Transcription

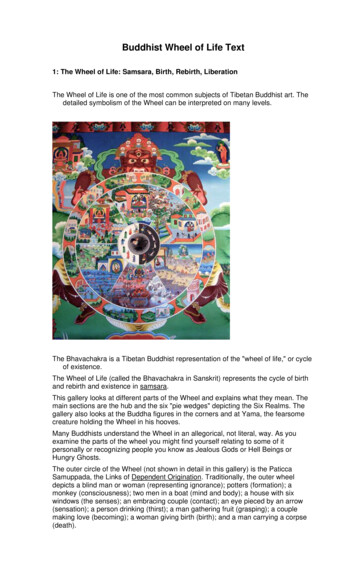

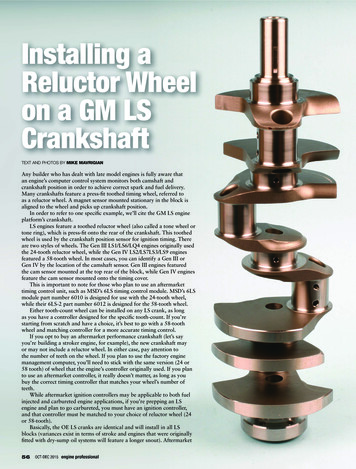

Installing aReluctor Wheelon a GM LSCrankshaftTEXT AND PHOTOS BY MIKE MAVRIGIANAny builder who has dealt with late model engines is fully aware thatan engine’s computer control system monitors both camshaft andcrankshaft position in order to achieve correct spark and fuel delivery.Many crankshafts feature a press-fit toothed timing wheel, referred toas a reluctor wheel. A magnet sensor mounted stationary in the block isaligned to the wheel and picks up crankshaft position.In order to refer to one specific example, we’ll cite the GM LS engineplatform’s crankshaft.LS engines feature a toothed reluctor wheel (also called a tone wheel ortone ring), which is press-fit onto the rear of the crankshaft. This toothedwheel is used by the crankshaft position sensor for ignition timing. Thereare two styles of wheels. The Gen III LS1/LS6/LQ4 engines originally usedthe 24-tooth reluctor wheel, while the Gen IV LS2/LS7LS3/LS9 enginesfeatured a 58-tooth wheel. In most cases, you can identify a Gen III orGen IV by the location of the camshaft sensor. Gen III engines featuredthe cam sensor mounted at the top rear of the block, while Gen IV enginesfeature the cam sensor mounted onto the timing cover.This is important to note for those who plan to use an aftermarkettiming control unit, such as MSD’s 6LS timing control module. MSD’s 6LSmodule part number 6010 is designed for use with the 24-tooth wheel,while their 6LS-2 part number 6012 is designed for the 58-tooth wheel.Either tooth-count wheel can be installed on any LS crank, as longas you have a controller designed for the specific tooth-count. If you’restarting from scratch and have a choice, it’s best to go with a 58-toothwheel and matching controller for a more accurate timing control.If you opt to buy an aftermarket performance crankshaft (let’s sayyou’re building a stroker engine, for example), the new crankshaft mayor may not include a reluctor wheel. In either case, pay attention tothe number of teeth on the wheel. If you plan to use the factory enginemanagement computer, you’ll need to stick with the same version (24 or58 tooth) of wheel that the engine’s controller originally used. If you planto use an aftermarket controller, it really doesn’t matter, as long as youbuy the correct timing controller that matches your wheel’s number ofteeth.While aftermarket ignition controllers may be applicable to both fuelinjected and carbureted engine applications, if you’re prepping an LSengine and plan to go carbureted, you must have an ignition controller,and that controller must be matched to your choice of reluctor wheel (24or 58-tooth).Basically, the OE LS cranks are identical and will install in all LSblocks (variances exist in terms of stroke and engines that were originallyfitted with dry-sump oil systems will feature a longer snout). Aftermarket56OCT-DEC 2015 engine professional

