Transcription

IMC SeriesNew solution for Motion Control604708/001GB

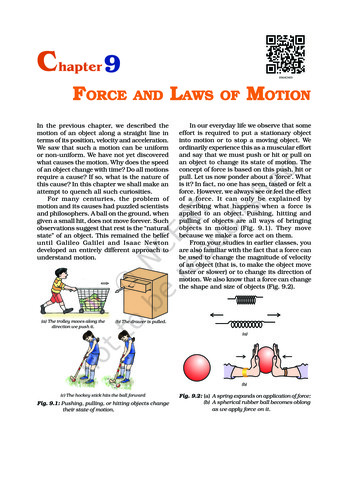

IMC SeriesTable of contentsTechnical specifications IMC 300/700 servoconverters . 4Electrical specifications IMC 300/700 servoconverters . 6Browser IMC 300/700 . 7Series 8 servomotors . 8Servomotors-servoconverters matching . 12Servoconverters-servomotors code . 13Servoconverters accessories . 14ABB SACE1

IMC The evolution200020031. Fieldbus2. Easy installation, commissioningand operation.3. Programmable “Motion Task”The new family of intelligentIMC servoconverterThe new family of full digital IMCservoconverter is a solution designedby ABB Sace SpA – Servo division forMotion Control and Industrial automation. The ultimate DSP components(Digital Signal Processing) enableABB to implement complex controlalgorithms and to build higher MotionTasks in the drive. Thanks to its newcompact design, the IMC Series hasvery small dimensions.2Easy to control, accurate andhighly dynamic.Advanced vectorial control algorithms(Space Vector Modulation) make theaxis easy to control both at low andhigh turns.The performances of the externalspeed and position loops can beoptimized for the mechanical characteristics of the load, thanks to aneffective autotuning procedure, whichcan be performed directly on themachine. Moreover, thanks to specialfilters, it is possible to eliminate thetorsional resonances originated bythe high inertia ratios. Innovationsin adjusting the current, speed andposition loops fully meet the needs foraccuracy, dynamic and repeatability,more and more essentials in everyfield of application: textile, mechanical, packaging.ConnectivityThe fast evolution of production processes requires a higher flexibility ofthe automation systems. The ideas ofDistributed Control Architectures andIntelligent Servodrives are becomingfamiliar.The new IMC is a solution for the needs of OEMs and automation systemsand comes in three different versions:IMCP (Profibus DP), IMCC (CanOpen)ed IMCD (DeviceNet).In the “Profibus DP” version, theIMCP servoconverter is perfect for theapplications that need to control andorganize a high number of axis in realtime. The CanOpen-IMCC version issuitable for machines (robot, toolsand packaging) which require highlyaccurate movements and interpolated trajectories.

of the species.20064. Compact design – Smalldimensions5. High dynamic performances6. Autotuning7. In-built EMC filters8. Fieldbus9. UL listingProgrammable Motion TasksThe majority of Motion Control applications do not require axis interpolation because trajectories are independent. Positioning and advancedMotion Control functions can bedemanded to the converter.In IMC Series servoconverter, severalmotion sequences can be programmed:- Zero search sequences (homing)- Absolute positioning sequences- Relative positioning sequences- Speed profiles- Torque reference commandThese sequences can be linked toeach other, and in case of achievement of targets and predefinedlogical conditions, they can form morecomplex sequences.All these functions can easily becontrolled and organized by machinePLC via digital I/Os or more effectivelyby means of a fieldbus. They areextremely useful in flexible productionand packing systems.3

IMC SeriesTechnical specifications IMC 300/700 servoconvertersPower connectionsDigital and analog I/OEmulation encoder Input OutputMotor transductor: resolverMotor transductor: encoderStatus DisplayPower connectionsMotor transductor: resolverDigital I/OCANopen InterfaceMotor transductor: encoderCANopen InterfaceStatus LedPower connectionsProfiBus InterfaceMotor transductor: encoderMotor transductor: resolverSpecific digital I/OProgrammable digital I/OEncoder emulation Input OutputStatus led4ABB SACE

