Transcription

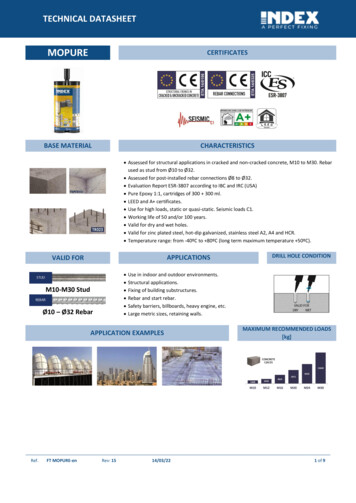

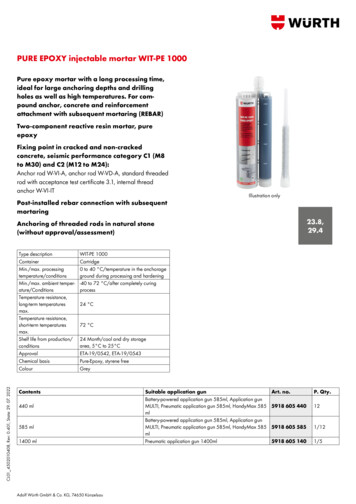

PURE EPOXY injectable mortar WIT-PE 1000Pure epoxy mortar with a long processing time,ideal for large anchoring depths and drillingholes as well as high temperatures. For compound anchor, concrete and reinforcementattachment with subsequent mortaring (REBAR)Two-component reactive resin mortar, pureepoxyFixing point in cracked and non-crackedconcrete, seismic performance category C1 (M8to M30) and C2 (M12 to M24):Anchor rod W-VI-A, anchor rod W-VD-A, standard threadedrod with acceptance test certificate 3.1, internal threadanchor W-VI-ITPost-installed rebar connection with subsequentmortaringIllustration only23.8,29.4Anchoring of threaded rods in natural stone(without approval/assessment)CL01 4502010408, Rev: 0.401, State: 29. 07. 2022Type descriptionContainerMin./max. processingtemperature/conditionsMin./max. ambient temperature/ConditionsTemperature resistance,long-term temperaturesmax.Temperature resistance,short-term temperaturesmax.Shelf life from production/conditionsApprovalChemical basisColourWIT-PE 1000Cartridge0 to 40 C/temperature in the anchorageground during processing and hardening-40 to 72 C/after completely curingprocess24 C72 C24 Month/cool and dry storagearea, 5 C to 25 CETA-19/0542, ETA-19/0543Pure-Epoxy, styrene freeGreyContents440 ml585 ml1400 mlAdolf Würth GmbH & Co. KG, 74650 KünzelsauSuitable application gunBattery-powered application gun 585ml, Application gunMULTI, Pneumatic application gun 585ml, HandyMax 585mlBattery-powered application gun 585ml, Application gunMULTI, Pneumatic application gun 585ml, HandyMax 585mlPneumatic application gun 1400mlArt. no.P. Qty.5918 605 440125918 605 5851/125918 605 1401/ 5

Cracked and non-cracked concrete: Performance dataCracked and non-cracked concrete: Performance data, individual anchor without influence of the edge distance (c 10 h ef)Temperature range: 24 C1)/40 C2) (temperature ranges 50 C/72 C see ETA-19/0542)Base material: Dry and wet concrete (water-filled drilled hole see ETA-19/0542)Concrete compressive strength: C20/25Drill hole cleaning: CAC (2x blow out with compressed air/2x brush out/2x blow out with compressed air; compressed air oil-free and min. 6 bar) or vacuum drill in cracked concrete (vacuum drill in non-cracked concrete see ETA-19/0542)Anchor diameterM8M10M12M1660 80 160 60 90 200 70 110 240 80 125 320Effective anchorage depthhef [mm]Cracked concreteAdmissible centricZinc-plated steel, 5.8Nperm [kN] 5,0 6,7 8,6 6,3 9,4 13,8 9,6 16,8 20,0 11,7 22,9 37,1tension load3)Zinc-plated steel, 8.8Nperm [kN] 5,0 6,7 13,4 6,3 9,4 20,9 9,6 16,8 31,9 11,7 22,9 59,5(individual anchor withoutinfluence of the edgedistance and withoutcongested reinforcement)Permissible shearload3)(individual anchor withoutinfluence of the edgedistance and withoutcongested reinforcement)Non-cracked concreteAdmissible centrictension load3)(individual anchor withoutinfluence of the edgedistance and withoutcongested reinforcement)Permissible shearload3)(individual anchor withoutinfluence of the edgedistance and withoutcongested reinforcement)Assembly