Transcription

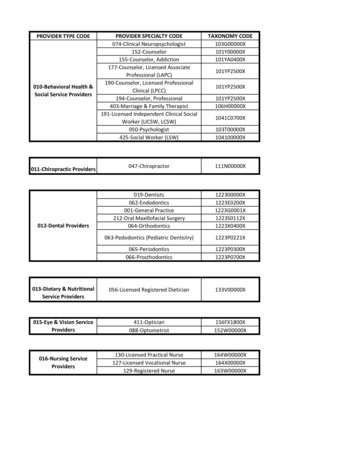

Code Requirements for ASTs at Motor Vehicle-Dispensing StationsThis table compares aboveground storage tank requirements in the 2015 edition of NFPA 30A, to the 2015International Fire Code (IFC). Please note that 2015 NFPA 1 references the 2015 NFPA 30A for all itsrequirements relating to ASTs at Motor Fuel Dispensing Stations. These are the three (NFPA 30A, NFPA 1,and IFC) most-referenced national fire code requirements for aboveground storage tanks at motor vehiclefuel dispensing facilities. This table is a partial list of the differences and similarities between these Codes,and is not intended to be a replacement for these Codes.NFPA 30A2015 EDITIONApproval/GeneralProvisions The use of aboveground storage tanks atmotor fuel dispensing facilities, fleetvehicle motor fuel dispensing facilities, andmarine motor fuel dispensing facilitiesshall be permitted when installed inaccordance with the requirements ofSection 4.3 and with all applicablerequirements of Chapters 21, 22 and 27 of2015 NFPA 30, and for tanks other thantanks in vaults, when the specificinstallation has been approved by the AHJ(30A: 4.3.2.1).IFC2015 EDITION Terminology Fire-Resistant Tank: An atmosphericaboveground storage tank with thermalinsulation that has been evaluated forresistance to physical damage; for limitingthe heat transferred to the primary tankwhen exposed to a hydrocarbon pool fire;and is listed in accordance with UL 2080 oran equivalent test procedure (30: 22.2.1and 30A: 3.3.15.2).Protected Aboveground Tank. Anatmospheric aboveground storage tankwith integral secondary containment andthermal insulation that has been evaluatedfor resistance to physical damage; forlimiting the heat transferred to the primarytank when exposed to a hydrocarbon poolfire; and is listed in accordance withANSI/UL 2085, or an equivalent testprocedure (30: 22.2.3 and 30A:3.3.15.3). When approved, aboveground tanks usedfor outside, aboveground storage of motorfuels classified as Class I, II or III liquidsshall be in accordance with Chapter 57(Flammable and Combustible LiquidsChapter) and as provided by Section2306.2.3.Outside storage of Class I liquid fuels shallbe in Protected aboveground tanks withrequired listing and labeling of tanks (IFC:2306.2.3(1)).Outside storage of Class II or IIIA liquidfuels shall be in Protected abovegroundtanks or, when approved by the AHJ,other aboveground tanks that complywith Chapter 57 (IFC: 2306.2.3(2)).Outside storage of Class IIIB liquid fuelsshall be in listed UL 142 or protectedaboveground tanks that comply withChapter 57 (IFC: 2306.2.3(5)).Protected aboveground tank separationrequirements are listed in Table 2306.2.3.Aboveground tanks are allowed in vaultsaboveground or below grade (IFC:2306.2.4).Special enclosures for tanks areallowed, in order to overcomeimpractical conditions (IFC: 2306.2.6).Protected Aboveground Tank: A listedtank system consisting of a primary tankprovided with protection from physicaldamage and fire resistive protection froma high intensity liquid pool fire exposure.The tank system may provide theseprotection elements as a unit, or may bean assembly of components or acombination thereof (IFC: 202).Special Enclosures: Enclosuresconstructed in accordance with Section2306.2.62.Vaulted Tank: Vaults shall be listed inaccordance with UL 2245 or, whenapproved, constructed on-site inaccordance with the International

