Transcription

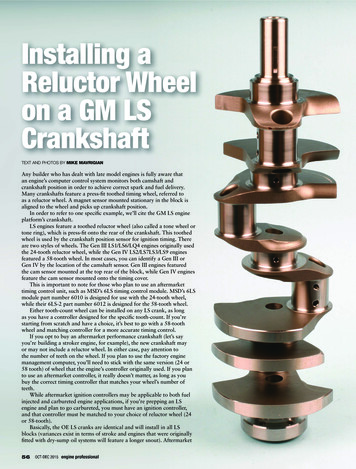

KG 119 kW (160 HP) at 2100 rpm (Straight / full turn) 9.0 / 7.8 t 1.9 m³KG 128 kW (172 HP) at 2100 rpm (Straight / full turn) 11.0 / 9.5 t 2.5 m³DL200-3 / DL250-3 Wheel Loader

Take a eTechnical specificationsEquipment2pages 4 - 5pages 6 - 7pages 8 - 9pages 10 - 11pages 12 - 13pages 14 - 15pages 16 - 21page 23

DL200-3 & DL250-3 – WE PREPARE THE WAYDO YOU WANT LOWER RUNNING COSTS, THE MOST EFFICIENT TECHNOLOGY AND FIRST-CLASSOPERATOR COMFORT?The new DL200-3 & 250-3 leave the competition behind, with technologies that reduce fuelconsumption and set new standards for comfort in the cab: EGR technology ensures the engine meets Stage IIIB regulations. Diesel Particulate Filter (DPF)technology provides cleaned exhaust gases suitable for environmentally friendly operation eveninside buildings and closed areas A 4-gear ZF powershift transmission delivers the highest traction and lowest fuel consumption Many extras are standard to increase operator comfort: heated air suspension seat, heated mirrors,load isolation system, automatically reversing fan, and many more.3

TAKE A TOURChoice of perfectly fittingattachmentsLoad isolation systemincluded as standard”Lift arm raise kick-out” and ”return to dig”functions operated electronically frominside the cabStandard 3rd spoolLatest generation ZF axles withautomatic limited slip differentialsand optional hydraulic differential lock4Load-sensing closed centrehydraulics ensure low fuel consumptionand a long service lifetime for components

COMFORT AND CONVENIENCE Spacious, comfortable cab Heated air suspension seatPOWER AND FUEL EFFICIENCY New LCD monitor Doosan DL06K engine (119 kW / 128 kW at 2100 rpm) Heated mirrors High torque at low rpm for better response Large storage compartments EGR technology provides simplified machineoperation with automatic regeneration of DPF, tomeet Stage IIIB regulations Large windows for better visibility Shark antenna Rear view camera (option) Clutch cut-off via brake pedal Power up function via acceleration pedal Load sensing hydraulic system Auto-idle function3-stage air filter with Turbo 3 cyclonedust separatorHydraulically driven, automaticallyreversing fan as standardEasy access to maintenancecomponents from the ground.Fenders, radiator grille, engine bonnet and other partsmade of robust steel4-gear ZF powershift transmission withautomatic and manual shift modesClean, solid articulationhinge design5

More power that lifts productivity to new heightsn Strength and intelligence – a winning combinationExceptional power combined with the finest workmanship results in a machine that will perform at thehighest level. The DL200-3 & DL250-3 enhance your output from every angle. Impressive digging powerand high traction make penetration easy and allow you to tackle the hardest materials.Work is quick and efficient with a powerful hydraulic system. A new Doosan DL06K engine withEGR technology provides the power you need while meeting Stage IIIB environmental regulations.5 ESSENTIAL ASSETS OF DL200-3 AND DL250-3: Power: 119 kW and 128 kW at 2100 rpm (SAE J1995) Productivity: lift arm raise speed: 5.6 and 6.0 seconds Breakout force: 99.0 kN and 121.5 kN Dump height at 45 : 2815 mm and 2745 mm Maximum steering angle: 40 6Load Isolation System (LIS)The bucket is suspended usinga closed accumulator to reducematerial loss as well as stresson the driver and machinestructure. The system isautomatic and depends onthe speed of operation.

