Cost of solar PV array for solar pump with head of 50m, 90m /dayand P35/Wp:Small truck:P121,092Average kg cabbages per year (20% production losses):224,000 kgAverage price of cabbage per kg:P1.62Wages labourers and manager:P11,700Insurance per year:P800Ploughing per ha per year:P1,200Vehicle maintenance cost per year:P10,000P200,0002

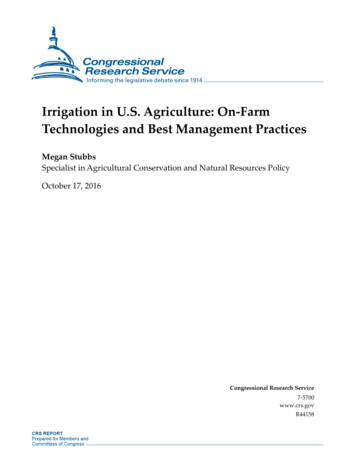

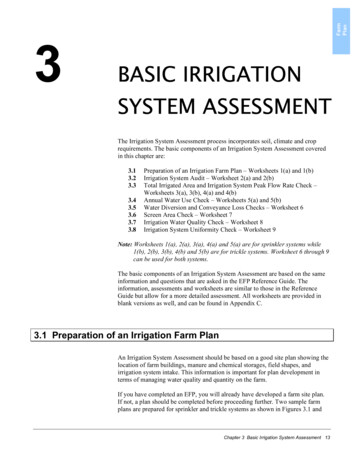

Covered areas where tomatoes are grown using hydroponicsBased on these figures a Pre-Assessment of the vegetable farm using drip irrigation with solarPV was carried out. Results are shown in Table 1. Also calculations were carried out comparinggrid electricity with PV solar electricity. Results of this assessment are shown in Table 2.Table 3 below shows a comparison between the two sources of energy.Solar PV ElectricityGridElectricityROI44%63%Paybackperiod (yrs)1.811.35It can be observed that growing vegetables in both cases is highly profitable. The largeinvestment for the solar panels has a limited impact on the ROI. The reason for this can beobserved from the sensitivity analysis below Table 3. The cost of energy/unit has only a limitedinfluence on the change of ROI.Market AssessmentMost of the vegetables are sold to the supermarketchains in Gaborone. Limited amounts are sold from thefarm to local customers. The vegetables aretransported in a small truck (bakkie). Since Mrs.Sibanda resides in Gaborone, she drives backward andforward between Otse and Gaborone and takes loadsof vegetables with her. There is not a plannedmarketing strategy and marketing is mostly donethrough word-of-mouth. The demand is currently higherthan supply therefore there are no problems selling thevegetables the market. Late payments for the sales ofvegetables sometimes cause problems.Seedlings are bought and readily available. To reducecosts, the farm will grow their own seedlings from seedsfor most vegetables in the future.Harvested and packed cabbagesready to be marketedThe cost of chemicals and fertilisers is perceived as very high and it was expressed thatgovernment should subsidise these items to help farmers.3

Operational PlanThe vegetable farm managed to develop into a successful business within a year, mainly due theenergetic input from Mrs. Sibanda. Although she did not have any prior farming experience, shestarted the business, and through her background in marketing and good communication skills,she managed to access the market easily and obtain information from experts as required.Strategic choices have been made to spread risk. Farming is carried out using differenttechnologies, e.g. open field with drip irrigation, net house with drip irrigation and covered areawith hydroponics. Risk is further spread through growing different type of crops.With the feasibility and viability firmly established in Tables 1 to 3, table 4 gives the dynamicdevelopment of income and cost during the first three years of operation. The cash flow analysisshows how much financing is required, which is P511,000. The graphs visualize this businessdevelopment for the first year and the first 3 years. Finally, Table 5 gives the profitability forecastand balance for the business.4

