Transcription

2014 U.S.-China Electric Vehicle and Battery Technology WorkshopBAK xEV Battery R&Dand IndustrializationJian Lin (林建)CTO of CBAK

Contents BAK Introduction Basic InformationProduction and Detection EquipmentsR&D Equipments xEV Battery Research NMC Background18650 EV 2.1AH18650 EV 2.4AH18650 EV 3.1AH18650 EV 3.4AH xEV1Battery Industrialization

China BAKCompany prospect: leading global manufacturer of Li-ion power batteryApplied area: EV, LEV, power tools, energy storage.Tianjin BAK: Established in 2006Registered capital: 99.99 millionLocation: Beichen District, Tianjin,520 acresProduction capability: 400MWH/YBAK Tianjin--xEV production baseDalian BAK: Established in 2014Location: Huayuankou District, Dalian,231acresProduction capability: 120MAH/YBAK Tianjin blueprint

BAK History BAK International (Tianjin)was founded in Tianjin, China BAK was BAK Internationalwent into production Signed afounded inShenzhen, China Cooperating with A123,BAK achieved lithium ironphosphate battery industrializationfirst in the world2001 Bulk supply to2002 2003 2004 Production capabilitywas increased to 1 millioncells/day from 2002to 200520052006contract of highpower batterysupply with theFirst AutomobileGroupBAK was giventhe status of“China’s famousbrands”2007 Entered NASDAQ.Code: CBAK20082009 20102011 2014 BAK carried out863 AutomobileEV Project of Ministry ofResearchScience and Technology Shenzhen BAK started toproduce Li ion batteries forLaptopchery and othercustomersInstitute wasestablished inBeijing Dalian BAKPower battery Co.Ltd wasestablished

Main Production sembling

Testing EquipmentsX-ray detectorVehicle module detection cabinetEV testing systemVehicle module detection

R&D EquipmentsSEM-EDS PSA 14 ARC XRD BET DSCFTIR ICP

Contents BAK Introduction Basic InformationProduction and Detection EquipmentsR&D Equipments xEV Battery Research NMC Background18650 EV 2.1AH18650 EV 2.4AH18650 EV 3.1AH18650 EV 3.4AH xEV1Battery Industrialization

Why NMC- Energy Density(Range)《Industry development plan of energy saving and new energy vehicles 》published by StateCouncil of China on Apr. 18, 2012.:By 2015, specific energy density of EV battery module should be over �神 11Ah万向 60Ah At present, ED of EV applying LFP cells is lower than 140Wh/kg. ED of BAK Gen.1 EV 18650-2.0Ah is over 160Wh/kg.盟固利100Ah

Why 18650-Energy Density(Range)Cathode18650NMCNCA/NMCFresh 1644362.11754572.41845233.1254675Fully charged or after cycleCircular structure is stable, pressure ofeach direction is even , could well acceptelectrodes swelling.CathodePrismatic largecell(PHEV2,2614891)NMCFresh cellCap.(Ah)SpecificED(Wh/kg)VolumeED (Wh/l)251202572814329634160349Full charge or after cycleMechanical strength along the thicknessdirection is weak; clamp and highpressure is used in module formation.

Why 18650 Safe- Low Unit Energy“Intrinsic” Safety:Device safety is based on energy amount contained. Eventhe basic unit has safety issue, it will not cause chain reaction which may result inhigher level damage issues.1865018.5*65mmEnergy Low Enough- FailSafeCapacity(Ah)Energy er 8*91mmEnergyper area(Wh/cm2)

