Transcription

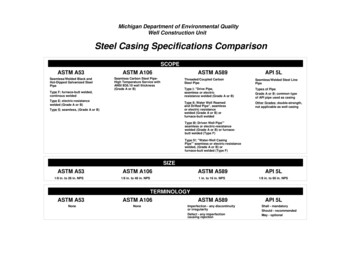

Michigan Department of Environmental QualityWell Construction UnitSteel Casing Specifications ComparisonSCOPEASTM A53ASTM A106Seamless/Welded Black andHot-Dipped Galvanized SteelPipeSeamless Carbon Steel PipeHigh Temperature Service withANSI B36.10 wall thickness(Grade A or B)ASTM A589Type F: furnace-butt welded,continous weldedType E: electric-resistancewelded (Grade A or B)Type S: seamless, (Grade A or B)API 5LThreaded/Coupled CarbonSteel PipeSeamless/Welded Steel LinePipeType I: "Drive Pipe,seamless or electricresistance welded (Grade A or B)Types of PipeGrade A or B: common typeof API pipe used as casingType II: Water Well Reamedand Drifted Pipe", seamlessor electric resistancewelded (Grade A or B) orfurnace-butt weldedOther Grades: double-strength,not applicable as well casingType III: Driven Well Pipe"'seamless or electric-resistancewelded (Grade A or B) or furnacebutt welded (Type F)Type IV: "Water-Well CasingPipe"' seamless or electric-resistancewelded, (Grade A or B) orfurnace-butt welded (Type F)SIZEASTM A531/8 in. to 26 in. NPSASTM A1061/8 in. to 48 in. NPSASTM A589API 5L1 in. to 16 in. NPS1/8 in. to 60 in. NPSTERMINOLOGYASTM A53NoneASTM A106NoneASTM A589Imperfection - any discontinuityor irregularityDefect - any imperfectioncausing rejectionAPI 5LShall - mandatoryShould - recommendedMay - optional

Michigan Department of Environmental QualityWell Construction UnitSteel Casing Specifications ComparisonMANUFACTUREASTM A53Open Hearth, Electric FurnaceBasic Oxygen Cast in ingotsor strand cast - Tempering orother processing required onERW weld seam (Grade B) toremove untempered martensiteASTM A106ASTM A589Open Hearth, Electric Furnace,Basic Oxygen Cast in ingotsor strand castAPI 5LOpen Hearth, Electric Furnace,Basic Oxygen cast in ingotsor strand castSeamless - steel hot workedto form tubular productwithout welded seamwelded - without filler1) Continuous: skelp heatedand mech. pressed togetherto form weld (butt-weld)2) Electric: steel mechanicallypressed together with heatto form weld generated byelectric currentwelded - with filler1) Submerged Arc:coalescence by heating withelectric arc, shielded byblanket of granular fusiblematerial, filler fromelectrodes, no pressureCHEMICAL COMPOSITIONASTM A53Composition,Max %Grade B &Type FGrade ation of these elementsshall not exceed 1.00%ASTM A106ASTM A589Composition,Max %GradeABC0.250.30 0.35Carbon0.29 0.290.27Manganese0.035 0.035 0.035Phosphorus0.035 0.035 0.035Sulfur0.10 0.100.10Silicon, Min.Copper0.400.40 0.40Nickel0.400.40 0.40Chromium0.400.40 0.40Molybdenum0.150.15 0.15Vanadium0.080.08 0.08See specification for range-2-API 5LComposition:Max %PhosphorusSulfur0.050.06Composition:Max %0.21 - 0.27Carbon0.60 - 1.15Manganese0.04 - 0.08Phosphorus0.06SulfurMax. % dependent on gradeof pipeSee specification for details.

Michigan Department of Environmental QualityWell Construction UnitSteel Casing Specifications ComparisonANALYSISASTM A53ASTM A106Chemical analysis shall conformto ASTM A 751ASTM A589Chemical composition of heatshall be performed by manufacturerAPI 5LChemical composition of heatshall be performed by manufacturerNOTE: Chemical analysis requirements are similar through all specificationsChemical composition of heatshall be performed by manufacturerRefer to individual specification for details.TENSILE REQUIREMENTSASTM A53ASTM A106Tensile Strength (min. psi):Types E and SType F48,000Grade AGrade BGrade AGrade B48,00060,00048,00060,000Yield Strength (min. psi):Types E and SType F30,000Grade AGrade B30,00035,000ASTM A589Grade C70,000Grade B30,00035,000Butt WeldedGrade A45,00048,000Grade B60,000Grade CButt WeldedGrade A25,00030,000Grade A48,000Grade B60,000Yield Strength (min. psi):Yield Strength (min. psi):Yield Strength (min. psi):Grade AAPI 5LTensile Strength (min. psi):Tensile Strength (min. psi):Tensile Strength (min. psi):Grade B35,000Grade A30,000Grade B35,00040,000(For other pipe grades,consult API specification)Elongation in 2": Similar values computed with same equation,Higher Tensile Strength Lower ElongationBENDING REQUIREMENTSASTM A53o90 /Cylindrical Mandrel 12xPipe Diameter/No CracksASTM A106ASTM A589oNoneStandard: 90 /CylindricalMandrel 12x Pipe Diameter/No CracksoClose Coiling: 180 /CylindricalMandrel 8x NPS/Without Failure-3-API 5Lo90 /Cylindrical Mandrel 12xPipe Diameter/No Cracks

