Transcription

Solutions to make yourlife easier and businessmore productiveCENTERLINE 2100 motor control centers link people,machines and data across your entire business

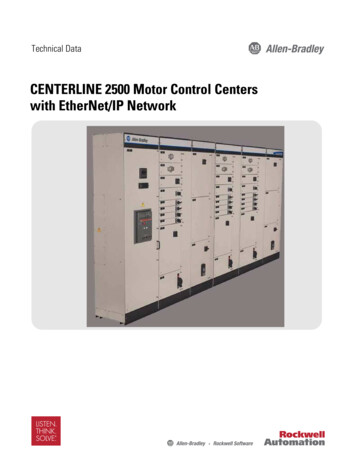

Motor control technology designed to bescalable, smart, safe and secureYou need a partner you can depend on.We engineer power and motor control solutions for the most demandingindustries. Food and beverage to oil and gas. And customers agree, theresults include increased productivity, safety and reliability.Integrating control and power into one centralized package, CENTERLINE2100 motor control centers (MCCs) have been the smart choice for smartmanufacturing and processing for more than 50 years.With many intelligent components and custom options available, we delivertailored solutions to meet the most demanding power, control and informationneeds. It’s all built on a common platform. And it delivers the maximum insafety, meeting all UL and NEMA standards.The CENTERLINE 2100 MCC is ideal for customers who want to leverage thesame architecture, components, programming language and networking,regardless of location. And they’re reassured, knowing they’ll receiveunparalleled support from the industry-leading single source provider.Increase your productivityCENTERLINE 2100 motor control centers are designed to be:Scalable – Integrate all of your motor, power and control needs into onecentralized package. The CENTERLINE 2100 MCC is designed and built withstandard features to provide years of dependable performance.Smart – When integrated with IntelliCENTER technology, CENTERLINEMCCs use intelligent motor controls in combination with built-inEtherNet/IP networking and pre-configured software to enhanceperformance by providing real-time access to information. This allowsyou to control, monitor and maintain operations from any location.Safe – In combination with the standard safety options built into everyCENTERLINE 2100 MCC, additional safety features including ArcShield andSecureConnect options allow you to design a CENTERLINE 2100 MCC thatbest satisfies the needs of your individual safety program.Secure – A centralized motor control solution allows tighter control of yoursensitive assets. In addition, CENTERLINE motor control centers are designedto meet the newest ISA/IEC 62443-3-3 standard, allowing greater peace ofmind that we are with you in the fight against threats – physical and cyber.2

CENTERLINE MCCs efficiently packageyour motor control needsArcShieldtechnologyhelps to reduce arcflash hazards whileproviding increasedprotection againstinternal electricalarcing faults.IntelliCENTERtechnologyprovides remote access todata and troubleshooting,minimizing the need toapproach the MCC.SecureConnect unitsallow users to disconnect powerfrom a MCC plug-in unit withoutopening the enclosure door.3

IntelliCENTER technologyOur technology features built-in EtherNet/IP,intelligent motor controls and advanced monitoringsoftware all preconfigured and tested at the factory.With its integrated network infrastructure, intelligentmotor control devices, and preconfigured userinterface software, you can monitor and diagnoseyour MCC from anywhere which: Reduces integration and setup time Improves process and diagnostic information Improves uptime, advance warnings andtroubleshooting tools Provides high availabilityBUILT-IN NETWORKYour startup is faster with built-in cabling. Complexinter-wiring is reduced to a single 600V-rated Ethernet cable.Because the network is preconfigured and validated, deviceconnections, IP addresses, subnet masks, custom parametersettings for PowerFlex drives and E300 electronicoverload relay, and advanced port settings are set for you.INTELLICENTER SOFTWAREIntelliCENTER software provides the ultimate window into yourMCC. It provides real-time diagnostics and MCC documentationto maximize MCC and related equipment performance.SMART DEVICESMCCs with IntelliCENTER technology combine intelligent motorcontrol and protection devices with advanced networking anddiagnostic capabilities to give you an inside look at your motorcontrol application.IntelliCENTER technologyprovides remote access todata and troubleshooting.4

