Transcription

ONE COMPANY MANY SOLUTIONSEPOXYPOTTING & MARINEMEDICALTELECOMMUNICATIONSCONSUMER ELECTRONICSUTILITIESISO 9001:2008 Registered Quality System SAI Global File #004008 Burlington, Ontario, Canada

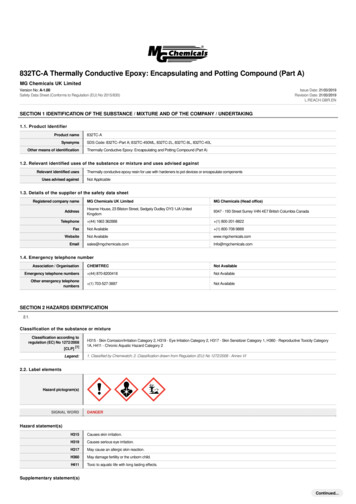

WHAT IS MG CHEMICALS?MG Chemicals is a manufacturer and wholesaler of chemical products for the electronics industry. Our chemicalproducts include dusters and circuit coolers, electronic cleaners, flux removers, contact cleaners, protectivecoatings, epoxies, adhesives, RTV silicones, lubricants, EMI/RFI shielding coatings, thermal management products,prototyping supplies, solders and more. We also distribute related non-chemical products such as wipes, swabs,brushes, desoldering braids, copper-clad boards and 3D printing filaments.MG SERVICEMG Chemicals understands that setting up production involves multiple challenges. Our service team has yearsof experience in production and equipment use, and understands the various technical issues you may encounterduring planning, pilot studies and production runs. To overcome these challenges, we offer the following professionalservices.MG Chemicals can Provide advice on equipment and materialsAssist with setup and troubleshootingReview your proposed application processesSuggest ways of optimizing and customizing processes to best meet your needsOffer training on the proper use of our productsQuality AssuranceSince 1955, MG Chemicals has provided the North American electronics industry with a full line of high performancechemicals and accessories. The MG Chemicals manufacturing facility operates under the ISO 9001 Quality SystemStandard. All products undergo MG Chemicals’ design process, including the testing and analysis of each productto maximize performance, user safety, environmental safeguards and market desirability.Customer Care Customer care is what separates MG Chemicals from the rest. Our commitment to all of these principles focuseson getting you the quality product and support you deserve.2

TABLE OF CONTENTSINTRODUCTION TO EPOXY ENCAPSULATING AND POTTING COMPOUNDS4-5832 SERIES - Non-UL spec products6832HD - Black, 1:16832C - Translucent6832B - Black, 2:1832WC - Water Clear6832FX - Flexible7832TC - Thermally Conductive7832HT - High Temperature7832 SERIES COMPARISON TABLE8Available Packaging (Cartridges)8834 SERIES - Compounds meeting the UL 746E standard834B - Balanced Formula9834FRB - Low Viscosity9834ATH - Economical10834FX - Flexible10834HTC - High Thermal Conductivity10834 SERIES COMPARISON TABLE11Available Packaging (Kits) 10-113