Michigan Department of Environmental QualityWell Construction UnitSteel Casing Specifications ComparisonFLATTENING TESTASTM A53ASTM A106Addresses seamless/centrifugally cast pipe andwelded pipe H as defined forseamless in A 53Required on pipe over 2 in.Separately addresses seamless,electric-resistance welded andcontinuous welded methods.Butt weld:Elec.-Resist:Seamless:ASTM A589NONEH 60% O.D.H 33% O.D.Flat to H("H" is defined by equation)API 5LRequired on electric orcontinuous-welded pipeGrade 25: Flatten to 75%O.D. without weld break;60% O.D. without cracksexcept weldOther Grades: Flatten 67%O.D. without weld break;33% O.D. without breakexcept weldHYDROSTATIC TESTASTM A53ASTM A106Each length must be tested bythe manufacturerNot Required on Seamless PipeASTM A589Required unless purchaser specifies nohydrostatic testing or NDE in lieu ofhydrostatic testingEach length of pipe must be testedthe millAPI 5LSimilar requirements andpressures to ASTM A 589Test Pressures: depends on weight or schedule, grade and manufacture.Similar Pipe Similar PressureNONDESTRUCTIVE ELECTRIC TESTS (NDE)ASTM A53ERW Pipe: must be testedSEAMLESS Pipe: NDT may beused as alternative to hydrostatictesting - Pipe marked "NDE"ASTM A106ASTM A589NDE may be used as alternativeto hydrostatic testing - Pipemust be marked "NDE"NONE[NOTE: NDT is test of structural integrity based upon electrical/ultrasonic or radiological continuity]-4-API 5LRequired Grade A, BSubmerged Arc: inspected byradiological and ultrasonicmethodsElectric Weld: inspected byultrasonic or electromagneticGas-Metal Arc: inspected byultrasonic and radiologicalmethods

Michigan Department of Environmental QualityWell Construction UnitSteel Casing Specifications ComparisonNUMBER OF TESTSASTM A53Seamless, ERW: one test fortensile, bending, and flatteningfor each 500 lengthsContinuous Weld: one test per50 ton lotASTM A106ASTM A589Tensile: Under 6" - 1 test/400 lengths; 6" - 1 test/200Bend: Under 2" - 1 test/400 lengths or 5% each lotFlattening: same as tensile testSimilar to A 53API 5LFull length inspection all pipeRETESTSASTM A53Failure: results in double teston remaining lotsSecond Failure: rejectASTM A53REQUIREDWeight: 10%Diameter: - 1%Wall Thickness: not more than12.5% under thickness listedin specificationASTM A106ASTM A589Failure: one retest allowedSame As A 53TOLERANCES ON WEIGHTS & DIMENSIONSASTM A106ASTM A589REQUIREDWeight: 10%Diameter: Variation spec.Wall Thickness: not more than12.5% under thickness listedin specification-5-REQUIREDWeight: 5% 1%O.D.:I.D.: permit drift to passWall Thickness: not more than12.5% under thickness listedin specificationAPI 5LRejection/Retestrequirements more complexand stricter than ASTMAPI 5LREQUIRED- 3.5%Weight: 10%,Diameter: 1%Wall Thickness: not morethan 12.5% under and 20%over thickness listed inspecification