Code Requirements for ASTs at Motor Vehicle-Dispensing Stations - Page 2 of 6 PagesNFPA 30A2015 EDITIONTerminology(cont.) Installation See the Approval/General Provisionsrow in this Table for additionalinformation. NFPA 30 providesadditional requirements for abovegroundtank systems spillage control, normaland emergency venting, corrosioncontrol, tank construction, supports andfoundation, flooding, and testing and maintenance.Tanks storing liquid motor fuels at anindividual site: 12,000 gal individual and48,000 gal aggregate (30A: 4.3.2.3)1. Tanks storing Class II and Class III liquidsat fleet vehicle motor fuel dispensingfacilities: 20,000 gallon individual and80,000 gallon aggregate (30A: 4.3.2.5). Individual tanks in vaults may store up to15,000 gallons (30A: 4.3.2.3).MaximumCapacitiesVault. The vault must be liquid-tight anddesigned to withstand loading from soil,water, traffic, etc. Vaults shall be providedwith approved vapor and liquid detectionsystems, including onsite audible andvisual warning devices with batterybackup (30A,4.3.3. through 4.3.3.9).Vaults with Class I liquids require exhaustventilation (30: 25.10 thru 25.10.6; 30A:4.3.3.6 thru 4.3.3.6.6) 3.IFC2015 EDITION Building Code, Section 1707. The designshall bear the stamp of a ProfessionalEngineer. Special inspections arerequired. IFC Section 5704.2.8.2 sets out18 conditions for vaulted tank compliance.Vaults with Class I liquids require exhaustventilation.3 Fuel dispensing systems are to beinstalled in accordance with Chapter 23,which incorporates all the motor fueldispensing facilities controls. Tankinstallations are to be in accordance withChapter 57, as modified by Chapter 23. Overfill/SpillPrevention Overfill: Alarm at 90% capacity; automaticshut-off at 98% capacity; or restricted flowat 95% capacity (30A: 4.3.6.3) 4.Means to determine liquid level shallbe accessible to delivery operator(30A: 4.3.6.2). Protected Aboveground Steel Tanks:(Gallons) 6,000 individual for Class I liquids,with reduced separation requirements (IFC,Table 2206.2.3); 12,000 individual, 48,000aggregate for Class I, II or III liquids. (IFC:2306.2.3(3)).Vaults at Public Motor Fuel- DispensingFacilities: (Gallons) For tanks storingClass I and Class II liquids: 15,000individual, 48,000 aggregate (IFC:2306.2.4.1).Vaults at Fleet Vehicle Motor FuelDispensing Facilities: (Gallons) For tanksstoring Class II and Class IIIA liquids:20,000 individual, 80,000 aggregate (IFC:2306.2.4.2).Special Enclosures: (Gallons) 6,000individual, 18,000 aggregate (IFC:2306.2.6(6)).Other Aboveground Tanks: Whenapproved by the AHJ, tanks shall complywith Chapter 57 at the same capacities asfor protected tanks noted above (IFC:2306.2.3(2) and (3)).Spill Containers: Min. 5 gallons(IFC,2306.6.2.6).Protected and Vaulted Tanks: Overfill:Alarm at 90%; shut-off at 95%; or reduceflow rate to not overfill for 30 minutes andprovide auto-shut-off prior to wetting tanktop fittings (IFC: 5704.2.9.7.5).Aboveground Steel Tanks: Overfill: anapproved means or method shall beprovided (such as Section 5704.2.9.7.7).