Table 1: Pre-Assessmentof vegetable farm using drip irrigation with solar PV electricityINSABA Preassessment of Project ProposalsBotswanaSouth East district, OtseSolar PV pumpVegetable Farm with drip irrigationCountry:Pilot Region:RE Technology:Business Idea:Proponent name, contactMrs SibandaYears of experience as owner of businessNumber of employees w/contractProponent uses bank acount(yes 5, No 0)Experience with formal loan(received 5, applied 3, no 0)Experience in cost calculations, business p(no 0, several 5)Practice in maintaining/operating equipment (RET) (none yet 0, regularly 5)Total16553020Calculation of ROIBWPDetermination of parametersInvestment Capital88,714Cost of equipping the borehole and irrigationsystem per hectareInvestment Capital14,250Cold room, office and office equipmentInvestment Capital49,120Drilling of the borehole and pumpInvestment Capital42,500Storage tank (370.000 litres). This is double thesize compared to pumping with grid electricityto cover for cloudy days.Investment Capital121,092Cost of solar PV array for solar pump with headof 50m, 90m3/day and P35/WpInvestment Capital200,000Small truckTotal InvestmentCapitalInvestmentLifespan515,6767 year loan period plus 2 years grace period for Life of the investment - i.e. period before it mustCEDA loanbe replaced224000Price/unitRevenueVariable cost/unitVariable cost/unitVariable cost/unitVariable cost/unitTotal 54Average kg cabbages per year (20%production losses)Average price of cabbage per kgPula/yearCabbage seedlingsFertiliserPest controlTransport cost0.00Cost of electricity per kg producedFixed costsFixed costsFixed costsFixed costs11,7008001,20010,000Wages labourers and managerInsurance per yearPloughing per ha per yearVehicle maintenanceTotal fixed costs23,700Total fixed costs per yearAmortization/unit:0.2657,297Direct costs perunit:0.55122,349Gross Margin/unit1.070.11Total costsNet Margin0.650.97Units produced per yearSales price per unit produced and soldSales price multiplied by number of units soldCost per unit produced e.g. material, processingpackaging0.29Fixed costs/unitDepth of b.h. is 162 mTotal cost of investment9ProductionCost of energy/unitDefinitionsCosts solar PV averaged over 20 yr, fuel for caradded to variable costAnnnualAnnnualAnnnualAnnnualAnnual indirect costs such as rent, telephones,salariesAmount needed per unit to cover investment inlifetimeVariable costs plus amortization plus cost ofenergySales price per unit less the direct costs per unitNote that all calculations are per hectarewith the exception of the drilling and146,049 equiping of the borehole216,831Total fixed costs divided by the number of unitsproducedDirect costs plus fixed costsRevenue less total costs5

Table 2: Pre-Assessmentof vegetable farm using drip irrigation with grid electricityINSABA Preassessment of Project ProposalsCountry:Pilot Region:RE Technology:Business Idea:BotswanaSouth East district, OtseGrid ElectricityVegetable Farm with drip irrigationProponent name, contactMrs SibandaYears of experience as owner of businessNumber of employees w/contractProponent uses bank acount(yes 5, No 0)Experience with formal loan(received 5, applied 3, no 0)Experience in cost calculations, business p(no 0, several 5)Practice in maintaining/operating equipment (RET) (none yet 0, regularly 5)Total16553020Calculation of ROI for Grid ElectricityBWPDetermination of parametersInvestment Capital88,714Cost of equipping the borehole and irrigationsystem per hectareInvestment Capital14,250Cold room, office and office equipmentInvestment Capital49,120Drilling of the borehole and pumpInvestment Capital21,250Storage tank (185.000 litres)Total InvestmentCapitalTotal InvestmentCapitalInvestmentLifespan200,000Total cost of investment7 year loan period plus 2 years grace period forCEDA loanAverage kg cabbages per year (20%production losses)Average price of cabbage per kgPula/yearCabbage seedlingsFertiliserPest controlTransport cost9Production224000Price/unitRevenueVariable cost/unitVariable cost/unitVariable cost/unitVariable cost/unitTotal 54Cost of energy/unit0.0321Cost of electricity per kg producedFixed costsFixed costsFixed costsFixed costs11,7008001,20010,000Wages labourers and managerInsurance per yearPloughing per ha per yearVehicle maintenanceTotal fixed costs23,700Total fixed costs per yearAmortization/unit:0.1941,482Direct costs perunit:0.51113,734Gross Margin/unit1.11Total costsNet Margin0.611.01ROI60%Life of the investment - i.e. period before it mustbe replacedUnits produced per yearSales price per unit produced and soldSales price multiplied by number of units soldCost per unit produced e.g. material, processingpackaging0.290.11Depth of b.h. is 162 mSmall truck373,334Fixed costs/unitDefinitionsCosts of electric energy, fuel for car added tovariable costAnnnualAnnnualAnnnualAnnnualAnnual indirect costs such as rent, telephones,salariesAmount needed per unit to cover investment inlifetimeVariable costs plus amortization plus cost ofenergySales price per unit less the direct costs per unitNote that all calculations are per hectarewith the exception of the drilling and137,434 equiping of the boreholeTotal fixed costs divided by the number of unitsproducedDirect costs plus fixed costs225,446Revenue less total costsReturn on Investment net margin divided bycapital investment6

