Transcription

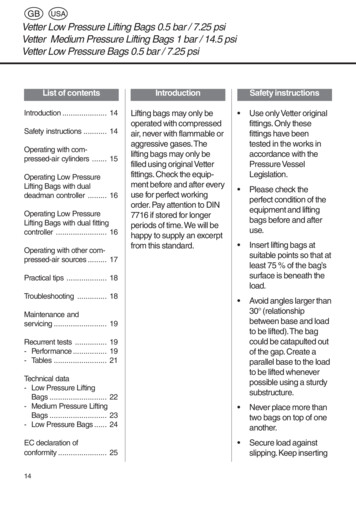

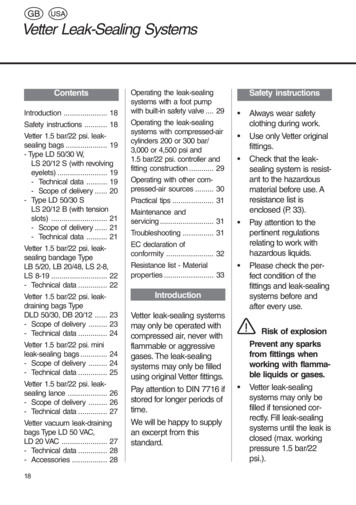

Vetter Leak-Sealing SystemsContentsIntroduction . 18Safety instructions . 18Vetter 1.5 bar/22 psi. leaksealing bags . 19- Type LD 50/30 W,LS 20/12 S (with revolvingeyelets) . 19- Technical data . 19- Scope of delivery . 20- Type LD 50/30 SLS 20/12 B (with tensionslots) . 21- Scope of delivery . 21- Technical data . 21Vetter 1.5 bar/22 psi. leaksealing bandage TypeLB 5/20, LB 20/48, LS 2-8,LS 8-19 . 22- Technical data . 22Vetter 1.5 bar/22 psi. leakdraining bags TypeDLD 50/30, DB 20/12 . 23- Scope of delivery . 23- Technical data . 24Vetter 1.5 bar/22 psi. minileak-sealing bags . 24- Scope of delivery . 24- Technical data . 25Vetter 1.5 bar/22 psi. leaksealing lance . 26- Scope of delivery . 26- Technical data . 27Vetter vacuum leak-drainingbags Type LD 50 VAC,LD 20 VAC . 27- Technical data . 28- Accessories . 2818Operating the leak-sealingsystems with a foot pumpwith built-in safety valve . 29Operating the leak-sealingsystems with compressed-aircylinders 200 or 300 bar/3,000 or 4,500 psi and1.5 bar/22 psi. controller andfitting construction . 29Safety instructions Operating with other compressed-air sources . 30Practical tips . 31Maintenance andservicing . 31 Troubleshooting . 31EC declaration ofconformity . 32Resistance list - Materialproperties . 33 IntroductionVetter leak-sealing systemsmay only be operated withcompressed air, never withflammable or aggressivegases. The leak-sealingsystems may only be filledusing original Vetter fittings.Pay attention to DIN 7716 ifstored for longer periods oftime.We will be happy to supplyan excerpt from thisstandard. Always wear safetyclothing during work.Use only Vetter originalfittings.Check that the leaksealing system is resistant to the hazardousmaterial before use. Aresistance list isenclosed (P. 33).Pay attention to thepertinent regulationsrelating to work withhazardous liquids.Please check the perfect condition of thefittings and leak-sealingsystems before andafter every use.Risk of explosionPrevent any sparksfrom fittings whenworking with flammable liquids or gases.Vetter leak-sealingsystems may only befilled if tensioned correctly. Fill leak-sealingsystems until the leak isclosed (max. workingpressure 1.5 bar/22psi.).

