Transcription

International Journal of Gas Turbine, Propulsion and Power SystemsDecember 2014, Volume 6, Number 3Conjugate Heat Transfer Analysis of Convection-cooled TurbineVanes Using γ-Reθ Transition ModelGang Lin1, Karsten Kusterer1, Anis Haj Ayed1, Dieter Bohn2, Takao Sugimoto31B&B-AGEMA GmbHJülicher Strasse 338, 52070 Aachen, GermanyE-mail: lin@bub-agema.de2RWTH Aachen University3University of Hyogoconduction, it is obvious that a coupled calculation of the fluid, theheat transfer and the heat conductivity in the solid body can lead toa higher accuracy in the design process.A little bit more than 20 years ago, in the early 1990s, theInstitute of Steam and Gas Turbines at RWTH Aachen Universityheaded by Prof. Dieter Bohn started a long-term development of amost sophisticated approach for the coupled calculation of fluidflows and heat transfer with focus on the hot gas components in agas turbine. The numerical group of the institute developed thehomogeneous method for the conjugate calculation technique(CCT). The method involves the direct coupling of the fluid flowand the solid body using the same discretization and numericalprinciple for both zones. This makes it possible to have aninterpolation-free crossing of the heat fluxes between theneighboring cell faces. Thus, additional information on theboundary conditions at the blade walls, such as the distribution ofthe heat transfer coefficient, becomes redundant, and the walltemperatures as well as the temperatures in the blade walls are adirect result of this simulation. First results and validation caseshave been published in the 1990s for convection-cooled cases (e.g.[3-6]) as well as for film-cooled configurations (e.g. [7-9]). Thedetailed description of the conjugate calculation technique and itsvalidation is provided by Bohn et al. in [10].ABSTRACTIn order to achieve high process efficiencies for the economicoperation of stationary gas turbines and aero engines, extremelyhigh turbine inlet temperatures at adjusted pressure ratios areapplied. The allowable hot gas temperature is limited by thematerial temperature of the hot gas path components, in particularthe vanes and blades of the turbine. Thus, intensive cooling isrequired to guarantee an acceptable life span of these components.Modern computational tools as well as advanced calculationmethods support essentially on the successful design of thesethermally high-loaded components. The homogeneous, orsometimes also mentioned as “full”, conjugate calculationtechnique for the coupled calculation of fluid flows, heat transferand heat conduction is such an advanced numerical approach in thedesign process and huge experiences on validation and applicationhave been collected throughout the years. This paper summarizesthe numerical approach for this method as well as provides acollection of numerical results obtained by the authors forvalidation cases for a convection-cooled turbine vane test case aswell as comparison to calculation data for this test case provided inopen literature. Furthermore, systematic studies on the impact ofcalculation parameters, e.g. hot gas fluid properties, and numericalmodels for turbulence calculation are performed and the numericalresults are compared to the experimental results of the test case.NOMENCLATUREINTRODUCTIONDue to the necessity of cooling technologies in modern gas turbines, turbulent heat transfer is of significant importance in thethermal design process of the cooled components. Tremendous efforts have been put into the determination of empirical correlationsfor the internal and external heat transfer, which are necessary forthe conventional design process. Here, analysis of turbine bladecooling and heat transfer consists of three areas (Patankar, [1]): (a)prediction of the heat transfer coefficients on the external surfaceof the airfoil (Kays and Crawford, [2]), (b) prediction of heattransfer in the internal cooling passages (Kays and Crawford, [2])and (c) calculation of the temperature distribution in the blade material.However, the accuracy of the approach based on heat transfercoefficients is very much limited by the uncertainties of thecorrelations if applied to the real gas turbine geometricconfigurations and conditions. With regard to the inter-relationsbetween the external fluid flow, the internal fluid flow and the heatFlengthFonsetHH0LMakRe Re cRe t Re tSTTrefXy γμμtManuscript Received on November 20, 2013Review Completed on November 26, 2014 function to control transition length function to control transition onset location heat transfer coefficient (W/m2/K) reference heat transfer coefficient (1135 W/m2/K ) axial chord length (m) Mach number turbulent kinetic energy (m2/s2) momentum thickness Reynolds number momentum thickness Reynolds number, where theintermittency starts to increase momentum thickness Reynolds number, where the skinfriction starts to increase transported variable for Re t streamwise distance temperature (K) reference temperature (811K) axiale chord position (m) non-dimensional wall-normal distance, intermittency dynamic viscosity (kg/m/s) turbulent viscosity (kg/m/s)Copyright 2014 Gas Turbine Society of Japan9

