Transcription

PRACTICAL PIPING COURSEOUTLINE1. Introduction1.1. Definition of Piping1.2. Piping Nomenclature & Components1.3. Regulatory Acts, Codes & Standards1.4. Line Designation TablesProblem Set 12. Codes & Standards2.1. ASME2.2. NEPA / NFC / NFPA2.3. CSA2.4. MSS2.5. API2.6. ASTMProblem Set 23. Supplemental Documents3.1. Owner’s Specifications & Documents3.2. Contractor’s Standards & DocumentsProblem Set 334689101213141516172021214. Piping Design4.1. Failure Mechanisms4.2. Code Considerations for Design4.3. Material Selection4.4. Fabricated Tees & Area Reinforcement4.5. Piping Flexibility Analysis22233444455. References46EDAEngineering Design & Analysis LtdCopyright 2012

Practical Piping CourseDisclaimer !This short course is not a substitute for accessing and using the Codes directly in conformanceto generally accepted engineering practice.Consult the appropriate Codes and references prior to designing and engineering any pipingsystems.In some jurisdictions, a Professional Engineer must design pressure piping.EDAEngineering Design & Analysis LtdCopyright 20122

Practical Piping Course1.0Introduction1.1Definition of PipingPipe is a pressure tight cylinder used to convey a fluid or to transmit a fluid pressure,ordinarily designated pipe in applicable material specifications. Materials designated tubeor tubing in the specifications are treated as pipe when intended for pressure service.Piping is an assembly of piping components used to convey, distribute, mix, separate,discharge, meter, control or snub fluid flows. Piping also includes pipe-supportingelements but does not include support structures, such as building frames, bents,foundations, or any equipment excluded from Code definitions.Piping components are mechanical elements suitable for joining or assembly intopressure-tight fluid containing piping systems. Components include pipe, tubing, fittings,flanges, gaskets, bolting, valves and devices such as expansion joints, flexible joints,pressure hoses, traps, strainers, in-line portions of instruments and separators.Piping is typically round.EDAEngineering Design & Analysis LtdCopyright 20123

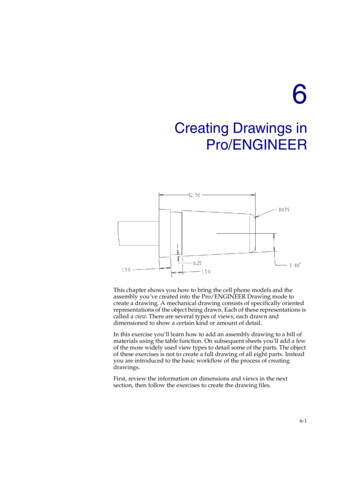

Practical Piping Course1.2Piping Nomenclature, ComponentsGraphic of piping system illustrating headerbranch connectionvalveflangeexpansion jointexpansion looppipe supportreducerelbowEDAEngineering Design & Analysis LtdCopyright 20124

Practical Piping CoursePipe system essentials:Header Main run of pipingTake off Branch runStub in Branch fitting connection made to header by direct attachment ofbranchBranchreinforcement Material added in the vicinity of a branch opening to restore themechanical integrity of the pipeNPS Nominal pipe sizePipe support Support elements which serve to maintain the structural integrityof the piping system, these are typically non-linear elementsSpring support Support provided by an element composed of a spring assembly,these are linear support elementsSnubber Support provided by an element composed of a non-linear,damping elementCategory D Within reference of B31.3, a service classificationCategory M Within reference of B31.3, a service classificationExpansiblefluid Any vapour or gaseous substance, any liquid under such pressureand temperature such that when pressure is reduced toatmospheric, will change to a gasHydro test Test pressure 1.5 x MAWP (some of the time)MAWP Maximum allowable working pressureMDMT Minimum design metal temperatureFracturetoughness Typically measured by CVN (Charpy V Number) at MDMTEDAEngineering Design & Analysis LtdCopyright 20125

Practical Piping Course1.3Regulatory Acts, Codes & StandardsCodesCodes are rules for the design of prescribed systems which are given the force of lawthrough provincial, state and federal legislation. In Canada, provincial governments havethe responsibility for public safety which includes these facilities, among others: Pressure pipingPressure vesselsBoilersPipelinesPlumbing systemsGas pipingAlberta Safety Codes Acts and Codes of PracticeThe following are applicable to the first four facilities listed above.Boilers and Pressure Vessels Regulation Prescribes requirements for registration of pressure vessels, boilers, pressurepiping and fittingsDesign, Construction and Installation of Boilers and Pressure Vessels Regulations Cites the codes and “bodies of rules” that form part of the regulations CSA B51 Boiler, Pressure Vessel and Pressure Piping Code CSA B52 Mechanical Refrigeration Code CAN/CSA Z184 Gas Pipeline Systems ASME Boiler & Pressure Vessel Code ASME B31 Pressure Piping Codes B31.1 Power Piping B31.3 Process Piping B31.4 Liquid Transportation Systems for Hydrocarbons, Liquid PetroleumGas, Anhydrous Ammonia and Alcohols B31.5 Refrigeration Piping ANSI K61.1 Safety Requirements for the Storage and Handling of AnhydrousAmmonia NFPA 58 Standard for the Storage and Handling of Liquefied PetroleumGases DOT Regulations of the Department of Transportation Governing theTransportation of Hazardous Materials in Tank Motor Vehicles MSS Standard Practice SP 25 Standard Marking System for Valves, Fittings,Flanges and Unions TEMA Standards of Tubular Exchanger Manufacturers AssociationEDAEngineering Design & Analysis LtdCopyright 20126

