Transcription

JÖNKÖPING INTERNATIONAL BUSINESS SCHOOLJÖNK ÖPING UNIVERSITYManaging Production Ramp-Up in ManufacturingNetworksMaster of Science ThesisAuthor:Patrik JohanssonTutor:Leif-Magnus JensenJönköping2011 January

AbstractProduction and manufacturing companies today, in a bid to achieve time tomarket and time to volume, makes use of production ramp-up. To achieve effective and rapid returns in investing in newly manufactured products it is necessary to maintain appropriate cost and volume as well as considerable manufacturing quality.This research is aimed at how to achieve cost effectiveness and market potentials, accomplished due to early market domination, by implementing ramp-upproduction process in manufacturing industries.Through production performance, speedy time to market and time to volumecould be achieved if there is an effective collaboration between production development performance and production ramp-up. This relationship promotes afast achievement of time-to-volume compared with the silent leading hypothesisof time-to-market.The study shows that the level of learning is very important as well as thesources of learning like engineering time, experiments as well as normal experience.Supply chain capabilities are used to promote and encourage meaningfulgrowth and development so as to achieve time to market and time to volume.These supply chain capabilities are integrating customers and manufacturers aswell as supply and demand in the market.

RecognitionsMy sister Yara: You have helped me so much with everything! Proud to be yourbrother!My mother Maud: Because you are my source for inspiration and at the sametime my best friend! You are an inspiration for life itself since you have leadedme through it!My wife Claudia: I love you since you have always supported me when my faithwas weak!My children Vale, Livf, Idun, Svea, and Freja: Thanks for existing. You lead me,even that you do not know this! I would not have been here if it was not for you,you are my everything, all of you!I also want to give great thanks to my tutor Dr. Jensen and my friendDr.Hilletofth for helping and encouraging me.

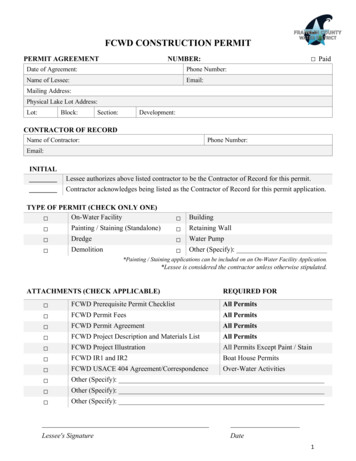

CHAPTER ONE: INTRODUCTION1.1Background . 31.2Aim of study. 71.3Research Questions . 71.4Significance of the Study . 81.5Methodology of the study . 81.6Content of the chapters . 9CHAPTER TWO: THEORETICAL FRAMEWORK2.1Introduction . 112.2Product Development Analysis . 112.3Product Development Performance . 132.4Relationship between Ramp-up Product Development and Performance . 172.5Capabilities for Rapid Supply Chain Operations Ramp-up . 192.5.1Timeliness and Visibility of Data . 192.5.2Effective Integration with Customers and Suppliers . 202.5.3Deploying Innovative Supply Chain Technologies that Act as Foundation forAchieving Partner Integration and Supply Chain Visibility . 212.5.4Promoting Cultural and Organizational Supports towards Growth Oriented SupplyChain 222.5.52.6Metrics that Reward Integration . 23Ramping up Quickly . 23CHAPTER THREE: RAMP UP PERFORMANCE ANALYSIS3.1Ramp-up Performance . 253.2Conceptual Model and Propositions . 33CHAPTER FOUR: THE SUPPLY CHAIN RAMP-UP PERFORMANCECAPABILITIES4.1Front End . 354.2Collaboration . 364.3Value Delivery . 374.4Support . 384.5Adaptability . 384.6Product Development Process. 394.6.1Design . 404.6.2Procurement . 424.6.3Pilot Production . 424.6.4Production . 434.6.5Distribution with Management and Information . 441

