Transcription

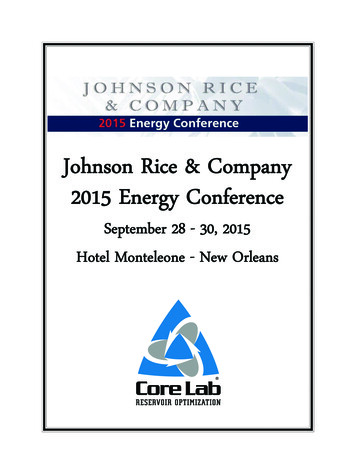

Johnson Rice & Company2015 Energy ConferenceSeptember 28 - 30, 2015Hotel Monteleone - New Orleans

Slide 1Johnson Rice & Company2015 Energy ConferenceSeptember 28 - 30, 2015Hotel Monteleone - New OrleansSlide 2Three principal business lines:1. Reservoir Description2. Production Enhancement3. Reservoir ManagementSlide 3The Horizontal WellThe Horizontal WellCore Lab’s operational focus remains on crude oilfield development projects, with growing emphasison delivering technology to our clients to assist intheir efforts to maximize the return from theirunconventional, conventional, onshore and offshoredevelopments.2

Slide 4The Horizontal WellPresentation Walk-away Points: The Decline Curve Will Always Win Core’s Differentiating Technologies Core’s Industry Leading Shareholder ReturnsSlide 5The Horizontal WellOur services and products focus on maximizingproduction rates and ultimate reserves to maximize ourclients’ return on their investments.Slide 6The Horizontal WellPrimary Business Drivers1. Reservoir Description:Laboratory-based Services with International& Oil Focus2. Production Enhancement:Products and Services for Wellbore Completions– 2/3 North America & 1/3 International3. Reservoir Management:Global Focus3

Slide 7The Horizontal WellCore Lab targets the more stable, less volatile,production and production enhancement componentof the oil companies’ budget.Slide 8The Horizontal WellThe Decline CurveCore Lab provides services through its three operatingsegments at points all along the decline curve: Reservoir Description Production Enhancement Reservoir ManagementSlide 9The Horizontal WellReservoir DescriptionOur first business unit – Reservoir Description – analyzesactual reservoir rocks and fluids to provide data sets thataccurately characterize the reservoir.These precise measurements create the “base truth”from which to build the field’s reservoir optimizationmodel. These measurements are invaluable in order todetermine probable versus proven reserves in-place.4

Slide 10The Horizontal WellReservoir DescriptionLeaders in rock property analysisfrom the traditional perspective to Slide 11The Horizontal WellReservoir Description the most advanced.Slide 12The Horizontal WellReservoir DescriptionLeaders in reservoir fluid analysis Analyses of reservoir fluid properties are gaining inimportance as the fluids (e.g. – oil and gas) are indeedthe economic driver in the reservoir.5

Slide 13The Horizontal WellReservoir DescriptionThe value of crude oil is directly related to the amount ofgasoline that can be refined from the particular crude oilbeing produced. Our clients want to know thecharacteristics of their crude oil to better assess theeconomics that can be obtained from the crude oil and itsderived products.Slide 14The Horizontal WellReservoir DescriptionFluids analysis range from traditional methods used toderive the basic characteristics of fluid, to the moreadvance fluids testing using medical imaging CT scanners(shown here), to perform enhanced oil recovery tests(“EOR”) at reservoir temperatures and pressure.Furthermore Slide 15The Horizontal WellReservoir Descriptionthe CT scanners can be used to produce 4D-time lapsedfluid analysis, showing the fluids moving through thereservoir rock and natural gas (depicted in red) displacingthe oil (depicted in green) over time.6

Slide 16The Horizontal WellProduction EnhancementOur next business unit – Production Enhancement –provides products and services designed to minimizeformation damage and maximize production flow rates.The Goal - optimizing reservoir value.Following are some of the most recent applications of ourservices and products aimed at enhancing productionfrom long-reach horizontal well bores being drilled toexploit unconventional reservoirs.Slide 17The Horizontal WellProduction EnhancementKODIAK Enhanced Perforating System The KODIAK Enhanced Perforating System combinesperforating and well stimulation in one operation. Thesystem integrates specifically designed perforating chargeswith a new energetic material. In stage one of the event,the detonation of the perforating charges cut theperforating tunnel and also initiates stage two, a complex,sequentially burning reaction of the energetic material (i.e.“solid rocket fuel”) generating a high pressure gas pulse.Slide 18The Horizontal WellProduction EnhancementKODIAK Enhanced Perforating System Stage one: the HERO , SuperHERO or HERO-HR perforation charges are detonated, creating the deepestperforation tunnel in the world and at some 30,000 feet persecond .7

