Transcription

Siemens 2019Motion Control DrivesSINAMICS V90Basic Servo Drive SystemCatalogD 33EditionMay2019siemens.com/drives

Siemens 2019Related catalogsMotion Control DrivesD 31.1SINAMICS Inverters for Single-Axis DrivesBuilt-In UnitsIndustrial ControlsSIRIUSE86060-K5531-A111-A1-7600PDF (E86060-K1010-A101-A9-7600)Motion Control DrivesD 31.5SINAMICS Converters for Single-Axis DrivesSINAMICS G120X infrastructure convertersfor HVAC/Water/WastewaterIndustrial ControlsSIRIUS ClassicPDF (E86060-K5531-A151-A1-7600)PDF (E86060-K1010-A191-A5-7600)SINAMICS S120Chassis Format Converter UnitsCabinet ModulesSINAMICS S150Converter Cabinet UnitsE86060-K5521-A131-A6-7600D 21.3Motion Control DrivesSINAMICS S120 and SIMOTICSD 21.4SIMATICProducts forTotally Integrated AutomationD 41SIMOTICS GP, SD, XP, DPD 81.1Low-Voltage MotorsType series 1FP1, 1LE1, 1LE5, 1MB1 and 1PC1Frame sizes 63 to 355Power range 0.09 to 500 kWE86060-K5581-A111-B2-7600Industrial CommunicationSIMATIC NETMD 10.1SITRAINTraining for Industrywww.siemens.com/sitrainSIMOGEARMD 50.1Geared MotorsHelical, parallel shaft, bevel, helical wormand worm geared motorsProducts for Automation and DrivesInteractive s.com/ca01downloadPM 21IK 00E86060-K4921-A101-A4-7600ST 70SIMATIC HMI /ST 80/ST PCPC-based AutomationHuman Machine Interface SystemsPC-based AutomationE86060-K4680-A101-C6-7600Motion Control SystemSIMOTIONEquipment for Production MachinesLV 10PDF (E86060-K4670-A101-B7-7600)PDF (E86060-K5541-A101-A4-7600)FLENDER CouplingsStandard CouplingsIC 10 AOSENTRON SIVACON ALPHAProtection, Switching, Measuring and MonitoringDevices, Switchboards and Distribution SystemsPDF (E86060-K8280-A101-A8-7600)Print 00SIMOTICS S-1FG1Servo geared motorsHelical, Parallel shaft, Bevel andHelical worm geared motorsLow-Voltage Power Distribution andElectrical Installation TechnologyIC 10Industry MallInformation and Ordering Platformon the Internet:www.siemens.com/industrymallCA 01

Siemens 2019SINAMICS V90Basic Servo Drive SystemMotion Control DrivesCatalog D 33 · May 2019Dear Customer,We are pleased to present you with the new edition for Catalog D 33 · May 2019. The catalog provides a comprehensive overview ofthe SINAMICS V90 basic servo drive system consisting of a SINAMICS V90 servo drive, a SIMOTICS S-1FL6 servomotor and a matchingMOTION-CONNECT connection system.The products listed in this catalog are also included in the Industry Mall.Please contact your local Siemens office for additional information.NEW: The WEB PDF enables the direct jump into the Industry Mall with further information incl. online order by clicking on anarticle number.Up-to-date information about SINAMICS V90 is available online atwww.siemens.com/sinamics-v90You can access our Interactive Catalog and our Industry Mall online atwww.siemens.com/industrymallYour personal contact is keen to receive your suggestions and recommendations for improvement. You can find your contactin our contact database atwww.siemens.com/automation-contactWe hope that you will often enjoy using Catalog D 33 · May 2019 as a selection and ordering reference document and wish you everysuccess with our products and solutions.With kind regards,Achim PeltzVice PresidentGeneral Motion ControlSiemens AG, Digital Industries, Motion Controlsiemens.com/drives