Code Requirements for ASTs at Motor Vehicle-Dispensing Stations - Page 3 of 6 PagesNFPA 30A2015 EDITIONPhysicalProtectionSecondaryContainment 6' high security fence located at least 10'from tank and a gate properly securedagainst unauthorized entry. Whenrequired, provide protection againstvehicular collision by suitable barriers,such as 4" diameter steel pipe filled withconcrete set 3' deep in a concretefooting and spaced no more than 4'apart. (30A: 4.3.7.1 through 4.3.7.2). Secondary containment tanks may beused to provide spill control, in additionto diking or remote impounding. Section22.11.4.1 of 2015 NFPA 30 limits such atank to a max. of 50,000 gallons.Means shall be provided to preventrelease of liquid by siphon flow (30A:4.3.6.4 and 30,22.11.4.3).All pipe connections shall be madeabove the normal maximum liquid level(30A: 4.3.6.1).Means to determine the level of liquidduring deliveries (30: 22.11.4.2 through22.11.4.4) and to meet spill preventionrequirements are noted herein.Enclosed secondary containment shall beprovided with emergency vents5 (30:22.11.4.8).The interstitial space shall be tested withair pressure, vacuum, or hydrostatics atthe specified limits. This tightness testingshall not be required for tanks thatcontinue to maintain a factory-appliedvacuum(30: 21.5.2).Tightness testing with air pressure shallnot be allowed on tanks that containflammable or combustible liquids orvapors (30:21.5.2.2). Tanks shall be permitted to operate atpressures from atmospheric to a gaugepressure of 1.0 psi and shall be limitedto a gauge pressure of 2.5 psi underemergency venting conditions. (30:21.4.2.1.4).Every aboveground storage tank shallhave emergency relief venting in theform of construction or a device ordevices that will relieve excessiveinternal pressure caused by anexposure fire (30: 22.7.1.1). Applies to: Each compartment of acompartmented tank, the interstitialspace (annulus) of a secondarycontainment–type tank, and theenclosed space of tanks of closedtop dike construction (30: 22.7.1.1.1) EmergencyVentingIFC2015 EDITION ASTs shall be safeguarded from publicaccess in an approved manner (IFC:2306.3).Impact protection required by systemdesign, barriers or posts.Steel posts of 4" diameter, concrete filled,spaced 4' on centers, 3' deep in concrete,protruding 3' above grade, set 3' from theprotected object. Barriers a minimum of 3'high, resisting 12,000 pounds of force.(IFC: 5704.2.9.7.4 and 312)Aboveground Tanks: Section 2306.5refers to Chapter 57 for drainage control ordiking. Not required for listed secondarycontainment tanks. Enclosed secondarycontainment required to have emergencyventing.Drainage and Diking: Section 5704.2.10 Required around a tank or group of tanks toprevent accidental discharge fromendangering adjacent tanks, adjoiningproperty or waterways. Waivers allowed forspecial features.Protected Tanks: Section 5704.2.9.7.3 Protected aboveground tanks shall beprovided with secondary containment,drainage control or diking. A means shall beprovided to establish the integrity of thesecondary containment in accordance withNFPA 30.Emergency venting shall be installed andmaintained in accordance with Section 22.7of 2015 NFPA 30 (IFC, 5704.2.7.4): Tanks storing Class IIIB liquids andthat are larger than 12,000 gallons(45,420 L) in capacity which are notwithin the diked area or the drainagepath of Class I or II liquids do notrequire emergency relief venting (IFC:5704.2.7.4 Exception #1).Emergency vents for Class I, II and IIIAliquids shall not discharge inside buildings(IFC: 5704.2.7.4): Emergency vents on Protected aboveground tanks complying with UL 2085containing Class II or IIIA liquids areallowed to discharge inside the building(IFC: 5704.2.7.4 Exception #2).