4.6.6Management . 444.6.7Information . 45CHAPTER FIVE: EMPERICAL fective Integration with Customers and Suppliers . 47Case .Fel! Bokmärket är inte definierat.Ramping up Quickly by the use of Outsourcing . 48Cases .Fel! Bokmärket är inte definierat.Effects of failure or success in Ramp-up . 49Cases .Fel! Bokmärket är inte definierat.Collaboration and value delivery . 49Cases .Fel! Bokmärket är inte definierat.Evolution . 51Case .Fel! Bokmärket är inte definierat.CHAPTER SIX: CONCLUSION AND DISCUSSION6.1Conclusion . 536.2Discussion . 566.3Further research . 58CHAPTER SEVEN: REFERENCES7CHAPTER SEVEN: REFERENCES . 59Table of FiguresFig. 1Time-to-market, Time-to-volume and the Ramp-up phenomenon . 4Fig. 2The triangel of Ramp-up . 6Fig. 3Product Development System of High-Performing Volume Producers . 13Fig. 4Flexible Information System . 29Fig. 5Correlations between Consistency and Performance . 32Fig. 6Proposed Framework for Measuring Product Development Performance . 33Fig. 7Matrix of Product Development Process . 39Fig. 8Four key Product Development Objectives . 41Fig. 9Timeline of an Alpha Model . 43Fig. 10Framework of the Beta Model . 432

CHAPTER ONEINTRODUCTION1.1 BackgroundRamp-up in business and economics is a term that is used in describing the increase in an organisation’s production ahead of planned or anticipated increasein the demand of the product. Also, ramp-up describes the time interval between developing or manufacturing a particular product and the complete utilityoffered by the product, which is characterised by a process and by product improvements and experimentation.Ramp up process begins when an organisation initiates a deal with a majorproducer, retailer as well as distributor and significantly increases the demandof a particular product. A ramp-up is normally in the early stage of an organisation or market development. It also involves and deals with venture capital andspeedily increases return rates on investment.For example, the manufacturer Honda has had great success, since they focuson ramp-up, in rapid development of platform projects. With its three to threeand a half years development time, it is among the fastest in the automobile industry today. Their focus on fast ramp-up has enabled them to create supplychain as well as completion of factory changeovers in only a single weekend forthe production of a new car model (Wheelwright and Clark, 1992).In organisations today, developing a new product is a very great challenge dueto a number of unmanageable forces that have come into play in the early 21stcentury. According to Barnett and Clark (1996), these have really put companies that manufacture and launch new products in the high-technology area under serious pressure. Some of the most significant forces in the market includeshrinking production life cycle, technological changes, and alternative materialsas well as increased global competition. Today, competition in the internationalmarket has constantly been very severe as new players are constantly cominginto the market with various styles.3

Fig. 1Time-to-market, Time-to-volume and the Ramp-up phenomenonTaken from Matta et al (2007).For example in the late 20th century, only a few mobile device suppliers existed,but today there are spread all over the globe. The fast diminishing brand preference is rapidly becoming a major difficulty for the world’s top ten mobile deviceproducers (Nokia, Samsung, LG, Research in Motion, Sony Eriksson, Motorola,Apple, HTC, ZTE and G five). The small players are often more automatic tochanges in market trends and also very competitive in price.Divided markets as well as refined customers are the effects of accumulatedexperience and individualism (Van der Merwe, 2004). This has put customerson the edge and sensitized them to select products for causes that do not in anyway have to be related to technical performance but to the accomplishment oftheir needs. Consequently, organizations and manufacturing companies develop strategies that make available products for various customer segments indifferent markets.4

Technological changes might be the most important driving force for hightechnology companies; this could evolve from the possible effect of new technologies on existing business models (Barnett and Clark, 2001). New innovations like short range communication services like the WLAN (Wireless LocalArea Network), the VOIP internet services (voice over internet protocol) as wellas the GPS (global positioning systems) has greatly affected the value chain oftelecommunication companies and the possibility for other players to achieve apledge in it (Pufall et al, 2007).Falling product lifecycles are another face up for high-technology industries, dueto the fact that product lifecycles and market windows are diminishing in lengthand on the other hand technology investments are rising. Also, competitorproduct gaining has broad significance and therefore, companies must reducetheir development time. That means reduced time to market and at the sametime they have to concentrate on the time it takes to arrive at complete production volume, which is also referred to as time to volume, so as to maintain highproductivity and business efficiency (Carillo and Franza, 2004).Early competitor to the market will take pleasure in higher profit margins as wellas longer product life cycles and can as a result set up a leading position in themarket place. Christopher (2008) explained that, a product that is on the financial plan, but was introduced late into the market couldcreate great losses of theprospective life cycle turnover. With this backdrop the economic accomplishment of manufacturing industries is greatly dependent on their capacity to discover the requirements of customers and to speedily develop products that willmeet these needs and that can be manufactured at low cost.Despite the considerable progress in new product development methods likethe synchronized engineering or design for manufacturing, the ramp-up periodremains the most important challenge and provides a considerable opportunityfor achieving competitive benefits in high-technology organizations.To elaborate on the role of rapid production ramp-up in manufacturing industriestowards achieving time to market, Wheelwright and Clark (1992) developed apractical and more functional definition of the term ramp-up as “a stage where5