IMC SeriesTechnical specifications IMC 300/700 servoconvertersTechnical specificationsIMC 300/700 Analog Speed and torque control through an analog command.Stepper motor emulation (Frequency/Sign input)Digital electrical axis (programmable reduction ratio)Motor transductor: Resolver, Absolute Encoder, Incremental EncoderTTL or SinCos, Incremental Encoder with effect Hall sensors1 analog input 10 V1 analog input 0 10 V for current limitation1 analog output 10 V configurable6 special digital inputs: “ENABLE”, “FC /-” Stop run, “CV0” speedcommand, “CI” current command, “RESET” faults1 special relay output for the “AOK” signal, (amplifier OK)1 special “MOTOR BRAKE” output for motor brake controlAuxiliary encoder inputProgrammable encoder emulation output (any values between512ppr and 16384 ppr)Dynamic control of emergency brakingAutophasing to control any brushless motorAutotuning for the automated tuning of regulation loops1 and 2 order filters , anti-resonance filterAuxiliary power supply 24V dcMain supply 230 Vac or 400/460 VacMain supply filters built-in the driveInternal or external braking resistor according to the needs.Setup software with digitizing oscilloscope, manual control andmotor database to create any configuration through the serialinterface RS232.Technical specificationsIMC 300/700 CANopen Fieldbus: CANopen Communication profile: DS301 version 4.01 Motor transductors: Resolver, Absolute Encoder, Incremental Encoder TTL or SinCos, Incremental Encoder with Hall effect sensors. 6 special digital inputs: “INHIBIT”, “FC /-” Stop, “INDEX” hominginput, “CAPTURE” of the position, “LOW SPEED” minimum speedinput 1 special relay output for the “AOK” signal, (amplifier OK) 1 special “MOTOR BRAKE” output for motor brake control Auxiliary encoder input Programmable encoder emulation output (any values between512ppr and 16384 ppr) Motion Control programmable profiles in accordance with DSP402version 1.1 (fieldbus operation): zero search, torque profile, speedprofile, position profile, interpolated position profile. Motion Control specific functions (fieldbus operation): Electrical axismode, linear or cubic interpolator for interpolated position profiles,level memorization for register control. Dynamic control of emergency braking Autophasing to control any brushless motor Autotuning for the automated tuning of regulation loops 1 and 2 order filters , anti-resonance filter Auxiliary power supply 24V dc Main supply 230 Vac or 400/460 Vac Main supply filters built-in the drive Internal or external braking resistor according to the needs. Setup software with digitizing oscilloscope, manual control andmotor database to create any configuration through the serialinterface RS232.ABB SACETechnical specificationsIMC 300/700 Profibus Fieldbus: Profibus-DP Motor transductors: Resolver, Absolute Encoder, Incremental Encoder TTL or SinCos, Incremental Encoder with Hall effect sensors. 7 special digital inputs: “ENABLE”, “FC /-” Stop, “INDEX” hominginput, “START” “STOP” movement sequence, “RESET” faults 3 special digital ouputs: “SEQ” sequences in progress, “POS” finalposition, “SPEED” final speed 6 Configurable digital outputs 4 Configurable digital outputs 1 analog input 10 V to limit the multiplex speed with 1 programmabledigital output. 1 multiplex configurable analog output with 1 programmable digitaloutput. 1 special relay output for the “AOK” signal, (amplifier OK) 1 special “MOTOR BRAKE” output for motor brake control Auxiliary encoder input Programmable encoder emulation output (any values between512ppr and 16384 ppr) 128 motion control programmable tables which can be connectedin sequences for the control of complex applications. Available motion control sequences : zero search, absolute andrelative positioning, speed profiles, torque control, electrical axis. Motion control sequences can be controlled via digital I/O (standalone mode) or via profibus (modo Profibus) Digital camma function on configurable digital output. Position profile: trapeze or S Dynamic control of emergency braking Autophasing to control any brushless motor Autotuning for the automated tuning of regulation loops 1 and 2 order filters , anti-resonance filter Auxiliary power supply 24V dc Main supply 230 Vac or 400/460 Vac Main supply filters built-in the drive Internal or external braking resistor according to the needs. setup software with digitizing oscilloscope, manual control and motordatabase to create any configuration through the serial interfaceRS232.General features present in the whole series Linear motor controlStepper motor controlMore effective braking cycles, thanks to the DC BUS ParallelingPossible options : automatic function for the compensation of “cogging torque”, serial interface RS422 for multiaxis connections.5

