Transcription

Smart Motor Control Increase productivity across theautomation lifecycleIncrease intelligence for betterdecision makingHelp enable safe operationsSecure your environment

Efficient motors driveindustrial performance75%Across multiple applications, the electric motor keeps industry running,from motion systems, ventilators and conveyors to pumps and compressors.Central as they are to manufacturing and industrial performance, the impactof motor failure can be significant, costing thousands or even hundredsof thousands per hour of lost production. The most expensive motor isn’tnecessarily the most critical: a failure on a small, single mixer motor can beenough to cause a major disruption to plant productivity.How much dounforeseen motorfailures cost you?Motor costs Motors are the largestconsumers of energyin industry Responsible for over50% of the total energyused by industry Running a motor cancost 10 times its initialpurchase price each year Reducing the speed of amotor by 20% can saveup to 50% energyWhy motors fail The most commoncauses of motorfailure are:- Thermal overloads- Single phasing- Bearing failure- Rotor failure- Stator failure- Contaminantsof motor failures could beprevented by appropriateprotection measuresSource: IEEE Petro-Chemical Paper PCIC-94-01Cost of downtime Loss of production ManufacturingscrappageMaintenance options Advanced diagnosticinformation Preventative notreactive maintenance Establishing cause offailure (mechanical/electrical) Planned downtimepossible Motor and systemrepair costs Be in control ofyour plant Safety issues Reducedmaintenance costs Impact onother equipmentIncreased productivity Reducing unplanneddowntime improvesproductivity Be in control of yourproduction process Reduce energy costs Make fact-baseddecisions withadvanced diagnosticinformationSmart Motor Control Solution2

Motors are used in many industrial applications andthese are critical to the productivity of the enterprise.With Smart Motor Control solutions, it is possible to monitorthe health and performance of each motor to help identify,in advance, potential issues that could lead to unwanteddowntime or reduced productivity levels.!Is a vital motorabout to fail?TIME TO TRIPON PUMP 1(SECONDS)1 2 5 0!Warning Vibrationalert On Pump 7.Are you aware of energy consumptionfrom motor applications?Maintenance requiredSCHEDULEMAINTENANCEON CRUSHERMOTOR (DAYS)UNDERLOADCONDITION0 0 2 5! ! ! !! OPERATIONHOURS MIXER 3Replace belton Motor 1!0 5 0 0!FLC – Mixer Number 2!Shift changeh– changehdrive parameters0 4 7 . 5 AmpsJam condition onconveyor infeedSmart Motor Control Solution3

Smart Motor ControlSmart Motor Control provides a continuous flow of valuableprocess and diagnostic data to your design environment,visualization system, information software and GuardLogix Programmable Automation Controller – facilitating TheConnected Enterprise and helping to increase productivity andminimize downtime while reducing total cost of ownership.The Connected Enterprise / Industry SoftwareEnergyProgrammableAutomation ControllerBenefits ofIntelligentMotor ControlSecurityMobilityFixed SpeedElectronicOverload RelaysSoftStartersEtherNet/IPArmorStart DistributedMotor ControllersVariable SpeedLow VoltageMedium VoltageDrivesDrivesIntelligent MotorControl CentersMotion ControlMotion ControlCondition MonitoringEtherNet/IPIntegrated ConditionMonitoringElectronicOverload RelaysSmart Motor Control Solution4

Smart Motor Control enables Smart Machinesfor use in The Connected EnterpriseSmart MotorControl solutions areprogrammed usingStudio 5000 softwareJust one developmentenvironment forconfiguring andprogrammingAdd-on profiles forsimplified machinedevelopment, operationand maintenance% Thermal Capacity UtilizationThe integration of Allen-Bradley SmartMotor Control solutions help reduce yourprogramming time, ease start up andcommissioning, and streamline diagnostics.By providing consolidated programming,device and system configuration, operationand maintenance within Studio 5000engineering environment, complexity andpotential errors can be minimized.Trip / Warning HistoriesCurrentVoltageTime to TripSmart Motor Control provides keydiagnostic information that optimizeperformance with real time access tooperation and performance trends.Time to ResetToday’s Smart Approach Seamless communication andsystem visibility for increasedperformance and flexibility Control & maintain motorperformance throughsmart equipment and networksEnergy & Power Reduce unplanned downtime withalarms and advanced diagnosticinformation Monitor energy consumption Simplify troubleshooting andreduce start up timesNumber of StartsOperational HoursSmart Motor Control Solution5