Why 18650 Safe-Simulation of Thermal Runaway18650 2.0Ah 1S28P (56Ah) ModulePrismatic 50Ah CellIf single cell thermal runaway:If single cell thermal runaway:18650 cell has low single cell energy, good heatconducting of steel can, and heat diffusion path islong between cells in module (isolated spacedesigned). Obtain enough escape andemergency rescue time.Cell with too large energy has poor internal heatdiffusion, results in serious consequence in shorttime.Real operation result of a mis-welding module (some cells were anti-welded).Over charge test of 20Ah prismatic cellOnly mis-welding cell failed, nearby cell isLarge deformation may cause chain-reaction inmodule.Over charge

xEV Battery t(g)PulseDischarge(A /2s)EnergyDensityWh/kgPowerDensityW/kg26650HP3.2 122.3 7870942153.826650MP3.2 202.9 7840118.91230.736800MP3.2 106.5 17880116.851078.626700HE3.6 505.0 9810183.67326.5H18650CB3.6 502.0 4512164853H18650CFL3.6 502.1 4512175850H18650CIL3.6 502.4 46151848431. 26650HP:HEV application2. 26650MP/36800MP:EV/PHEV application3. H18650CB/CFL/CIL:EV application

Contents BAK Introduction Basic InformationProduction and Detection EquipmentsR&D Equipments xEV Battery Research NMC Background18650 EV 2.1AH18650 EV 2.4AH18650 EV 3.1AH18650 EV 3.4AH xEV1Battery Industrialization

18650 EV 2.1AH General PerformanceTest ItemTest ConditionCriteriaTest standardAssessment 0.5C,4.2V,21mA/0.5C,3.0VOK5.4.1. Dischargerate capabilities25 ,Charge at 0.5CDischarge at:0.2C/0.5C/1C/2C0.5C/0.2C 95%1.0C/0.2C 90%2.0C/0.2C 85%5.4.2. Cycle lifeCharge at 0.6C, discharge at0.6C, 2000 cycles, Roomtemp.2000th Residual capacity/Original dischargecapacity 70%.BAK H18650CFLspec.OK5.4.3. High-LowtemperaturedischargeperformanceCharge :0.5C at RTDischarge :0.5C, at -10 ,0 ,25 ,60 ,-10 /25 60%0 /25 75%60 /25 . 100%BAK H18650CFLspec.OKFully charged, stored at 25 for 28 days.Residual capacity / originalcapacity 90%.Recovery capacity / originalcapacity 95%BAK H18650CFLspec.OK5.5.4. StoragePerformanceWe use stable NMC111 and AG plus ceramic coating on anode to ensure long cycle lifeand safety.

18650 EV 2.1AH Safety PerformanceTestStandardAssessment5.5.1. VibrationFully charged, Simple harmonic, 0.8mm, 10 55Hz,1Hz/min, 90 100min 1 cycles, 2 mutually tFully discharged, 12V ,1C for 1.5hrsUL1642OK5.6.2.130 OvenTestFully charged cell is risen from RT with a rate of 5 /min,remain for 1 hour @ 130 UL1642OK5.6.3.Overdischarge TestFully charged, discharged by 0.2C current for 12 hoursUL1642OK5.6.4. Crush TestFully charged cell,apply pressure of 13KN,32mmdiameter piston.UL1642OK5.6.5 Short CircuitTest25 &60 , fully charged cell, to short the cell with acopper wire of less than 50mΩ.UL1642OK5.6.6. IncinerationtestFully charged cell, test according to UL1642.UL16425.6.7.Impact testFully charged, 7.9mm diameter bar. 9.1kg weight,610mmUL1642OK5.6.8 Drop testDrop ,1.1m height on hard board, with three directionsBAKOKTest ItemTest ageSmoke, 200 Smoke, 200 FireExplosionExplosion where batterypenetrates wire screen

18650 EV 2.1AH Rate PerformanceCapacity/AhTemperaturerise/ 721.06C0.240.256.27#0.52.44.712.821.125.921.86.5

18650 EV 2.1AH high-Low Temp. Discharge Perf.0.5C capacity/mAh60 /250 /25 10 /25 20 /25 25 60 0 -10 -20 3.0105.7%86.7%79.9%74.1%