IMC SeriesTechnical specifications IMC 300/700 servoconvertersElectrical specificationsIMC 300 SizeRated supply voltagePower supply frequencyRated auxiliary voltageMax Current auxiliary supply @ 24 VdcRated input current I vnRated output current I anOutput voltage phase to phaseMax output current I maxExternal brake resistorMechanical dimensionsWidth x Height x DepthWeight (approx.)Room temperatureMax room temperatureDerating between 40 50 CHumidity (no condensation allowed)AltitudeFrequency S][ohm]05/101 x or 3 x 230 VAC50/6024 VDC0.3205.255.25200 Vrms10.5100/100 or 50/2002.252.254.5[W]65x200x220[Kg][mm][ C][ C][%/ C][%][m s.l.m.]1 5 40503 50 % to 40 C and 90 % and 20 C1000808/168.258.2516.5Electrical specificationsIMC 700 SizeRated supply voltagePower supply frequencyRated auxiliary voltageMax Current auxiliary supply @ 24 VdcRated input current I vnRated output current I an[VRMS][Hz][VDC][ADC][ARMS][ARMS]Output voltage phase to phase[VRMS]Max output current I maxExternal brake resistorExternal braking resistor powerWeight (approx.)Mechanical dimensionsWidth x Height x DepthRoom temperatureMax room temperatureDerating between 40 50 CHumidity (no condensation allowed)AltitudeFrequency /06[ C][ C][%/ C][%][m s.l.m.][KHz]3.63.607/1410/2015/303 x 230 VAC oppure 3 x 400/460 VAC50/6024 VDC0.3207101571015It depends on supply voltage:200 Vrms if 230 VAC380 to 460 Vrms if 400/460 3020/45202045332804.8110x288x230 5 40503 50 % to 40 C and 90 % to 20 C10008ABB SACE

IMC SeriesBrowser IMC 300/700The new browser“ABB Visual Setup” isstraightforward andextremely easy to use.It assists the user in selectinga motor, setting parametersin the drive and in MotionTasks programming.In order to make theadjustment of axis easier ,some functions of theMultichannel DigitizingOscilloscope, built in “ABBVisual Setup”, have beenfurther developed.Thanks to a wave generatorand to the advancedtrigger functions, the tuningof speed loop earnings andthe adjustment of the axisare much easier now.ABB SACE7

IMC SeriesServomotors Series 8Brushless servomotors series 8CBrushless servomotors series 8NPermanent magnets NdFeB combined with an optimized configuration of active parts provide a great increase in torque density and adecrease in cogging torque. Upon request they are available in theterminals or signal and power connectors versions, built in the motorto reduce overall dimensions.This series is characterized by compact dimensions. Operation temperature: 0 40 C, up to 50 C derating 1% C ofrated value Stocking: - 30 85 C Constructive form: IM B5, IM V1, IM V3, IM B14, IM V18, IM V19 Flange: for any size it is available a standard flange and other optional. Ventilation: IC-0041 (EN 60034-6) operating in a closed environment,cooling without fans Insulation class: F Protection class:- Motor body: IP54 with terminal boxIP65 with connectors- Motor shaft: IP54 standardIP64 with oil seal not assembled (IMV1-IMB5)IP65 upon request Optionally integrated parking torque. Upon request it is possible toprovide brakes with the following features, without changing theexternal dimensions:type 8C1: 4 Nmtype 8C4: 20 Nmtype 8C5: 36 Nm Integrated bipolar Resolver or sinusoidal encoder 1 Vpp. Force on sinusoidal electromotive. Series 8C1/4/5: 6 poli - Series 8C6: 8 poli Certification CE class F - Certification UL class A8 Operation temperature: 0 40 C. Insulation class: F Protection degree: motor IP65 compliant to EN 6034-5motor shaft IP54 Available in 45 mm e 55 mm boards. Magneti NdFeB in 4 poles, sinusoidals. Brake integrated by permanent magnet. Certifications: CE class F Available in two versions: with signal and power connectors on themotor or with free cables.ABB SACE