A leak in a tank or pipeis a weak spot. Youshould thus avoid anyother damage by onlyinflating the leak-sealingsystem until no moreliquid escapes. Thismay occur at a pressure lower than themaximum workingpressureThe PVC acidproofenvelope (accessory)for the leak-sealing bagprovides additionalprotection against acidsplashes.Sharp edges or pointsin the area of the leakmust be adequatelycovered with suitablydimensioned sealingplates before fitting theleak-sealing systems.Vetter leak-sealing bagsLD 50/30Apply leak-sealing bags insuch a way that the complete leak is covered.Tensioning the strapsPass the end of the strapthrough the slot in theratchet and tighten byhand. The strap is tensioned with the operating lever.The leak-sealing bag canbe filled following correcttensioning (see section“Operating the leak-sealingsystems”, P. 29-30).LD 50/30 W / LS 20/12 S(with revolving eyelets)Fit tensioning and ratchetstraps to the rotatingeyelets on the bag withcarbine swivels.Pass straps around tankmaking sure that they runparallel. Differentiation isfacilitated by differentcoloured straps (orange/blue).Technical data Vetter leak-sealing bags LD 50/30W;LS 20/12 STypeLD 50/30 WLS 20/12 SArticle no.155 01 000155 01 000Sizecmin.69 x 3127 x 12Sealing areacmin.50 x 3020 x 12Max. working pressurebarpsi.1.522Test pressurebarpsi.1.9528Max. sealing pressurebarpsi.1.420Nominal contentlitrescu.ft.7.00.25Weightkglbs.6.915.219

Vetter Leak-Sealing SystemsScope of deliveryLD 50/30W; LS 20/12 S(Figure 1)Vetter 1.5 bar/22 psi. leaksealing bag set, Type LD50/30 W; LS 20/12 S (withrevolving eyelets), Art. No.155 00 000, consisting of:1 x foot pump with safety valve1 x filling hose, 10 m/ 32 ft., blue1 x leak-sealing bag, TypeLD 50/30 W; LS 20/12 S withrevolving eyelets1 x ratchet strap 2 m/6.6 ft.,orange1 x ratchet strap, 2 m/6.6 ft., blue1 x extension strap, 5 m/16 ft.,orange1 x extension strap, 5 m/16 ft.,blue1 x tensioning and extensionstrap, 10 m/32 ft., orange, withratchet1 x tensioning and extension strap,10 m/32 ft., blue, with ratchet2 x sealing plates,600 x 300 x 30 mm/24 x 12 x 1.2 in.1 x sealing plate,1000 x 300 x 30 mm/39 x 12 x 1.2 in.1 acidproof envelope, PVC,yellow, for LD 50/30 W;LS 20/12 SFigure 1: Scope of delivery Vetter 1.5 bar/22 psi. leaksealing bag set, type LD 50/03 W; LS 20/12 S(with revolving eyelets)Weight: 25 kg/55 lbs.Alternative accessories:1 x pressure reducer200/300 bar/3,000/4,500 psi.1 x controller 1.5 bar/22 psi., fitting20Figure 2: Scope of delivery Vetter 1.5 bar/22 psi. leaksealing bag set, type LD 50/30 S; LS 20/12 B(with tension slots)