INTRODUCTION TO EPOXY POTTINGAND ENCAPSULATING COMPOUNDSEpoxy Potting and Encapsulating CompoundsPotting compounds are designed to provide a high level of protection to printed circuit boards and electronicdevices by embedding them in a thick, durable polymer. Epoxies are used when extreme operatingconditions require optimum protection. They offer different physical and chemical properties from otheralternatives, and these properties are listed below.Physical Protection – These compounds hold components firmly in place, preventing damage from vibration,mechanical shocks, abrasion, bending, tension, compression and torsion.Environmental Protection - They are non-porous, providing complete protection from humidity and water,allowing for direct submersion in salt water, and granting complete protection from dust, soil, corrosion andfungus. They also are extremely chemically resistant and can resist most fuels, oils, alcohols, mild solvents,and strong acids.Electrical Protection - Epoxies have inherent insulative properties that result in a high volume resistivityand dielectric strength. These features allow epoxies to provide protection from static discharge, electricalshocks and arcing, and also allow tighter spacing between components.Thermal Protection – They provide a high level of resistance to thermal cycling and thermal shock, which isan important requirement for many customers who are looking to protect their electronics from temperatureswings.Technology Protection – Black systems block visual inspection and are very difficult to remove withoutdestroying the underlying device, making it more difficult for competitors to reverse engineer.The three main chemistries in thermosetting, potting and encapsulation compounds are epoxies, siliconesand polyurethanes. Epoxies provide a set of benefits not seen with the other chemistries, some of which arelisted below:BENEFITS & FEATURES Cost effectiveEasy to useExtended shelf lifeRoom temperature shipping and storageRoom temperature cures are the normCuring can usually be accelerated with heatLow VOC’sIsocyanate-freeChemical resistancePrimerless adhesion to many substratesMore rigidExcellent moisture resistanceExcellent durabilityExcellent bond strengthMultifunctional protection4

All of our epoxy compounds share certain characteristics; however, the characteristics of each of our productsvary to meet the specific needs of the different applications they are intended to serve. Here are some of theways the characteristics of our compounds vary:UL Ratings – In the epoxy potting compound line, this comprises the UL 94 flammability rating and the UL746A certification for electrical and mechanical properties. Some industries, such as aerospace and defense,require UL listings to even consider using a product. All compounds in our 834 series are either in theprocess of being certified or are already UL certified to UL 94V-0.Thermal Conductivity – Certain applications involve a lot of heat generation at the board level, requiringthermal management considerations. As polymers are generally thermally insulative on their own, formulatingspecifically for thermal conductivity is important. Our thermally conductive compounds address the issueof thermal management by transferring the heat from the electronics through the potting compound, thusincreasing life span and reliability as well as reducing the overall temperature of components.Hard or Flexible – We offer epoxy potting compounds that are either hard (70-90 Shore D) or flexible (80-90Shore A). Certain applications require hard compounds; however, hard compounds can introduce stressesthat affect sensitive components in situations where a lot of thermal cycling occurs. Flexible epoxies providea low-stress option in sensitive applications where traditional hard options cannot be used but the corechemical properties of an epoxy are still desired.Optical Clarity – Most potting compounds are pigmented black to prevent visual inspection and maximizeradiative cooling. However, we offer products that are clear to allow visual inspection: 832C, which istranslucent amber, and 832WC, which is water-clear for maximum optical transmission.Mix Ratios – MG Chemical formulates epoxies with convenient 1:1 or 2:1 mix ratios for easy processing.In some of our specialty products, we utilize mix ratios that are 4:1 or 5:1 to achieve certain desirableproperties.Viscosity – Viscosity is the measurement of a product’s resistance to flow, and is usually measured incentipoise (cP). The viscosity is important for an application and should be considered during the designstage. Our products vary from low viscosity (less than 1000 cP, thin) to high viscosity (greater than 18000cP). Products that contain a lot of filler are usually thick, while some compounds can be extremely thin.Working Time – Our epoxies have various working times, depending on the specific resin and hardener beingused. Epoxies cure exothermically, and the reaction is accelerated through heat, meaning that a curing epoxyis self-accelerating. Depending on application needs, a low exotherm epoxy may be desired when workingwith larger quantities, and higher exotherm options may be desired for throughput when working with smallquantities. We measure and list our working times using 100 g batches of epoxy.Cure Schedule– Most epoxies can be cured at room temperature; however, optimal properties are achievedwhen using an elevated temperature. Generally, we try to provide multiple cure schedules, and the mostcommonly used cure temperatures are 25 C, 65 C, and 80 C. Typically, increasing temperature willdecrease cure time. Each system has a limit as to how high it can be heated without impairing the qualitiesof the cured product.5