Connect your entire enterpriseMore information – where you need it and when you need it for advanced plantasset management. EtherNet/IP helps enhance integration, reduces your MCCsetup time and allows you to quickly monitor, troubleshoot and diagnose yourMCC using a network that communicates with your entire enterprise.Easily integrate your manufacturing operations network with the corporatenetwork, helping reduce maintenance cost by reusing existing networkresources and tools.Seamlessly integrate production data and business systems by removing anetwork layer between devices and higher level networks without sacrificingnetwork security. Modbus TCP/IP options are available to provide easierintegration with third-party control systems.FAST INTEGRATIONFor even greater control over your operations,CENTERLINE MCCs networked with EtherNet/IPcan be easily integrated into a Logix-based PlantPAx distributed control system. The Integration Assistantwithin IntelliCENTER software provides:CL 2100 LV MCCStratix 5700Ethernetswitch Quick addition of intelligent motor control devicesinto the Studio 5000 Automation Engineering& Design Environment . Reduced programming time by automatically addingintelligent devices to the Studio 5000 Logix Designer I/Otree with appropriate EtherNet/IP network configuration Simplified integration by automatically creating devicecontroller tags using the device add-on profilesCONNECTED TECHNOLOGYFrom installation to configuration to operation –IntelliCENTER technology saves time at every step. Save up to 90% on your wiring installation time witha pre-configured and pre-tested CENTERLINE MCCwith IntelliCENTER technology. With IP addresses and subnet masks pre-configuredfor your MCC, you are ready to immediately communicatewith your intelligent motor control devices and configuredevice parameters over the network. Use Studio 5000 software to leverage a singleprogramming environment for all intelligent motorcontrol devices.IntelliCENTERsoftwareStudio 5000Logix DesignerFor more information visit rok.auto/intellicenter5

Safety by designCENTERLINE 2100 MCCs are engineered to increase industrial safety and mitigate risk – while increasing performanceand reliability. For over 50 years, these MCCs have been the industry leaders in helping customers with motor and powercontrol while meeting industry standards. Every CENTERLINE MCC is built with a structural foundation of standard highquality design and materials that provide the first level of protection.1Automatic Shutters – Immediately isolatesand minimizes exposure to energized verticalpower bus when unit is removed, enhancingpersonnel safety.2Sheet metal thickness4 Major structural components: 10–16 gauge steel Covers & plates: 14–16 gauge steel1 Units doors: 12–14 gauge steel Unit wrap & support pans: 14 gauge steel34Horizontal & vertical bus – Machine-torqued,two-bolt fastening system, used for thehorizontal to vertical bus connection,reducing periodic maintenance andminimizing exposure to hazardous voltages.235Structural isolation – Two side sheets persection provide isolation between sections,helping prevent faults from propagating toadjacent sections.5Standard vertical power bus – 300 A aboveand 300 A below the horizontal bus for aneffective 600 A capacity per section.6Unit isolation – Solid top and bottom unitsupport pans provide exceptional unitisolation to help prevent a single fault fromcascading throughout the enclosure, and limitequipment damage.7NEMA components – Allen-Bradley pushbuttons, pilot lights, selector switches,contactors and starters deliver proven andpredictable performance over the full lifeof the product, to help maximize theefficiency and performance of your MCC.8687Interlocks – With versatile interlock mechanism,the unit cannot be inserted or withdrawn whenthe disconnect handle is ON.6

ArcShield technologyArcShield helps to reduce arc flash hazards while providingyou with increased protection against internal electricalarcing faults.You can’t predict when an arc blast will occur, which makesarc resistant designs an important topic. Greater emphasishas been placed on acknowledging arc flash dangers instandards such as the National Electrical Code (NEC),Standard for Electrical Safety in the Workplace NationalFire Protection Agency (NFPA), and the Instituteof Electrical and Electronics Engineers (IEEE).An arc blast can result from many factors, including droppedtools, accidental contact with electrical systems, buildupof conductive dust, corrosion, rodents or improper workprocedures. When this occurs, ArcShield can help mitigateand protect from an arc flash incident.Pressurerelief systemAutomaticshuttersArc-resistantlatches onall doorsReinforcedback platesHorizontalground bus at topand/or bottom7