an organization or an industry begins commercial manufacture or production ata comparatively low level volume”. As an organization develops confidence inits manufacture and production process to implement constant production aswell as develop its marketing abilities to market the product, the manufacturingvolume increases. Therefore, at the end of the rampramp-upup stage, the manufactureor production system must have achievedachieved its planned or anticipated goals totgether with the targeted levels of quality, cost as well as volume.Volume alone has no impact on rampramp-upup unless it reaches the market (time tomarket) and has acceptable quality (time to quality). Because of this reachingreaone of these factors without fulfilling of the others has no impact on the ramp-uprampeffect.Fig. 2The triangle of Ramp-upIn the triangle the base is quality,quality since without quality the volume is only a waste, since end consumers will not accept aproduct without the essential quality that is demanded by thecustomer.6

1.2 Aim of studyThe major aim and purpose of this study is to investigate and assess the roleand function of rapid production ramp-up of manufacturing industries towardsachieving fast fulfilment of customer demand. However, to achieve rapid returnsin investment in newly manufactured products, production and manufacturingcompanies must reduce their time to market and also, the time it takes them toachieve reasonable as well as considerable manufacturing quality, cost andvolume, which is also known as ramp-up. As described in the background chapter the traditional research has, for the most part, been focusing on time to market, time to volume or time to quality. Because of this there is a lack in researchof how they are combined as well as to why they interact. The few exceptionsare the research of Terwiesch and of course Clark and Fujimoto. NeverthelessRamp-up is still a quite virgin area of study and still holds great potentials forfirms in maximizing their efforts in getting payback as well as achieving fastmarket penetration.1.3 Research QuestionsThis research paper will answer questions that relate to the effective management of speedy production ramp-up in the manufacturing and production industries. It also try to explain how these manufacturing industries will achieve rampup in the production and manufacturing process so as to achieve time to marketas well as time to volume. These questions include: What kind of capabilities is necessary for rapid supply chain operationsramp-up? What kind of aspects influences the performance of rapid supply chainoperations ramp-up?7

1.4 Significance of the StudyThis study will research on how companies can through ramp-up, easily achievetime to market and time to volume of products to meet up competitive challenges in the emerging markets. It will state the differences that exist betweentime to market and time to volume in the commercial manufacture and production process. It will also demonstrate how ramp-up is very necessary for fullscale production and the assessment of the functions played by ramp-up inmanufacturing industries.1.5 Methodology of the studySince earlier research has mostly been done in the three areas of TTV (time tovolume), TTM (time to market) and TTQ (time to quality/total quality management) these where the search criteria in order to find material for the thesis, aswell as ramp-up itself (although very limited amount available). The articles andbooks had to be published as well as recognised in order to be of relevance.Another criterion was that the articles and books had to have a relevant conclusion in the subject at study. Since the three areas (described above) are quitecomplex the material had to be extensive in order to create valid and reliableconclusions (Easterby-Smith et al, 1991). In comparison to a qualitative methodthere was no case study or any other gathering of primary information; insteadthe entire thesis is built on already existing studies, thus secondary information(Bell, 2008). The sources of information had to pass criteria’s as if they whererelevant for the thesis as well as if they were credible (Ejvegård, 2009).Since the thesis is a meta-analysis(Cooper and Hedges, 1994) it is based onsecondary findings in order to detect the divergent ways of efficient ramp-up.Since the thesis is not aimed at finding ways to optimise the entire product lifecycle the research takes the three factors (TTM, TTQ and TTV) into consideration as it analyses the production from the very beginning (design) until itreaches the final customer. Because of this the thesis will not analyse areassuch as product afterlife (recycling as an example).The research analyses howthe supply of innovative new products to the market increases rapidly with costeffective prices. It also analyses how manufacturing companies that are not8