Tone wheel clock position and method of installation is critical. Don’t attemptit if you don’t know what you’re doing, as you can easily ruin the wheel.Pictured right is an aftermarket performance crankshaft with thereluctor wheel already installed. The wheel (also called a tone wheelor tone ring), as the teeth pass by a block-mounted crank positionsensor, provides crankshaft position signals to the ECU.Pictured below isan example of aperformance aftermarketLS crank that waspurchased without atone wheel. Performancecrank makers usuallyoffer cranks with orwithout a tone wheelalready installed.The specially-designed installertool is absolutely necessary fortone wheel installation, as itprecisely indexes to the 8mmhole in the tone wheel.cranks are available in a range of strokesto suit your planned build, based ondeck height, rod length and pistoncompression distance. Regardless, oneof the features common to all is the needfor a toothed reluctor wheel.The only exception is for thosebuilds that will feature both a carburetorand a distributor. Such conversionsfrom electronically managed ignitionto a distributor are much less popular;primarily due to the high cost of theparts needed to utilize a distributor (thisinvolves a unique distributor housing,a unique camshaft or cam nose gearextension, a unique water pump, and anew pulley system).Whether you plan to re-use the OEcrankshaft that was included in your newor used engine, or if you plan to installan aftermarket performance crankshaft,you may run into a situation where thereluctor wheel must be serviced. Perhapsthe original tone wheel is damaged (teethmissing or bent), or maybe you have acrank with a 24-tooth wheel and youwant to switch to a 58-tooth wheel, orpossibly new crank that you boughtdoes not include an already-installedwheel. Most aftermarket crank makerswill sell their LS cranks with the wheelalready installed, but you can run intoa situation where the wheel is soldseparately.Here we’ll explain the procedureinvolved in installing a reluctor wheel.It’s not a simple matter of hammeringthe wheel onto the rear of the crank. Thetone wheel must be indexed correctly tothe crank. If not timed correctly relativeto the crank’s rod throws, the engineeither won’t fire at all or it will run soout of time that it’ll be worthless.(continued)www.engineprofessional.com57

INSTALLING A RELUCTOR WHEEL BY MIKE MAVRIGIANREMOVING/INSTALLING THERELUCTOR WHEELThe reluctor wheel (also referredto as a timing wheel or tonewheel) is interference-fit ontothe rear of the crankshaft, withno key or other registeringdevice. If you’ve removed thetone wheel from a productioncrank, or if you’re faced withinstalling a new tone wheelonto a new aftermarket crank,where the two components werepurchased separately, it’s criticalto understand how the wheel is tobe installed.If an original tone wheel isto be removed, first place matchmarks on both the tone wheel andcrank rear flange. The position ofthe wheel is critical.Note: Do not attempt toremove the wheel with a puller,since you’ll bend/distort therelatively thin wheel. Instead,carefully and evenly heat thewheel with a torch to roughly 200degrees F. As the wheel expandsas a result of heat, it can easilybe pulled off by hand (obviouslyyou’ll need to wear heavy welder’sgloves). This can also be done inyour cleaning oven.The reluctor wheel featuresa series of teeth that providecrankshaft position signals (via asensor) to the ECM. The wheelinterference-fits to the rear of thecrank, immediately forward ofthe No. 5 main bearing. Typicallythe wheel features about a 0.007”interference fit.Since LS cranks feature nokeyway or other index point(thanks a lot, GM), how do youknow where to locate the wheel?Luckily, aftermarket indexingtools are available, such as theunit developed by Goodson ShopSupplies that we’re featuring inthis article. They offer a veryhandy and absolutely essentialindexing and installation tool forLS reluctor wheel mounting.The RRJ-350 Reluctor RingJig is comprised of a short steeltube that’s equipped with twoindexing pins. An external tangsecures a threaded stud, with thestud tip turned down to 8mmdiameter. This pin engages into the58OCT-DEC 2015 engine professionalTone wheels are available in both 24-tooth (LS1/LS6 versions) and 58-tooth (Gen IV/LS2, LS3, LS7, etc.). Selectingthe tooth count all depends on your ECU (if you plan to use an OE harness and computer) or an aftermarket timingcontrol module. The two need to match .if you have a 24-tooth wheel, you need a controller for a 24-tooth wheel.The same goes for the 58-tooth wheel (where you’d need a 58-tooth controller). If you already have a controller,then you need to buy the correct tone wheel to match up to that controller.Goodson’s reluctor wheelinstallation tool (Goodsonrefers to this as their RRJ-350Reluctor Ring Jig) enables youto accurately locate and installthe tone wheel.The Goodson RRJ-350 tool willaccommodate either the 24or 58-tooth wheel (a 24-toothwheel is shown below).