Passing IEEE C37.20.7 TestingAny manufacturer that can not provide documentation that they meet this criteria does not have arc resistant equipment.1. Doors and covers do not open (bowing is allowed)2. No parts are ejected from the equipment3. T he arc does not burn any holes in the exterior of the tested structure (in the applicable planes for theaccessibility level)4. Untreated cotton test indicators must not ignite or be perforated (equivalent to typical industrial work clothes)5. The grounding connections remain effectiveIncreased protectionfrom arc flash hazardsThe CENTERLINE 2100 MCC with ArcShield offersindustry-leading arc resistent features and has beentested in accordance with the IEEE C37.20.7 standard forType 2 accessibility.Type 2 accessibility allows personnel to be shielded at thefront, rear and sides of the enclosure in the unlikely eventof an arcing fault. Special door latches help to provideadditional protection by allowing pressure to releasewhile the door remains closed during an arcing event. Thepressure relief system at the top of the CENTERLINE MCCwith ArcShield vents and redirects arc blasts out the topand away from personnel, adding additional protection.TWO VERSIONS OF ARCSHIELD TECHNOLOGY:1. Device Limited – The ArcShield MCC is designed tocontain an arcing fault for the time it takes a pre-testedmain protective device to clear the fault. The mains arechosen to limit the amount of available incident energy.Recommended for applications needing a wider varietyof structural or unit options.2. D uration Rated (100 ms) – The ArcShield MCC isdesigned to contain an arcing fault for up to 100 ms induration. Any main protective device, either in the MCCitself or upstream through the use of main lugs, may beused. Recommended for applications needing high buscurrents or specific main devices, typically external tothe MCC.CENTERLINE 2100 with ArcShield technologyARC RESISTANT RATINGDEVICE LIMITEDDURATION RATED (100 MS)Rated VoltageUp to 600VUp to 480VAvailable Fault CurrentUp to 65 kAUp to 65 kAHorizontal Bus Current Rating600 1200 A600 3000 ANot RequiredRequiredVertical Wireway BaffleNot RequiredRequiredArc Containment Latches2 Latches/DoorAll LatchesUnit Support PansBoltedBoltedVented Units AllowedYes (Arc Resistant Baffles)NoYesYes*Top-plate Pressure Relief System(Requires 12" minimum clearance above MCC)Door Mounted Devices Allowed(Control stations, HIMs, viewing widows, etc.)8

SecureConnect unitsMulti-point validationport helps electricallyverify that the stabs arewithdrawn and the unitshutters closed.SecureConnect technology helps reduce exposure toelectrical hazards by allowing a unit to be disconnectedfrom the vertical power bus with the enclosure door stillclosed. Its “snap action” retractable stab mechanism helpsto reduce exposure to electrical shock and hazards byquickly disconnecting the stabs and isolating them behindshutters while the unit is still installed.With a multi-point validation system, SecureConnectprovides both electrical and mechanical indications thatthe unit is disconnected from the vertical power bus.SecureConnect units have an extra lock-out/tag-outlocation to help prevent any three-phase power from beingsupplied to the unit. The integrated lock-out mechanism,which is standard on all SecureConnect units, consistsof an unobtrusive arm that can be pulled out and lockedwhen desired.SecureConnectallows users todisconnect powerfrom a MCC plug-in unitwithout opening theenclosure door.Lock-out mechanismHelp reduce electricalshock hazards andexposure to harmfulvoltages withSecureConnectPOWER STABSPOWER STAB WITHDRAWALSTAB HOUSING SHUTTERSThe power stabs, locatedon the back of the unit,connect the individual unitto the MCC vertical bus toestablish power.When the stabs are disconnected, they are withdrawninto the power stab housing. The withdrawn stabs completea continuity circuit that can be tested with a standard meterusing the multi-point validation port. Continuity ismeasured directly through the withdrawn stabs.Shutters on the back of theunit close when the stabs aredisconnected and withdrawninside the unit for increasedelectrical isolation.Patented “snap action” mechanism makes and breaks the connection to the horizontal bus in less than one second, with just a quarter-turnof a standard hex head tool.9