IMC SeriesServomotors Series 8Electrical specificationTYPE(4)StalltorqueM0[Nm](3) (6)8NB.2.40.8N0.1.40.8N0.2.40.8C1.1.30 0.8C5.5.15.8C5.5.30.8C5.6.15.8C5.6.30.8C6.1.20 8C6.2.15 8C6.3.10 825.8303034.134.138.238.24069*100*Current atstall torqueI0[A](1) (2) m](3)RatedcurrentIN[A](1) (2) 0119.0119.0134.0134.0158.0266.0368.0(1) Current values shown in the table are RMS values.(2) Tolerance 5%.(3) Duty type S1, ambient temperature mounted on 40 C, steel flange(dim. 300x300x20mm - 600x400x25 for 8C6), altitude 1000 m s.l.m.(4) See table 2/4 for Servo motor code.Current atpeak .8159.4-RotorinertiaJm[kgcm2](2) 666666666666666666666666888(5) Inertia can be increased, if necessary(6) Motor overtemperature: Δ 100 C* The torque of this motor is derated, due to the converter (IMC).Braking featuresSupply voltage (tolerance: 10%) 24 V dcMotorStatic Torque (20 C)Magnet8NB8N0.(1-2)8C1.(1-4).(30, 60)8C4.(0-4).(15, 30)8C5.(0-6).(15, (1)21232InertiaSupplyJbr[kgcm2 ]Ibr[A]0,010,0450,44110,340,460,50,751,2(1) Available upon request(2) Permanent magnet, standard version(3) Permanent magnet, upgraded versionABB SACE9

IMC SeriesServomotors Series 85312 PolesMechanical dimensions8C12190 DDGAFST8 Poles 35 80 ØDØ N j6ØPØMEACLB83Standard dimensionsMotorLenght8C18C18C18C11234Association 0953115Ø1014019k640M6x16621.5Optional 0 M2580 FGA8 Poles 52 3.591ØS854116.590ØDD 118 ØDØ N j6ØM651130912 PolesØP15.5195312 Polesx1.540 LBAC Standard dimensionsAssociation 8x19827XXCLB220251276299332Optional 34XXXXFlange0Flange9XXXXXXXXXXXXShaftGShaftLABB SACE

IMC SeriesServomotors Series 8Mechanical dimensions358013M25FT106Standard 48 ØDDDEAssociation XShaftNXXCLB276306336ØMØM1GAØPS153 LBS23 90 8 PolesØ N j635 12 Polesx1.51321208C5AC 035DDM8x19Optional 12130M8x1219032k658M12x281035 DDØPS 80 200ø N j6øDM3212 Polesx1.58C6ØM8C58C58C5T20140FAC LB 155Standard dimensionsMotorLenght8C68C68C6123Association 873MBACNTMSPDE2001804215Ø1525038k680DDM12x28HC HC 12.5 F Ø N h7ØDADADLHTLA8NB.28N0.18N0.2ACLB Type000000GAEStandard .C Ø43Ø43Ø5.5Ø5.5Ø5.5Ø5.56 h66 h69 h69 h69 h69 202620* For the motor with brake included, pls add 30 mm to dimension column “LB”ABB SACE11

IMC SeriesServomotors-servoconverters matches3X400 VacServomotorConverterIMC 700Size8C1.1.30. .M8C1.1.60. .M8C1.2.30. .M8C1.2.60. .M8C1.3.30. .M8C1.3.60. .M8C1.4.30. .M8C1.4.60. .M8C4.0.15. .M8C4.0.30. .M8C4.1.15. .M8C4.1.30. .M8C4.2.15. .M8C4.2.30. .M8C4.3.15. .M8C4.3.30. .M8C4.4.15. .M8C4.4.30. .M8C5.0.15. .M8C5.0.30. .M8C5.1.15. .M8C5.1.30. .M8C5.2.15. .M8C5.2.30. .M8C5.3.15. .M8C5.3.30. .M8C5.4.15. .M8C5.4.30. .M8C5.5.15. .M8C5.5.30. .M8C5.6.15. .M8C5.6.30. .M8C6.1.20. .M8C6.2.15. .M8C6.3.10. .M3x230 VACServomotor8NB.2.40. .E8N0.1.40. .E8N0.2.40. .E8C1.1.30 .E8C1.1.60. .E8C1.2.30. .E8C1.2.60. .E8C1.3.30. .E8C1.3.60. .E8C1.4.30. .E8C1.4.60. .E8C4.0.15. .E8C4.0.30. .E8C4.1.15. .E8C4.1.30. .E8C4.2.15. .E8C4.2.23. .E8C4.2.30. .E8C4.3.15. .E8C4.3.30. .E8C4.4.15. .E8C4.4.30. .E8C5.0.15. .E8C5.0.30. .E8C5.1.15. .E8C5.1.30. .E8C5.2.15. .E8C5.2.30. .E8C5.3.15. .E8C5.3.30. .EStall 35**Current atstall 1,921,212,523,419,325,026,8ConverterIMC700IMC3003 x 2301 or 3 x 230 Stall Current atVACVACtorque stall torqueSizeSizeM0 [Nm]I0 8,013,010,017,013,221,116,925,3Peak stalltorqueM ent atMmaxI 30,045,030,070,030,070,070,070,070,0Peak torqueat rated speedM 284,069,779,2102,585,0104,1121,7177,9241,5Current atMmnI 50.212950.213050.213150.213250.213350.2134Peak torque atCurrentPeak stall torque Current at Mmaxrated speedat MmnM max [Nm]I max [A]M mn [Nm]I mn [A]IMC700 IMC300 IMC700 IMC300 IMC700 IMC300 IMC700 5,690,465,665,670,047,449,9-Operatingcurve50.2140 / 150.2142 / 350.2144 / 550.2146 / 750.2148 / 950.2150 / 150.2152 / 350.2154 / 550.2156 / 750.2158 / 950.216050.2162 / 350.2164 / 550.2166 / 750.2168 / 950.2170 / 150.217250.217350.2174 / 550.217650.2177 / 850.217950.2180 / * The torque of this motor has been derated due to the converter** For the electrical characteristics pls apply to the commercial office.12ABB SACE

