Transcription

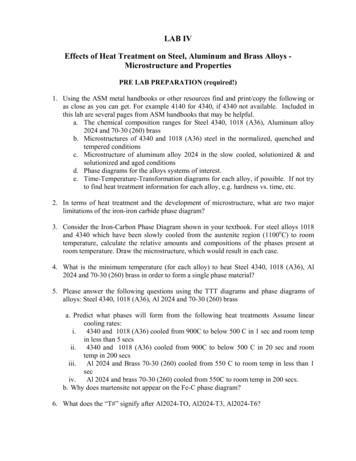

Heat Treating Aluminum for Aerospace ApplicationsD. Scott MacKenzie, PhDHoughton International, Inc.Valley Forge, PAAbstractAluminum has been used in the aerospace industrysince the original Wright Flyer. While there have beeninroads made by composites and plastics, the primarystructural material for aerospace is heat treatedaluminum. In this paper, a brief overview of theapplication of aluminum to aerospace will be discussed.A short review of aluminum physical metallurgy willalso be provided. Common defects observed duringaluminum heat-treating will be shown, with possiblecorrective actions.IntroductionAluminum in many forms has been used in aircraftsince the early beginning. This is because aluminumalloys can be heat-treated to relatively high strengths,while maintaining low weight. It is easy to bend andmachine, and cost of material is low. Because of theseadvantages, it is the most common material used inaerospace today. It is used in the manufacture ofadvanced commercial aircraft such as the Boeing 777,Airbus 380, and military aircraft such as the BoeingUCAV (Figure 1) or the Boeing F/A-18 E/F (Figure 2).Figure 1 – Artist conception of the Boeing UCAV(Unmanned Combat Air Vehicle).Figure 2 - Boeing F/A-18F during sea trials.Typically, the aluminum alloys used in aerospacestructures are the heat treatable grades, such as 2XXX,6XXX, and 7XXX. 7XXX alloy grades such as 7075,7040, and 7050 predominate in aerospace structures.Some of the Al-Li alloys such as 2090 and 8090 havealso found application. These alloys are commonly usedbecause they are commonly available and readily formedand heat-treated to high, corrosion resistant strengths.Most commonly, the aluminum alloys used are7XXX wrought products. The thickness of parts usedrange from 0.6 mm to 250 mm. Aluminum alloy 7075,7050 extrusions are used extensively for stringers, andother structural requirements. Some extrusions of 2024,and 2014 are also used. Sheet, both clad and non-cladsheet of 2024, 7475 and 7075 is used for wing andfuselage skins. Sheet is also formed and built-up to formbulkheads and other structural requirements. For heavyloading, large forgings of 7050 and 7040 are commonlyused, particularly in military aircraft.1

Recently, there has been much interest in the use ofheat treated 7050 and 7040 plate to eliminate the cost offorgings. In this case, the plate (heat treated at thealuminum mill) is supplied to the airframe manufacturer.There the plate is heavily machined to fabricate largeribs and bulkheads. The advantage of this is that itavoids heat-treating small parts and may have betterdistortion and residual stress control. Unfortunately,there is a significant property variation through thethickness of thick plate. This variation has been studiedin detail, and the microstructure development in thicksections has been extensively studied [1].Because of affordability, the use of castings has alsobeen used. However, the use of castings has beenlimited because of design factors and the limitedductility of castings. Typically casting alloys such asA356, and A357 are used. Applications of castings aresimple, non-flight critical applications, such as doorhandles and avionics cabinets.Heat-treating of aluminum requires stringentcontrols. These controls are in place to avoid meltingthe alloy during solution heat treatment, and to insurethat a safe and durable product is manufactured andcreated. Temperature uniformity requirements insidefurnaces are tight ( 5ºF) to prevent eutectic melting, andinsure uniform properties throughout the workload.Because of the sensitivity of aluminum to processvariations, and to achieve repeatable results, and toprovide a quality product, the airframe manufacturers,suppliers, and heat-treaters have developed a series ofspecifications. The most widely used specification isAMS-2770 “Heat Treatment of Aluminum Parts” [2].This specification details solution heat treating times,temperatures, quenchants, quenchant concentrations, andaging practices.It also details the requireddocumentation for heat treat lot traceability.Furthermore, this specification details the qualityassurance provisions needed to insure that a qualityproduct is provided to the airframe manufacturer.Aluminum Heat TreatingAluminum Solution Heat