market leaders create their own supply chain or numerous supply chains, so asto balance the uncertainty in the market to meet customer demands of theirproducts. The research critically analyses the ramp-up time or production timeinterval between one cycle of producing a particular product and producing another product. This research was performed to compare how ramp-up production time to market and time to volume could be achieved in the productionprocess. The research also greatly elaborated on the role of rapid productionramp-up in manufacturing industries towards achieving time to market. Thevarious capabilities required for supply chain operation ramp-up as well as thevarious aspects that influence performance of rapid supply chain operationsramp-up were analysed. The research was performed to analyze how ramp-upproduction process is achieved through a product developmental process thatincludes design, procurement, pilot production, production as well as distributionwith information and management. The whole process of production from design down to distribution with proper and effective management and informationwas analysed to see how effective and efficient production or manufactureprocess is undergone in manufacturing companies. All the processes constituting the production process are discretely defined and to show and demonstratea well and elaborate production process of goods so as to achieve time to market.To facilitate for the reader several models (Ejvegård, 2009) are also included inthe work, some taken from named authors and others made by the writer himself. The references are made according to the Harvard system (Bell, 2008) ofreferencing with the name of the author and the year of publishing cited in thetext.1.6 Content of the chaptersChapter one gives an oversight of the study. It explains why and how the studyis done.Chapter two will establish the main purpose of the study. It is dedicated to review the literature and study significant interfaces between new product development as regards time to market as well as time to volume. The chapter will9

also compare and contrast different ideas and existing theories on ramp-upmanagement. The fundamental and critical factors that control the productramp-up will be put forward including the role of product development, capabilities for a rapid ramp-up of the supply chain operations and it will also take culture and partner integration into concern.Chapter three is focused on the proper ways of ramp-up performance measurements as well as indicators that can show whether the performance is increasing or decreasing. It compares different models and shows the difficultiesto create a ramp-up performance measurement system that is reliable. Thechapter takes up weaknesses and strengths in different systems.Chapter four is concerning the supply chain ramp-up performance capabilitiesand how these can be enhanced by using technology as well as by the simpleuses of collaboration and profit sharing. It also emphasises on the significanceof observing the complete process, from design to distribution, as a part of theramp-up process.Chapter five displays empirical findings that supports or interacts with the theories displayed by earlier chapters and tries to give answers to questions askedin Chapter one. It also gives examples of how important ramp-up can be in order for an organisation to survive in today’s severe business climate.In Chapter six, the final chapter, the conclusions are presented, as well as discussion and further research.10

CHAPTER TWOTEORETICAL FRAMEWORK2.1 IntroductionThis section will establish the main purpose of the study and answer researchproblems relating to the study. Through existing body of knowledge as well asprevious research made on the topic, the study will compare and contrast various ideas and existing theories on ramp-up management in the manufacturingenvironment. The literature will review significant interfaces between new product developments as regards time to market as well as time to volume.2.2 Product Development AnalysisA lot of cost and time to market potentials can be achieved if major factors ofsuccessful ramp-up management are employed in production processes in themanufacturing industries. Though, several researches have been done in lots ofother industry sectors abound, but the most common research has been performed in industries to investigate the ramp-up of time to market and time tovolume in manufacturing industries together with its effective management.Clark and Fujimoto (1991) performed research to analyse and understand hownew product development is done in the automobile industry. Their field research combined surveys and case studies of several manufacturing companies. The main focus of the research was impact of effective management, organization and strategy on product development. In their research, they discovered four fundamental and critical factors that control the product ramp-up:1. Integrated product process linkage: Integrating problem solving cycles inproduct as well as process engineering enables producers to reduce timewithout having to reengineer or compromising the quality. The capacity tomake production rapid and efficient; a high manufacturing capacity results in rapid model cycles, high-speed tool development times as well asefficient ramp-up volume production.2. Integrated customer/concept/product linkage: A product managementsystem as well as broad engineering tasks tightens the information link-11