IMC SeriesServomotors-servoconverters codeServodrive code IMC300 - IMC700SeriesFieldBusVoltageRated 036,7A8009,100011,12Drive seriesPos. 1,2,3IMC300IMC700IMC Pos. 4IMC300IMC700OptionsAnalogA CANopenC ProfibusP DevicenetDPos. 8IMC300A Pos. 9,10IMC300IMC700Standard00 Cogging torque compensationCT RS422RS Cogging torque compensation RS422CR Pos. 5IMC300IMC700Pos. 11,12IMC300IMC70000 315E16B17IMCFieldbusSupply voltage230Vac single/3-phaseE 400Vac 3-phaseM Rated currentIMC700RevisionLast revisionPersonalizationPos. 6,7IMC3002/4 Amp (for voltage 230Vac)02 3/6 Amp (for voltage 230Vac)035/10 Amp (for voltage 230Vac)057/14 Amp (for voltage 400Vac)078/16 Amp (for voltage 230Vac)0810/20 Amp (for voltage 400Vac)10 15/30 Amp (for voltage 400Vac)15 20/45 Amp (for voltage 400Vac)20 IMC700 Series 8 servomotors codeSeries8C1-213Motor seriesBrushless sinus. 6-8 poles NdFeBBrushless sinus. 4 poles NdFeBMotor panel45 mm55 mm80 mm118 mm148 mm200 mmActive parts lengthSee Mechanical dimensionsSpeedSee Electrical specificationsEs. 30 3000 rpm - i.e. 30 3000 rpmFlangeSee Mechanical dimensionsBrake and resolverWith resolver, without brakeWith resolver and brakeConnectionsShaft side terminal boxBack terminal boxShaft side connectors*Back connectorsFree cables (2,5 mt)*8N motors top outputABB SACEPerformance13045-60708Pos. 1,28C8NPos. 3B01456Pos. 4NumberPos. 5,6Number8C Pos. 7NumberPos. 806Pos. 9VWYZ08C 8C 8C V98N 8C 8C 8N 8N 8N 8N 8N 010Product codes / Variant code02SE11121314IP protection (motor)IP54 (with terminal box)IP65 (with connectors and free cable)Toll. mecc. and vibrationN sec. DIN42995-DIN45665R upon reqquestKey and oil sealKey oil seal (not assembled)No key oil seal (not assembled)key, no oil sealNo key, no oil sealPos. 100APos. 1101Pos. 1201238C 8C 8C 8NRevolver PhasingIMC300 - IMC700ShaftSee Mechanical dimensionsThermal protectedPTC on 8C, Contact NA on 8NBUS DC voltage310 Vdc560 VdcReserved to ABBCodeCodePos. 13SPos. 14NumberPos. 153Pos. 16EMPos. 17BC8C 8C 8C 8C 8C 8N 8N 8N 8N 8N 8N 8N 13