Treating. Aluminumalloys are classified as either heat treatable or not heattreatable, depending on whether the alloy responds toprecipitation hardening.In the heat treatable alloysystems like 7XXX, 6XXX, and 2XXX, the alloyingelements show greater solubility at elevatedtemperatures than at room temperature.This isillustrated for the Al-Cu phase [3] (Figure 3).Table 1 - Solution heat treatment temperature rangeand eutectic melting temperature for 2XXX alloys.Alloy201420172024Solution HeatTreatmentTemperatureRange, C496-507496-507488-507InitialEutectic MeltingTemperature, C510513502Figure 3 – Partial aluminum-copper phase diagram (afterVan Horn [4])The Al-Cu phase diagram shows that holding a 4.5%alloy at 515 to 550ºF will cause all the copper to gocompletely into solution. This is the typically know asthe “solution heat treating temperature”. If the alloy isslowly cooled, then the equilibrium structure of Al CuAl2 will form. The CuAl2 that forms is large, coarseand incoherent. However, if the alloy is cooled rapidly,there will be inadequate time for the CuAl2 toprecipitate. All the solute is held in a supersaturatedcondition. Controlled precipitation of the solute infinely dispersed particles at room temperature (naturalaging) or at elevated temperatures (artificial aging) isused to develop the optimized mechanical and corrosionproperties of these alloys.Solution heat treatment involves heating thealuminum and alloys to a temperature slightly below theeutectic melting temperature. Solution heat treatmentdevelops the maximum amount of solute into solidsolution. This requires heating the material close to nearthe eutectic temperature and holding the material attemperature long enough to allow close to completesolid solution.After solution heat treatment, thematerial is quenched to maintain the solute insupersaturated solid solution.Because the solution heat treatment temperature isso close to the eutectic melting temperature, temperaturecontrol is critical. This is especially true for 2XXX2

supersaturation is relatively high, as is the diffusion rate.Therefore the heterogeneous precipitation rate is thegreatest at intermediate temperatures. This is shownschematically in Figure 5. The amount of time spent inthis critical temperature range is governed by the quenchrate.The amount of precipitation occurring duringquenching reduces the amount of subsequent hardeningpossible. This is because as solute is precipitated fromsolution during quenching, it is unavailable for anyfurther precipitation reactions. This results in lowertensile strength; yield strength, ductility and fracturetoughness.Temperatureseries alloys. In this alloy group, the initial eutecticmelting temperature is only a few degrees above themaximum recommended solution heat treatmenttemperature (Table 1).Solution heat treating and quenching of these alloysis typically accomplished in large high temperatureovens. In some applications, the furnace is supportedabove the quench tank. The quench tank moves underthe furnace on rails. Sometimes there is more than onequench tank, with each tank containing a differentquenchant. A typical solution heat-treating furnace andquench tank used for heat-treating aluminum aerospacecomponents is shown in Figure 4.RatePrecipitationSupersaturationDiffusion RateFigure 5 - Schematic showing the interrelationshipbetween the amount of solute supersaturation anddiffusion rate on the amount of heterogeneousprecipitation occurring during quenching.Figure 4 - Large drop-bottom furnace used to solutionheat- treat and quench aluminum alloys.Quenching. An understanding of heterogeneousprecipitation during quenching can be understood bynucleation theory applied to diffusion controlled solidstate reactions [5]. The kinetics of heterogeneousprecipitation occurring during quenching is dependenton the degree of solute supersaturation and the diffusionrate, as a function of temperature. So, as an alloy isquenched, there is greater supersaturation (assuming nosolute precipitates). But the diffusion rate increases as afunction of temperature. The diffusion rate is greatest atelevated temperature. When either the supersaturationor the diffusion rate is low, the precipitation rate is low.At intermediate temperatures, the amount ofQuantifying quenching, and the cooling effect ofquenchants have