Siemens 2019

Siemens 2019SINAMICS V90 Basic Servo Drive SystemMotion Control DrivesSystem overview1SINAMICS V90 servo drive2SIMOTICS S-1FL6 servomotors3MOTION-CONNECT connection systems4Engineering tools5Services and documentation6Appendix7Catalog D 33 · May 2019Refer to the Industry Mall for current updates ofthis catalog:www.siemens.com/industrymallThe products contained in this catalog can also be foundin the Interactive Catalog CA 01.www.siemens.com/ca01downloadPlease contact your local Siemens branch.Click on an Article No. in the catalog PDF to call it up in theIndustry Mall and to obtain all the information.Article No.6SL3070-0AA00-0AG06SL3072-0AA00-0AG0Or directly on the Internet, e.g.www.siemens.com/product?6SL3070-0AA00-0AG0The products and systems described inthis catalog are manufactured/distributedunder application of a certified qualitymanagement system in accordance withEN ISO 9001.The certificate is recognized by all IQNetcountries.

Siemens 2019Digital EnterpriseThe building blocks that ensureeverything works togetherperfectly in the digital enterpriseDigitalization is already changing all areas of life and existingbusiness models. It is placing greater pressure on industrywhile at the same time creating new business opportunities.Today, thanks to scalable solutions from Siemens, companiescan already become a digital enterprise and ensure theircompetitiveness.Industry faces tremendous ovequalityBoostefficiencyIncreasesecurityToday manufacturershave to bring products tomarket at an ever-increasing pace despite thegrowing complexity ofthese products. In thepast, a major manufacturer would push aside asmall one, but now it is afast manufacturer thatovertakes a slow one.Consumers want customized products, but ata price they would payfor a mass-produceditem. That only worksif production is moreflexible than everbefore.To ensure a high level ofquality while meetinglegal requirements,companies have toestablish closed qualityloops and enable thetraceability of products.Today the product itselfneeds to be sustainableand environmentallyfriendly, while energyefficiency in productionhas become a competitive advantage.Increasing networkingescalates the threat toproduction facilitiesof cyberattacks. Todaymore than ever, companies need suitablesecurity measures.2Siemens D 33 · May 2019

Siemens 2019The digital enterprise has alreadybecome a realityTo fully benefit from all the advantages ofdigitalization, companies first have toachieve complete consistency of their data.Fully digitally integrated business processes,including those of suppliers, can help tocreate a digital representation of the entirevalue chain. This requires the integration of industrial softwareand automation, expansion of the communication networks, security in automation, and the use of business-specificindustrial services.MindSphereThe cloud-based open IoT operatingsystem from SiemensWith MindSphere, Siemens offers a costeffective and scalable cloud platform as aservice (PaaS) for the development of applications. The platform, designed as an openoperating system for the Internet of Things,makes it possible to improve the efficiencyof plants by collecting and analyzing largevolumes of production data.Totally Integrated Automation (TIA)Where digitalization becomes realityTotally Integrated Automation (TIA) ensuresthe seamless transition from the virtual tothe real world. It already encompasses allthe necessary conditions for transformingthe benefits of digitalization into true addedvalue. The data that will form the digitaltwin for actual production is generated froma common base.Digital PlantLearn more about thedigital enterprise for theprocess industrywww.siemens.com/digitalplantDigital Enterprise SuiteLearn more about thedigital enterprise for thediscrete emens D 33 · May 20193