dataNominal drill ØStainless steel A4 and HCR Nperm [kN] 5,06,79,96,3Vperm [kN] 6,3Vperm [kN] 8,66,38,66,38,69,7 9,7 9,7 14,3 14,3 14,3 26,9 26,9 26,912,6 13,1 13,1 19,2 19,4 19,4 23,5 36,0 36,0Stainless steel A4 and HCR Vperm [kN] 6,06,06,09,2Zinc-plated steel, 5.8Zinc-plated steel, 8.8Zinc-plated steel, 5.8Zinc plated steel, 8.89,215,7 9,69,216,8 22,5 11,7 22,9 42,013,7 13,7 13,7 23,5 25,2 25,2Nperm [kN] 8,6 8,6 8,6 10,9 13,8 13,8 13,7 20,0 20,0 16,8 32,7 37,1Nperm [kN] 10,9 13,8 13,8 10,9 20,0 21,9 13,7 27,0 31,9 16,8 32,7 59,5Stainless steel A4 and HCR Nperm [kN] 9,99,99,910,9 15,7 15,7 13,7 22,5 22,5 16,8 32,7 42,0Vperm [kN] 6,3Vperm [kN] 8,66,38,66,38,69,7 9,7 9,7 14,3 14,3 14,3 26,9 26,9 26,913,1 13,1 13,1 19,4 19,4 19,4 33,5 36,0 36,0Stainless steel A4 and HCR Vperm [kN] 6,06,06,09,2Zinc-plated steel, 5.8Zinc-plated steel, 8.8Drill hole depth/effective anchorage depthMinimum edge distanceMinimum axis distance5)Minimum member thicknessThrough hole in the component being connected4)CL01 4502010408, Rev: 0.401, State: 29. 07. 20229,4Torque while installing anchord0 [mm]h0/hef[mm]cmin [mm]smin [mm]hmin [mm]df [mm]Tinst [Nm]10609,21280160 60909,213,7 13,7 13,7 25,2 25,2 25,21418200 70110 240 80125 3203540455040506075100 110 190 100 120 230 100 140 270 116 161 356912141810204060Maximum long-term temperatureMaximum short-term temperature3) The partial safety factors of the resistances regulated in the approval and a partial safety factor of the effects of γF 1.4 have been taken into account. The tensile load portion “continuous load”(including constant loads and constant portions of variable loads) is less than 60 % of the total tensile load. For a combination of tensile and shear loads, for the influence of edge distance and theanchor groups please see standard EN 1992-4.4) If the characteristic edge distance is not met, the maximum load capacity is reduced. The smallest possible edge distance is cmin5) If the characteristic axis distance is not met, the maximum load capacity is reduced. The smallest possible axis distance is smin1)2)Adolf Würth GmbH & Co. KG, 74650 Künzelsau

Cracked and non-cracked concrete: Performance dataCracked and non-cracked concrete: Performance data, individual anchor without influence of the edge distance (c 10 h ef)Temperature range: 24 C1)/40 C2) (temperature ranges 50 C/72 C see ETA-19/0542)Base material: Dry and wet concrete (water-filled drilled hole see ETA-19/0542)Concrete compressive strength: C20/25Drill hole cleaning: CAC (2x blow out with compressed air/2x brush out/2x blow out with compressed air; compressed air oil-free and min. 6 bar) or vacuum drill in cracked concrete (vacuum drill in non-cracked concrete see ETA-19/0542)Anchor diameterM20M24M3090 170 400 96 210 480 120 270 600Effective anchorage depthhef [mm]Cracked concreteAdmissible centric tension load3)Zinc-plated steel, 5.8Nperm [kN] 14,0 36,3 58,1 15,4 49,9 83,8 21,6 72,7 133,3Zinc plated steel, 8.8Nperm [kN] 14,0 36,3 93,3 15,4 49,9 134,3 21,6 72,7 213,8(individual anchor without influence of theedge distance and without congested rein- Stainless steel A4 and HCR Nperm [kN] 14,0 36,3 65,3 15,4 49,9 