Michigan Department of Environmental QualityWell Construction UnitSteel Casing Specifications ComparisonLENGTHASTM A53Single-Random:16 to 22 ft.,Not more than 5% jointersPlain-Ends: 5% may be 12 to 16 ft.Extra-Strong and Lighter: variesASTM A106ASTM A589Single-Random: 16 to 22 ft.,5% 12 to 16Double-Random: Average 35 ft.,min 22 ft., and 5% 16 to 22Jointers: None allowedType I, II, IV: random 16-22 ft.Type III: random 3 - 6 or 6 - 10 ft.subject to order change/negotiation[NOTE: All lengths subject to order]API 5LT & C: Nominal 20 ft.Minimum - 16 ft.Maximum - 22.5 ft.Minimum Average - 17.5 ft.T & C: Nominal 40 ft.Minimum - 20 ft.Maximum - 45 ft.Minimum Average - 35 ft.Plain End: Nominal 20 ft.Minimum - 9.0 ft.Maximum - 22.5 ft.Minimum Average 17.5 ft.Plain End: Nominal 40 ft.Minimum - 14 ft.Maximum - 45 ft.Minimum Average - 35 ft.WORKMANSHIP, FINISH & APPEARANCEASTM A53Requires: inspection,imperfection 12.5% into wallconsidered defects, removalby grinding if wall thicknessOK, repair by welding subjectto agreement, pipe to be straightASTM A106ASTM A589Same as A 53Requires: straight and free ofdefects, allows imperfectionsless than 12.5% wall, free ofburrs, zinc coating/galvanizedfree of voids-6-API 5LRequires: visual inspectiondefects include dents, offsetof plates, weld bead flaws.Correction includes repair bygrinding welding orshortening

Michigan Department of Environmental QualityWell Construction UnitSteel Casing Specifications ComparisonEND FINISHASTM A53Standard Weight or Extra Strong:plain-end with bevelDouble Extra Strong: plain-endsquare cutThreaded: requires compliancewith ANSI B1.20.1, protectionASTM A106ASTM A589NPS 2" or Smaller: plain-endwith square cut or beveledOver 2" NPS: standard weightor extra strong plain-end beveled;over extra strong plain-end squareThreaded: required of all,protection, dimensions specifiedin specifications(ANSI B1.20.1)API 5LAll pipe threaded plain-end,or bell and spigot.T & C: thread conformingto API Standard 5B, threadprotection required.Plain-End: BeveledMinimum Average - 35 ft.ASTM A53Coated inside/out by hot-dip2Weight Coat: 1.8 oz/ftTest: specifiedOther Test: per on base materialGALVANIZED PIPEASTM A106ASTM A589Same as A 53NONEAPI 5LNo reference - pipe to becoated to protect againstrustINSPECTIONASTM A53Purchaser: right to inspect withreasonable facilities to satisfyProducer: responsible forperformance of inspectionand tests as specifiedASTM A106ASTM A589Same as A 53NONE-7-API 5LSimilar to A 53

Michigan Department of Environmental QualityWell Construction UnitSteel Casing Specifications ComparisonREJECTIONASTM A53Based upon compliance withtest and inspection bymanufacturer or purchaser.Disposition matter ofagreement.ASTM A106ASTM A589NONESame as A 53API 5LSimilar to A 53MARKINGASTM A53Legibly marked by rolling,2stamping or stencil with:1) manufacturer2) kind of pipe, i.e., continuous,electric resistance (Grade Aor B), seamless (Grade A or B)3) specification number4) lengthASTM A106ASTM A589Legibly marked with:1) manufacturer2) specification number3) grade4) heat number5) schedule number6) length7) weight ( 4")Legibly marked by rolling,stamping or stencil with:1) manufacturer2) type number3) kind of pipe (i.e., butt-welded,electric resistance, seamless)4) grade5) diameter6) wall thickness7) specification number8) length-8-API 5LLegibly stenciled or stamped with:1) manufacturer2) "Spec 5L" or "API 5L"3) size4) weight/ft.5) grade6) process manufacturer7) test pressure if higher spec.8) thread typeSupplemental requirements existwhich are Group specific.

Plastic Casing MarkingsRequired by Michigan Well CodeEach length of pipe must be legibly marked with all of the following information:MANUFACTURER'S NAME &RESIN MANUFACTURERIMPACT CLASSIFICATIONSIZE & SDRLOT NUMBERDATE MANUFACTUREDASTM NUMBERDESIGNATED ASWELL CASINGNSF MARKINGTYPE OF PLASTIC

Steel Well Casing MarkingsRequired by Michigan Well CodeEach length of pipe must be legibly marked, by the producing mill, with all ofthe following information:MANUFACTURER'SNAMEWEIGHTORSCHEDULEKIND OF PIPE(CONTINUOUS WELDED, ELECTRICRESISTANCE WELDED, OR SEAMLESS)NOMINAL OROUTSIDE DIAMETERSPECIFICATIONNUMBERLENGTHHEAT NUMBERORLOT NUMBER