EFFICIENT FUEL AND HYDRAULICS MANAGEMENT”Common Rail” Doosan DL06K engineThe heart of the DL200-3 & DL250-3 is the ”Common Rail” DOOSANDL06K 6 cylinder engine, carefully designed with common rail injectionand 4 valves per cylinder. The engine delivers from 119 kW to128 kW at only 2100 rpm. Powerful torque allows efficient useof the hydraulic system and faster working cycles.Already known for its outstanding reliability, the DOOSANDL06K engine has been optimised for the DL200-3 & DL250-3and is now compliant with the Stage IIIB European regulationsusing EGR (Exhaust Gas Recirculation) and DPF (Diesel Particulate Filter).EGR with DPFEGR, which requires enhanced cooling capacity, reducesNOx by recirculating exhaust back into the engine.This dilutes the amount of oxygen in the combustionchamber and lowers the combustion peak temperature.DOCExhaustExhaust with higher PMconcentration goes in.DPFCleaned exhaust with lowerPM (Particulate Matter)concentration comes out.DPF (Diesel Particulate Filter) filtersexhaust to remove PM.DOC (Diesel Oxidation Catalyst) reacts with exhaust andtransforms PM emissions into harmless substances.ZF Powershift TransmissionThe new Doosan ZF transmission has4 gears to boost acceleration performance, especially on slopes. The gear ratios are optimisedand smooth; shock-free shifts contribute to the high overall level of operator comfort.Traction force is also maximised. Together, these qualities enable a high working speed in allconditions. Excellent penetration power ensures optimum bucket filling during each cycle.The transmission has 3 modes of operation: Manual Automatic (travelling, 2nd to 4th gear) Automatic (working, 1st to 4th gear)A kick-down function enables manual shifting down in automatic modes.Load sensing hydraulic systemThis system provides maximumhydraulic performance, withoutproducing excess capacity.This saves fuel and extends thelifetime and reliability of vitalcomponents such as the pumpsand main control valves.”Z” kinematicsThe ”Z” form lifting geometry is extremely robust andespecially tailored for demanding jobs. Particularly effectivein penetrating piles of hard material, it delivers superiorbreakout force and loader stability. This is achieved withfewer moving parts and reduced stress on components.Performance improves with rapid bucket movements andcorrect angle positioning in every situation. With greaterdumping and lifting speed for the bucket and lift arm,faster cycle times and increased productivity are ensured.7

Comfort at its best – take a seat!n The workspace you’ve always wantedThe productivity of your wheel loader is directly linked to the operator’s performance. That’s whyDoosan has placed comfort at the very centre of its design priorities for the DL200-3 & DL250-3.More space, better visibility, air conditioning, a comfortable seat and plenty of storage space make iteasy to work for hours without fatigue or discomfort. There’s no need to pay extra for the options youwant – most of them are standard features on this loader.Heated air suspension seatVertical and horizontal airsuspension reduce vibrationfor maximum operator comfortand less fatigue.8Enhanced viewThe front and side windowswere enlarged to provide theoperator with a better overviewof the worksite, especially theareas to the left and right ofthe bucket.

Air conditioning with climate controlThe automatic climate control is newlydesigned. Its 6000 kcal capacity ensuresquick warming up and plenty of coolingpower. A recirculated air function isalso available. Extras CD/MP3 radio (optional) Heated mirrors Shark antenna Large storage compartmentsand cool box behindthe seat9