INSTALLING A RELUCTOR WHEEL BY MIKE MAVRIGIANThe jig tool’s 8mm locating dowel (shown above)engages into the tone wheel and is located on awelded tang on the outside of the tool body.single 8mm indexing hole in the reluctorwheel. An internal guide pin (a threadedstud with the tip turned down to 11mm)engages into the 11mm blind dowel holein the crank’s flywheel flange. This jigorients the reluctor wheel precisely in thecorrect timing position. The two dowelstuds feature jam nuts, to allow depthadjustment (you simply want to makesure that the 8mm dowel passes throughthe wheel’s 8mm hole, and that the11mm dowel projects out far enough toengage into the crank flange dowel hole).For purposes of this article, Iperformed a sample installation. First, Ilightly chamfered the entry hole of thereluctor wheel, and lightly chamferedthe edge of the crank’s reluctor wheelflange. Goodson’s instructions advisethis chamfering to ease installation.The instructions also state that thewheel may be pressed onto the crank orheated to 450 degrees F for a slip-on fit.Attempting to cold-press the wheel ontothe crank can be tricky since maintaininga square alignment of the wheel tothe crank may be difficult. Pre-heatingthe wheel (resulting in the center holeexpanding) makes the job easier andeasier to control. I heated the reluctorwheel’s I.D. lip with a torch, slipped thewheel onto the Goodson jig, and thewheel slid onto the crank as easily as arock drops into water.My advice: install the ring by preheating it, instead of potentially ruiningthe ring by cold pressing. Pressing, ifnot done with a high degree of precisionand care, can easily warp the reluctorwheel, rendering it useless. DO NOTtry to force the wheel onto the crankby striking it with a hammer. That’s aguaranteed way to ruin the wheel.Caution: The tone ring is made oftwo plates riveted together. If you areusing a press, and if you cock it out60OCT-DEC 2015 engine professionalThe installation tool’s internal dowel engages intothe crankshaft’s rear flange dowel hole.Shown here is the dowel pin hole in the crank’srear flange. The tool’s internal locating pin fits thishole very precisely.An LS reluctor wheel typically features an interference fit of about 0.007” onto the smooth outer surface ofthe crankshaft’s rear flange. The crank flange must be clean and free of burrs. Do not attempt to “make thejob easier” by grinding material from either the crank flange or the inside edge of the tone wheel’s centerhole.Here we see the installer tool’s outer dowel pinengaged into the tone wheel’s 8mm indexing hole.A closeup view of the tone wheel’s indexing hole.

INSTALLING A RELUCTOR WHEEL BY MIKE MAVRIGIANWith the tone wheelheated and installedto the tool, the tooland tone wheel, asan assembly, willslip onto the crankflange. Do not whackthe tool or the tonewheel with a hammer.Heating the wheel canbe accomplished in aconvection oven or bycareful use of a torch.This photoshows thereluctor wheelinstalled ontothe crank, withthe installertool removed.ABOVE: The tone wheel is positioned on thecrankshaft with the two “arrowhead” shapedholes at 90 to the number 1/2 rod pin, with theseries of large holes in the wheel positionedopposite from the first rod pin. That’s only a roughdescription. DO NOT attempt to install a tonewheel by eyesight. It is absolutely critical to usethe proper installation tool.LEFT: Here’s a view of a 4.000” stroker crankpositioned onto the block’s upper main bearings.Notice the tone wheel at the far right in this photo.BELOW: Notice the tight clearance of the tonewheel relative to the counterweight and maincap. With all main bearings lubed and main capsfully installed to final torque, carefully rotate thecrank to check tone wheel runout. If you findmore than about 0.002” runout, the tone wheel isprobably bent, in which case you’ll probably needto replace it.of alignment and continue to press,the plates can begin to separate. Ifthis happens, you can pinch the platestogether with C-clamps and carefullytack-weld it back together at the rivethole locations. Just be careful to avoidcreating a warp/runout condition.Again, because the jig indexes to boththe wheel and to the crank, misalignmentisn’t an issue. If you expect to build LSengines, I highly recommend buying thisjig. It takes all of the guesswork andtime consuming measuring out of theequation. Don’t even try to press it on62OCT-DEC 2015 engine professionalcold. Simply heat the ring, seat it ontothe jig, and place the jig and wheel ontothe crank. With heat and the right tool,it’s easy.Once the wheel has been installed andallowed to cool, test fit the crankshaftinto the block and carefully inspect toverify that the wheel won’t come intocontact with the rear main cap area.Check to make sure that the wheelfeatures no discernable runout, and makesure that it aligned with the crankshaftposition sensor, which is located at theleft rear side of the block.n

it if you don't know what you're doing, as you can easily ruin the wheel. Pictured right is an aftermarket performance crankshaft with the reluctor wheel already installed. The wheel (also called a tone wheel or tone ring), as the teeth pass by a block-mounted crank position sensor, provides crankshaft position signals to the ECU. (continued)