Slide 19The Horizontal WellProduction EnhancementMini‐fracturesKODIAK Enhanced Perforating System Stage Two: the perforation charge initiates the secondcharge of energetic material (“solid rocket fuel”) whichcreates a high pressure pulse of gas causing “minifractures” in the perforating tunnel and when the highpressure pules of gas exits the perforating tunnel itclears any remaining debris.Slide 20The Horizontal WellProduction EnhancementKODIAK Enhanced Perforating System The end result after the KODIAK Enhanced PerforatingSystem shown here. These mini-fractures created in theperforation tunnels reduce the formation break-down pressureneeded to perform the pressure pumping/hydraulic fracture ofthe reservoir rock, thereby saving the operator cost to completeand stimulate the well. Additionally, the deeper and cleanerperforation tunnel will also improve the flow and recovery ofhydrocarbons from the reservoir.Slide 21The Horizontal WellProduction EnhancementFLOWPROFILER and well completion diagnosticsFlowProfiler is the industry's first comprehensive after frac flow profile technologythat simultaneously evaluates both frac fluid clean-up and hydrocarbon productionover time. Designed for multiple stage completions in both vertical and horizontalwell applications, providing critical information such as: Simultaneous Zonal Flowback; Frac Fluid Clean-up; Hydrocarbon Contributionand Production Log Analysis Indexing hydrocarbon production to geologic horizons Evaluating Production Over Time Well Spacing Issues such as Frac and Production interference with Offset Wells.Shown here is a log of the production flow from the well by stage, giving thecustomer a visual of the well’s stage by stage contribution of both hydrocarbon fluidsand water.8

Slide 22The Horizontal WellProduction EnhancementFLOWPROFILER and well completion diagnosticsShown here , FlowProfiler has been combined with SPECTRACHEM (frac fluidflowback), with ZeroWash (the placement of completion proppants). FlowProfilertechnology is being combined with Core’s other diagnostic services to provide acomprehensive understanding of the completion and to identify opportunities toincrease hydrocarbon production and ultimate recovery.Core Laboratories is the only tracing and imaging company that provides essentialdirect measurements of: Fracture height Zonal coverage Proppant distribution Wellbore connectivity Fracture fluid performanceSlide 23The Horizontal WellProduction EnhancementFLOWPROFILER FlowProfiler technology employs a specific, unique oilsoluble tracer, or combination of unique oil-solubletracers, introduced into specific and isolated stages viathe stimulating proppant stream.Slide 24The Horizontal WellProduction EnhancementFLOWPROFILER The unique oil-soluble tracers are absorbed by the crudeoil associated with each stage.9

Slide 25The Horizontal WellProduction EnhancementFLOWPROFILER When the well is flowed, crude oil samples are collected andanalyzed by gas chromatography-mass spectrometry to identifyand quantify flow from each stage. Stages not flowing optimallycan be identified, precipitating remedial efforts and providingvaluable insights for future wells.The combined knowledge of both the zonal water and oil profilesprovide unique data sets to accurately understand the total afterfrac flow profile for evaluating individual well production andmaking critical next well decisions.Slide 26The Horizontal WellProduction EnhancementFLOWPROFILER FlowProfiler diagnostic tracers are also being used toidentify communication between frac stages from thetreatment well to surrounding offset wells, enabling theoperator to make informed decisions on lateral spacingand, of increasing importance, on the vertical spacing ofhorizontal wells.Slide 27The Horizontal WellReservoir ManagementOur third unit – Reservoir Management – focuses onleveraging the knowledge gained from the data sets wecreated in our Reservoir Description unit along with ourProduction Enhancement projects to solve reservoir-wideissues which a client may have.Our integrated approach is designed to help clients solvewide ranging production problems they may be incurring.10

Slide 28The Horizontal WellReservoir ManagementInternationally, Reservoir Management continued to focus onWest and East Africa development projects. Regionalpetroleum systems studies are being performed incooperation with national oil and gas ministries in Coted’Ivoire, Senegal, Tanzania and Mozambique.Slide 29The Horizontal WellReservoir ManagementThese Pre-Salt Angola Deepwater studies are directedtoward providing data sets consisting of biostratigraphy,geology, reservoir quality, petrophysical properties, andseal evaluation with ties to seismic data sets forcompanies exploiting these deepwater provinces.Slide 30The HorizontalReservoir ManagementThis study proposes to integrate previously evaluatedwell log and rock data with a comprehensive suite ofnewly acquired log, cuttings and key core material. Thisextension to our Pre-Salt, West African Margin Study, willprovide a detailed and fully integrated regionalassessment of the sedimentological and diageneticcharacteristics of Pre-Salt carbonates and will alsoevaluate the complex relationship between tectonic andigneous activity and sedimentation patterns within thesyn-rift basins from this region.11

Slide 31Our operating margins have continued to expandas we have been able to develop new technologies- which we then strive to offer our clientsthroughout our existing international platform.These three growth strategies have been essentialingredients to our improving performance.Slide 32Global distribution system;70 offices in 50 countries.12

Johnson Rice & Company 2015 Energy ConferenceNew Orleans, LASeptember 29, 2015Notes Page13

Johnson Rice & Company 2015 Energy Conference September 28 - 30, 2015 Hotel Monteleone - New Orleans Core Lab's operational focus remains on crude oil-field development projects, with growing emphasis on delivering technology to our clients to assist in their efforts to maximize the return from their unconventional, conventional, onshore and .