been extensively studied [6] [7] [8] [9].The first systematic attempt to correlate properties to thequench rate in Al-Zn-Mg-Cu alloys was performed byFink and Wiley [10] for thin (0.064") sheet. ATime-Temperature-Tensile Property curve was createdand was probably the first instance of a TTT diagram foraluminum.It was determined that the criticaltemperature range for 75S (7075) is 400 C to 290 C.This is similar to the critical temperature range found forAl-Zn-Mg-Cu alloys [11]. At quench rates exceeding450 C/sec., it was determined that maximum strengthand corrosion resistance were obtained. At intermediatequench rates of 450 C to 100 C/sec., the strengthobtained is lowered (using the same age treatment), butthe corrosion resistance was unaffected. Between100 /sec and 20 C/sec, the strength decreased rapidly,and the corrosion resistance is at a minimum. At quenchrates below 20 C/sec, the strength decreases rapidly, butthe corrosion resistance improved. However, for a givenquenching medium, the cooling rate through the critical3

temperature range was invariant no matter the solutionheat treat temperature.One method that quantifies the quench path andmaterial kinetic properties is called the “Quench Factor”and was originally described by Evancho and Staley[12]. This method is based on the integration of the areabetween the Time-Temperature-Property Curve and thequench path. Wierszykkowski [13] provided analternative explanation of the underlying principles ofthe Quench Factor. However, his discussion is moregenerally applied to the thermal path prior to isothermaltransformation. The procedures for developing theQuench Factor have been well documented [14] [15][16] [17] [18] [19]. This procedure could be used topredict tensile properties [20], hardness [21] andconductivity [15]. It was found that the Quench Factorcould not be used to predict elongation because of itsstrong dependence on grain size [15]. This method tendsto overestimate the loss of toughness [19]. This methodalso can be used to determine the critical quench rate forproperty degradation [22].Natural Aging.Some heat treatable alloys,especially 2XXX alloys, harden appreciably at roomtemperature to produce the useful tempers T3 and T4.These alloys that have been naturally aged to the T3 orT4 tempers, exhibit high ratios of ultimate tensilestrength/yield strength.These tempers also haveexcellent fatigue and fracture toughness properties.Natural aging, and the increase in properties occursby the rapid formation of GP (Guinier-Preston) Zonesfrom the supersaturated solid solution and fromquenched-in vacancies. Strength increases rapidly, withproperties becoming stable after approximately 4-5 days.The T3 and T4 tempers are based on natural aging for 4days. For 2XXX alloys, improvements in propertiesafter 4-5 days are relatively minor, and become stableafter one week.The Al-Zn-Mg-Cu and Al-Mg-Cu alloys (7XXX &6XXX), harden by the same mechanism of GP Zoneformation. However, the properties from natural agingare less stable. These alloys still exhibit significantchanges in properties even after many years.The natural aging characteristics change from alloyto alloy. The most notable differences are the initialincubation time for changes in properties to be observed,and the rate of change in properties. Aging effects aresuppressed with lower than ambient temperatures. Inmany alloys, such as 7XXX alloys, natural aging can benearly completely suppressed by holding at -40 C.Because of the very ductile and formable nature ofas-quenched alloys, retarding natural aging increasesscheduling flexibility for forming and straighteningoperations. It also allows for uniformity of propertiesduring the forming process. This contributes to a qualitypart. However, refrigeration at normal temperaturesdoes not completely suppress natural aging. Someprecipitation still occurs.Table 2 shows typicaltemperature and time limits for refrigeration.Table 2 Typical time and temperature limits forrefrigerated parts stored in the as-quenchedcondition.Maximum Storage Timefor Retention of the AQMaximumConditionDelay TimeAlloyafter-12 C-23 C18 CQuenching(10 F)(-10 F)(0 F)Max.Max.Max.20143015 minutes1 day90 days2024days221960613030 minutes7 days90 days7075daysArtificial Aging. After quenching, most aerospacealuminum alloys are artificially