94,3 21,6 70,2 70,2forcement)Permissible shear load3)Zinc-plated steel, 5.8Vperm [kN] 28,0 42,3 42,3 30,8 60,6 60,6 43,1 96,0 96,0(individual anchor without influence of the Zinc-plated steel, 8.8Vperm [kN] 28,0 56,0 56,0 30,8 80,6 80,6 43,1 128,0 128,0edge distance and without congested reinStainless steel A4 and HCR Vperm [kN] 28,0 39,4 39,4 30,8 56,8 56,8 42,0 42,0 42,0forcement)Non-cracked concreteAdmissible centric tension load3)Zinc-plated steel, 5.8Nperm [kN] 20,0 51,9 58,1 22,0 71,3 83,8 30,8 103,9 113,3Zinc plated steel, 8.8Nperm [kN] 20,0 51,9 93,3 22,0 71,3 134,3 30,8 103,9 213,8(individual anchor without influence of theedge distance and without congested rein- Stainless steel A4 and HCR Nperm [kN] 20,0 51,9 65,3 22,0 71,3 94,3 30,8 70,2 70,2forcement)Permissible shear load3)Zinc-plated steel, 5.8Vperm [kN] 40,0 42,3 42,3 44,1 60,6 60,6 61,6 96,0 96,0(individual anchor without influence of the Zinc-plated steel, 8.8Vperm [kN] 40,0 56,0 56,0 44,1 80,6 80,6 61,6 128,0 128,0edge distance and without congested reinStainless steel A4 and HCR Vperm [kN] 39,4 39,4 39,4 44,1 56,8 56,8 42,0 42,0 42,0forcement)Assembly data222835Nominal drill Ød0 [mm]h0/hef90 170 400 96 210 480 120 270 600Drill hole depth/effective anchorage depth[mm]6580cmin [mm] 60Minimum edge distance4)5)115140Minimum axis distancesmin [mm] 95Minimum member thicknesshmin [mm] 134 214 444 142 266 536 190 340 6702633Through hole in the component being connecteddf [mm] 22Tinst 100170300Torque while installing anchor[Nm]Maximum long-term temperatureMaximum short-term temperatureThe partial safety factors of the resistances regulated in the approval and a partial safety factor of the effects of γF 1.4 have been taken into account. The tensile load portion “continuous load”(including constant loads and constant portions of variable loads) is less than 60 % of the total tensile load. For a combination of tensile and shear loads, for the influence of edge distance and theanchor groups please see standard EN 1992-4.4) If the characteristic edge distance is not met, the maximum load capacity is reduced. The smallest possible edge distance is cmin5) If the characteristic axis distance is not met, the maximum load capacity is reduced. The smallest possible axis distance is smin1)2)CL01 4502010408, Rev: 0.401, State: 29. 07. 20223)Cracked and non-cracked concrete: Performance dataCracked and non-cracked concrete: Performance data, individual anchor without influence of the edge distance (c 10 h ef)Temperature range: 24 C1)/40 C2) (temperature ranges 50 C/72 C see ETA-19/0542)Base material: Dry and wet concrete (water-filled drilled hole see ETA-19/0542)Concrete compressive strength: C20/25Drill hole cleaning: CAC (2x blow out with compressed air/2x brush out/2x blow out with compressed air; compressed air oil-free and min. 6 bar) or vacuum drill in cracked concrete (vacuum drill in non-cracked concrete see ETA-19/0542)Anchor diameterIG M6IG M8IG M10IG IGMaximum long-term temperatureMaximum short-term temperatureThe partial safety factors of the resistances regulated in the approval and a partial safety factor of the effects of γF 1.4 have been taken into account. The tensile load portion “continuous load”(including constant loads and constant portions of variable loads) is less than 60 % of the total tensile load. For a combination of tensile and shear loads, for the influence of edge distance and theanchor groups please see standard EN 1992-4.1)2)3)Adolf Würth GmbH & Co. KG, 74650 Künzelsau