18650 EV 2.1AH Cycling Performance2.0H18650CFL-2.1Ah 0.6C/-0.6C(4.05V-3.0V)100H18650CFL-2.1Ah 0.6C/-0.6C(4.05V-3.0V)252525456060 25 C25254560601.9 95 Dis. Cap./Ah 1.71.6 8580701.42.0 90751.505001000 cycleNo. 15002000H18650CFL-2.1Ah 0.6C/-1C(4.05V-3.0V)1.90250025252545455001000cycle No.150020002500H18650CFL-2.1Ah 0.6C/-1C(4.05V-3.0V)100 2525254545 1.895 1.7Dis. Cap. Ret./%Dis. Cap. /Ah Dis. Cap. Ret. le 000

18650 EV 2.1AH Cycling PerformanceH18650CFL-2.1Ah ) 2.12.0Dis. Cap./Ah1.91.81.71.61.5100H18650CFL-2.1Ah 0.6C/-0.6C(45 4.05V4.05V4.15V4.15V4.15V4.2V4.2V4.2V)959085Dis. Cap. Ret./%2.2807570651.4601.3551.202.2Cycle No.10001500500502000H18650CFL-2.1Ah 0.6C/-0.6C(60 250030002.1Dis. Cap./Ah2.01.91000 Cycle 15V4.2V4.2V)0H18650CFL-2.1Ah 0.6C/-0.6C(60 15V4.2V4.2V85801.71.6751.5700500Cycle No. 1000150020000500Cycle No. 100015002000

Safety Enhancement with Ceramic CoatingBAK can coat highly uniform safety layer on electrodes to improve internal short,hot box performance.Metalparticlesize2μmcell with ceramic coating on anodeVoltagMetaleNo. cell No. particle size Fire 000 21cell without ceramic coating on anodeNo.cell No.123252525Metal particleVoltagFire No.size(μm)e No.50-10050-10050-1002028131

Safety Enhancement with Ceramic CoatingCeramic coating for hot box (150 /10min).cell with ceramic coating on anodeNO 5160.7162.6159.0154.9cell without ceramic coating on sPassPassPassPassNO 8370.0183.9182.2425.9Atmos.Temp. lCeramic coating on anode is used for EV batteries in BAK toimprove thermal stability.22

Contents BAK Introduction Basic InformationProduction and Detection EquipmentsR&D Equipments xEV Battery Research NMC Background18650 EV 2.1AH18650 EV 2.4AH18650 EV 3.1AH18650 EV 3.4AH xEV1Battery Industrialization

18650 EV 2.4AH Rate PerformanceDischarge Capacity (Ah)No.1.5C dischargecapacity/0.33Cdischarge capacity4C dischargecapacity/0.33Cdischarge K

18650 EV 2.4AH High-Low Temp. Discharge Perf.-20 60 25 60 0 -10 -20 -30 dischargedischargeDischarge Discharge Discharge Discharge Discharge Dischargecapacitycapacity/25Capacity Capacity Capacity Capacity Capacity Capacity/25 pacitycapacity-30 dischargecapacity/25 OK2# Cell H-L temperature /mAh200025 60 0 -10 25003000

18650 EV 2.4AH Cycling Performance2.52525254545606060 2.4 2.3 Dis.Cap. /Ah2.2 H18650CIL-2.4Ah100 0.5C/-1C,4.1V 0.5C/-1C,4.1V 0.5C/-1C,4.1V 1C/-1C ,4.2V 1C/-1C ,4.2V 1C/-1C,4.2V 1C/-1C,4.2V 1C/-1C,4.2V252525454560606095Dis. Cap.Ret/%H18650CIL-2.4Ah2.12.090 0.5C/-1C,4.1V 0.5C/-1C,4.1V 0.5C/-1C,4.1V 1C/-1C ,4.2V 1C/-1C ,4.2V 1C/-1C,4.2V 1C/-1C,4.2V 1C/-1C,4.2V85801.9751.81.7700200400600800Cycle No.10001200140016000200400600800Cycle No.100012001400Electrolyte optimization: by optimizing solvents ratio and additives to reduce gassing,BAK EV 2.4AH can cycle up to 1600 times.1600