IMC SeriesAccessoriesCableFeatures of Resolver Cables Multipolar cable, with double shield for mobile application (Al/polyester and copper tape)3 couples AWG 26 and 3 AWG 20 singleExternal sheath in transparent PVC style UL 2095Operation temperature: 80 COperation voltage: 300 VCapacity: 120 pF/m between the conductors of each couple at 20 CNumber of cycles: 3 millions min.Minimum bending radius 65 mmReference standard: UL 758Complete codes to order signal cables resolver/analog and ProfibusIMC 300/700 (8C C 300/700 (8N ngth [m]2.5510152025304050mtwith connectorsFree without connectorsComplete codes to order signal cables resolver/ CANopenIMC 300/700 (8C C 300/700 (8N ngth [m]2.5510152025304050mtwith connectorsFree without connectorsFeatures of Power cables Multipolar cable, movable laying, shieldedExternal sheath in a polyurethane mixOperation temperature: - 20 C / 80 COperation voltage: 600 VCapacity 75/80 pF/m (Phase/Phase) – 150 pF/m (Phase/Screen)Number of cycles: 3 millions min.Minimum Bending radius : 6 times the external diameterReference standards: UL 758, UL 1581Speed: 200 m/minAcceleration: 10 m/sec2Ordering codes for power cables2.5 mm2 (8N with PTQL30CBXBVC1CCPTQL40CBXBVC1CCPTQL50CBXUCAV60032.5 mm2 (8C with IMC up to15 PTNL30CBXBVC1CCPTNL40CBXBVC1CCPTNL50CBXUCAV60034 mm2(8C with IMC up to 35 gth [m][m]2.5510152025304050mtwith connectors motor sideFree without connectorsiSerial Cable CodeDescriptionSerial cable for IMC 300/700Serial cable for IMC 300/700CodeIMC1CCRSN2L0X1XIMC1CCRSN5L0X1XLength [m]25ConnectorsComplete codes to order connectorsMotor type8C/8N8C/8N14Connector code400014056400014057Power connectorSignal connectorABB SACE

IMC SeriesAccessoriesBraking resistorsConvertersizeConvertercodeIMC3002/4, 5/10, 8/16 ArmsIMC- -E02IMC- -E05IMC- -E08IMC- -M03IMC7003/6 ArmsIMC7007/14 ArmsIMC70010/20, 15/30, 20/45ArmsIMC- -M07IMC- -M10IMC- -M15IMC- W]ResistanceRemarks220 VACUREP100100100100External400/460 VACUREP100200100200External400/460 VACUREP20005020050External400/460 VACUREP28003328033External[Ohm] A (analog) or C (CANopen) or P (Profibus)ACABB SACE834077BDimensionsUREP100100, UREP100200UREP20050UREP280033A157 mm290 mmB145 mm278 mmC52 mm57 mm15

ABB office in Vittuone istoday the reference point forthe market of motors “made inItaly”.ABB Vittuone was well knownfor the quality of its mediumvoltage motors, but thanks toits new areas of productions, itbecame an excellent center ofproduction for all the motorsproduced in Italy by ABB.Alongside with the traditionalproduction of medium voltagemotors, they started producingalso low voltage motors, directcurrent motors and servomotors.Moreover, with a 4,000 m2warehouse, close to theproduction areas, ABB Vittuonecan dramatically reduce delivery times and meet the requestsof the customers, even themore demanding ones, thanksto a good logistic, always inconnection with the productiveareas and with the areas wheregoods are customized.16

ABB SACE S.p.A.ABB SACE S.p.A.An ABB Group companyAn ABB Group companyServodrives & servomotorsFactory20010 Vittuone (MI) - ItalyViale Dell’Industria, 18Phone.: 39-02-9034.1 - Fax: 39-02-9034 7609Servodrives & servomotorshttp://www.abb.com20099 Sesto San Giovanni (MI) - ItalyVia Luciano Lama, 33Phone.: 39-02-2414 1 - Fax: 39-02-2414 3972604708/001 GB- July ‘06Printed in ItalyIn consideration of modifications to Standards and materials, thecharacteristics and overall dimensions indicated in this catalogue maybe considered binding only following confirmation by ABB SACE

IMC 300/700 Analog Speed and torque control through an analog command. Stepper motor emulation (Frequency/Sign input) Digital electrical axis (programmable reduction ratio) Motor transductor: Resolver, Absolute Encoder, Incremental Encoder TTL or SinCos, Incremental Encoder with effect Hall sensors 1 analog input 10 V