Practical Piping CoursePipeline ActCites the “minimum requirements for the design, construction, testing, operation,maintenance and repair of pipelines”: CSA Z662 Oil and Gas Pipeline SystemsCAN/CSA Z183 Oil Pipeline Systems (superceded)CAN/CSA Z184 Gas Pipeline Systems (superceded)CSA Z169 Aluminum Pipe and Pressure Piping SystemsCanadian Petroleum Association Recommended Practice for Liquid PetroleumPipeline Leak Prevention and Detection in the Province of AlbertaIn the US:As in Canada, some facilities are governed by federal regulations. Interstate pipelinefacilities are defined by the: Code of Federal Regulations, Title 49 Part 192 Transportation of Natural and Other Gas by Pipeline – MinimumFederal Safety Standards Part 193 Liquefied Natural Gas Facilities Part 195 Transportation of Hazardous Liquids by PipelineOther pipeline pressure piping codes include: ASME B31.4 Pipeline Transportation Systems for Liquid Hydrocarbons andOther LiquidsASME B31.8 Gas Transmission and Distribution SystemsEDAEngineering Design & Analysis LtdCopyright 20127

Practical Piping Course1.4Line Designation TablesThe Province of Alberta Safety Codes Act "Design, Construction and Installation ofBoilers & Pressure Vessels Regulations" par 7(2) requires that construction of a pressurepiping system must include submission of drawings, specifications and other informationand include:(a) flow or line diagrams showing the general arrangement of all boilers, pressurevessels, pressure piping systems and fittings(b) pipeline identification lists showing the maximum pressures and temperatures foreach pressure piping system(c) a list of pressure relief devices, including the set pressure(d) material specifications, size, schedule and primary service rating of all pressure pipingand fittings(e) the welding procedure registration number(f) the pressure pipe test procedure outlining the type, method, test media , test pressure,test temperature, duration and safety precautions(g) a form, provided by the Administrator, completed by the engineering designer orcontractor which relates to the general engineering requirements for design and fieldconstruction of pressure piping systems(h) such other information as is necessary for a safety codes officer to survey the designand determine whether it is suitable for approval and registrationEDAEngineering Design & Analysis LtdCopyright 20128

Practical Piping CourseProblem Set 11Which Act governs the design of plant pressure piping systems in Alberta?2Are process plant water lines considered pressure piping systems?3For what fluid service category may a hydro test be waived per B31.3?4What is the difference between a pipe elbow and a bend?EDAEngineering Design & Analysis LtdCopyright 20129

Practical Piping Course2.0Codes and StandardsThe following codes are used for the design, construction and inspection of pipingsystems.2.1The ASME B31 Piping CodesPiping codes developed by the American Society of Mechanical Engineers:B31.1 Power PipingPiping typically found in electric power generating stations, in industrial andinstitutional plants, geothermal heating systems and central and district heatingand cooling plants.B31.3 Process PipingPiping typically found in petroleum refineries, chemical, pharmaceutical, textile,per, semiconductor and cryogenic plants and related processing plants andterminals.B31.4 Pipeline Transportation Systems for Liquid Hydrocarbons and Other LiquidsPiping transporting products which are predominately quid between plants andterminals and within terminals, pumping, regulating, and metering stations.B31.5 Refrigeration PipingPiping for refrigerants and secondary coolants.B31.8 Gas Transportation and Distribution Piping SystemsPiping transporting products which are predominately gas between sources andterminals including compressor, regulating and metering stations, gas gatheringpipelines.B31.9 Building Services PipingPiping typically found in industrial, institutional, commercial and public buildingsand in multi-unit residences which does not require the range of sizes, pressuresand temperatures covered in B311.1B31.11 Slurry Transportation Piping SystemsPiping transporting aqueous slurries between plants and terminals withinterminals, pumping and regulating stations.EDAEngineering Design & Analysis LtdCopyright 201210