Expert control for stress-free operationPower alone is not enough. For maximum efficiency, it needs to be matched by precise control.Our unique range of features allows any operator to get the most out of this impressive machine.Colour LCD monitor panelThe 5.7” LCD panel is suitable forday and night work. The monitor isuser-friendly and gives full access tomachine settings and maintenancedata. Any abnormality is clearlydisplayed on the screen, allowing youto work safely and confidently with anaccurate overview of all conditions.User menuGaugesEngine coolant and transmission oiltemperatures, fuel and urea (AdBlue )levels.Anti-theft protectionECO barInforms the operator about the fuelefficiency of the current driving profile.Fan reverse intervalsAuto-idleAutomatically decreases engine rpmTailored performance for maximum efficiencywhen the controls are not operated.The DL200-3 & DL250-3 allow you to select from 3 different working modes:ECO, Normal and Power.It also features a Power-up function which lets the operator switch the machine into a higher working mode with lowertransmission shift intervals by fully applying the acceleration pedal.Monitoring Auto-idle Diesel Particulate Filter (DPF) regeneration systemThe DL200-3 and the DL250-3 wheel loaders are equipped with an automatic regeneration system to clean the DPF.This system removes all diesel particulate matter with no need for manual activation. The loader can be operatednormally during the regeneration process. It is possible to start the regeneration process manually and automaticregeneration can be stopped if needed. Automatic lift arm kick-out switchThe boom raise kick-down positions create faster cycle times and can be adjusted from within the cab. An optional”return to dig” position is available.Rear view cameraA camera provides a clear view of what’shappening behind the machine foradded safety and peace of mind.The monitor is aligned with the rearmirrors.Central indicator panelAn easy-to-read LCD indicator panelgives the operator full visibility ofessential loader functions.10

Easy-to-reach control panelAll controls are placed to the right, top and front of the operator. They are clearly positioned for comfortable access and grouped by function,enabling safe, confident operation.Transmission cut-offThe transmission cut-off function disconnectsthe driveline from the engine if the brakepedal is engaged. This delivers the full enginepower to the hydraulics, speeding up cycletimes and boosting fuel efficiency. The brakepressure for activation can be adjusted frominside the cab.Joystick or fingertip controlThe bucket can be moved using a convenient joystick with an FNR switch and kick-down function. The operator can also choose the optionof fingertip control.11

Doosan reliability – whatever the job!n Dependable performance for low lifetime costDoosan has been building heavy construction equipment for 40 years. This long experience is reflectedin the superior design and development of our wheel loaders as well as by an extensive logisticsnetwork. Our machines include as standard many features that other manufacturers offer as options.Designed to lastWe pay the highest attention to the design and manufacture ofstructural components.Finite Element Analysis is used to ensure an extended lifetime for mainstructures such as the chassis, joints and lift arm. After modelling,they are subjected to intensive laboratory and field testing in extremeconditions. Ongoing statistical analysis is used to constantly increasethe level of reliability.Limited slip differentialsLimited slip differentials at the front and rear automatically ensuremaximum tractive effort and easy driving over soft and muddy groundwith no need for a manual differential lock. They also reduce therisk of skidding and prevent excessive tyre wear. The brake discs inthe planetary reduction gears are reinforced, ensuring long hours ofoperation and easy maintenance access.Auto-lubeThe DL200-3 & DL250-3 can be equipped withan SKF automatic central greasing system as anoption.Auto lube protects components for a longermachine lifetime.12Hydraulic differential locksHydraulic differential locks are available as an option. Two modesare available. In manual mode, the operator can use a foot switch tolock the differential completely. Alternatively, it can be automaticallyengaged, depending on transmission torque, in the first and secondgears.3rd spoolAn auxiliary line for hydraulicattachments is included asstandard.Turbo 3 pre-cleanerThe loader features a3-stage air filtration system asstandard. The Turbo 3 cycloneseparator pre-cleans the airbefore filtering it through aninner and outer filter.ORFS (O-Ring Face Seal)All hydraulic lines, includingthe low pressure circuits, aresealed with ORFS couplings toprevent leaks.

Durable steel partsRear parts such as the radiator grille, enginebonnet and fenders are made of solid steel.They are designed for easy repair, reducing theneed to replace them in the event of damage.Articulation hingesThe robust hinges featurea clean, solid design.The articulation angle andsteering radius are the bestin their class.ExhaustThe inner exhaust pipesucks air out of the enginecompartment through anouter pipe. This ”chimney”effect provides constantair circulation and preventsdeposits of flammable materialon hot parts.Cab filterDouble cab filtration ensuresa constant supply of freshair to the cab, even in dustyenvironments.13

Easy maintenance for more uptimeShort and simple maintenance operations at long intervals mean that your machine is available on sitewhen you need it. Our service centre in the heart of Europe has more than 40000 parts in stock to supplyyou with top quality components as quickly as possible.Reversing fanStandard intervals for fan reverse can be set by the operator from inside the cab. The hydraulic fan motor is controlled by the ECU. Its performance isregulated for lower fuel consumption and shorter warm-up periods.Accessible components The front and rear of the radiator are easily accessible. It is made of aluminium for the highest pressure resistance and a long lifetime The radiator is in one block. This design offers the best access from both the front and rear14