Scenario 1Motor underload Helps detect and inform of mechanical failures3 Reduces costs associated with production loss Can help minimize repair costs due tocontrolled shutdownSmart Motor Control deviceinforms personnel of issueMixer blade damaged,mixing less efficient1Mechanical damage on mixer.2Automatic notification sent to operator.4Location of fault can be quickly located. Time to repair and restart process reduced Allows maximum efficiency to be benchmarkedand monitoredWarning indicated byactual current reduction3Actual current reduction in the SMC -50 SoftStarter triggered warning.Mixing vessel emptied,cleaned, blade replaced5Fault is identified quickly and repaired.Expected normal MotorFull Load Current (FLC) observed6Equipment operating normally.Historical data available.Visit www.rockwellautomation.com/global/go/smartdevices to see moreSmart Motor Control Solution6

Scenario 2Process optimizationWhat is the time tooptimum consistency? Can help increase production throughput3 Reduces unnecessary wait times Helps increase product quality Optimizes efficient use of energyNow it is managedautomatically by thecurrent consumption ofthe motor, which helpsincrease batch throughputStart mixprocessoptimum batch consistency is no1 Estimatinglonger guess work.2 Operator starts batch process.3 Batch viscosity draws more current the closer4 draw reaches 4.4 Amps.it gets to optimum state.Optimum mix viscosity achieved when currentAutomaticnotification tooperator5 Operator notified automatically of batch completion.6 Optimized mix released to next stage of production.Visit www.rockwellautomation.com/global/go/smartdevices to see moreSmart Motor Control Solution7

Scenario 3Motor overload Early warning and diagnostic functions provided3 Minimizes production downtime Helps protect your critical assets from costly failure Fact-based decision making using real timediagnostic information Opportunity for predictive, rather thanreactive maintenance1Cleaning before batch one starts.2 Cleaning before batch 74 starts.Increased friction increased currentconsumption by motor3Repetitive cleaning may impact moving parts.Operator automatically notified of4 overcurrent on motor and its location.Maintenance actioneddue to Smart MotorControl warning5Preventative maintenance can beconducted mimimizing downtime.6 Planned maintenance is minimized as machinewill alert when maintenance is needed.Visit www.rockwellautomation.com/global/go/smartdevices to see moreSmart Motor Control Solution8

Scenario 4Ground faultcurrent detection Predictive monitoring of motor health Proactive maintenance can be achieved3Allen-Bradley E300 Electronic Overload Relay1 Motor winding insulation breaking down over time.2 monitors motor for ground fault.3 Ground fault notification sent to operator4 Motor location and fault type communicated.5 Motor can be quickly replaced.6 Production running with minimum downtime. Reduced downtime of critical equipmentfrom E300 Smart Motor Control Device.Visit www.rockwellautomation.com/global/go/smartdevices to see moreSmart Motor Control Solution9

Scenario 5Smart Motor Control(Soft Starter)controlling mixer motorNetwork interruptionNetwork issue Local management of process in event of networkcommunication issue DeviceLogix allows for decentralized intelligenceand reduces unnecessary network traffic31SMC-50 Soft Starter controlling mixer motor. Critical asset health can be maintained2 Communication lost to SMC-50 Soft Starter.Lost communicationfrom PLC. Batch production can be completed reducingclearing and cleaning issuesLost communicationfrom PLC. DeviceLogixtakes overDeviceLogix inSMC-50 Soft Startertakes over and runsto end of batchDeviceLogix in SMC-50 Soft Starter takes3Automatic communication to operator about issue.4 over and runs to end of batch.5Batch completed and DeviceLogix stops process.6 Communication restored.Faulty ethernet cable replaced.Visit www.rockwellautomation.com/global/go/smartdevices to see moreSmart Motor Control Solution10