Code Requirements for ASTs at Motor Vehicle-Dispensing Stations - Page 4 of 6 PagesNFPA 30A2015 EDITIONEmergencyVenting(cont.)SeparationDistance Spaces or enclosed volumes, suchas those intended for insulation,membranes, or weather shields, thatare capable of containing liquid dueto a leak from the primary vessel.The insulation, membrane, orweather shield shall not interfere withemergency venting (30: 22.7.1.1.2).Tanks storing Class IIIB liquids and that arelarger than 12,000 gal (45,400 L) capacity andare not within the diked area or the drainagepath of tanks storing Class I or Class II liquidsshall not be required to meet the requirementsof 2015 NFPA 30 Section 22.7.1.1 (30:22.7.1.1.3). Except as provided for in 2015 NFPA 30Sections 22.7.3.5, 22.7.3.6 and 22.7.3.7,the total emergency relief venting capacityof both normal and emergency ventingdevices shall be not less than thatdetermined in Table 22.7.3.2 (30:22.7.3.2). Weak roof-to-shell seams are no longerallowed as a means of emergency ventingfor shop- fabricated atmospheric tanks,such as tanks built to UL 142 (30: 22.7.2).8 For tanks in vaults, emergency vents shallbe vapor-tight and shall be permitted todischarge inside the vault. Long-boltmanhole covers shall not be permitted forthis purpose (30A: 4.3.3.5.2). For Fire-Resistant tanks and Protectedtanks, reduction in sizing of theemergency vents in accordance withSection 22.7.3.5 of 2015 NFPA30 shallnot be permitted (30A: 4.3.4(2) and4.3.5.1(2); 30: 22.9.2(2) and 22.10.2(2)). Emergency venting devices shall have theflow capacity at the pressure at which thevalve reaches the full open position eitherstamped or cast into the metal body of thedevice or included on a metal nameplatepermanently affixed to it. (30: 22.7.3.10) Protected Tank, less than 6,000gallons: 15' from property line5' from building orpublic way 3' betweeneach tank0' from fuel dispensersProtected Tank, more than 6,000gallons: 25' from property line15' from building orpublic way 3' betweeneach tank0' from fuel dispensersVaulted Tank7:0-15,000 gal. Individual tank capacityIFC2015 EDITION For tanks in vaults, emergency vents shallbe vapor-tight and shall be allowed todischarge inside the vault. Long-boltmanhole covers shall not be allowed for thispurpose (IFC: 5704.2.8.14).For Protected tanks, emergency ventingshall be provided in accordance withSection 5704.2.7.4. The vent capacityreduction factor shall not be allowed (IFC:5704.2.9.7.2).For Protected tanks, flame arresters orpressure-vacuum breather valves arerequired only for tanks storing Class Iflammable liquids (IFC: 5704.2.9.7.3).Aboveground Tank:100' to property line which can be builtupon50' to building on same property,dispenser, or nearest side of public wayProtected Tank, less than or equal to6,000 gallons:5' to building on same property or publicway15' to property line which can be builtupon25' to fuel dispenser0' to fuel dispenser at fleet vehicle station0’ to fuel dispenser for Class IIIB liquids

Code Requirements for ASTs at Motor Vehicle-Dispensing Stations - Page 5 of 6 PagesNFPA 30A2015 EDITIONSeparationDistance(cont.) Piping Dispensers Tank FillingOperationsFire-ResistantTank: 50' fromproperty line25' from building orpublic way 3' betweeneach tank25' from fuel dispensers6Other tanks meeting therequirements of NFPA 30:100' from property line50' from building or public way3' between each tank, except that forvaulted tanks, each vaulted tank isrequired to be in a separatecompartment.50' from fuel dispensers (30A: Table4.3.2.4)Openings in tank shall be locatedabove the maximum liquid level (30A:4.3.6.1).Provide means to prevent release ofliquid by siphon flow (30A: 4.3.6.4).Shut-off and check valves requirepressure relief dev

NFPA 30A 2015 EDITION IFC 2015 EDITION Emergency Venting (cont.) Spaces or enclosed volumes, such as those intended be vafor insulation, membranes, or weather shields, that are capable of containing liquid due to a leak from the primary vessel. The insulation, membrane, or weather shield shall not interfere with emergency venting (30: 22.7.1.1.2). Tanks storing Class IIIB liquids and that .