Yard HydrantWithStop and WasteValveNot Approved

MICHIGAN DEPARTMENT OF ENVIRONMENTAL QUALITYDRINKING WATER AND RADIOLOGICAL PROTECTION DIVISIONGROUND WATER SUPPLY SECTION - WELL CONSTRUCTION UNITWATER SYSTEM WITH SUBMERSIBLE PUMP(Typical Household Installation)WATERTIGHT & VERMIN-PROOF WELL CAP(WITH SCREENED VENT)POWER SUPPLYDISCONNECTDISCHARGE LINETO HOUSEWELL MUST BE AT LEAST 3 FEETFROM BUILDING AND OVERHANGPRESSURE TANK(DIAPHRAGM ORBLADDER TYPE)CASING AT LEASTSURFACE GRADEDAWAY FROM WELLGATE VALVE12" ABOVE GRADEUNIONCONDUITPUMP CONTROLBOXPRESSURE RELIEFVALVEELECTRICAL CABLEIN CONDUIT ORAPPROVED DIRECTBURIAL CABLEPRESSURESWITCHWATERPROOF SEALINGCOMPOUND AROUND PIPESWATER SERVICE LINETANKSTANDSAMPLING TAP(UNTHREADED)AT LEAST 8"OFF FLOORPRESSUREGAUGEMDEQAPPROVEDPITLESSADAPTEROR UNITBASEMENTUNIONO-RINGS PRESSURIZEDON BOTH SIDES OF CASINGOPTIONALCHECK VALVE(MUST BE LOCATEDWITHIN CASING)U-BOLT(IF CLAMP-ONTYPE ERSIBLE PUMPNOTE: ELECTRICAL WIRING WITHIN WELL CASING NOT SHOWN.WIRING MUST COMPLY WITH STATE ELECTRICAL CODE.

MICHIGAN DEPARTMENT OF ENVIRONMENTAL QUALITYDRINKING WATER AND RADIOLOGICAL PROTECTION DIVISIONGROUND WATER SUPPLY SECTION - WELL CONSTRUCTION UNITWATER SYSTEM WITH SHALLOW WELL JET PUMP ANDPRESURIZED CONCENTRIC PIPING- WELL SEAL METHOD -PRESSURIZINGCOPPER TUBING FORANNULAR SPACE BETWEENCONCENTRIC PIPING(MIN. 1/2 IN. DIAMETER)BASEMENTPUMP DISCHARGELINE (TO TANK)WATERTIGHT & VERMIN-PROOFWELL CAP(WITH SCREENED VENT)CASING AT LEAST12" ABOVE GRADESURFACE GRADEDAWAY FROMWELLPRESSURESWITCHPRESSUREGAUGEPRESSURE LINETHREADED INTOVENT OPENINGIN SEALPUMPMOTORWELL MUST BE AT LEAST 3 FEETFROM BUILDING OR OVERHANGWATERPROOFSEALINGCOMPOUNDAROUNDPIPESMDEQ APPROVEDPITLESS UNIT(THREADS OR WELDSTO CASING)SPOOL WITHO-RINGSSHALLOW WELL JETPUMP2" X 1 1/4"WELL SEALUNIONIMPELLERHOUSING2 IN. OUTERCONCENTRICPIPINGWATER IN ANNULAR SPACEKEPT UNDER SYSTEMPRESSUREJET PEFOOTVALVE1 1/4" SUCTION LINEPROTECTED BY OUTERCONCENTRIC PIPINGWATER SYSTEM WITH SHALLOW WELL JET PUMPAND OUTER CONCENTRIC PIPING DRAINED BYGRAVITY INTO BASEMENTWATERTIGHT & VERMIN-PROOF WELL CAP (WITHSCREENED VENT)NOTE: THIS METHOD MAY BE USED ONLY WHERE THE WELL IS WITHIN 20 FEETOF THE BUILDING AND THE PUMP IS LOCATED WITHIN AN APPROVED BASEMENT,BASEMENT OFFSET, OR PUMP ROOMCASING AT LEAST12" ABOVE GRADESURFACE GRADEDAWAY FROM WELLPUMP DI

of API pipe used as casing Other Grades: double-strength, not applicable as well casing ASTM A53 ASTM A106 ASTM A589 API 5L SIZE 1/8 in. to 26 in. NPS 1/8 in. to 48 in. NPS 1 in. to 16 in. NPS 1/8 in. to 60 in. NPS ASTM A53 ASTM A106 ASTM A589 API 5L TERMINOLOGY None None Imperfection - any discontinuity or irregularity Defect - any imperfection causing rejection May - optional Shall .