age among engineers, concepts, development as well as the crucial linkto the customer. Also, Brown et al (1997) explained that if new production techniques are introduced (with the new product) they should bemonitored by new performance measurement systems, since suitableperformance measures must be designed to measure the impact of thenew manufacturing techniques. They also point out that the old measurement techniques must be abandoned in favour of the new ones, because if this is not done, people will tend to use the old ones in favour ofthe new, since they are more familiar with these.3. Integrated supplier linkage: Close and early or on-going communicationswith selected first tier suppliers can reduce late reengineering as well asit can increase the speed of prototype parts procurement and improvingcomponent integration. This mostly affects the ramp-up as a result of itsimpact on general operation time per day, the complexity of products inthe line as well as the assembly speed.4. Flexible, short cycle manufacturing capability: JIT (just in time) as well asTQM (total quality management) emphasises short throughput times,adaptability, fast problem detection and continuous improvement (kaizen)and applies to prototyping, tooling, production start up and engineeringchanges. Since the short cycle times will create unevenness in themanufacturing environment this will demand for various policies to bringinto line the work force and balance it with the production rate. A particular manufacturing industry can either try to maintain a steady work forceover a period of time, discharge and recruit during transition or enhancethe work force provisionally during the changeover phase. Therefore, thelearning and performance rate tends to be elevated if the working circumstances and job assignments are also steady.12

Fig. 3Product Development System of High-Performing Volume ProducersTaken from Clark and Fujimoto (1991)2.3 Product Development PerformanceHowever, product development performance is closely related to successfulramp-up development. Clawson (1985) explained that, product developmentperformance help manufacturing companies achieve timely manufacture andlaunch of products in order to achieve time to market and time to volume underreal time production. However, these findings are based on established concepts in the automobile industry in the late 20th century, therefore cannot bemade comprehensive without allowing for the specific characteristics in othermanufacturing industries today. Pufall et al (2007) explained that the mobile device industry is an example of an industry that is characterized by very short development times and life cycles, various sales means as well as diverse manufacturing/logistic models that are the product of the volume, time, price as well13

as size differences. Also, one major aspect of the ramp-up management research performed by Perks et al (2005) is to achieve a position analysis so as toproperly categorise research demands that leads to quantum increase in theaspect of ramp-up management and performance. This study takes more directsteps and addresses the area of ramp-up management and performance compared to the study performed by Clark and Fujimoto (1991) that was mostly focused on product development performance in general. With on-site researches, public discussions and workshops in three business areas like theengineering industry, electronics and automobile industries, Gevers (2004)identified the various factors that influence ramp-up performance and categorized them into six different classes that include:1. Product development: Which is the level of innovation as compared to already existing products2. Production processes: This involves the measure of process strength,suppleness and newness3. Organization and personnel: It is the measure of qualification and responsibility transparency4. Logistics: Which is considered as the general term for the accessibilityand quality of the various parts and subassemblies5. Networks and cooperation: Is characterized by the information flow andinformation clearness6. Methods and tools: Involves project management as well as transformation management practicesBased on these features, five achievement areas for additional research like holistic knowledge management, improved cooperation models, changed management procedures, robust manufacturing systems as well as the developmentof advanced methods to control ramp-up complexities are to be integrated in theproduction process. Also, similar research conducted by Ghiani et al (2004) intheir standard project in the automobile industry refer to the theory of complexitymanagement and performance as an effect of the dynamics and multitude ofmutually dependent objects and their communication with diverse work functions. However, these features are in consonant with the ones recognized by14

Gupta et al (2007) when they researched on the work function and classifiedthem based on their logistics and sourcing, production level as well as developmental process. Yet, none of these two researches included a more comprehensive analysis of the difficult rela

Falling product lifecycles are another face up for high-technology industries, due to the fact that product lifecycles and market windows are diminishing in length and on the other hand technology investments are rising. Also, competitor product gaining has broad significance and therefore, companies must reduce their development time.