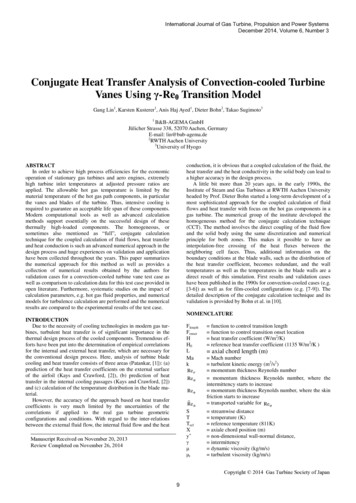

JGPP Vol.6, No. 3ρω density (kg/m3) specific turbulence dissipation rate (s-1)mentioned, presented results from the CCM solver have beenobtained by application of this model.TEST CASE DESCRIPTIONThe famous Mark II test case for a convection-cooled vane hasbeen chosen for comparative calculations of the thermal load byapplication of the CCT. The vane has been investigated extensivelyby Hylton et al. [11] over a wide range of operating conditions in ahot gas duct. Mark II is a high-pressure turbine nozzle guide vane,which is convectively cooled with air by ten radial cooling channels.Figure 1 shows the vane geometry and the arrangement of thecooling passages. The test case no. 5411 has been chosen for thenumerical investigations. The numerical validations have beencarried out in both 2-D and 3-D cases. In 2-D case the heat transfercoefficients and cooling air temperatures have been defined asboundary conditions for calculation of heat transfer from internalcooling air. In 3-D case the heat transfer from internal cooling air tosolid is calculated by given cooling air mass flow and cooling airinlet temperature. After Hylton et al. [11] the inlet turbulenceintensity was 6.5% in the experiment, which has also be used in thenumerical investigations. Instead of turbulence length scale theturbulent viscosity ratio has been applied as another inlet boundarycondition for turbulence conditions. The inlet turbulent viscosityratio has been set at 10. In the study by Mansour et al. [12] the inletturbulent viscosity ratio has insignificant impact on the heattransfer coefficient distribution prediction at suction side in the caseMark II.Fig. 2 Mid-section of 3D polyhedral mesh for CCM applicationThe SST turbulence model [15] is a two-equation turbulencemodel, which combines the advantages of both k-ω and k-ε model.With the help of a blending function F1, the turbulence model canbe transformed between k-ε model in the freestream zone and κ-ωmodel in the boundary layer zone. With this method, the advantagesof near-wall performance of k-ω model can be implementedwithout any influence on sensitivity of any boundary condition infree stream, which can lead to errors in the original k-ω model. Theequations of two transport models, one for turbulent kinetic energyk and the other for specific turbulence dissipation rate ω, are givenas follows: u j Dk k 2 k S k t Dt x j xj x j eff t min max eff ,0.1 ,1 kThe own-developed solver, CHTflow, is based on thehomogeneous method as it is described in [10]. Conjugatecalculations have been performed with structured hexahedral gridsfor 2-D case. The y in the boundary layer is approximately y 1.The Baldwin-Lomax algebraic turbulence model [13] has beenapplied. The model has been established during the validationprocedure of the CHTflow code in the mid 1990s and the resultshave been presented in [4, 10]. These results are taken as thereference for the present calculations with commercial CFDsoftware. In the recent years, this kind of homogeneous conjugatemethodology found its way also into the commercial CFD codesand, thus, the Star CCM solver [14] has been applied for the newcalculation and comparison to the CHTflow results. Figure 2 showsthe mid-section of the 3-D polyhedral mesh, which has been usedfor the CCM application. In order to establish an appropriatecalculation of the local heat transfer, the y value of the first cell inthe boundary layer is less than y 1. The suitable cell number of thegrid after mesh independency study is 2.86 million including theprism layers on the fluid-solid boundaries. Best results have beenobtained with the SST k-ω turbulence model and if not otherwise uj D 2 2 S k t t Dt x j x j x j 2 1 F 1 2Fig. 1 Geometry and boundary conditions for Mark II test case 1 k xj xj Usually the γ-Reθ transition model is applied in the SSTturbulence model [15]. This transition model is build up by twotransport equations: one is for the intermittency γ and the other isfor the transported transition momentum thickness Reynolds .number Re t D t S Dt x j x j F length ca1 ca 2 F turb 1 ce 2 10 F 1 c 0.5onsete1

