Transcription

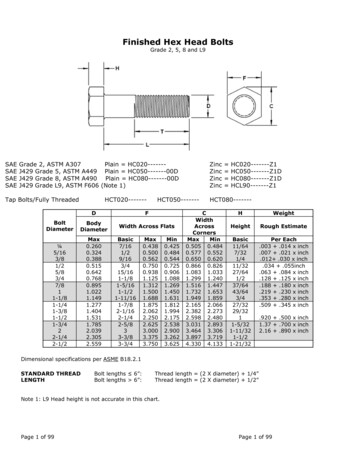

Driving Fastener Access

FASTENER ACCESSWith Specialty OutputsFour output styles and many standard designs enable unique geometries thatfit the application. Torque Levels From 3 to 1250 Nm and Higher Hundreds of Unique Designs From Over 50 Years Experience Outputs Matched to the Tool Helps Optimize PerformanceHOLD and DRIVEHold the Bolt - Drive the NutBolt with TangHold and drive tools simultaneously hold the boltwhile the nut is tightened. A formed end on thebolt interfaces with a mating tang holder or bitto prevent bolt rotation. The nonrotating tangholder or bit retracts into the tool to allow therotating socket to engage the nut.A Tang holds the boltwhile the nut istightenedTravelSocket ReachBoltNutTang HolderFLUSH ANGLETorque Range:3 - 400 NmTypical Tang OptionsCROWFOOTTorque Range:4 - 1250 NmFemale Torx Female HexHundreds ofoutput designsenable solutions thatfit your application.STANLEY manufactures a complete rangeof outputs to access all types of threadedfasteners. By controlling both the designof the tool and the output, STANLEY can properly matchcomponents in the tool design to help optimize performanceand long life. With over 50 years of experience in developingstandard and special outputs, STANLEY has the expertise to handlethe most challenging fastening requirements.RectangularBolt with RecessTUBENUTTorque Range:4 - 650 Nm2MinimumSocket SizeA Bit holds the bolt whilethe nut is tightenedHOLD and DRIVETorque Range:11 - 380 NmOutput DimensionsOutputSocket ReachTravelBoltBit HolderNutMinimumSocket SizeBitTypical Bit 321.251556.1602.4H322380281321.251807.1873.4Male Hex Male Torx3

CROWFOOTTUBENUTHUNDREDS of Crowfoot and Tubenut Options . . . . . . . . . . . Drive Fasteners in Hard to Access SpacesVerticalcrowfootoutputs fitapplicationswhere thefastener isparallelto the accessdirection.InlineCrowfootoutputs alsoavailable.Anglecrowfootoutputs fitmost applications.Inline outputs lower the tool heightand weight as compared toangle versions.Angle tubenut outputs fit mostapplications.Crowfoot dimensions are derived fromthe application’s access area dimensions.Output DimensionsOutputTypeMaxRatingMax HexSize“W”Width“R” NoseRadius“T”ThicknessOutput 417.7130.51321.25130.51140.55471.86Crowfoot nutrunners can accessfasteners in unique, hard toaccess spaces. Tighteningtorque can range from 4Nm to over 1250 Nm.Fixtured toolshelp to improveergonomics andproductivity.4Tubenut dimensions are derived from theapplication’s access area dimensions and tube size.These are examplesof the manycrowfoot toolsavailable.OutputTypeMaxRatingMax HexSizeMax TubeSize“W”Width“R” NoseRadius“T”ThicknessVertical tubenut outputsfit applications where thefastener is parallel to theaccess 1.34These are examplesof the manytubenut toolsavailable.Tubenut nutrunners can accessfasteners in unique, hard toaccess spaces. Tighteningtorque can range from 4Nm to over 650 Nm.Tubenut insertsallow for quickchange of sockets formultiple tasks per job.5