Easy accessAll maintenance and control points are easy to reach from ground level.PC monitoringA PC monitoring function enables connectionto the ECU. Various parameters can be checkedduring maintenance, including pump pressures,engine rotation and engine speed. These can besaved and printed for analysis.Failure codesFailure codes and descriptionsare clearly communicated tothe operator. This reduces thetime needed for diagnosticsand repair.DrainsCoolant and engine oil drainsmake cleaning and changingmore convenient.Hydraulic test pointsThe pressure test points(main pressure, steering,braking, etc.) are groupedtogether for easy access.15

Technical specificationsQ EngineQ Transmission Model4-Gear powershift transmission with 3 operating modes: manual,fully automatic or semi-automatic with ”kick-down” function.Based on high quality components. Equipped with a modulationsystem for protection and smooth gear and direction changes.A manual transmission control lever is located to the left of theoperator. Direction change function also available in automaticor semi-automatic mode. Transmission can be disengaged by thebrake pedal to deliver full engine power to the hydraulics. A safetydevice prevents the engine from starting if the transmission is not inneutral. Transmission testing and adjustment equipment available.PC-compatible for operation history monitoring.Doosan DL06K - EU Stage IIIB compliant - EGR DPFTurbo-charged, air-to-air intercooledDirect injection Common Rail No. of cylinders6 Nominal powerDL200-3: 119 kW (160 HP) at 2100 rpm (SAE J1995)DL250-3: 128 kW (172 HP) at 2100 rpm (SAE J1995) Maximum powerDL200-3: 119 kW (160 HP) at 2100 rpm (SAE J1995)DL250-3: 128 kW (172 HP) at 2100 rpm (SAE J1995) Maximum torqueDL200-3: 75 kgf/m (735 Nm) at 1400 rpmDL250-3: 82 kgf/m (804 Nm) at 1400 rpm Engine rpm low / highDL200-3: 800 25 / 2300 50 rpmDL250-3: 800 20 / 2300 50 rpm Piston displacementDL200-3:DL250-3: Torque converter100 mm x 125 mm Starter24 V / 6.0 kW BatteriesDL200-3:DL250-3: Maximum gradeability2 x 12 V / 100 Ah Air filterDouble element and pre-filtered Turbo 3 cyclone dustseparator with automatic dust evacuation. CoolingReversing fan to facilitate cleaning.Automatic rotation speed adjustment according totemperature conditions.DL200-3:DL250-3: Breakout forceDL200-3:DL250-3:Q AxlesZ-kinematics with simple lifting piston system designed for heavyduty. From 10.0 to 12.3 t breakout force combines with a bucket anglethat is maintained throughout the range of movement. Bucket anglesare optimised in the travelling position and at ground level.Load Isolation System (LIS) is fitted as standard for improved comfortand output. ZF AxlesQuantityBore x rod diameter x stroke (mm)7.1 / 12.8 / 24.3 / 39.08.1 / 13.7 / 26.5 / 38.07.5 / 13.5 / 25.58.5 / 14.4 / 27.711.5 t13.0 t58% / 30 Braking distanceQ Lift armCylindersZF 4 WG 160ZF 4 WG 190Simple stage / mono phase / fixed wheel stator Speeds km/hForward 1 / 2 / 3 / 4:DL200-3:DL250-3:Reverse 1 / 2 / 3:DL200-3:DL250-3: Maximum traction5.9 litres Bore x stroke6.3 m at 32 km/h6.5 m at 32 km/h99.0 kN121.5 kNFully suspended front and rear drive axles with planetaryreduction gears in the hubs. Front and rear equipped withlimited slip differentials. Optimum traction in all conditions.From 11.5 to 13.0 t traction power allows operation on slopesof 58%.Front axle Differential Hydraulic Lock available as an option. Differential lock ratioFront (45%) / Rear (45%) Oscillation angleDL200-3Lift2110 x 75 x 790Bucket1120 x 75 x 515Lift2130 x 80 x 785Bucket1145 x 80 x 510DL250-3The optional parallel kinematics (tool carrier) provide a constant tiltangle for all lifting to height operations as well as a higher tiltingperformance at the maximum height. This feature is mandatory whenusing attachments such as pallet forks.16 Gearbox /- 11 BrakesDual multi-disc circuit with sintered metal discs for extendedservice life. Braking system activated by a pump andaccumulator circuits. Spring-applied, hydraulically releasedparking brake mounted on the transmission shaft.