aged. This is a complexprocess, and requires an understanding of vacancies, andthe interaction of precipitation and metastable phases. Ingeneral, the sequence of precipitation occurs byclustering of vacancies, formation of GP Zones;nucleation of a coherent precipitate; precipitation of aincoherent precipitate, and finally the coarsening of theprecipitates.Precipitation hardening is the mechanism where thehardness, yield strength, ultimate strength dramaticallyincrease with time at a constant temperature (the agingtemperature) after rapidly cooling from a much highertemperature (solution heat treat temperature). This rapidcooling or quenching results in a supersaturated solidsolution, and provides the driving force for precipitation.This phenomenon was first discovered by Wilm [23],who found that the hardness of aluminum alloys withminute quantities of copper, Magnesium, Silicon, andIron, increased with time, after quenching from atemperature just below the melting temperature.4

Figure 6 - Aging sequence in 7050: (A) Initial GPZ formation; (B) GPZ present and the formation of the semi-incoherent ?’;(C) The semi-incoherent ?’ and the formation of the coherent equilibrium precipitate ?; and (D) The precipitation of theequilibrium precipitate ?.Precipitation hardening (aging) involves heating thealloyed aluminum to a temperature in the 200?-450?Frange. At this temperature, the supersaturated solidsolution created by quenching from the solution heattreating temperature, begins to decompose. Initiallythere is a clustering of solute atoms near vacancies.Once sufficient atoms have diffused to these initialvacancy clusters, coherent precipitates form. Becausethe clusters of solute atoms have a mismatch to thealuminum matrix, a strain field surrounds the soluteclusters. As more solute diffuses to the clusters,eventually the matrix can no longer accommodate thematrix mismatch. A semi-coherent precipitate forms.Finally, after the semi-coherent precipitate grows toa large enough size, the matrix can no longer support thecrystallographic mismatch, and the equilibriumprecipitate forms. This is shown in Figure 6 for 7050,showing the structural changes that occur from theformation of GP Zones, to the final overagedequilibrium precipitate.Heating the quenched material in the range of 95205 C accelerates precipitation in heat treatable alloys.5

This acceleration is not completely due to changes inreaction rate. As was shown above, structural changesoccur that are dependent on time and temperature. Ingeneral, the increase in yield strength that occurs duringartificial aging increases faster than the ultimate tensilestrength. This means that the alloys lose ductility andtoughness. T6 properties are higher than T4 properties,but ductility is reduced. Overaging decreases the tensilestrength, and increases the resistance to StressCorrosion-Cracking. It also enhances the resistance tofatigue crack growth. It also imparts dimensionalstability of the part.Precipitation hardening curves have been developedfor all the most common alloys. Figure 7 shows agingcurves for 2024 and 6061. Both alloys show evidence ofreversion of GP Zones by initial reductions in hardness.This is caused by the destruction of small GP Zones thatare below the critical size. Similar aging curves havebeen developed for 7075 and casting alloys.Figure 7 - Aging curves for 2014 and 6061.The aging curves for the different alloys vary;however, generally the higher the aging temperature, theshorter the time required to attain maximum properties.When high aging temperatures are used, properties arereached very rapidly with time. For this reason, agingtemperatures are usually lower to assure that the entireload is brought to the required aging temperature withoutrisk of reduced properties caused by over-aging of thefastest rising aluminum.Defects Occurring During Heat TreatmentDuring the production of a part, defects can occur.These can come from operations before heat treatment,such as midline porosity, inclusions that are formedduring casting the ingot. Further defects can formduring homogenization of the ingot, such as segregation,the formation of hard intermetallics and second phaseparticles.Most defects associated with heat treatment ofaluminum occur either during solution heat treatment, orduring quenching. Solution