A comprehensive family ofSmart Motor Control solutionsFor fixed and variable speed control to precise torque and position control,Rockwell Automation supports you with application knowledge, industryexperience and a complete portfolio of Smart Motor Control solutions,helping you achieve the control you need.Fixed Speed ControlVariable Speed ControlMotion ControlCondition MonitoringMotor Starters and ProtectionFor fixed speed control of yourapplication, the comprehensiveportfolio of direct online starters,electronic overloads and soft starterswith embedded protection capabilitiesallows you to achieve the control,protection and integration you need.With electronic overload protection andcommunication capabilities networkedinto your Integrated Architecture , youcan achieve system visibility, protectionand diagnostics that conventionalsolutions simply cannot offer.PowerFlex AC DrivesA comprehensive portfolio from 0.2 kWlow voltage to 25 MW medium voltagedrives, including options of configuredversions to your specific needs areavailable. With built-in specific featuresto benefit many applications andseamless integration into the RockwellAutomation Integrated Architecture ,the PowerFlex family of AC drives offeryou powerful performance and flexiblecontrol whatever your needs.Kinetix Integrated MotionKinetix integrated motion providesyou with the hardware, software andapplication knowledge to achieve fullintegration of logic and motion controlwithin the Rockwell AutomationIntegrated Architecture.Detect and Protect SolutionsCondition monitoring products helpyou keep your plant floor runningproductively by detecting potentialequipment failures. Smart ConditionMonitoring solutions include real timeprotection modules, sensors, portableinstruments and surveillance software.With a comprehensive portfolioof motion drives matched to servomotors, integration of Kinetix cansimplify your application withoutcompromising the control you need.Smart Motor Control Solution11

Working together with Rockwell AutomationMake more of your Connected Enterprise by connecting withRockwell Automation and our PartnerNetwork program member companies.Get answers to your questions on sales, products, services and technical support onwww.rockwellautomation.com/global/supportAccess help to design, build and maintain your system solution through the RockwellAutomation PartnerNetwork program of leading distributors, system integrators andothers. Find a Sales office or Partner location ockwell Automation, Inc. (NYSE:ROK), the world’s largest company dedicated to industrial automation, makes its customers more productive and the world more sustainable.Throughout the world, our flagship Allen-Bradley and Rockwell Software product brands are recognized for innovation and excellence.Follow ROKAutomation on Facebook, Twitter and Google Plus.Subscribe to us on YouTube. Connect with us on LinkedIn.Allen-Bradley, ArmorStart, E300, DeviceLogix, GuardLogix, Integrated Architecture, Kinetix, LISTEN. THINK. SOLVE., PartnerNetwork, PowerFlex, Rockwell Software, SMC-50, Studio 5000 and Studio 5000 Logix Designer software are trademarksof Rockwell Automation, Inc. Trademarks not belonging to Rockwell Automation are property of their respective companies.Publication SMC-BR001A-EN-P March 2018Copyright 2018 Rockwell Automation, Inc. All Rights Reserved.

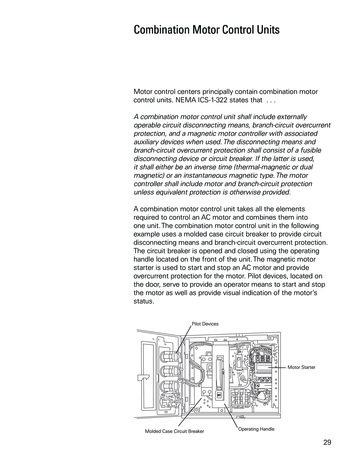

Smart Motor Control Solution 4 Smart Motor Control Smart Motor Control provides a continuous fl ow of valuable process and diagnostic data to your design environment, visualization system, information software and GuardLogix Programmable Automation Controller - facilitating The Connected Enterprise and helping to increase productivity and