Cracked and non-cracked concrete: Performance dataEffective anchorage depthCracked concreteAdmissible centric tensionload3)(individual anchor without influenceof the edge distance and withoutcongested reinforcement)Permissible shear load3)(individual anchor without influenceof the edge distance and withoutcongested reinforcement)Non-cracked concreteAdmissible centric tensionload3)hef [mm]80908010080100 125 170Nperm [kN] 4,88,111,713,8 20,0Stainless steel A4 and HCR Nperm [kN] 5,39,911,715,7 22,5Vperm [kN] 2,95,18,612,0Stainless steel A4 and HCR Vperm [kN] 3,26,09,213,7Nperm [kN] 4.88,113,820,0Nperm [kN] 5,39,915,722,5Vperm [kN] 2,95,18,612,0Vperm [kN] 3,26,09,213,7Zinc-plated steel, 5.8Zinc-plated steel, 5.8Zinc-plated steel, 5.8(individual anchor without influence Stainless steel A4 and HCRof the edge distance and withoutcongested reinforcement)Permissible shear load3)Zinc-plated steel, 5.8(individual anchor without influenceof the edge distance and withoutStainless steel A4 and HCRcongested reinforcement)Assembly dataInternal threadEffective anchorage depthNominal drill ØMinimum edge distanceMinimum axis distance5)Minimum member thicknessThrough hole in the component being connectedTorque while installing anchorhef [mm]d0 [mm]cmin [mm]smin [mm]hmin [mm]df [mm]Tinst [Nm]IG M680 90124050110 1207IG M88014456011091010100130IG M10IG80100 125182250607595116136 1691214IG170286511522618206040Maximum long-term temperatureMaximum short-term temperature3)The partial safety factors of the resistances regulated in the approval and a partial safety factor of the effects of γF 1.4 have been taken into account. The tensile load portion “continuous load”(including constant loads and constant portions of variable loads) is less than 60 % of the total tensile load. For a combination of tensile and shear loads, for the influence of edge distance and theanchor groups please see standard EN 1992-4.1)CL01 4502010408, Rev: 0.401, State: 29. 07. 20222)Mortar requirements for metric anchor rods or threaded rods (W-VI-A, W-VD-A)Anchor rod ØM8M10M12M16M201012141822Nominal drill Ø[mm]0,650,820,981,361,79[ml]Mortar requirements per anchoring depth hef 10 mm6,538,169,8213,6117,89Mortar requirements per anchoring depth hef 100 mm[ml]Number of anchors [pcs] per cartridge for anchoring depth hef 100 mmAnchor rod ØM8M10M12M16M201012141822Nominal drill Ø[mm]5947392821Cartridge 440 ml[pcs]8165543929Cartridge 585 ml[pcs]2061651379975Cartridge 1400 ml[pcs]Required fill quantity per anchorage in [mm] for anchoring depth hef 100 mm, scale on the cartridgeAnchor rod ØM8M10M12M16M201012141822Nominal drill Ø[mm]33456Cartridge 440 ml, 2.74 ml/mm[mm]33456Cartridge 585 ml, 2.74 ml/mm[mm]11223Cartridge 1400 ml, 8.47 ml/mm[mm]Adolf Würth GmbH & Co. KG, 74650 303581027M242812124M303517175