Contents BAK Introduction Basic InformationProduction and Detection EquipmentsR&D Equipments xEV Battery Research NMC Background18650 EV 2.1AH18650 EV 2.4AH18650 EV 3.1AH18650 EV 3.4AH xEV1Battery Industrialization

Electrolyte Additives for NCA/NMC811Blank: 15% LiPF6, EC:EMC:DMC 2:1:7, VC 1, FEC 2Ni,Co,Mn content in electrolyte after storage with NCM811 cathode at 70 for7daysContent (ppm)10.8NiCoMn0.60.40.20cont.LA1%LA2%LiBOB LiODFB LiFSISNDTDESPRSMMDS LA and SN can obviously suppress Ni dissolution from NMC811 after HTStorage.

Electrolyte Additives for NCA/NMC811RTcyclingwithvariousadditives �DTD90%control85%SN80%0100100%20045 cycling300withvarious400500 cycleNo.600additives 0.5C/-0.5C70080090010004.1V 3.0VPST95%ES90%Capacity rerentionDTDControl85%SN80%75%70%Cycle No.0100200300400500600PRS,ES,SN deteriorate the RT cycling performance, while DTD slightly improves it.For 45 cycling, due to strong gassing, additives don’t make difference except SN.

Electrolyte Additives for NCA/NMC81125 cycling, NCA/graphite,additive LA vs control, %80%0200 cycle No.100300400NCA/graphite 45 cycling, additive LA vs control, 80%75%0100200300400500600700800cycleNo.900LA can greatly improves NCA RT cycling performance.100011001200130014001500

18650 EV 3.1AH Cycling Perf. after ElectrolyteOptimization18650 EV 3.1AH 0.5C/-0.5C 4.1V 3.0V2.845 0cycle No. 0.5C/-0.5C10001200140016004.1V 3.0V100%45 0120014001600

Anode Area Density Study (N/P Ratio)We change N/P ratio to find a suitable value for capacity, cycling and safety balance.Capacity sorting0.2C0.2C precharge0.5CCapC CapC CHARDISCHfirst effi.C N/P 12771.8170.22700.2165.83364.32882.185.7%176.9N/P P h-low temp. discharge 0.5C/-0.5C 4.2V 2.5V18650 EV 3.1AH 0.5C/-various C (4.2 2.5V)115%N/P 1.0106%110%104%102%100%100%cap.ret.cap.ret.N/P 1.05105%98%N/P 1.195%90%85%96%80%94%75%92%70%90%0.2C/0.2C%N/P 1.00.5C/0.2CN/P 1.051C/0.2C2C/0.2C3C/0.2C-20 -10 0 Temp.45 N/P 1.1Increasing N/P ratio can increase capacity, but lower the rate performance and lowtemp.discharge performance.60

18650 EV 3.1AH Cycling PerformanceRT cycling with various N/P ratio 0.5C/-0.5C(3.0-4.1V)RT cycling with various N/P ratio 0.5C/-0.5C(3.0-4.1V)105%2600N/P 1.02500100%N/P 1.052400230022002100cap.ret.dis.capa.(mAh)N/P 1.195%N/P 1.090%N/P 1.0585%N/P 1.1cycle No.2000010020030040050060070080080%0900 1000 1100 1200 1300 1400 1500 1600100200300400500600700cycle900No.1000 1100 1200 1300 1400 1500 160080045 cycling with various N/P ratio 0.5C/-0.5C(3.0-4.1V)45 cycing with various N/P ratio 0.5C/-0.5C(3.0-4.1V)105%2800N/P 1.0N/P 1.02700100%N/P 1.05N/P 1.05N/P 1.1cap.ret.dis.cap.(mAh)260025002400N/P 00cycle 00800cycle No.900 1000 1100 1200 1300 1400 1500

18650 EV 3.1AH Cycling Performance60 cycling with various N/P ratio 0.5C/-0.5C(3.0-4.1V)3000100%N/P 1.02900N/P 1.052800N/P 1.0N/P 1.0595%N/P 1.1N/P 1.1270090%cap.ret.dis.cap.(mAh)60 cycling with various N/P ratio 0cycle No.500700800900cycle No.The lower N/P ratiolower cathode potential when chargingdeintercalation from cathode and less discharged capacity.Lower cathode potentialperformance.600less side reaction with electrolyteless lithiumbetter cycling1000