Siemens 2019Integrated Drive SystemsFaster on the market and in the black with Integrated Drive SystemsIntegrated Drive Systems are Siemens’ trendsetting answer to the highdegree of complexity that characterizes drive and automation technologytoday. The world’s only true one-stop solution for entire drive systems ischaracterized in particular by its threefold integration: Horizontal, vertical,and lifecycle integration ensure that every drive system component fitsseamlessly into the whole system, into any automation environment, andeven into the entire lifecycle of a plant.The outcome is an optimal workflow – from engineering all the way toservice that entails more productivity, increased efficiency, and betteravailability. That’s how Integrated Drive Systems reduce time to marketand time to profit.Horizontal integrationIntegrated drive portfolio: The core elements of a fully integrated driveportfolio are frequency converters, motors, couplings, and gear units.At Siemens, they‘re all available from a single source. Perfectly integrated,perfectly interacting. For all power and performance classes. As standardsolutions or fully customized. No other player in the market can offer acomparable portfolio. Moreover, all Siemens drive components areperfectly matched, so they are optimally interacting.You can boost the availabilityof your application or plantto up to99%**e.g., conveyor applicationVertical integrationThanks to vertical integration, the complete drive train isseamlessly integrated in the entire automation environment –an important prerequisite for production with maximumvalue added. Integrated Drive Systems are part of TotallyIntegrated Automation (TIA), which means that theyare perfectly embedded into the system architectureof the entire industrial production process. Thisenables optimal processes through maximumcommunication and control.With TIA Portal you cancut your engineering timeby up to30%Lifecycle integrationLifecycle integration adds the factor of time: Software and serviceare available for the entire lifecycle of an Integrated Drive System.That way, important optimization potential for maximumproductivity, increased efficiency, and highest availabilitycan be leveraged throughout the system’s lifecycle –from planning, design, and engineering to operation,maintenance, and all the way even tomodernization.With Integrated Drive Systems, assetsbecome important success factors. Theyensure shorter time to market, maximumproductivity and efficiency in operation,and shorter time to profit.With Integrated DriveSystems you can reduceyour maintenance costsby up to15%www.siemens.com/ids4Siemens D 33 · May 2019

1 Siemens 2019System overview1/21/2The SINAMICS drive familyOverview1/61/61/6Drive selectionOverviewMore 1/17SINAMICS V90 basic servo drive systemOverviewBenefitsApplicationDesignSelection and ordering dataAccessoriesFunctionConfigurationTechnical specificationsMore informationIntegration1/201/201/201/20SINAMICS V90 Starter KitOverviewBenefitsSelection and ordering data1/211/21Recommended SIMATIC S7 controllerSelection and ordering dataSiemens D 33 · May 2019

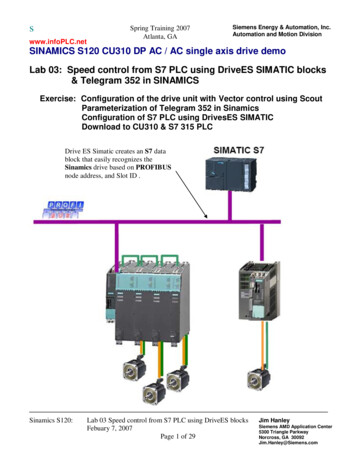

Siemens 2019System overviewThe SINAMICS drive family OverviewIntegration in automationManagement levelOffice environment: SIMATIC IT / COMOS.Process control levelControl center / control system:SIMATIC PCS 7 / WINCCAutomation systems / HMI:SIMATIC / SIMOTION / SINUMERIKControl levelFieldbusSINAMICS VSINAMICS GSINAMICS VSINAMICS GSINAMICS SpumpingventilatingcompressingmovingSINAMICS VSINAMICS GSINAMICS SprocessingSINAMICS SmachiningG D011 EN 00337d1Totally Integrated Automation and communicationApplicationsSINAMICS is an integral component of the Siemens "TotallyIntegrated Automation" concept. Integrated SINAMICS systemscovering configuration, data storage, and communication atautomation level ensure low-maintenance solutions with theSIMATIC, SIMOTION and SINUMERIK control systems.SINAMICS is the comprehensive family of drives from Siemensdesigned for machine and plant engineering applications.SINAMICS offers solutions for all drive tasks: Simple pump and fan applications in the process industry Demanding single drives in centrifuges, presses, extruders,elevators, as well as conveyor and transport systems Drive line-ups in textile, plastic film, and paper machines aswell as in rolling mill plants Highly dynamic servo drives for machine tools, as well aspackaging and printing machinesDepending on the application, the appropriate variable frequency drives can be selected and incorporated in the automation concept. With this in mind, the drives are clearly subdividedinto their different applications. A wide range of communicationoptions (depending on the drive type) are available for establishing a communication link to the automation system: PROFINET PROFIBUS EtherNet/IP Modbus TCP Modbus RTU AS-Interface BACnet MS/TP1/2Siemens D 33 · May 2019