ADDED SAFETYCENTERLINE 2100 MCCs are designed to enhance safe operation byhelping isolate you from potentially hazardous voltages and offeringa solid grounding system. Additional options such as IntelliCENTERtechnology, blown fuse indicators, exterior windows on unit doors,infrared inspection ports and fingersafe component barriers can helpyou create a safer working environment by reducing your potentialchances of making contact with energized components.1KEY INTERLOCK2Lock out mains or feeder units with provisions for customermounted key interlocks from Superior or Kirk.341Yellow door – helps identifymain disconnect forMCC lineup2Voltage indicator – visibly verifiesvoltage has been disconnectedwithout opening the door3Infrared viewing window – allowsyou to perform thermograph scansof equipment without openingthe door4Patented arc resistant baffles –allow ventilation of units suchas drives and SMCs while stillproviding arc resistance10

CertificationsUL 845 FOR MOTOR CONTROL CENTERSUL is a global independent safety sciencecompany offering expertise across fivekey strategic businesses: Product Safety,Environment, Life & Health, Knowledge Servicesand Verification Services. When you see the ULsymbol on a product, it indicates that UL hastested and evaluated representative samples ofthat product and has determined that it meetsUL requirements. The UL standard for MotorControl Centers is UL 845 which includesthe following: Motor control centers for use on circuitshaving available short-circuit currents notmore than 200,000 A rms symmetrical or200,000 A DC. Applies to single- and three-phase 50 and 60Hz and DC motor control centers rated notmore than 600V AC or 1000V DC.The CENTERLINE 2100 meets thefollowing standards: ABS Type Certified (Marine & Coast Guard) International Building Code – IBC andCalifornia Building Code - CBC (Seismic) UL 845/cUL NMX-353-ANCE ISO 9001 CertificationFor more information about productcertification, visit: rok.auto/certifications11

CENTERLINE motor control centersAllen-Bradley CENTERLINE low and medium voltage motor controlcenters offer optimal safety, performance and reliability to meet yourglobal needs.If you are looking for a solution that leverages the same architecture,components, programming language and networking – look to theentire portfolio of CENTERLINE motor control centers. Regardlessof where you do business, you will receive unparalleled support froma single-source provider to meet all of your motor control needs.CENTERLINE 2500 motor control centersDesigned to address the wide range of IEC application requirementsfound throughout the world, CENTERLINE 2500 MCCs offer fixedor withdrawable units, high density columns, and fully type testedstandard designs.CENTERLINE 1500 motor control centersAvailable in a wide range of configurations from across-the-line tosolid-state SMC starters, medium voltage NEMA CENTERLINE 1500MCCs provide the flexibility to select the best match for your application.Learn more at rockwellautomation.com12

Workforcesupport & trainingPeople & assetsafetyAsset & plantoptimizationRemediateHazardous energycontrolInventory servicesEnableSupplementElectrical safetyMachine safetyInformationinfrastructure &securityAsset modernizationInfrastructure developmentand managementAsset performanceAsset performanceOptimizeProduct & application lifecycle supportOn-demand support Integrated support Managed supportROCKWELL AUTOMATION SERVICESFor more information about how we can help you solve your unique business challenges, contact your localauthorized Allen-Bradley distributor or Rockwell Automation sales office, or visit: rok.auto/servicesConnect with us.Allen-Bradley, ArcShield, CENTERLINE, E300,expanding humanPowerFlex,SMC, Stratix, Studio 5000,Alphabeticallylist ntPAx,trademarksused inSecureConnect,the udio(7.62mm)above listlocations ofandfrom belowpublicationnumber.Studio 5000 AutomationEngineering& beDesignEnvironment and5000 fromLogix : BarlowRegular,8 pt.,companies.80% black,centered.is a trademark of ODVA, Inc.Trademarks not belonging to Rockwell AutomationareCondensed,property of theirrespectiveEthernet/IPAll other trademarks and registered trademarks are property of their respective companies.Publication ENCOMP-QR004I-EN-P - February 2019 Supersedes Publication ENCOMP-QR004H-EN-P - February 2018Publication 2100-BR006D-EN-P – June 2021 Supersedes Publication 2100-BR006C-EN-P – April 2016Copyright 2019 Rockwell Automation, Inc. All Rights Reserved. Printed in USA.Copyright 2021 Rockwell Automation, Inc. All Rights Reserved. Printed in USA.

We engineer power and motor control solutions for the most demanding industries. Food and beverage to oil and gas. And customers agree, the results include increased productivity, safety and reliability. Integrating control and power into one centralized package, CENTERLINE 2100 motor control centers (MCCs) have been the smart choice for smart