Transcription

Standard PipeA53 CW and ERW

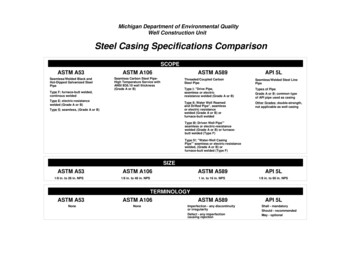

Standard PipeA53 CW and ERWWheatland Tube is known as a leader in the standardpipe industry. We’ve been producing tube and pipefor more than 75 years and our reputation for qualityand durability is unmatched. We’re the only full-lineproducer of continuous welded and electricresistance weld 1/4” to 12” pipe, and we set thestandards worldwide for hot dip galvanized products.We produce from 1/4” to 12” Nominal sizes and stock1/8” to 12” pipe sizes in a variety of ASTM standards sowe can meet all of your requirements.Wheatland offers over 350 different combinations offinish, end treatments and lengths on our standardpipe. We’re strategically located and carry a largeinventory so we can ship quickly to satisfy yourdelivery schedules.We’re the only CW producer in the North America.Hot-Dipped GalvanizedOur standard process is to galvanize to the ASTM A53requirements. UL Listed; FM Approved : NSF61 Suitable for Welding, Threading,Grooving and Bending Produced to ASTM A53A 53M, FederalSpecification WW-P404 and ASME B36.10MHydrostatic TestingHydrostatic test pressures for plain-end pipe are indicated below.StandardExtra StrongNPSWeight -PSIWeight -PSI1/2 through 1150015001-1/4 -1-1/2200020002 through 3250025003 1/2 -428002800Surface and End FinishesTensile RequirementsSurface Finishes: black, passivate, galvanized,uncoated, pickled and oiled, pickled, bare andsoluble oil.End Finishes: plain ends, roll groove, cut groove,threaded and coupled, and threads only (one orboth ends).Choose From a Full Line of Standard PipeASTM A53 is used for mechanical and low pressureapplications and in ordinary uses in steam, water, gasand air lines. It can be formed and welded. Ourproducts include:A53 Continuous Welded Pipe Type F, Grade A Black, Passivate, Bare, Pickled and Oiled,and Hot-dipped Galvanized Sizes: 1/2” – 4” Standard and Extra Heavy MIC Shield Coatings Compatible with CPVCTensile Strength, min. 48,000 psiYield Strength, min.30,000 psiElongation in 2”Refer to A 53 table x 4.1, latestrevisions - ASTM A53/A 53MBending Test – Less than NPS 2''DegreeDiameterof Bendof MandrelStandard90º12 x outside pipe diameterClose Coiling90º8 x outside pipe diameterFlattening Test – NPS 2 1 2'' and GreaterAs a test for quality of the weld, position the weld at90º from the direction of force and flatten until theOD is ¾ of the original outside diameter. No cracksshall occur along the inside or outside surface of theweld.

Dimensions and Weight Chart - ASTM A 53 Type ENominal Size2"2-1/2"3"4"5"6"8"10"12"STANDARD (SCHEDULE 40) BLACK PLAIN ENDO.D. InchesNominal .625.2808.625.32210.750.36512.750.375Weight/Lb. Ft.3.665.807.5810.8814.6318.9928.5840.5249.61A53 Electric-Resistance WeldedType E, Grade BTensile Requirements Black and hot-dipped galvanized Nominal Sizes: Schedule 40 2” – 12” UL Listed; FM Approved Suitable for welding, threading and grooving Produced to ASTM A 53/53M, Federal SpecificationWW-P404 and ASME B36.10M.Tensile Strength, min. 60, 000 psiYield Strength, min. 35,000 psiHydrostatic Testing andNondestructive Electric TestingBending Test (Cold)Degree of BendDiameter of MandrelFor NPS 2 and under90º12 x outside pipe diameterFlattening TestHydrostatic inspection test pressures for plain-endpipe are listed in Table X 2.2 of the A53/A 53Mspecification. Test pressures shall be maintained for aminimum of five seconds.Nondestructive electric testing of the weld seam isrequired on each length of ERW pipe NPS 2 andlarger.As a test for ductility of the weld for pipe 2-1/2” NPSand larger, position the weld at 0º and alternately at90º to the direction of force and flatten until the OD is2/3 of the original outside diameter. No cracks shalloccur along the inside or outside surface of the weld.All of our facilities have quality systems inplace. At a minimum, they’re registered toISO 9001:2008 Quality Management Systems.

Dimensions and Weight Chart - ASTM A53 Type 4"BLACK PLAIN ENDSch. 40WalI InchesWeight hes0.841.051.3151.661.92.3752.8753.544.5Sch. 80Wall 37Weight rd Pipe Schedule 40 - ASTM A53 Grades A and BOutside DiameterNPSDNDesignator Designator (Inches)Inside DiameterWall Thickness(mm)(Inches)(mm)(Inches)(mm)Nominal Weight (Mass) per unit LengthThreads & Threads &Plain End Plain EndCouplings 6.21

Extra Heavy Pipe Schedule 80 - ASTM A53 Type AOutside DiameterNPSDNDesignator DesignatorInside DiameterWall al Weight (Mass) per unit LengthThreads & Threads &Plain End Plain EndCouplings rmissible Variations - ASTM A53 Grades A and B PipePermissible Variations for ASTM A53 Grades A and B PipeO.D.OverUnderNPS 1/8 to 1-1/2DN 6 to 401/64"(0.4mm)1/64"(0.4mm)NPS 2 and up DN 50 and up1%1%Wall Thickness at Any Point--------12.50%Weight10%10%Outside DiameterMechanical PropertiesGrade A: Yield 30,000 [205 Mpa] psi minimum Tensile: 48,000 psi [330 Mpa] minimumGrade B: Yield 35,000 [240 Mpa] psi minimum Tensile: 60,000 psi [415 Mpa] minimum

Corporate Office3201 Enterprise ParkwaySuite 150Beachwood, OH 44122Ph: m700 South Dock StreetSharon, PA 16146Ph: 800.257.8182Fax: nd produces a full line of standard pipe — A53 CW and ERW pipe, lance pipe and seamlesspressure pipe. We’re the industry leader in hot-dip galvanized pipe, and we offer more than 350different combinations of finish, end treatments and length on our standard pipe.All Wheatland manufacturing locations’ quality management systems are certified to ISO 9001:2008requirements.For more information contact Wheatland’s Pipe Product at (888) 442-8880, email:info@wheatland.com or visit our website at www.wheatland.com.Made in America

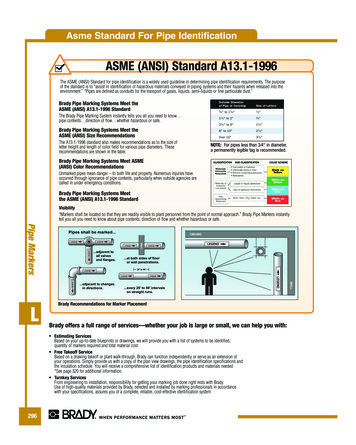

Our standard process is to galvanize to the ASTM A53 requirements. Surface and End Finishes Surface Finishes: black, passivate, galvanized, uncoated, pickled and oiled, pickled, bare and soluble oil. End Finishes: plain ends, roll groove, cut groove, threaded and coupled, and threads only (one or both ends). Choose From a Full Line of Standard Pipe