heat treating defects includeoxidation, incipient melting and under-heating. Defectsoccurring during quenching are typically distortion orinadequate properties caused by a slow quench, resultingin precipitation during quenching, and inadequatesupersaturation.Figure 8 - Oxidation evident on a 7050 extrusion that hasbeen exposed to extended times at the solution heattreating temperature.Oxidation. If parts are exposed to temperature toolong, high temperature oxidation could become aproblem. The term high temperature oxidation is reallya misnomer. The culprit is actually moisture in the airduring solution heat treatment. This moisture is a source6

of hydrogen, which diffuses into the base metal. Voidsform at inclusions or other discontinuities.Thehydrogen gas gathers, and forms a surface blister on thepart. In general, 7XXX alloys are the most susceptible(particularly 7050), followed by the 2XXX alloys.Extrusions are the most prone to blistering, followed byforgings. An example of surface blistering that canoccur is shown in Figure 8.Eliminating the moisture will minimize the problemof surface blistering.This is accomplished bysequencing of door over quench tanks, and thoroughlydrying and cleaning furnace loads prior to solution heattreatment. It is also important to make sure that the loadracks used for solution heat treatment are also dry.However, it is not always possible to eliminate highhumidity in the air to prevent surface blistering. Oftenthe ambient relative humidity is high, so that othermeasures may have to be taken.The use of ammonium fluoroborate is typically usedto prevent blistering on 7XXX extrusions and forgings.An amount equivalent to 5 g per m3 of workload space isusually used to prevent surface blistering.This isapplied as a powder in a shallow pan hanging from thefurnace load rack. This material is very corrosive andrequires operators to wear the appropriate personalprotective safety equipment. Because the material iscorrosive at temperature, it is recommended that theinside panels in the furnace be manufactured withstainless steel.This will reduce corrosion andmaintenance.Anodizing parts prior to solution heat treatment is analternative to ammonium fluoroborate. This is generallypractical for larger extrusions and forgings, where thecost of anodizing is small compared to the cost of thepart. However, for small parts, the additional added costdoes not generally justify the possible benefit ofanodizing prior to solution heat treatment.Incipient Melting. Non-equilibrium conditions canoccur because of localized solute concentrations.Because of the increased concentration of solute, theeutectic temperature could be decreased, causinglocalized melting. This is often called incipient melting.An example is shown in Figure 9. When this occurs,significant decreases in properties. Properties mostaffected include toughness, ductility and tensileproperties.Local melting can also occur if it is heated tooquickly. This is particularly true of 2XXX alloys. In thisalloy system, there are local concentrations of Al2Cu. Atslow heating rates, the Al2Cu dissolves slowly into thematrix. At high heating rates, there is inadequate timefor the Al2Cu to dissolve. Local concentrations causethe local eutectic temperature to drop, resulting inlocalized melting. If inadequate time is allowed for thismetastable liquid to dissolve into the matrix, then ingeneral, there is no decrement in properties.Figure 9 - Incipient melting observed in a 2024 alloy.Figure 10 - Rosette formed in 6061 during excessiveheating during solution heat treatment.Under-heating. Under-heating during solution heattreatment can causes problems by not allowing enoughsolute to go into solid solution. This means that lesssolute is available during subsequent precipitationhardening reactions. As an illustration of this, Figure 11shows the effect of solution heat-treating temperature onthe yield strength and ultimate tensile strength. As thetemperature is increased for both alloys, the tensilestrength is also increased. For 2024-T4, it can be seen7