832 SERIES– Non-UL spec products832B - Black, 2:1832HD - Black, 1:1A general epoxy potting and encapsulating compoundthat is extremely tough and durable.A general epoxy potting and encapsulatingcompound with a 1:1 volume mix ratio.BENEFITS & FEATURESBENEFITS & FEATURES 2:1 volume mix ratioVery high tensile strengthVery strong compressive strengthStrong flexural strength Cat. NumberPackagingNet VolumeNet Weight832B-375MLKit375 mL12.6 fl oz403 g832B-3LKit2.55 L0.68 gal2.74 kg832B-12LKit10.8 L2.88 gal832B-60LKit60 L16 galVery high lap shear strengthCat. NumberPackagingNet VolumeNet Weight0.89 lb832HD-25MLDual syringe*25 mL0.8 fl oz26.2 g0.92 oz6.04 lb832HD-50MLDual cartridge*50 mL1.6 fl oz52.5 g1.85 oz11.6 kg25.6 lb832HD-400MLDual cartridge400 mL 13.5 fl oz420 g14.8 oz64.5 kg142 lb832HD-7.4LKit7.4 L1.9 gal7.77 kg17.1 lb832HD-40LKit40 L10 gal42 gal92 lb832C - Translucent832WC - Water ClearA general epoxy potting and encapsulating compoundthat is a translucent amber color.An optically clear compound for encapsulatingLED’s, fiber optics, or any potting or adhesiveapplication requiring optimal clarityBENEFITS & FEATURES BENEFITS & FEATURES2:1 volume mix ratioAmber color allows for visual inspectionVery high tensile strengthVery strong compressive strengthVery high electrical resistivity Cat. NumberPackagingNet Volume12.9 oz832WC-375MLKit375 mL 12.6 fl oz483 g15.5 oz832WC-3LKit2.7 L2.85 qt5.39 pt2.73 kg6.0 lb832WC-12LKit10.8 L16 gal64.3 kg142 lb832WC-60LKit60 LCat. NumberPackagingNet Volume832C-375MLKit375 mL 12.7 fl oz402 g832C-450MLDual cartridge450 mL 25.3 fl oz832C-3LKit2.55 L832C-60LKit60 L62:1 volume mix ratioOptically clearMinimal yellowing over timeNet Weight*Dispensing gun(s) and / or additional static mixers available. See website for details.Net Weight401 g14.1 oz2.89 kg6.37 lb2.88 gal 11.5 kg25.5 lb16 gal64.2 kg141 lb

832FX - FlexibleFor use in stress-sensitive or low temperatureapplications.BENEFITS & FEATURES 1:1 volume mix ratioSoft, 88 Shore A hardnessLow mixed viscosity of 700 cPLow Tg of 8.8 CCat. NumberPackagingNet VolumeNet Weight832FX-450MLKit450 mL15.2 fl oz475 g1.05 lb832FX-1.7LKit1.7 L57 fl oz1.8 kg3.9 lb832FX-7.4LKit7.4 L1.9 gal7.82 kg17.2 lb832FX-40LKit40 L10 gal42.2 kg93.2 lb832TC - Thermally Conductive832HT - High TemperatureFor use when potting heat generating components.For use in high temperature applications, orapplications requiring strong chemical resistance orphysical strength.BENEFITS & FEATURESBENEFITS & FEATURES 1:1 volume mix ratioGood thermal conductivityGood lap shear strengthLow exothermLong working time of 2 hoursNet VolumeNet Weight2:1 weight mix ratioHigh tensile strengthVery high dielectric strengthStrong compressive strengthStrong flexural strengthGood lap shear strengthExcellent chemical resistanceHigh Tg of 89 CCat. NumberPackagingCat. NumberPackaging832TC-450MLKit450 mL15.2 fl oz752 g1.66 lb832HT-375MLKit340 mL11.5 fl oz377 g12.1 oz832TC-2LKit1.7 L0.45 gal2.84 kg6.26 lb832HT-3LKit2.3 L2.43 qt2.55 kg5.62 lb832TC-8LKit7.2 L1.92 gal12.0 kg26.5 lb832TC-40LKit40 L10.7 gal66.8 kg147 lbNet VolumeNet Weight7