Siemens 2019System overviewThe SINAMICS drive family Overview (continued)SINAMICS as part of the Siemens modular automation systemSIMOTIONSINUMERIKSIMATICSINAMICSSIMOTICSG D011 XX 00515bSIMOGEARInnovative, energy-efficient and reliable drive systems andapplications as well as services for the entire drive trainThe solutions for drive technology place great emphasis on thehighest productivity, energy efficiency and reliability for alltorque ranges, performance and voltage classes.Siemens offers not only the right innovative variable frequencydrive for every drive application, but also a wide range ofenergy-efficient low voltage motors, geared motors, explosionprotected motors and high-voltage motors for combination withSINAMICS.Furthermore, Siemens supports its customers with global presales and after-sales services, with over 295 service points in130 countries – and with special services e.g. applicationconsulting or motion control solutions.Energy efficiencyEnergy management processEfficient energy management consultancy identifies the energyflows, determines the potential for making savings and implements them with focused activities.Almost two thirds of the industrial power requirement is fromelectric motors. This makes it all the more important to use drivetechnology permitting energy consumption to be reduced effectively even in the configuration phase, and consequently tooptimize plant availability and process stability. With SINAMICS,Siemens offers powerful energy efficient solutions which, depending on the application, enable a significant reduction inelectricity costs.Siemens D 33 · May 20191/31

Siemens 2019System overviewThe SINAMICS drive family Overview (continued)Up to 70 % potential for savings using variable speed operationRegenerative feedback of braking energySINAMICS enables great potential for savings to be realized bycontrolling the motor speed. In particular, huge potential savingscan be recovered from pumps, fans and compressors which areoperated with mechanical throttle and valves. Here, changing tovariable-speed drives brings enormous economic advantages.In contrast to mechanical control systems, the power consumption at partial load operation is always immediately adjusted tothe demand at that time. So energy is no longer wasted, permitting savings of up to 60 % – in exceptional cases even up to70 %. Variable-speed drives also offer clear advantages overmechanical control systems when it comes to maintenance andrepair. Current spikes when starting up the motor and strongtorque surges become things of the past – and the same goesfor pressure waves in pipelines, cavitation or vibrations whichcause sustainable damage to the plant. Smooth starting andramp-down relieve the load on the mechanical system, ensuringa significantly longer service life of the entire drive train.In conventional drive systems, the energy produced duringbraking is converted to heat using braking resistors. Energyproduced during braking is efficiently recovered to the supplysystem by versions of SINAMICS G and SINAMICS S drives withregenerative feedback capability and these devices do nottherefore need a braking resistor. This permits up to 60 % of theenergy requirement to be saved, e.g. in lifting applications.Energy which can be reused at other locations on a machine.Furthermore, this reduced power loss simplifies the cooling ofthe system, enabling a more compact design.Energy transparency in all configuration phasesEarly on, in the configuration phase, the SIZER for SiemensDrives engineering tool provides information on the specificenergy requirement. The energy consumption across the entiredrive train is visualized and compared with different plantconcepts.SINAMICS in combination with energy-saving motorsEngineering integration stretches beyond the SINAMICS drivefamily to higher-level automation systems, and to a broad spectrum of energy-efficient motors with a wide range of performanceclasses, which, compared to previous motors, are able todemonstrate up to 10 % greater efficiency.VariantsDepending on the application, the SINAMICS range offers the ideal variant for any drive task.PerformanceSINAMICS VSINAMICS V drives focus onthe essentials both in terms of hardwareand functionality.This results in a high degree of ruggednesscombined with lower investment costs.1/4Siemens D 33 · May 2019SINAMICS GSINAMICS SSINAMICS G drives function perfectly for lowand medium demands on the dynamicresponse of the control system.SINAMICS S drives are predestinedfor demanding single - and multi-axisapplications in machine and plant engineeringas well as for numerous motion control tasks.PriceG D011 EN 00449b1