that there is a change in slope and rapid rise in propertiesas the temperature is increased past about 488 C.Figure 11 - Tensile strength as a function of solution heattreating temperature for 6061 and 2024 (after Hatch [5]).Distortion during Quenching. Of all the possible“defects” occurring during the heat treatment ofaluminum, distortion during quenching is the mostcommon. It is probably responsible for most of the nonvalue added work (straightening) and costs associatedwith aluminum heat-treating. An extreme case ofdistortion is shown in Figure 12.austenitizing temperature for steel). Much higherquench rates are necessary in aluminum to preventpremature heterogeneous precipitation occurring duringquenching, and to maintain supersaturation of the solute.In steel, there is a coupled phase transformation ofaustenite to Martensite. This causes a 3% volumechange during quenching. There is no coupled phasetransformation in aluminum that can cause cracking ordistortion. However, the coefficient of linear expansionof aluminum is approximately twice that of steel(2.38x10-5 mm/mm compared to 1.12x10-5 mm/mm).This causes much greater changes in length or volume asa function of temperature, and increases the probabilitythat distortion will occur.Racking of the parts is critical. The parts should befully supported, with the loads spread out over a largearea, since the creep strength of aluminum is poor. Theeffect of this is illustrated in Figure 13. Parts should bewired loosely to prevent the parts from hitting each otherduring solution heat treatment. If wired too tightly, thewire could cut the parts. The use of pure aluminum wireminimizes this problem.Figure 12 - Distortion of a large aerospace rib resultingfrom improper quenching and racking practiceFigure 13 - Distortion from racking. The part wasinadequately supported over a large area.Distortion during quenching is caused by differentialcooling, and differential thermal strains developedduring quenching. These thermal strains could bedeveloped center-to-surface, or surface-to-surface. Thisdifferential cooling can be caused by large quench rates,so that the center is cooled much slower than the surface(non-Newtonian cooling) or by non-uniform heattransfer across the surface of the part.Aluminum is more prone to quenching distortionthan steel. This is because solution heat treatingtemperatures are so close to the liquidus temperature.Aluminum exhibits less strength and greater plasticitythan steel at the solution heat-treating temperature (orBecause of the poor strength of the heat-treatedaluminum parts, distortion of the parts can occur as theyenter the quenchant. As a general rule, parts shouldenter the quenchant aerodynamically to avoid distortionthe part before it even enters the quenchant. It shouldenter the quenchant smoothly – it should not “slap” thequenchant. This is shown in Figure 14.Racking a part so that it enters the quenchantsmoothly also offers the benefit that it is more likely tohave uniform heat transfer across the part. Distortion ismore likely to occur because of horizontal changes inheat transfer than by vertical differences in heat transfer.8

Figure 14 - Typical racking procedures for aerospaceparts. Note that the parts are racked vertically so thatheat transfer occurs evenly on all sides.Polyalkylene Glycol polymer quenchants are used inthe aerospace industry to control and minimize thedistortion occurring the quenching of aluminum.Typically these quenchants are governed by AMS 3025,and are either Type I or Type II. Type I quenchants aresingle polyalkylene glycol polymers, while Type IIquenchants are multiple molecular weight polyalkyleneglycol polymers.Each offers different benefits.Because of the higher molecular weight of the Type IIPAG quenchants, lower concentrations can be used.However, Type II polymers have a lower cloud pointtemperature, which can cause higher drag-out if parts areremoved from the quenchant before they reach thequenchant temperature (typically 80-100ºF).Thebenefits of quenching aluminum in the PAG quenchantsis shown in Figure 15.Polyalkylene glycols exhibit inverse solubility inwater. They are completely soluble in water at roomtemperature, but insoluble at elevated temperatures. Theinverse solubility temperature can range from 60ºC to90ºC depending on the molecular weight of the polymer,and the structure of the polymer.This phenomenon of inverse solubility modifies theconventional three-stage quenching mechanism [24] andprovides great flexibility to control the cooling rate.Figure 15 - Comparison of the distortion