832 Series Epoxy Comparison ChartUncured Properties832B832C832HD832TC832HT832FX832WCMix Ratio by Vol. (A:B)2:12:11:11:11.7:11:12:1Viscosity Mixture3 300 cP2 700 cP4 100 cP18 000 cP21 900 cP700 cP979 cPPart A2 200 cP1 900 cP5 900 cP36 000 cP46 400 cP800 cP2 860 cPPart B5 800 cP5 800 cP2 300 cP14 000 cP6 600 cP165 cP340 cPWorking Time @22 C1h1h45 min2h1h2.5 h1hFull Cure @22 C24 h24 h24 h96 h24 h48 h72 hFull Cure @65 C1h1h2h2h1h2hTBDCured ackTranslucentBlackBlackBlackBlackOptically clearDensity1.11 g/mL1.12 g/mL1.07 g/mL1.83 g/mL1.10 g/mL1.08 g/mL1.06 g/mLHardness80D84D80D82D87D88A82DTensile Strength57 N/mm256 N/mm232 N/mm218 N/mm248 N/mm29.6 N/mm210 e Strength155 N/mm2182 N/mm275 N/mm229 N/mm2130 N/mm2TBD157 N/mm2Flexural Strength114 N/mm38 N/mmTBD37 N/mm101 N/mmTBDTBDLap Shear Strength, Stainless steel4.2 N/mm24.4 N/mm221 N/mm213 N/mm215 N/mm2TBD3.3 N/mm2Izod Impact0.93 kJ/m1.5 kJ/mTBD1.7 kJ/mTBDTBDTBDVolume Resistivity5.3 x 1012 Ω cm1.2 x 1016 Ω cm1.4 x 1013 Ω cm2.6 x 1015 Ω cm1 x 1013 Ω cm5.8 x 1012 Ω cm1.6 x 1017 Ω cmSurface ResistivityTBD5.5 x 1015 ΩTBD3.2 x 1015 ΩTBDTBDTBDDielectric Strength @1/8”442 V/mil406 V/mil365/mil370 V/mil 430 V/mil343 V/mil394 V/milBreakdown Voltage @1/8”55.3 kV50.7 kV45.7 kV46.2 kV 54 kV42.8 kV49 kVDielectric Constant @1 MHz2.77TBD2.534.412.833.063.23Dielectric Dissipation @1 MHz0.017TBD0.0410.0110.0140.0500.028Thermal Conductivity @25 C0.26 W/(m K)0.28 W/(m K)0.27 W/(m K)0.68 W/(m K)0.27 W/(m K)0.26 W/(m K)TBDSpecific Heat Capacity @25 C2.2 J/(g K)2.1 J/(g K)2.0 J/(g K)TBD1.6 J/(g K)2.7 J/(g K)TBDHeat Deflection Temp.47 C44 CTBD35 C54 CTBDTBDGlass Transition Temp. (Tg)49 C35 C41 C25 C89 C8.8 C33 CCTE prior Tg79 ppm/ C77 ppm/ C73 ppm/ C66 ppm/ C86 ppm/ C114 ppm/ C80 ppm/ CCTE after Tg196 ppm/ C195 ppm/ C207 ppm/ C167 ppm/ C152 ppm/ C218 ppm/ C192 ppm/ CConstant Service Temp.-40 to 140 C-40 to 140 C-40 to 150 C-30 to 175 C-40 to 225 C-40 to 140 C-40 to 140 CMaximum Intermittent Temp.175 C175 C175 C200 C250 C150 C155 CMechanical Properties2222222Electrical PropertiesThermal PropertiesTBD To be determined11 December 2017Available Packaging (cartridges)For kits packaging see pages 10 & 11Dispensing tools(Sold separately)Dispensing tools(Sold separately)8DG-450-2-1825 mL DualCartridge50 mL DualCartridge8DG-50-1-18MT-258MT-50450 mL DualCartridge8MT-450