JGPP Vol.6, No. 3 D Re t Re t U 2 ( t c tt Dt xj 500 Re tx j Re t ) 1 F t The intermittency γ determines the production of turbulentkinetic energy in the boundary layer. It is 0 in the laminar boundary is used as the criterionlayer and 1 in the fully turbulent layer. Re tof transition onset position, which transforms non-local free streaminformation into a local quantity. So that the function Fonset (shownin eq. 3), which is used to control transition onset location, can beexpressed.Open literature numerical data by other authors for this testconfiguration can be found in [16-19], for example, as well asnumerical data [20-24] for the similar C3X test case from Hylton etal. [11]. The same test configuration Mark II has been studied byYan et al. [16] using a structured mesh in the commercial solversCFX and Fluent with different turbulence models. The results ofSST Gamma Theta calculation in CFX solver have shown a goodagreement with the experimental data in temperature distribution.The temperature at the reattachment point on suction side was overpredicted by about 6% to 7%. Lin et al. [17] have done the analysisof this test case also in the CFX solver but using unstructured meshwith the SST-γ-Reθ model. The numerical results capture the trendsof temperature along the surface with an under prediction by about5% to 8% on the pressure side. Zeng and Qing [18] have completedanother 2D and 3D conjugate heat transfer simulation of Mark IIwith unstructured mesh. The grid in the 3D calculation wasobtained by extruding of the 2D grid. The boundary conditions inthe cooling channels, for both 2D and 3D simulation, were appliedwith cooling temperature and heat transfer coefficient. The SSTγ-Reθ model again showed the best accuracy among all of the usedturbulence models. The maximum difference between predictionand test data occurred at the reattachment point with about 3% to4% over prediction.a) CHT flow resultRESULTSBoth applied numerical codes show reasonable results for theMach-number distribution in the mid-section of the vane as it iscompared in Fig. 3. There is a strong and sharp compression shockon the front part of the vane suction side. In front of the shock theflow is accelerated up a Mach-number of slightly over Ma 1.6.Downstream the strong shock, the flow is accelerated again, beforea second, weaker shock can be observed shortly in front of thetrailing edge.b) CCM resultFig. 3 Mach-number distribution (mid-section)The temperature distribution in the mid-section for the fluidregion as well as for the solid body of the vane is shown in Fig. 4.The lowest temperature inside the vane appears near the leadingedge between the 2nd and the 3rd cooling hole. The hottest regioncan be found in the trailing edge. As shown in the distribution ofisotherms in the vane, the temperature gradients are high at twopositions: One near the stagnation point at the leading edge and theother at the suction side after the first shock. Such a high density ofthe isotherms indicates locally a high heat transfer between thefluid and solid region.11

JGPP Vol.6, No. 3Fig. 5 Comparison of numerical and experimental results of thevane surface temperaturea) CHT flow resultThe effect of turbulence modelsAs shown in Fig. 6, the results obtained by application of CCM depend on the chosen turbulence model in the 2-D cases. The SSTk-ω model provided by the CCM code performs the best for theconjugate application. Applying other turbulence models, thecalculated temperature distributions in the front part of the vanesuction side, i.e. the region with a laminar boundary layer, show asignificantly reduced accuracy. The major reason for this is the fact,that those turbulence models provide no possibility to prescribe orinfluence the turbulence onset location. The results have shown thatfor all tested turbulence models the onset of turbulence productionis located to far upstream. Figure 7 illustrates this for the Realizablek-ε model. Compared to the calculation with the SST-γ-Reθ model,the Realizable κ-ε model starts much earlier (by X/L 0.044) to overpredict the turbulence at the suction side, which results in too muchheat flux in this laminar region. By the calculation with theSST-γ-Reθ model, the turbulence is firstly produced at position byX/L 0.45, which is the same as in the experiment. Although theSST-γ-Reθ model can predict a quite well transition at the suctionside, the temperat

Conjugate Heat Transfer Analysis of Convection-cooled Turbine . headed by Prof. Dieter Bohn started a long-term development of a most sophisticated approach for the coupled calculation of fluid flows and heat transfer with focus on the hot gas components in a gas turbine. The numerical group of the institute developed the homogeneous method for the conjugate calculation technique (CCT). The .