Q Hydraulic systemQ Cab Main pumpsSpacious modular cab with excellent all-round visibility, ample storagespace and cool box. Good overview of the bucket, tyres and loadingarea. Push button controlled air conditioning and heating with airrecirculation function. Double cab air filter installed in the cab withextra protection for the operator in dusty or polluted environments.Viscous suspension mount for maximum comfort. High quality heatedseat with air suspension. All operating information clearly displayed infront of the operator. Control functions are centralised on a console onthe right. Adjustable seat, arm rests and steering column.Axial piston pump with variable flow, load sensing-controlled Maximum flowDL200-3:DL250-3: Operating pressure160 l/min210 l/min250 5 bar Pilot systemAutomatic functions for positioning the bucket for diggingas well as a function for stopping the lift arm at the desiredheight and low position by manual adjustment by switchare standard.A simple levelling function is also standard. FiltersIn the oil return to the tank, the glass fibre filter has a filteringcapability of 10 micron. Loading cycle (seconds)Lift arm:DL200-3:DL250-3:Bucket dump:DL200-3:DL250-3:up: 5.6 / down: 3.5up: 6.0 / down: 2.71.11.3Q Steering system1 Emergency exits2 Safety standardsROPS ISO 3471:2008FOPS ISO 3449 Noise levelsLwA external noise:DL200-3:DL250-3:LpA operator noise:103 dB(A) (ISO 6395)104 dB(A) (ISO 6395)72 dB(A) (ISO 6396)Q Pressure settingsSensing type with flow amplification valve and priority valve. Steering angle40 Steering cylinders (2)Emergency steering system with electric motor-drivenhydraulic pump.Cylinders DoorsQuantityBore x rod diameter x stroke (mm)270 x 35 x 370270 x 45 x 466Working (pump cut-off):Steering relief (LS port side):(steering pump side):Pilot control:Brake accumulator charging:Service brake:Fan motor:Parking brake release:Transmission selection pressure:250 5 bar175 10 bar200 10 bar30 2 bar120 140 bar60 3 bar160 10 bar120 5 bar16 2 barDL200-3SteeringDL250-3SteeringQ Fluid capacities (litres)Fuel tank:DL200-3:DL250-3:Cooling system:Engine oil:Front axle:DL200-3:DL250-3:Rear axle:Hydraulic 617

MDimensions and operational dataLJIHCKGEABD40 OQBF18

Q Dimensions & operational dataDL200-3 – Bucket mountingPin-onKinematicsZ-barTyre size 20.5 R25 (L2)ConfigurationBHIJKMLOQEDFGACCapacity heaped ISO/SAEBucket widthBreakout forceStatic tipping load (straight)Static tipping load (at 40 )Dump height (at 45 – fully raised)*Dump reach (at 45 – fully raised)*Dump height (at max. dump) - (at max. reach)*Dump reach (at max. dump) - (at max. reach)*Digging depthHeight at bucket pivot pointMax. tilt angle in carry positionMax. tilt angle fully raisedMax. tilt angle on groundMax. tilt angle at max. reachMax. dump angle at max. reachMax. dump angle on groundMax. dump angle fully raisedExternal radius at tyre sideExternal radius at bucket edgeWheel baseWidth at tyresTreadGround clearance (at 12 osc.)Overall lengthOverall heightOperating weightParallel kinematics (Tool Carrier)General purposeTeethm³mmkNkgkgmmmmmmmmmmmm 328012110Long lift 0-3 – Bucket mountingJKMLOQEDFGACParallel kinematics(Tool Carrier)General 7410328012110Z-barTyre size 20.5 R25 (L2)Capacity heaped ISO/SAEBucket widthBreakout forceStatic tipping load (straight)Static tipping load (at 40 )Dump height (at 45 – fully raised)*Dump reach (at 45 – fully raised)*Dump height (at max. dump) - (at max. reach)*Dump reach (at max. dump) - (at max. reach)*Digging depthHeight at bucket pivot pointMax. tilt angle in carry positionMax. tilt angle fully raisedMax. tilt angle on groundMax. tilt angle at max. reachMax. dump angle at max. reachMax. dump angle on groundMax. dump angle fully raisedExternal radius at tyre sideExternal radius at bucket edgeWheel baseWidth at tyresTreadGround clearance (at 12 osc.)Overall lengthOverall heightOperating 8012170TeethPin-onKinematicsBGeneral 5328012720TeethTeethm³mmkNkgkgmmmmmmmmmmmm 4157770328014350Long lift 0328014870General 8014410* Measured to the tip of the bucket teeth or bolt-on edge. All dimensions given with 20.5 R25 (L2) tyres.19