834 Series– Compounds meeting the UL 746A StandardAll compounds in the 834 series are designed to meet the UL746A Standard for polymeric materials.The UL 746A Standard provides data regarding the physical, electrical, flammability, thermal, and otherproperties of the materials, and is intended to furnish guidance to the material manufacturers, molders, endproduct manufacturers, safety engineers, and other interested parties.834B - Balanced Formula834FRB - Low ViscosityA good standard potting compound. Suitable formost applications.Flame retardant but not thermally conductive. Thelack of thermal fillers allows better flow and physicalstrength.BENEFITS & FEATURESBENEFITS & FEATURES 2:1 volume mix ratioHigh thermal conductivityHalogen freeCat. NumberPackagingNet Volume834B-375MLKit375 mL 12.6 fl oz834B-2.7LKit2.7 L2.85 qt834B-10.8LKit834B-60LKitNet Weight2:1 volume mix ratioVery high lap shear strengthVery flowableExcellent CTI ( 600 V, PLC 0)Low thermal conductivityCat. NumberPackagingNet VolumeNet Weight597 g1.31 lb834FRB-375MLKit375 mL12.6 fl oz475 g1.05 lb4.3 kg9.48 lb834FRB-3LKit3L3.17 qt3.81 kg8.39 lb10.8 L2.85 gal 17.2 kg37.9 lb8324FRB-60LKit60 L16 gal76.1 kg167 lb60 L15.8 gal 95.6 kg210 lb9

834ATH - Economical834FX - FlexiblePigmented with aluminum trihydrate (ATH),providing a cost-effective solution with some thermalconductivity.For use in stress-sensitive or low temperatureapplications.BENEFITS & FEATURESBENEFITS & FEATURES 2:1 volume mix ratioThermally conductiveCost EffectiveGood compressive strengthGood lap sheer strengthLow impact resistanceNet Volume Cat. NumberPackagingNet Weight834ATH-375MLKit375 mL12.6 fl oz516 g1.13 lb834ATH-3LKit2.55 L2.69 qt3.5 kg7.73 lb834ATH-60LKit60 L16 gal82.5 kg182 lb1:1 volume mix ratioGood thermal conductivity: 0.61 W/m.KSoft, 88 Shore A HardnessLow Tg of 0.7 C.Halogen freeLow constant service temperature limitLong working time of 2.5 hoursLow exotherm834HTC - High Thermal ConductivityUse when high thermal conductivity is essential.BENEFITS & FEATURES 5:1 volume mix ratioHigh thermal conductivity of 1.0 W/m.KHalogen freeCat. NumberPackagingNet Volume834THC-900MLKit900 mL1.9 pt1.53 kg834THC-4.25LKit4.25 L1.13 gal7.25 kgCat. NumberPackaging3.38 lb834FX-450MLKit450 mL15.2 fl oz728 g1.6 lb15.9 lb834FX-1.7LKit1.7 L1.79 qt2.75 kg6.06 lb834FX-7.4LKit7.4 L1.92 gal11.6 kg25.6 lb834FX-40LKit40 L10.6 gal64.8 kg142 lbNet WeightNet VolumeNet WeightAvailable Packaging (kits)10375mL Kit900mL Kit1.7L Kit3L Kit4.25L Kit