Binder StudyBesides electrolyte, we study binders to improve low temp. and fast charging perf.140SBR 4SBR 3SBR 2O cycle 0.5C/-0.5C for various SBRSBR 1.8SBR 1.5Cathodic specificcapacity mAh/gcathodic specific capacitymAh/gEffect of SBR amount on 0 0.5C/-0.5C cycle performance135130125120115024 cycle No. 6810140130120Tg 35 110Tg 5 10090012The higher SBR amount, the worse lowtemp. cycling performance.Tg -15 Tg -50 80246cycle No.81012The higher Tg, the better low temp. cyclingperformance.capacity retentionRT 1C/-1C cycling perf with diff.SBRTg -50 degree C100%SBR with different Tg do not95%Tg 35 degree Cgreatly influence RT cycling90%85%perf.80%050100cycle No.150200250300

Binder Study700cap aft formationretained caprecovered capret. raterec. .755005.6Tg -50 degree CTg 35 degree C423048-650mAh LCO/NG after 70 degree C/24h storagethickness aft formationthic. af. 70C/24h hotthic. af. 70C/24h coldhot swell ratecold swell rate0.350.305.45.20.20swell ratethickness/mm0.255.00.154.80.104.6JSR: With rigid binder( high Tg),lithium ion pathways are preservedunder dense electrodes, resultingless press density, but better lowtemp performance.0.054.44.20.00Tg -50 degree CTg 35 degree C423048-650mAh LCO/NG after 70 degree C/24h storageTg is important for low and high temp. perf.Soft binder (low Tg) will result inhigher press density and betterhigh temp. perf., which also acts asa preformed SEI.

Binder SynthesisCNOR1R1CCOR2OO(CH2CH2O)nOHPolystyrene: stabilityPolyacrylonitrile: used to be a polymer electrolyte due to high polarity and highlithium ion mobility.Polyacrylates: by adjusting R1 and R2 functional groups, we can control polymerpolarity, Tg.Poly(oxyethylene)acrylates: used to be a polymer electrolyte for high lithium ionmobility.

Fluorine-Substituted CMC SynthesisCMC(sodium carboxymethyl cellulose) is apolyelectrolyte (single ion conductor). Due tostrong bonding between -OCH2COO- andNa , it is a bad ion conductor.C6H7O2(OH)3n LiOHClCF2COOH LiOHC6H2O2(OH)2OLinC6H2O2(OH)2OLin H2OClCF2COOLi H2O ClCF2COOLiC6H2O2(OH)2OCF2COOLi LiCln

Contents BAK Introduction Basic InformationProduction and Detection EquipmentsR&D Equipments xEV Battery Research NMC Background18650 EV 2.1AH18650 EV 2.4AH18650 EV 3.1AH18650 EV 3.4AH xEV1Battery Industrialization

18650 EV 3.4AH By combining high Ni content NCA/NMC811 and SiC anode, we havedeveloped 3.4AH 18650 cells in lab. Electron conducting additive optimization Electrolyte additive optimization (very important!) Anode binder optimization (LiPAA, conventional SBR, new lab-synthesizedbinder, polyimide?) Copper foil optimization (better elongation!) SiC optimization (SiC or SiOx?)