FLUSH ANGLESOCKET SELECTIONAccess Smaller Vertical SpacesFlush angle headswith built-in socketallow access intosmaller verticalspaces thanstandard angleheads.Base/Note: Specify socket sizeno larger than Max Hex Size.Flush AngleClearance HeightStandard Clearance HeightType/BaseCodeTypeSHOutputSize130Angle Output/Standard Socket907050Flush Socket Angle OutputMaxRating“R” HeadRadiusClearanceHeightMax 1/82A15 (as in 3M 61518M1811619M191 1/161720M2021M2122M2223M23Single HexDHDouble HexSDSurface DriveFLerExample Ord NumberFlush SocketFlush angle tools can accessvertical spaces 40-55% lowerthan standard angle tools atsimilar torque levels.Size/Size(in)Fast Lead3010Torque (Nm)“R” Side toCenter (mm)Step 2: Add Type, Size andExtension from their tablesseparated by forward slashesSize(mm)Output DimensionsClearance Height (mm)Step 1: Select the Base Codefrom the Head Number tableChoose mm or inMax Hex SizeFlush AngleHead Number110SocketChoose YourA new part number system for standard flush angle head sockets enablescustomers to select standard sockets for each application.The part number includes information on head number of the tool, sockettype, socket size and extension length. For special sockets or dimensionsnot included on this page contact your local Stanley sales /89121/212155/815183/418217/82124124271 1/1627301 1/830331 1/433361 3/836391 1/239421 5/842451 3/445481 7/84851251Example: An A19 flush angle head requires a 3/8 in surface drivesocket with a 1 in extension. Select the BASE (20D222300), TYPE(SD), SIZE (6) and EXTENSION (24).Write the Socket Part Number with the (/) separating each number.BaseTypeSizeExt.20D222300/SD/6/247

Crowfoot/ Tubenut Socket SelectionA new part number system for standard crowfoot and tubenut socketsenables customers to select standard sockets for each application. Thepart number includes information on head number of the tool,socket type,socket size and extension length. For special sockets or dimensions notincluded on this page contact your local Stanley sales representative.Base/ Type/Note: Specify socket sizeno larger than Max Hex Size.Crowfoot or TubenutHead NumberSocketChoose YourSize/ExtensionChoose mm or inMax Hex 4M41/82Size(mm)Size(in)7, 16, 299, 306, 353193/4L32585M53/1638, 61, 106, 174, 178, 311, 420, 445131/2L32246M61/445, 10, 19, 31, 70, 83, 126, 406,193/4L32177M75/16513, 228, 230, 308, 333, 394, 443131/2L32138M83/8620271 1/16L32559M97/16721, 98, 225, 284, 416271 1/16L324010M101/2823, 84, 95, 135, 3091811/16L320929, 35, 121, 152, 175, 221, 234, 278,287, 496193/4L321847, 170, 294117/16L322269, 173, 279, 301, 307, 313, 317,327, 362, 379, 381, 385, 448, 455,477, 487, 516, 521131/2L320174, 164, 261, 265, 269, 271, 273,274, 286, 291, 3121879, 82, 103, 167, 508,1399, 116, 283, 285, 296147, 32, 75, 91, 92, 132, 136, 137,138, 182, 184, 190, 202, 208, 209,211, 212, 213, 266, 267, 270, 288,300, 302, 303, 305Single HexDHDouble HexSDSurface DriveFL11/161/2L3211L3202271 1/16L3267117/16L328212 or 13only1/2onlyL328112 or 13only1/2onlyL3283Thru Hex "BASE" number for thissection131/2L3392160131/2L3228200, 324, 396193/4L3220203, 456193/4L3221216131/2L3225246, 297, 315,139/16L3256252, 346, 349, 387, 358, 408, 513131/220D280700264, 3042415/16L3259Thru Hex "BASE" number for thissection2415/16L3260Fast Lead11M119/16912M125/81013M 61518M1811619M191 93/89121/212155/815183/418217/82124124271 1/1627301 1/830331 1/433361 3/836391 1/239421 5/842451 3/445481 7/84851251erExample Ord NumbersSocketExtensionExample 1: A #8 crowfoot headrequires a 3/8 in surface drive socketwith a 1 in extension. Select theBASE (L3224), TYPE (SD), SIZE (6)and EXTENSION (24).STANLEY Engineered FasteningAssembly Technologies5335 Avion Park DriveCleveland, Ohio 44143United StatesBaseTypeSizeExt.L3224/SD/6/24Phone: 1 440.461.5500Sales: 1 877.709.8006Email: SATinfo@sbdinc.comDFA 0114 ENU 2014 Stanley Black and Decker, Inc.,All Rights Reserved

C h o o s e Yo u r Socket E x a m p l e O rde Nu mber Step 1: Select the Base Code from the Head Number table Step 2: Add Type, Size and Extension from their tables separated by forward slashes Example: An A19 flush angle head requires a 3/8 in surface drive socket with a 1 in extension. Select the BASE (20D222300), TYPE (SD), SIZE (6) and EXTENSION (24). Write the Socket Part Number with