LD 50/30 S; LS 20/12 B(with tension slots)Pass tensioning andextension straps throughtension slots in bag.The straps over the leaksealing bag exert anadditional pressure.Make sure that the strapsrun parallel. Differentiationis facilitated by differentcoloured straps (orange/blue).Leak-sealing bags mayonly be filled when strapped in place correctly.The leak-sealing bag canbe emptied if there is nolonger any counterpressure.Then relieve the ratchetstraps by releasing theshackle.Scope of deliveryLD 50/30 S; LS 20/12 B(Figure 2)Vetter 1.5 bar/22 psi. leaksealing bag set, Type LD50/30 S; LS 20/12 B (withtension slots), Art. No.156 00 000, consisting of:1 x foot pump with safety valve1 x filling hose, 10 m/32 ft., blue1 x leak-sealing bag, Type LD 50/30 S; LS 20/12 B with strapslots2 x tensioning and extensionstrap, 10 m/32 ft., orange, withratchet2 x tensioning and extensionstrap, 10 m/32 ft., blue, withratchet2 x sealing plates,600 x 300 x 30 mm/24 x 12 x 1.2 in.1 x sealing plate,1000 x 300 x 30 mm/39 x 12 x 1.2 in.1 x acidproof envelope, PVC,yellow, for LD 50/30 S; LS 20/12 BWeight: 16.9 kg/37 lbs.Alternative accessories:1 x pressure reducer200/300 bar/3,000/4,500 psi.1 x controller 1.5 bar/22 psi., fittingTechnical data Vetter leak-sealing bags LD 50/30S;LS 20/12 BTypeLD 50/30 SLS 20/12 BArticle no.156 01 000156 01 000Sizecmin.61.5 x 3124 x 12Sealing areacmin.50 x 3020 x 12Max. working pressurebarpsi.1.522Test pressurebarpsi.1.9528Max. sealing pressurebarpsi.1.420Nominal contentlitrescu.ft.7.00.25Weightkglbs.4.29.221

Vetter Leak-Sealing SystemsVetter leak-sealingbandageDetermine the diameter ofthe pipe and select thesuitable leak-sealingbandage size.Place the leak-sealingbandage around the pipe.The bandage shouldsurround the pipe with atleast one overlap. Theenclosed spacers ensure aparallel arrangement of thestraps.Pass the strap through thecentral part of the ratchetand tighten.Fill the leak-sealing bandage in the manner described in the section“Operating the leak-sealingsystems” (P. 29-30).Empty the leak-sealingbandage if there is nolonger any counterpressure in the pipelineand release the ratchetstraps.22Figure 3: Scope of delivery Vetter 1.5 bar/22 psi. leaksealing bandage setTechnical data Vetter 1.5 bar/22 psi. leak-sealingbandageTypeLB 5-20LS 2-8LB 20-48LS 8-19Article no.185 01 000185 01 000185 02 000185 02 000Sizecmin.98 x 2139 x 8177 x 2170 x 8Sealing areacmin.19 wide7 wide19 wide7 wideWorking pressurebarpsi.1.5221.522Test pressurebarpsi.1.95281.9528Sealing pressurebarpsi.1.4201.420Nominal 8

Vetter leak-draining bagsPosition leak-draining bagsover the leak. Pay attentionto the drain chamber sizeof 32 x 13 cm/13 x 5 in.Tensioning the strapsPass the tensioning andextension straps throughthe tension slots in the bag.Pass the end of the strapthrough the slot in theratchet and tighten byhand. The strap is tensioned with the operating lever.The leak-draining bag canbe filled following correcttensioning (see section“Operating the leak-sealingsystems”, P. 29-30).Then relieve the ratchetstraps by releasing theshackle.2 x tensioning and extensionstrap, 10 m/32 ft., blue, withratchet1 x ball valve, stainless steel,Storz DScope of delivery(Figure 4)Vetter 1.5 bar/22 psi. leakdraining bag set, Type DLD50/30; DB 20/12, Art. No.157 00 000, consisting of:Weight: 21.7 kg/48 lbs.Alternative accessories:1 x pressure reducer200/300 bar/3,000/4,500 psi.1 x controller 1.5 bar/22 psi., fitting1 x foot pump with safety valve1 x filling hose, 10 m/32 ft., blue1 x leak-draining bag, type DLD50/30; DB 20/12, with stainless steel coupling, Storz D2 x tensioning and extensionstrap, 10 m/32 ft., orange, withratchetThe excess pressure canbe relieved via the drainchamber and the mediumdrained.For this purpose the, stainless steel ball valve (accessory) must be fitted beforefilling the leak-draining bagand a collecting vessel provided.The leak-draining bag canbe emptied if there is nolonger any counterpressure.Figure 4: Scope of delivery Vetter 1.5 bar/22 psi. leakdraining bag set23