Mortar requirements, concrete: Female thread anchor (W-VI-IG)Female thread ØIG M6Effective anchorage depthhef [mm]Nominal drill Ø[mm]Mortar requirements per anchoring [ml]Number of anchors [pcs.] per cartridge80126,53Female thread ØIG M6IG M8907,3480147,86IG M6Effective anchorage depthNominal drill ØCartridge 440 ml, 2.74 ml/mmCartridge 585 ml, 2.74 ml/mmCartridge 1400 ml, 8.47 ml/mmhef [mm][mm][mm][mm][mm]80123311009,82IG M89080Effective anchorage depthhef [mm] 801214Nominal drill Ø[mm]595349Cartridge 440 ml[pcs]817268Cartridge 585 ml[pcs]206183171Cartridge 1400 ml[pcs]Required fill quantity per anchorage in [mm], scale on the cartridgeFemale thread ØIG M10331801433110013,61IG M101003954137IG M890801810,8980183549123100283999IG 63612Details/Application Suitable for attaching metal structures, metal profiles, wooden structures, brackets etc. Suitable for structural expansions, ceiling and wall attachments, expansion of load-bearing structures, reinforcement of loadbearing structures, attachment of balconies and canopies, sealing of temporary openings and “forgotten” reinforcement barsMinimum curing timesCL01 4502010408, Rev: 0.401, State: 29. 07. 2022Concrete temperature0 C to 4 C 5 C to 9 C 10 C to 14 C 15 C to 19 C 20 C to 24 C 25 C to 34 C 35 C to 39 C 40 CCartridge temperatureProcessing time90 min80 min60 min40 min30 min12 min8 min8 min 5 C to 40 CMinimum curing time in dry concrete144 hours48 hours28 hours18 hours12 hours9 hours6 hours4 hoursMinimum curing time in wet concrete288 hours96 hours56 hours36 hours24 hours18 hours12 hours8 hoursMinimum curing timesConcrete temperature Maximum processing time1)tgel0 C to 4 C80 min 5 C to 9 C80 min 10 C to 14 C60 min 15 C to 19 C40 min 20 C to 24 C30 min 25 C to 34 C12 min 35 C to 39 C8 min1)2)Initial curing time in dry concrete2)tcure,ini30 hours20 hours15 hours9 hours6 hours4 hours3 hourstgel: Maximum time from injecting the mortar to the end of the setting processAt the end of tcure,ini, installation of the connection reinforcement and construction of the formwork may be continuedAdolf Würth GmbH & Co. KG, 74650 KünzelsauMinimum curing time in dry concretetcure,dry144 hours48 hours28 hours18 hours12 hours9 hours6 hours

Minimum curing timesConcrete temperature Maximum processing time1) Initial curing time in dry concrete2) Minimum curing time in dry concrete 40 C8 min1.5 hours4 hoursCartridge temperature 5 C to 40 C1)2)tgel: Maximum time from injecting the mortar to the end of the setting processAt the end of tcure,ini, installation of the connection reinforcement and construction of the formwork may be continuedBase material: Non-cracked concreteCreate the drill holeCut anchor rod to lengthand mark the desiredinsertion depthsBase material: Non-cracked concrete2xCreate the drill holeCL01 4502010408, Rev: 0.401, State: 29. 07. 2022Insert the reinforcementbar until it reaches themark, turning slightly2x2xPlace the embedmentdepth mark on the rodand check the drillinghole depthVisual check of the mortarvolume, observe maximumprocessing timeProof of performance European Technical Assessment ETA-19/0542: Single-point fastening cracked and non-cracked concrete (anchor rodW-VI-A, anchor rod W-VD-A, standard threaded rod with acceptance test certificate 3.1, anchor with internal thread W-VI-IT),seismic performance category C1 (M8 to M30) and C2 (M12 to M24) European Technical Assessment ETA-19/0543: Post-installed rebar connection with subsequent mortaring (REBAR)Related productsMixer nozzle WIT-MXAdolf Würth GmbH & Co. KG, 74650 KünzelsauArt. no.0903 488 103