Practical Piping CourseThe following codes are used to specify the geometric, material and strength of piping andcomponents:ASME B16 Dimensional CodesThe ASME B16 Piping Component StandardsPiping component standard developed by the American Society of Mechanical Engineersor the American National Standards Institute 7B16.38B16.39B16.40B16.42B16.47Cast Iron Pipe Flanges and Flanged FittingsMalleable Iron Threaded Fittings, Class 150 and 300Cast Iron Threaded Fittings, Classes 125 and 250Pipe Flanges and Flanged FittingsFactory Made Wrought Steel Buttwelding FittingsFace to Face and End to End Dimensions of ValvesForged Fittings, Socket Welding and ThreadedCast Iron Threaded Drainage FittingsFerrous Pipe Plugs, Bushings and Locknuts with Pipe ThreadsCast Bronze Threaded Fittings Class 125 and 250Cast Copper Alloy Solder Joint Pressure FittingsRing Joint Gaskets and Grooves for Steel Pipe FlangesNonmetallic Flat Gaskets for Pipe FlangesWrought Copper and Copper Alloy Solder Joint Pressure FittingsCast Copper Alloy Solder Joint Drainage Fittings – DWVCast Copper Alloy Pipe Flanges and Flanged Fittings Class 150, 300,400,600, 900, 1500 and 2500Buttwelding EndsCast Copper Alloy Fittings for Flared Copper TubesWrought Steel Buttwelding Short Radius Elbows and ReturnsWrought Copper and Wrought Copper Alloy Solder Joint Drainage Fittings– DWVCast Copper Alloy Solder Joint Fittings for Sovent Drainage SystemsManually Operated Metallic Gas Valves for Use in Gas Piping systems Upto 125 psig (sizes ½ through 2)Valves – Flanged, Threaded and Welding EndOrifice FlangesHydrostatic Testing of Control ValvesLarge Metallic Valves for Gas Distribution (Manually Operated, NPS 2 ½ to12, 125 psig maximum)Malleable Iron Threaded Pipe Unions, Classes 1150, 250 and 300Manually Operated Thermoplastic Gs Shutoffs and Valves in GasDistribution SystemsDuctile Iron Pipe Flanges and Flanged Fittings, Class 150 and 300Large Diameter Steel Flanges (NPS 26 through NPS 60)EDAEngineering Design & Analysis LtdCopyright 201211

Practical Piping CourseASME B36 Piping Component StandardsPiping standards developed by the American Society of Mechanical Engineers /American National Standards Institute:B36.10B36.19Welded and Seamless Wrought Steel PipeStainless Steel PipeOther ASME or ANSIB73.1B73.2B133.22.2Horizontal, End Suction Centrifugal PumpsVertical In-line Centrifugal PumpsBasic Gas TurbineNEPA CodesNational Electrical Protection AssociationPiping covering fire protection systems using water, carbon dioxide, halon, foam,dry chemical and wet chemicals.NFC - NFPA CodesNational Fire Code / National Fire Protection AssociationNFPA 99 Health Care Facilities CodeEDAEngineering Design & Analysis LtdCopyright 201212

Practical Piping Course2.3CSA StandardsCanadian Standards AssociationCSA Z662 - 94 Oil & Gas Pipeline SystemsThis standard supercedes these standards: CAN/CSA Z183 Oil Pipeline SystemsCAN/CSA Z184 Gas Pipeline SystemsCAN/CSA Z187 Offshore PipelinesOther CSA Piping and Component Codes:B 51B 53B 52B 63B 137.3B 137.4W 48.1W 48.3Z 245.1Z 245.11Z 245.12Z 245.15Z 245.20Z 245.21Z 276Boilers and Pressure VesselsIdentification of Piping SystemsMechanical Refrigeration CodeWelded and Seamless Steel PipeRigid Poly-Vinyl Chloride (PVC) PipePolyethylene Piping Systems for Gas ServiceMild Steel Covered Arc-Welding ElectrodesLow-Alloy Steel Arc-Welding ElectrodesSteel Line PipeSteel FittingsSteel FlangesSteel ValvesExternal Fusion Bond Epoxy Coating for Steel PipeExternal Polyethylene Coating for PipeLNG - Production, Storage and HandlingEDAEngineering Design & Analysis LtdCopyright 201213

Practical Piping Course2.4MSS Standard PracticesThese are piping and related component standards developed by the Manufacturer’sStandardization Society. The MSS standards are directed at general industrialapplications. The pipeline industry makes extensive use of these piping component andquality acceptance standards.SP-6Standard Finishes for Contact Faces Pipe Flanges and Connecting EndFlanges of Valves and FittingsSP-25Standard Marking System for Valves, Fittings, Flanges and UnionSP-44Steel Pipeline FlangesSP-53Quality Standards for Steel Castings and Forgings for Valves, Flanges andFitti

Piping standards developed by the American Society of Mechanical Engineers / American National Standards Institute: B36.10 Welded and Seamless Wrought Steel Pipe . B36.19 Stainless Steel Pipe . Other ASME or ANSI . B73.1 Horizontal, End Suction Centrifugal Pumps . B73.2 Vertical In-line Centrifugal Pumps . B133.2 Basic Gas Turbine. 2.2 NEPA Codes : National Electrical Protection