Contents BAK Introduction Basic InformationProduction and Detection EquipmentsR&D Equipments xEV Battery Research NMC Background18650 EV 2.1AH18650 EV 2.4AH18650 EV 3.1AH18650 EV 3.4AH xEV1Battery Industrialization

xEV Battery Developing Axis of BAK20052006FirstIndustrialization of LFP(Co-workwith A123)BAKInternationalFoundationFocusedon wEnergyVehicle”ProgramDevelopedand MP2.0Ah NMC18650 forEV27 LuxgencarsmountingBAK NMC18650 wereused inTaipei FloraExposition200 FotonTaxismountingBAK NMC18650startedoperation,over 100kkm/carBAK NMC18650 wasawardednational“25supportingnew energyprogram”Co-workedwith FAW todevelop 4 Evswhichentered“national newenergy carlist”2014Successfullydeveloped 2.4Ah18650New sailingof BAK NewEnergy

BAK EV Solution IntroductionNMC 18650 cell Low single unit energy-good safetyHigh energy densityGood high/low temperature performanceLong lifespanStandard product, low cost, flexible configuratioStandard Module Large number cell parallelimproves uniformity Patent module design, balancingsafety, strength, weight, reliabilityand cost Auto-manufacture Separate module to enhancesafetySmart BMSBAK EV SolutionNMC 18650 Standard Module Smart BMSFirst Chinese cell manufacturer to study,18650 for EV application Multi-level safety control Optimized for extend lifespan Slow-normal-quick chargecontrol and management Heat balance/managementsystem Other option to extend batteryperformancedevelopand successfully MPNMC

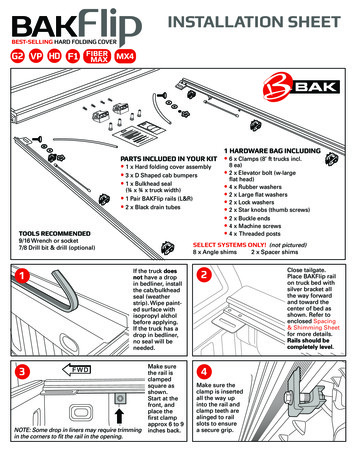

YUT HEV Project (LFP)Spec:40Ah/576V Combination Mode:18P180S Cell model: 26650HP Car model: Bus HEV① battery pack picture② bus picture using the pack

Singapore HEV Bus project (LFP)Spec: 345.6V/57.2Ah, Combination Mode:108S/26P Cell model: 26650MPModule number :120 Module Size:260*74.5*288.5mm

Wu Zhoulong PHEV Project (LFP)Spec:70Ah/339.2V Combination Mode:25P106S Cell model: 26650MP Car model: PHEV① battery pack picture② bus picture using the pack

Bailujia Bus- SinoEV Project (LFP)Spec:487.2Ah/403.2V Combination Mode:174P126S Cell model: 26650MP Car model: EVbus① battery pack picture② bus picture using the pack

Great Wall Motors EV Project (LFP)Shipment number :7sets Spec:60Ah/320V Combination Mode: 9P100SCell model:36800FE Car model: Tengyi C20 EV① battery pack picture② car picture using the pack

Chery A5 EV Project (LFP)Shipment number :3sets Spec:45Ah/332V Combination Mode:17P104S Cell Model:26650MP Car model: A5 EV① battery pack picture② car picture using the pack

FAW Qiming (Bora) Project (NMC)Spec:70Ah/331V Combination Mode:33P92SCar Model: Bora EV① battery pack pictureCell Model : H18650CFL2.1Ah② car picture using the packIn 2012 VW MMD compaign,it achieved “the best driving experience” honor.

FAW B50 (NMC)Spec:67.2Ah/302.4V Combination Mode:32P84S Cell Model: H18650CFL① battery pack picture② car picture using the pack100 Cars have been assembled using BAK batteries.

Yulong Huachuang (NMC)Spec:106Ah/374.4V Combination Mode:53P104S Cell Model: H18650CB① battery pack picture② car picture using the pack600 cars have been assembled from 2009 and no accidents.

Thank you for your attention!32

Tianjin BAK: Established in 2006 Registered capital: 99.99 million Location: Beichen District, Tianjin, 520 acres Production capability: 400MWH/Y China BAK BAK Tianjin--xEV production base BAK Tianjin blueprint Company prospect: leading global manufacturer of Li-ion power battery Applied area: EV, LEV, power tools, energy storage.

![Smarter Battery Crack [2022-Latest]](/img/13/eliamari.jpg)