##keep##Related productsHand slide valvePneumatic hose WIT-SDDPneumatic hose WIT-SDDBlow gunMachine chuck SDS-plus M8Handle for cleaning brushExtension for cleaning brush with M8 connecting threadCleaning brush for concrete and REBAR with M8 connecting thread WIT-RB Nominal drill hole diameter 10 mmCleaning brush for concrete and REBAR with M8 connecting thread WIT-RB Nominal drill hole diameter 12 mmCleaning brush for concrete and REBAR with M8 connecting thread WIT-RB Nominal drill hole diameter 14 mmCleaning brush for concrete and REBAR with M8 connecting thread WIT-RB Nominal drill hole diameter 18 mmCleaning brush for concrete and REBAR with M8 connecting thread WIT-RB Nominal drill hole diameter 22 mmCleaning brush for concrete and REBAR with M8 connecting thread WIT-RB Nominal drill hole diameter 28 mmCleaning brush for concrete and REBAR with M8 connecting thread WIT-RB Nominal drill hole diameter 35 mmMixer nozzle extension WIT-MVMixing extension WIT-MV, flexibleMixer nozzle extension WIT-MVWasher system hosePiston plug WIT-VS Nominal drill hole diameter 14 mmPiston plug WIT-VS Nominal drill hole diameter 16 mmPiston plug WIT-VS Nominal drill hole diameter 18 mmPiston plug WIT-VS Nominal drill hole diameter 20 mmPiston plug WIT-VS Nominal drill hole diameter 22 mmPiston plug WIT-VS Nominal drill hole diameter 25 mmPiston plug WIT-VS Nominal drill hole diameter 28 mmPiston plug WIT-VS Nominal drill hole diameter 32 mmPiston plug WIT-VS Nominal drill hole diameter 35 mmPiston plug WIT-VS Nominal drill hole diameter 40 mmArt. no.0699 903 380699 903 70699 903 130714 921 40903 489 1010903 489 1030903 489 1110903 489 5100903 489 5120903 489 5140903 489 5180903 489 5220903 489 5280903 489 5350903 420 0040903 488 1230903 488 1220895 8120903 488 0550903 488 0560903 488 0570903 488 0580903 488 0620903 488 0590903 488 0520903 488 0530903 488 0600903 488 061##keep##CL01 4502010408, Rev: 0.401, State: 29. 07. 2022Related productsDesignationfor5918 605 140Pneumatic 2C application gun WITApplication gun WIT-MultiGun for chemical anchoring products WIT-PE 5005918 605 440Cordless application gun WITPneumatic 2C application gun WITApplication gun WIT-MultiGun for chemical anchoring products WIT-PE 5005918 605 585Cordless application gun WITPneumatic 2C application gun WITAdolf Würth GmbH & Co. KG, 74650 KünzelsauArt. no.0891 0150891 003 1050891 0180891 003 5850891 0170891 003 1050891 0180891 003 5850891 017

24 Month/cool and dry storage area, 5 C to 25 C Approval ETA-19/0542, ETA-19/0543 Chemical basis Pure-Epoxy, styrene free Colour Grey 23.8, 29.4 Illustration only. CL01_4502010408, Rev: 0.401, State: 29. 07. 2022 . Anchor diameter M20 M24 M30 Effective anchorage depth h ef [mm] 90 170 400 96 210 480 120 270 600