Vetter Leak-Sealing SystemsTechnical data Vetter 1.5 bar/22 psi. leak-draining bagTypeDLD 50/30DB 20/12Article no.157 01 000157 01 000Sizecmin.62 x 3024 x 12Sealing areacmin.50 x 3020 x 12Drain chambercmin.40 x 20 x 3.516 x 8 x 1.3Max. working pressurebarpsi.1.522Test pressurebarpsi.1.9528Max. sealing pressurebarpsi.1.014Nominal contentlitrescu.ft.2.50.09Weightkglbs.7.617Vetter Mini leak-sealingbagsSelect the largest possiblebag according to the sizeof the leak and tank.Prepare tensioning straps.Place bag over centre ofleak and lay tensioningstraps under tensionaround the tank and overthe mini leak-sealing bag.Press hook-and-eyefastener together overcomplete surface.24Tensioning straps can becoupled together for tankswith larger diameters.When using LDK 10/25 orLDK 20/20, MS 6/12 or MS10/10 it may prove practicalto use the tensioningstraps in pairs and inparallel.The mini leak-sealing bagcan be filled followingcorrect tensioning (seesection “Operating theleak-sealing systems”, P.29-30).Once the tank has beenemptied, empty the minileak-sealing bag andrelease the tensioningstraps.Scope of delivery(Figure 5)Vetter mini leak-sealingbag set, Art. No.158 10 000, consisting of:Mini leak-sealing bag, TypeLDK 10/10, LDK 10/25,LDK 20/20, MS 6/6,MS 6/12, MS 8/81 x foot pump with safety valve2 x tensioning straps 150 cm/5 ft.long, blue, with hook-and-eyefastener3 x tensioning straps 350 cm/10 ft. long, blue, with hookand-eye fastener1 x carrying case. dimensions 37x 35 x 13.5 cm/ 15 x 15 x 5 in.Weight: 11.5 kg/25 lbs.

Technical data Vetter 1.5 bar min leak-sealing bagTypeModelLDK 10/10MS 6/6LDK 10/25MS 6/12LDK 20/20MS 10/10Article no.158 01 000158 01 000158 02 000158 02 000158 03 000158 03 000Size (L x W x H)cmin.15.0 x 15.0 x 1.26 x 6 x 0.515.0 x 31.0 x 1.26 x 12 x 0.525.0 x 25.0 x 1.210 x 10 x 0.5Sealing areacmin.9.5 x 9.54x49.5 x 25.54 x 1019.5 x 19.58x8Max. working pressurebarpsi.1.5221.5221.522Test presurebarpsi.1.95281.95281.9528Max. sealing pressurebarpsi.1.4201.4201.420Nominal bs.0.51.10.81.81.02.2Figure 5: Scope of delivery Vetter 1.5 bar/22 psi. minileak-sealing bag set25

Vetter Leak-Sealing SystemsVetter leak-sealing lanceSelect a wedge or conicalbag according to the sizeof the leak.Connect bag, lance andconnection hose for thefoot pump.Press the nipple into thecoupling until it catches inplace.Insert the bag into the leak.Fill the bag using the footpump until the leak issealed (max. workingpressure 1.5 bar/22 psi.).Scope of delivery(Figure 6)Vetter 1.5 bar/22 psi. leaksealing lance set, Art. No.158 20 000, consisting of:1 x wedge bag size 6 cm/2.4 in.1 x wedge bag size 8 cm/3.2 in.1 x wedge bag size 11cm/4.3 in.1 x conical bag size 7 cm/2.8 in.1 x lance, 35 cm/13.8 in. long,with chain and ventilatingnozzle3 x lance, each 35 cm/13.8in. long1 x shut-off device1 x foot pump with safetyvalve1 x carrying case. dimensions37 x 35 x 13.5 cm/14 x 13 x 5 in.Weight: 9 kg/20 lbs.Close ball valve.AttentionSharp edges aroundthe leak hole candamage the bag.At the end of work, emptythe bag using the pressurerelief device of the footpump’s safety valve. Do notuse the wedge or conicalbags if they display visiblesigns of damage.Figure 6: Scope of delivery Vetter 1.5 bar/22 psi. leaksealing lance set26