AttachmentsQ AttachmentsWhether direct-mounted or with quick-coupler, all our attachments are of the same high quality as the machines themselves, to make a perfect matchoffering better durability and the optimum level of productivity.Doosan genuine attachments will be the best partners for your Doosan wheel loader!Bucket, light materialIdeally suited for materials suchas corn, silage, hay, cottonseed,snow.Bucket, general purposeGeneral purpose bucketsprovide good all-roundperformance for stockpiling,rehandling, excavating andand other material-handlingoperations.Bucket, heavy-dutyEspecially useful in demolitionor recycling.Kg/m³Density of operating cium rockBasaltGranite (shale)Rocks erParticularly interesting whenthe machine has a widevariety of jobs to carry out,this hydraulic quick couplerenables a fast and safe changeof different attachments.Snow600Pallet forksFor loading and unloadingdifferent types of palletsas well as normal forkliftoperations.The specific weight of the material largely depends on the level of humidity,the degree of compaction, composition, etc.ADAPTED TO THE TIPPING LOADOPERATOR VIEWTo ensure the stability and safe operation of themachine.Optimized visibility of the attachment ensures safeand easy operation.PERFECT FIT GUARANTEEDKINEMATICS SIMULATIONTo ensure an easy and quick installation ofattachments on the machine without wasting timelooking for specific connectors. prevents collisions or kinematic lock-out ensures the bucket stops moving when it should ensures forces are transferred from the bucket tothe carrier in the right directions ensures optimum digging, crowding and dumpingangles

Q Bucket selection chart DL200-3Lift armBucketGeneralpurposeStandardlift armm³ToothGeneralpurposeHighlift arm1.92.2 m³1.9ToothCuttingedge tooth 2.01.8 m³2.3 m³1.9 m³2.2 m³2.3 m³Standardlift arm2.3 m³Tooth1.9 m³1.8 m³Generalpurpose1.9 m³Material Density [t/m³]1.0 1.1 1.2 1.3 1.4 1.5 1.6 1.7 1.8 1.9 2.0 2.1 2.22.52.9 m³Highlift arm3.2 m³2.7 m³Cuttingedge tooth 2.63.0 m³Cuttingedge tooth 2.6ToothGrading2.6 m³2.9 m³2.52.9 m³3.0 m³2.5Cuttingedge tooth 2.62.5 m³3.1 m³2.5Tooth2.4 m³3.0 m³Cuttingedge tooth 2.81.8 m³2.2 m³m³Cutting 2.6General edge toothpurposeTooth 2.7Grading1.9Cuttingedge tooth 2.0BucketTooth1.9 m³2.2 m³1.9Lift arm1.8 m³2.3 m³Cuttingedge tooth 2.0ToothGradingMaterial Density [t/m³]1.0 1.1 1.2 1.3 1.4 1.5 1.6 1.7 1.8 1.9 2.0 2.1 2.2Cuttingedge tooth 2.0ToothGradingQ Bucket selection chart DL250-32.4 m³2.5 m³2.4 m³2.5 m³2.9 m³3.0 m³2.4 m³2.5 m³Bucket filling factor115 %100 %95 %Compliant with ISO 14397-1 (2007)The filling factor depends on the type of material, the working conditions and theexperience of the operator.21