occurring whenquenching in cold water and in a 20% Type I PolyalkyleneGlycol quenchant.When a component is first immersed, the solution inthe immediate vicinity of the metal surface is heated toabove the inverse solubility temperature. The polymerbecomes insoluble and a uniform polymer-rich filmencapsulates the surface of the part. The stability andthe duration of this polymer film is dependant on thetemperature, concentration and amount of agitationpresent.The stable polymer-rich film eventually uniformlycollapses, and cool quenchant comes into contact withthe hot metal surface. Nucleate boiling results, withattendant high heat extraction rates.As the period of active boiling subsides, coolingoccurs by conduction and convection into the quenchant.When the surface temperatures fall below the inversiontemperatures, the polymer dissolves, forming ahomogeneous solution again.These stages areillustrated in Figure 16.The cooling rate of these polymers can be readilyvaried to suit the specific application by changing theconcentration, quenchant temperature, and the amount ofagitation. Typically, for most applications, the agitationis usually fixed, while the concentration is changed.9

References:Figure 16 - Various stages during the quenching processusing a PAG based polymer quenchant.The concentration of the polymer influences thethickness of the polymer film that is deposited on thesurface of the part during quenching.As theconcentration increases, the maximum rate of cooling,and the cooling rate in the convection phase decrease.Agitation has an important effect on the quenchingcharacteristics of the polymer quenchant. It ensuresuniform temperature distribution within the quench tank,and it also affects the quench rate. As the severity ofagitation increases, the duration of the polymer-richphase decreases and eventually disappears, and themaximum rate of cooling increases. Agitation hascomparatively little effect on the cooling rate during theconvection stage.ConclusionsIn this short paper, typical applications of aluminumheat-treating in the aerospace industry have been shown.A brief overview of the physical metallurgy of thevarious alloys used in aerospace was detailed. Finally, adescription of typical heat-treating defects observed wasillustrated. The benefits and advantages of polymerquenchants for aluminum were shown.[1] D.S. MacKenzie, “Quench Rate and Aging Effects inAluminum Al-Zn-Mg-Cu Alloys”, PhD Dissertation,University of Missouri-Rolla, Dec. 2000.[2] AMS 2770 “Heat Treatment of Aluminum Alloy Parts”,Society of Automotive Engineers, Warrendale, PA.[3] Metals Handbook, 8th Ed. Metallography and PhaseDiagrams, ASM.[4] K. R. Van Horn, Aluminum Properties, PhysicalMetallurgy and Phase Diagrams, Vol. I, ASM (Metals Park:1967) p. 372.[5] Hatch,J.E., Aluminum: Properties and PhysicalMetallurgy, ASM (Metals Park:1984) 154.[6] Grossman, M.A., Metal Progress, 4 (1938) 373.[7] Scott, H., “Quenching Mediums,” Metals Handbook,ASM (1948) 615.[8] Wever, F., Archiv fur das Eisenhuttenwesen, 5 (1936) 367.[9] Dakins, M., Central Scientific Laboratory, Union Carbide,Report CSL-226A.[10] Fink, W. L., Wiley, L. A., Trans. AIME 175 (1948) 414.[11] Suzuki, H., Kanno, M., Saitoh, H., Keikinzoku 33 1(1983) 29.[12] Evancho, J.W., Staley, J.T., Met. Trans. 5 1 (1974) 43.[13] Wierszykkowski, I.A., Met. Trans. A 22A (1991) 993.[14] Bates, C.E., Totten, G.E., Heat Treatment of Metals 4(1988) 89.[15] Swartzenruber, L., Beottinger, W., Ives, I., et al, NationalBureau of Standards Report NBSIR 80-2069 (1980).[16] Bates, C.E., Landig, T., Seitanakis, G., Heat Treat 12(1985)13.[17] Bates, C.E., “Recommended Practice for Cooling RateMeasurement and Quench Factor Calculation”, ARP 4051Aerospace Materials Engineering Committee (SAE) 1 (1987).[18] Staley, J.T., Doherty, R.D., Jaworski, A.P., Met. Trans.A. 24A 11 (1993) 2417.[19] Staley. J.T., Mat. Sci. Tech. 3 11 (1987) 923.[20] Hall, D.D., Mudawar, I., J. Heat Transfer 117 5 (1995)479.[21] Kim

quenchant. A typical solution heat-treating furnace and quench tank used for heat-treating aluminum aerospace components is shown in Figure 4. Fink and Wiley Figure 4 - Large drop-bottom furnace used to solution heat- treat and quench aluminum alloys. Quenching. An understanding of heterogeneous precipitation during quenching can be understood by