Technical data Vetter 1.5 bar/22 psi leak-sealing lanceTypeModelWedge bag 6Wedge bag 8Wedge bag 2.4 Wedge bag 3.2Wedge bag 11Wedge bag 4.3Conical bag 7Conical bag 2.8Article no.158 21 000158 21 000158 22 000158 22 000158 23 000158 23 000158 24 000158 24 000cmin.cmin.23 x 6 x 59x2x229 x 6 x 59.24 x 2 x 223 x 8 x 5,59x3x229 x 8 x 5,59.24 x 3 x 223 x 11 x 79x4x329 x 11 x 79.24 x 4 x 323 x 7 Ø9x3xØ29 x 7 Ø9.24 x 3 ØMax. working pressurebarpsi.1.5221.5221.5221.522Nominal ightkglbs.0.240.50.280.60.420.90.160.4For leak openingscm1.5 - 4.5width 6-80.6-1.8width 2.4-3.11.5 - 4.5width 8-110.6-1.8width 2.4-4.33-6width 11-171.2-2.4width 4.3-6.73-9Bag size (L x W x H)with coupling (L x W x H)in.Vetter vacuum leakdraining bagsVacuum leak-draining bagscan only be used on surfaces with a small curvature and smooth structure.The surface of the tankshould be clean.Use only Vetter original fittings with the vacuum leakdraining bags.The following information relates to the use ofcompressed-air fromcompressed-aircylinders 200 or 300bar/3,000 or 4,500 psi.Set the back pressure atthe pressure reducer to atleast 2 bar/28 psi. Checkthe display at the manometer.Connect the pressurereducer’s hose to thevacuum nozzle, if necessary this can be extendedwith the 10 m/32 ft. airsupply hose, green (accessory). Push nipple intocoupling until it catches.Connect and lock thevacuum nozzle with venthose to the bag’s vacuumconnection.1.2-3.6Couple the stainless steelball valve with drain hose tothe vacuum leak-drainingbag and open the ballvalve. Open the shut-offvalve of the pressurereducer and the vacuumvalve until air is heard toflow through these.Press the vacuum leakdraining bag against thewall of the tank so that thedrain chamber lies over thecentre of the leak (payattention to the drainchamber diameter of200 mm/8 in.).27

Vetter Leak-Sealing SystemsThe complete outer rubberlip of the bag must restagainst the wall of the tank.You may have to press thevacuum leak-draining bagagainst the wall of a curvedtank with both hands.Always keep an eye on thevacuum manometer andvacuum leak-draining bagand do not interrupt theflow of air.The liquid can be drainedinto a collecting vessel withthe ball valve. The vacuumnozzle’s vent hose mustalso end in a tank to safelydrain any remaining liquidwithin the vacuum chamber.Figure 7: Scope of deliveryof Vetter vacuum leakdraining bag setExample of air requirementCompressed air cylinder6 l, 300 bar/4,500 psi. at28SupplypressureVacuumDuration2 bar28 psi0.15 bar2.1 psi20 min.3 bar42 psi0.25 bar3.5 psi14 min4 bar56 psi0.38 bar5.3 psi10 minMinimum compressoroutput: 200 l/min at 4 bar/56 psiUse a Y-adapter if anumber of compressed-aircylinders are used.The bag’s vacuum can beincreased if necessary bywetting the sealing lips withsoap or water before use.Marks on the defectivetank facilitate a centringof the vacuum leakdraining bag’s drainchamber.Accessories:Ball valve, stainless steel,Storz DY-adapterTechnical data for Vetter vacuum leak-draining bagsTypeModelLD 50 VACLD 20 VACArticle no.157 05 000157 05 000Size500 mm diameter20 in. diameterSize of drain chamber200 mm diameter8 in. diameterHeight40 mm1.6 in.Height with fittings105 mm4 in.Weight5.2 kg11 lbs.Max. working pressure6 bar87 psiAir requirements200 l / min7 cu.ft.Drain connectionStorz Size D1“, V4AStorz Size D1“, V4A