Siemens 2019System overviewThe SINAMICS drive family Overview (continued)Platform conceptIDS – Integration at its very bestAll SINAMICS variants are based on a platform concept. Jointhardware and software components, as well as standardizedtools for dimensioning, configuration, and commissioning tasksensure high-level integration across all components. SINAMICShandles a wide variety of drive tasks with no system gaps. Thedifferent SINAMICS variants can be easily combined with eachother.The Siemens Integrated Drive Systems (IDS) solution offers perfectly matched drive components with which you can meet yourrequirements. The drive components reveal their true strengthsas an Integrated Drive System over the full range from engineering and commissioning through to operation: Integrated systemconfiguration is performed using the Drive Technology Configurator: Just select a motor and an converter and design them withthe SIZER for Siemens Drives engineering tool. The STARTERand SINAMICS Startdrive commissioning tools integrate the motor data and at the same time simplify efficient commissioning.Integrated Drive Systems are incorporated in the TIA Portal – thissimplifies engineering, commissioning and diagnostics.Quality management according to EN ISO 9001SINAMICS conforms to the most exacting quality requirements.Comprehensive quality assurance measures in all developmentand production processes ensure a consistently high level ofquality.Of course, our quality management system is certified by anindependent authority in accordance with EN ISO 9001.DCvoltageLow voltageBasic performanceSINAMICSV20SINAMICSV90General DG110MDCapplicationsHigh performance0.05 kW to7 kW0.37 kW to630 kWPumps, yorpackagingcompressors,belts, mixers,machines,conveyormills, spinningautomaticbelts, uders,machines,metal g ngle-axisventilationpositioningsystemsapplications inmachine andplantengineeringCatalogD 31.1CatalogD 33CatalogsD 31.1, D 31.50.37 kW to7.5 tions(G120D)CatalogD 31.2Applicationswith DCMSINAMICSGH150GH180GM150SM150GL150SL150SM120CM75 kW to2700 kW2.2 kW to6600 kW0.55 kW to132 kW0.05 kW to7 kW0.55 kW to5700 kW75 kW to1200 kW6 kW to30 MW0.15 MW to85 MWSIMATICET 200pro FC-20.12 kW to30 hines,fans,positioningspecific forhandlingcompressors,applications inpumps,equipment,conveyormachine andfans,feed andbelts, mixers, ordevices,extrudersbelts,stacking units,extruders,automaticmixers, toryseparatorsautomation,wood, glassand ceramicsindustry,digital printingmachinesCatalogD 11CatalogD 18.1CatalogD 31.1CatalogD 32Pumps, fans,Test bays,Rolling millProductioncross geswire-drawing(packaging,machines, extruders, mills,textile andcrushers,extruders andprintingrolling mills,kneaders,machines,conveyorcableways andpapertechnology,lifts,machines,test bay drives excavators,plastictest bays,processingmarine drives,machines),blast furnacemachinefans, retrofittools, plants,process linesand rollingmills, marinedrives, testbaysCatalogsD 21.3, D 21.4NC 62CatalogD 21.3CatalogD 23.1CatalogsD 15.1, D 12Engineering tools (e.g. Drive Technology Configurator, SIZER for Siemens Drives, STARTER and SINAMICS Startdrive)G D011 EN 00450mSiemens D 33 · May 20191/51