22

Standard and optional equipmentQ Standard equipmentEngineThree-stage air cleaner with cyclone pre-cleanerWater separatorFuel filterHydraulically driven fan, automatically reversingExternal drains for engine oil and coolant changesEngine power mode selector switch (Standard / Economy & Power mode)Self-diagnosis systemPower-up pedal function by full stroke of accelarationLifting and hydraulic systemRobust Z bar lifting systemGeneral purpose bucketHydraulic control valve with 3 spoolsAutomatic lift arm kick-outLevelling functionFast couplers for hydraulic checkVariable displacement load sensing pumpMono control lever (FNR)Additional lever for 3rd functionLoad isolation system (LIS)Automatic return to digSteering systemEmergency steering pump driven by electric motorLoad sensingExternal equipmentBottom protection platesLifting hooksArticulation lock in the transport positionTowing hitchTool compartmentFront semi-fender rear full fendersWheel chocksLift arm float kick-outElectric systemAlternator 60 A / 24 VWork lights: 2 at the front and 4 at the rear (6 x 70 W)Travel lights: low and high beamTail indicators, stop, reversing lightsReverse travel alarmRotating beaconDrive line and brake systemTransmission clutch cut-off via the brake pedalTransmission with self-diagnosis and monitoring indicator, plus electronicplug for fast adjustmentTransmission mode selector switch(Manual / Auto 1 ‹–› 4 / Auto 2 ‹–› 4 with kick-down)Starting safety systemLimited slip differentials on front and rear axlesDual brake circuits with accumulatorTyres: 20.5 R25 (L2)Dual service brake pedalsParking brake on the transmission, spring-applied hydraulic releaseCabROPS cab (SAE J 394, SAE 1040, ISO 3471)FOPS cab (SAE J 231, ISO 3449)Air conditioning with climate controlDouble filtered air cabAir suspension seat with safety beltAdjustable steering column (inclination & telescopic)Floor matTinted glassLeft sliding windowFront and rear wiper and washerSun visorInterior cab lightInterior rear view mirrors and heated side mirrorsMachine monitoring (dials, gauges and lamps)HornCigarette lighter and 12 Volt power socketCup holderMultiple storage compartmentsShark antennaLoudspeakers and connections for radioQ Optional equipmentEngineDiesel heaterTyresL3, L4, L5, various brandsLifting and hydraulic systemThree hydraulic levers with FNR switch4th hydraulic circuitElectric systemAdditional lightingFuel filling pumpCabVideo system with colour LCD and O Lux cameraRadio / CD / MP3Fuel heater switchExternal equipmentFull fenders with rubber protectionAdditional counterweightHydraulic differential lock on front axlesLong lift armParallel kinematics (Tool Carrier)Auto-lube systemMudguardsLong lift armBetter dump reach and height atbucket pivot point.Parallel kinematics (Tool Carrier)Provides maximum force for highreach and a constant tilt angle ofthe attachment at any height.Fingertip control3-lever control for lift arm, bucketand 3rd circuit. FNR switch forchanging travel direction as wellas kick-down, return to dig, lift armraise kick-out and floating mode.Hydraulic differential lockFor automatic (depending ontransmission torque) or manualdifferential lock.Heavy-duty tyreTo ensure the best performanceof your machine in the toughestconditions.Some of these options may be standard in some markets. Some of these options maynot be available for certain markets.Please check with your local DOOSAN dealer for more information about availabilityor to adapt your machine to your application needs.23

Doosan InfracoreThe pulse of transformationPantone 871 CPantone Black 7 CPantone 7505 CConstruction EquipmentMachine ToolsEnginesThe spirit of challenge and innovation has led Doosan. We started out as a small store in Seoul in 1896 and have expanded into a global company.Today we are engaged in the infrastructure support business (ISB), which encompasses industrial facilities, machinery, heavy equipment andconstruction. You can also see the Do

Manual Automatic (travelling, 2nd to 4th gear) Automatic (working, 1st to 4th gear) A kick-down function enables manual shifting down in automatic modes. Cleaned exhaust with lower PM (Particulate Matter) concentration comes out. Exhaust with higher PM concentration goes in. Exhaust DPF (Diesel Particulate Filter) filters exhaust to .