Operating the leaksealing systems with afoot pump with built-insafety valvevalve by turning to the leftto empty the leak-sealingsystem.Operating the leaksealing systems withcompressed-air cylinders 200 or 300 bar/3,000or 4,500 psi. and 1.5 bar/22 psi. controller andfitting constructionConnect supply hose offoot pump to filling hose ofleak-sealing system withnipple.Push nipple into couplinguntil it catches.Fill leak-sealing systemwith foot pump.Keep an eye on the manometer and leak-sealingsystem during filling.The safety valve blows off ifthe working pressureexceeds 1.5 bar/22 psi.The maximum tolerancefor an opening and closingof the safety valve may be 10 %.The manometer at the footpump shows the pressurein the bag. Open the venton the head of the safetyVetter leak-sealing systemscan be operated with compressed-air cylinders 200or 300 bar/3,000 or 4,500psi. and 1.5 bar/22 psi.controller and fittingconstruction.Connect the controller tothe leak-sealing systemwith the filling hose (blue).12534Push nipple into couplinguntil it catches.Connect pressure reducerwith T-screw to compressed-air cylinder.Close handwheel (3) ofpressure reducer and opencylinder valve (5).Manometer (1) shows thepressure in the cylinder.Set the back pressure tomax. 3 bar with the adjusting screw (4). Keep aneye on the back pressuremanometer.Connect pressure reducer’s supply hose(green) to controller.Push brass nipple intobrass coupling until itcatches.Slowly open the controller’sball valve to fill the leaksealing system.Keep an eye on the manometer and leak-sealingsystem.The safety valve blows off ifthe working pressure exceeds 1.5 bar/22 psi.The maximum tolerancefor an opening and closingof the safety valve may be 10 %.29

Vetter Leak-Sealing SystemsThe manometer at thecontroller shows thepressure in the bag. Openthe vent on the head of thesafety valve by turning tothe left to empty the leaksealing system.9Operating with othercompressed-air sourcesVetter leak-sealing systemscan also be operated withother compressed-air witha 1.5 bar/22 psi. controller(fitting construction) andfilling hose. Compressed-air mains(3) Truck tyre inflator (6)WarningThe supply pressure of thecontroller may not exceed3 bar/44 psi.Use a series pressurereducer with higherpressures.Tyre inflation connector must be protectedby a safety valve. Vetter adaptor sets areavailable for other compressed-air sources. 6530Seal off control linewith the dummycoupling (2). Securetruck with wheelblocks.43Truck air brakesystems (1)Warning217 Truck tyre valve connector (5). To take airfrom the spare tyre. Building site compressor (7). Hand (8) or foot (9)pump with manometerand 2 m/6.6 ft. airsupply hose for directconnection to thecontroller.8Truck tyre valve (4). Forinflation with a normalhand or foot pump.