Siemens 2019System overview1Drive selection OverviewSINAMICS selection guide – typical applicationsUseRequirements for torque accuracy/speed accuracy/position accuracy/coordination of axes/functionalityContinuous ingMachiningNon-continuous motionBasicMediumHighBasicMediumHighCentrifugal pumpsRadial / axial fansCompressorsCentrifugal pumpsRadial / axial fansCompressorsEccentric screwpumpsHydraulic pumpsMetering pumpsHydraulic pumpsMetering pumpsDescaling pumpsHydraulic pumpsV20G120CG120XG120XG130/G150G180 1)S120G120S110S120Conveyor beltsRoller conveyorsChain conveyorsConveyor beltsRoller conveyorsChain s/movingwalkwaysIndoor cranesMarine drivesCable railwaysElevatorsContainer cranesMining hoistsExcavators foropen-cast miningTest baysAccelerationconveyorsStorage and retrievalmachinesAccelerationconveyorsStorage and retrievalmachinesCross cuttersReel changersStorage and retrievalmachinesRoboticsPick & placeRotary indexing tablesCross cuttersRoll feedsEngagers/disengagersV20G110DG110MG120CET 200pro FC-2 2)G120G120DG130/G150G180 Rotary furnacesExtrudersWinders/unwindersLead/follower drivesCalendersMain press drivesPrinting machinesTubular baggingmachinesSingle-axis motioncontrolsuch as Position profiles Path profilesTubular baggingmachinesSingle-axis motioncontrolsuch as Position profiles Path profilesServo pressesRolling mill drivesMulti-axis motioncontrolsuch as Multi-axis positioning Cams InterpolationsV20G120CG120G130/G150G180 1)S120S150DCMV90G120S110S210S120S210DCMMain drives for Turning Milling DrillingMain drives for Drilling SawingMain drives for Turning Milling Drilling Gear cutting GrindingAxis drives for Turning Milling DrillingAxis drives for Drilling SawingAxis drives for Turning Milling Drilling Lasering Gear cutting Grinding Nibbling andpunchingS110S110S120S120S110S110S120S120Using the SINAMICS selection guideThe varying range of demands on modern variable frequencydrives requires a large number of different types. Selecting theoptimum drive has become a significantly more complexprocess. The application matrix shown simplifies this selectionprocess considerably, by suggesting the ideal SINAMICS drivefor examples of typical applications and requirements. The application type is selected from the vertical column- Pumping, ventilating, compressing- Moving- Processing- Machining The quality of the motion type is selected from the horizontal row- Basic- Medium- High More informationFurther information about SINAMICS is available on the Internet atwww.siemens.com/sinamicsPractical application examples and descriptions are availableon the Internet y-specific converters.1/6Siemens D 33 · May 2019Information on the SIMATIC ET 200pro FC-2 frequency converter is available inCatalog D 31.2 and atwww.siemens.com/et200pro-fc