Table 3: Competitive AnalysisINSABA Verification & Market-Assessment of Project ProposalsBotswanaSouth East district, OtseMains ElectricityVegetable Farm with drip irrigationCountry:Pilot Region:RE Technology:Business Idea:Market Context : describeMarket Size & PotentialThere appears sufficient potential for vegatable gardening using drip irrigation. Thebusiness is scalable to a certain degree. When more energy is required due to anincrease of cultivated land area, solar panels may be added as long as the pump canhandle the increased power, provided this has been considered when purchasing thepump. The same business model is replicable for different parts of the country.However, pumping head is an important parameter deteriming the Wp of solar panelsrequired.Market Need, RiskThe demand for fresh vegetables overrides the supply in Botswana and there is a largemarket for fresh vegetables. Presently fresh vegetables are imported from SouthAfrica, where the conditions of growing vegetables may be better, due to better climaticand topographic conditions.CompetitorThere is competition from vegetable farms that are connedted to the mains electricgrid. Also competition from imports from South Africa.Competing TechnologyAppropriateness of RETMains electricity (subsidized) and diesel/petrol pumping.The water requirement matches the availability of solar energy. In Botswana irrigation isrequired almost throughout the year since rainfall is erratic. There is a limitation to thequantity and head that a solar pump is able to handle.Market SegmentPumping with grid electricity and diesel/petrol pump is on demand and therefore lessstorage of water is required.Compared to diesel/petrol pump easier to operate since operation is automatic and noneed for hauling fuel.n.a.Main DifferentiatorSustainable ProductionIrrigation with solar PV pumpCompared to irrigation with grid el.Calculation of CompetitivenessSolar PV ElectricityGrid estment CapitalPrice/unitRevenueVariable cost/unitCost of energy/unitFixed costsFixed costsFixed costsTotal fixed costsBWPPloughing per ha per yearTotal fixed costs0.1941,482Direct costs perunit:0.55122,3490.51113,734Gross Margin/unit1.071.11Fixed costs/unit0.060.06Total costsNet Margin0.611.0144%Average price of cabbage per kgInsurance per year57,297ROI7 year loan period plus 2 years grace period forCEDA loanAverage kg cabbages per year (20%production losses)Wages labourers and manager0.260.571.05Pump that operates on grid electricityCost of grid electricity per cabbage n of Alternative127,434235,446Due to the high cost of the solar panels the ROIis less compared to using grid electricity forwater pumping. However, in both cases thefarming of vegetables is very profitable.63%7

Cash Flow Analysis: First -500,000100,000-600,0000Month-1Month-2Month-3TOTAL Cash Inflow, accMonth-4Month-5Month-6Month-7TOTAL Cash Outflow, accMonth-8Operating ResultMonth-9Month-10 Month-11 Month-12Operating Result, accCash FlowCash Flow Analysis: 1st - 3rd 00,000-400,000100,000-500,0000Year 1TOTAL Cash InflowYear 2TOTAL Cash OutflowOperating ResultYear 3Operating Result, accCash Flow8

72925,125Capital inputCash 130,2400030,24030,24018,66700Month-2Year 9CostPrice1.62Sales224000Month-1Year 1-510,561Operating ResultTOTAL capitalTOTAL Cash Ouflowinterest, redemptionCapital costInvestment LifespanTOTAL OverheadInvestmentVehicle maintenancePloughing per ha per yearWages labourers and manaInsurance per yearOverhead CostCabbagesProduct 2Product 3TOTAL MaterialMaterialCash OutflowCabbagesProduct 2Product 3TOTAL TurnoverTOTAL Cash InflowTurnoverCash InflowProductsCabbagesProduct 2Product 3Cash Flow AnalysisTable 4: Cash Flow 0Month-3Year 4Year 5Year 6Year 7Year 8Year 9Year 10Year 11Year h-12Year 1

/accumulatedannual surplus/deficitTOTAL Expensespersonnel costshire depreciationother expensesother operating incomeSalesCost of SalesGross 348,835.38297,828297,828174,417.69Year 2362,88065,052Year 1362,88065,052Profitability PreviewTable 5: Profitability and Balance 357,2970123,410297,828Year 3362,88065,052Assetsfixed assetscurrent assetsSYear 3Assetsfixed assetscurrent assetsSYear 2Assetsfixed assetscurrent assetsSYear 1BalanceLiabilities343,784 shareholders equity179,469 liabilities523,253 SLiabilities401,081 shareholders equity118,087 liabilities519,169 SLiabilities458,379 shareholders equity56,706 liabilities515,084 7515,08410

5 Table 1: Pre-Assessment of vegetable farm using drip irrigation with solar PV electricity INSABA Preassessment of Project Proposals Country: Botswana Pilot Region: South East district, Otse RE Technology: Solar PV pump Business Idea: Vegetable Farm with drip irrigation Proponent name, contact Mrs Sibanda Years of experience as owner of business 1 Number of employees w/contract 6