Practical tipsTanks and pipelines up to amax. counterpressure of1.4 bar/20 psi. can besealed with Vetter leaksealing systems.In special cases the leaksealing systems can beprotected by more resistantmaterials inserted betweenthe leak-sealing systemand tank.To ensure that the correctside of the leak-sealingdevice is placed againstthe tank in unfavourableconditions, e.g. in darkness, the outer face has afluted surface.Maintenance andservicingAfter every use Check Vetter leaksealing systems andaccessories for completeness and perfectcondition. Clean the bag with luke,warm soapy water andcheck for damages. Remove and replacethe acidproof protectiveenvelope if necessary.After longer periods ofstorage Check Vetter leaksealing systems andaccessories for completeness and perfectcondition.Visual and functionalchecks Hoses: check operability of couplings Control organs: checkoperability of safetyvalves, couplings andmanometer.The leak-sealing bags canbe cleaned with soap andwarm water.Dry at room temperature.TroubleshootingIf a safety valve opensprematurely because aforeign body has penetrated the system, open thedischarge device (2) at thehead of the safety valvebriefly by turning anticlockwise so that compressedair can escape.If this does not remove theforeign body the top part ofthe valve must be unscrewed. Use a pipewrench at point 1.2131

Vetter Leak-Sealing SystemsCarefully remove the valvecone and remove theforeign body in front of thesealing plate.Screw the top part of thevalve back on tight andcheck for perfect operation.The pre-set pressure maynot be changed.If the lead or leaded plateon the top part of the valveis removed a safe functioncan no longer be guaranteed and the device shouldbe returned to the manufacturer.If this ices up because ofan excess atmospherichumidity in connection withlow temperatures use anormal defroster (such asis used for car locks).EC Declaration of Conformity in the intendment ofthe EC Machine Directive 89 / 392 / EECWeManfred Vetter GmbH & Comp.Blatzheimer Strasse 10-12D-53909 Zülpichhereby declare that the leak-sealing systems(LD 50/30, LB 5-20, LB 20-48, DLD 50/30, LDK 10/10,LDK 10/225, LDK 20/20, leak-sealing lance, LD 50VAC) to seal leaksSerial No.:Design:(see ratings plate, to be completed by customer)comply with the following pertinent regulations in theirstandard design:Machine Directive 89 / 392 / EECas amended by Directives 91 / 368 / EEC,93 / 44 / EEC, 94 / 68 / EEC.Harmonised standards employed:EN 292 Part 1 / 2National standards and technical specifications employed:Pressure Vessel LegislationInternal measures ensure that the standard leak-sealingsystems always comply with the requirements of the latestEC Directives and applicable standards.Zülpich, October 27, 199532

Resistance list - Material propertiesPipe-sealing bags(standard)Gully-sealing bagsLeak-sealing lancesVacuum leakdraining bagsMini lifting bags(special)Leak-sealing bagsType WLeak-sealingbandagesMini lifting bagsViton* sealing(standard)bagsLifting bags0.5/1.0 bar/7/14 psi.Pipe-sealing bags(special)Leak-sealing bagsType SLeak-sealing bandagesLeak-draining bagsUniversal gully-sealingbagsMaterial AMaterial BMaterial CAbrasion resistanceexcellentgoodexcellentgoodDielectric propertiesexcellentlowgoodgoodElectrical isolationresistancegood to excellentlowmoderate to goodmoderate to goodmoderate to goodmoderate to oderate to goodexcellentgoodlowmoderate to temoderatelow to moderatelowlowlow to moderatelow to moderatelow85 C/185 Fvery goodexcellentvery goodmoderatelow115 C/240 Fgoodlowgoodvery good to excel.very good95 C/200 85 C/185 Flowgoodexcellentlowgoodgoodvery goodmoderate to good goodMaterial Viton*Resistance to diluted acids concentrated acidsResistance to solvents aliphatic hydrocarbons aromatic hydrocarbons oxygenic solvents(ketones, etc.) paint solventsResistance to swelling in lubricant oilsmineral oils and fuelsanimal/vegetable oilsozonesunlightheat ageing (upper temp.for permanent use) flames high temperatures coldexcellentoutstandinggood*Registered trademark DU PONT33

Vetter leak-sealing systems may only be operated with compressed air, never with flammable or aggressive gases. The leak-sealing systems may only be filled using original Vetter fittings. Pay attention to DIN 7716 if stored for longer periods of time. We will be happy to supply an excerpt from this standard. Vetter Leak-Sealing Systems 18 Contents