Siemens 2019System overviewSINAMICS V90 basic servo drive system OverviewSINAMICS V90 servo drive systemThe performance-optimized, user-friendly servo drive systemcomprises a SINAMICS V90 servo drive and a SIMOTICS S-1FL6servomotor. There are eight different servo drive frame sizes andseven motor shaft heights for operation on single and threephase line supplies with power ratings ranging from0.05 to 7.0 kW, to realize a wide range of applications, with thefocus on dynamic motion and processing - for example positioning, transporting and winding.In addition to operation in the TIA Portal V14 with the newSIMATIC 1500 T-CPU Advanced Controller, the servo drive system is also suitable for use with the SIMATIC S7-1500 AdvancedController and the SIMATIC S7-1200 Basic Controller. BenefitsCost-effective - many integrated functions to reducemachine costsIntegrated control modesPulse train input position control mode (PTI), internal positioncontrol mode (IPos) with traversing block or Modbus, speedcontrol mode and torque control are all integrated in theSINAMICS V90.Easy to use - Simple tuning and quick commissioningEasy servo tuning and machine optimizationThe system can be automatically optimized using the auto tuning function and automatic suppression of machine resonances.Simply plug & play, no in-depth servo know-how required.The drive has various integrated control modes to address awide range of applications.Easy commissioning using the SINAMICS V-ASSISTANT engineering toolIntegrated PROFINET – the industrial Ethernet standard forautomationGraphic user interface guides the user when setting applicationspecific parameters; intuitive drive and motor status check; integrated trace and measuring functionality.SINAMICS V90 PROFINET version features PROFINET, enablingreal-time transmission of user/process data and diagnostic datawith a single cable.This solution offers wide-ranging functions with reducedcomplexity.Integrated positioning function Positioning function is integrated in the drive. Target positionsand respective speeds can be stored in the drive during commissioning or changed via communication. Absolute or relative positioning Rotary or linear axes Referencing in the drivePoint-to-point positioning possible using a PLC without positioning functionality.Integrated braking resistor for all frame sizes and max. motorpower 0.2 kWAll frame sizes with max. motor power 0.2 kW have an integrated braking resistor to dissipate the regenerative power forfast braking.SINAMICS V-ASSISTANT makes commissioning and diagnostics quick and imple connection to a control system Two-channel pulse train for position setpoint, one exclusivelyfor 5 V differential (RS422 standard), one for 24 V single endedsignal (for pulse train version) Standard RS485 interface supports USS and Modbus RTU(pulse train version) Industrial Ethernet standard PROFINET with PROFIdrive(PROFINET version)Standard interface makes it easy to connect the drive withPLCs and motion controller.Easy, all from a single source Predefined drive/motor bundles and accessories, easy to select Tested with SIMATIC PLC/HMI and ready-to-run applicationexamples for connecting a SINAMICS V90 drive to a controller Different application examples can be downloaded free ofcharge from the Online Support PortalMost applications can be realized without an additional braking resistor.Parameter cloningIntegrated holding brake switch (SINAMICS V90, 400 V version)Integrated holding brake switch - the brake can be directly connected to the drive if a motor with holding brake is used.Holding brake can be connected without requiring an external relay (only for SINAMICS V90, 400 V version).SINAMICS V90 servo drives are equipped with a standardSD card slot (400 V version) and a Micro SD card slot (200 Vversion), so that parameter settings can be easily transferred between drive devices.Efficient commissioning of machine series.Siemens D 33 · May 20191/71

Siemens 2019System overview1SINAMICS V90 basic servo drive system ApplicationApplication examplesSINAMICS V90 servo drive system200 V . 240 V 1 AC/3 AC380 V . 480 V 3 ACLow Inertiafor high dynamic performanceHigh Inertiafor smooth operational performanceElectronic assembly industry,for example Pick and place machineStencil cutting machinePCB assembly machineIC handling machineChip sorting machineBonding machineMetal forming machinery,for example Punching machine Engraving machine Edging pressConverting/printing industry,for example Labeling machineSlitter machineLaminating/coating machineScreen printing machineConverting/printing industry,for example Packaging industry,for example Filling and sealing machine Blister machine(pharmaceutical packaging) Bag packing machinePackaging industry,for example Filling machine Blister machine(pharmaceutical packaging) Bag packing machineMaterial handling machinery,for example Automatic palletizersMaterial handling machinery,for example Storage and warehouse systems Conveyor systems1/8Siemens D 33 · May 2019WindersSlitter machineLaminating/coating machineScreen printing machineWire drawing machine

Siemens 2019System overviewSINAMICS V90 basic servo drive system DesignSystem topologySIMATIC PanelSIMATIC s RTUSINAMICS V20PCG D011 EN 00407aSINAMICS V90SIMOTICS S-1FL6Siemens D 33 · May 20191/91

Siemens 2019System overviewClicking to the Industry Mall6SL3255-0AA00-5AA01SINAMICS V90 basic servo drive system Selection and ordering dataSIMOTICS S-1FL6 servomotors Configuration with SINAMICS V90 servo driveFurther info in section SIMOTICS S-1FL6 servomotors.Max. Ratedspeed power 1)Statictorquenmax. Prated at T 100 KM0 atMrated at Mmax T 100 K T 100 KIrated atImax T 100 KrpmNmAkW (hp)Ratedtorque 1)NmMax.Ratedtorque 1) currentNmTorque Moment of inertia Recom- Weight 2)constant of rotormendedload tomotorinertiaratio,J

Related catalogs Motion Control Drives D 31.1 SINAMICS Inverters for Single-Axis Drives Built-In Units E86060-K5531-A111-A1-7600 Motion Control Drives D 31.5 SINAMICS Converters for Single-Axis Drives