834 Series Epoxy UL Rated Comparison ChartUncured Properties834B834FRB834FX834HTC834ATHMix Ratio by Vol. (A:B)2:12:11:15:12:1Viscosity Mixture16 200 cP2 600 cP10 800 cP10 500 cP5 900 cPPart A27 500 cP1 900 cP4 560 cP55 900 cP4 600 cPPart B2 100 cP4 800 cP4 670 cP24 cP12 900 cPWorking Time @22 C1h1h2.5 h1.5 h2hFull Cure @22 C48 h24 h48 h24 h24 hFull Cure @65 C3h1h3h2h1 h @80 CCured ckBlackBlackBlackDensity1.59 g/mL1.39 g/mL1.64 g/mL1.69 g/mL1.40 g/mLHardness85D83D88A91D85DUL 94V-0 Certification File #MeetsE334302MeetsMeetsE334302Halogen FreeNoNoYesYesNoTensile Strength17 N/mm223 N/mm25.3 N/mm222 N/mm228 N/mm2Compressive Strength74 N/mm2140 N/mm214 N/mm2123 N/mm2100 N/mm2Flexural StrengthTBD65 N/mm2TBDTBD51 N/mm2Lap Shear Strength, Stainless steel8.2 N/mm224 N/mm23.7 N/mm26.7 N/mm215 N/mm2, AlIzod ImpactTBD2.39 kJ/m2TBDN/A0.02 kJ/m2Volume Resistivity2.1 x 1012 Ω cm1.4 x 1015 Ω cm7.5 x 1011 Ω cm3.0 x 1013 Ω cm7 x 1014 Ω cmDielectric Strength @1/8”376 V/mil344 V/mil330 V/mil345 V/mil380 V/milBreakdown Voltage @1/8”47 kV43.0 kV41.4 kV43.1 kV47 kVDielectric Constant @1 MHz3.102.804.503.913.07Dielectric Dissipation @1 MHz0.0100.0110.0440.0190.016Thermal Conductivity @25 C0.79 W/(m K)0.28 W/(m K)0.61 W/(m K)0.94 W/(m K)0.37 W/(m K)Specific Heat Capacity @25 C1.5 J/(g K)TBD1.4 J/(g K)1.3 J/(g K)1.2 J/(g K)Heat Deflection TemperatureTBDTBDTBDTBD54 CGlass Transition Temperature (Tg)56 C39 C0.7 C52 C51 CCTE prior Tg74 ppm/ C50 ppm/ C71 ppm/ C34 ppm/ C84 ppm/ CCTE after Tg107 ppm/ C178 ppm/ C137 ppm/ C116 ppm/ C178 ppm/ CConstant Service Temperature-40 to 175 C-40 to 175 C-50 to 150 C-50 to 150 C-40 to 175 CMaximum Intermittent Temperature200 C200 C165 C165 C200 CMechanical PropertiesElectrical PropertiesThermal PropertiesTBD To be determined11 December 2017Available Packaging (kits)7.4L Kit10.8L Kit40L Kit60L Kit11

HEAD OFFICE 9347 - 193rd StreetSurrey, B.C., CanadaV4N 4E7Phone te mgchemicals.comMANUFACTURING 1210 Corporate DriveBurlington, Ontario, CanadaL7L 5R6Phone te mgchemicals.comCUSTOMER SERVICENORTH AMERICA Phone 1-800-340-0772Fax1-800-340-0773Email East SalesEast@mgchemicals.comEmail west SalesWest@mgchemicals.comEUROPE AND UK Phone 44 1663 362888Email SalesUK@mgchemicals.com comFOR SAFETY DATA SHEETS PhoneFaxEmail OR TECHNICAL Toll-free line 1-800-340-0772or 1 905 331-139612Printed in Canadawww.mgchemicals.comVersion # 18120

A general epoxy potting and encapsulating compound that is extremely tough and durable. A general epoxy potting and encapsulating compound with a 1:1 volume mix ratio. A general epoxy potting and encapsulating compound that is a translucent amber color. An optically clear compound for encapsulating LED's, fiber optics, or any potting or adhesive