Transcription

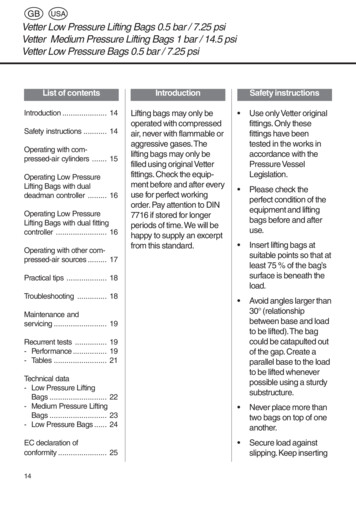

Vetter Low Pressure Lifting Bags 0.5 bar / 7.25 psiVetter Medium Pressure Lifting Bags 1 bar / 14.5 psiVetter Low Pressure Bags 0.5 bar / 7.25 psiList of contentsIntroductionIntroduction . 14Lifting bags may only beoperated with compressedair, never with flammable oraggressive gases. Thelifting bags may only befilled using original Vetterfittings. Check the equipment before and after everyuse for perfect workingorder. Pay attention to DIN7716 if stored for longerperiods of time. We will behappy to supply an excerptfrom this standard.Safety instructions . 14Operating with compressed-air cylinders . 15Operating Low PressureLifting Bags with dualdeadman controller . 16Operating Low PressureLifting Bags with dual fittingcontroller . 16Operating with other compressed-air sources . 17Safety instructions Use only Vetter originalfittings. Only thesefittings have beentested in the works inaccordance with thePressure VesselLegislation. Please check theperfect condition of theequipment and liftingbags before and afteruse. Insert lifting bags atsuitable points so that atleast 75 % of the bag’ssurface is beneath theload. Avoid angles larger than30 (relationshipbetween base and loadto be lifted). The bagcould be catapulted outof the gap. Create aparallel base to the loadto be lifted wheneverpossible using a sturdysubstructure. Never place more thantwo bags on top of oneanother. Secure load againstslipping. Keep insertingPractical tips . 18Troubleshooting . 18Maintenance andservicing . 19Recurrent tests . 19- Performance . 19- Tables . 21Technical data- Low Pressure LiftingBags . 22- Medium Pressure LiftingBags . 23- Low Pressure Bags . 24EC declaration ofconformity . 2514

props the higher thelifting height. If a substructure is usedalways ensure that thisis stable and firm. Thesubstructure mustsupport at least thecomplete area of thebag and should bewider and longer than itis high.DangerRisk of slipping Place stones, branchesor similar materialsunder the bag to improve adherence if usedon slippery sur-faces(ice, snow, mud, etc.). Avoid point loads, e.g.building cramps, bolts. Never use bags onsharp edges or on veryhot days. Use suitableliners and cover thecomplete surface of thebag.Do not place extra loadson bags, e g. hydraulicprops, winches, fallingloads.Never work undersuspended loads,never reach underload. Keep yourdistance. Avoid shearing stressesby squeezing the bagwhen the load islowered. Never stand in front ofthe bag, always to oneside when in usesince it can be catapulted out from underthe load.Never place metal onmetal when proppingup loads! Protect bags againstflying sparks duringwelding and cuttingwork.Operating with compressed-air cylindersConnect pressure regulatorwith T-screw to compressed-air cylinder.Close handwheel (3) ofpressure reducer.Open cylinder valve (5):manometer (1 ) shows thepressure in the cylinder.Set the back pressure toapprox. 2 bar with the adjusting screw (4) (display onmanometer (2)).12534Connect pressure reducer’s air supply hose todual controller with nipple.Push nipple into couplinguntil it catches.15

Vetter Low Pressure Lifting Bags 0.5 bar / 7.25 psiVetter Medium Pressure Lifting Bags 1 bar / 14.5 psiVetter Low Pressure Bags 0.5 bar / 7.25 psiOperating Low PressureLifting Bags withdual deadman controller7.25 psi or 1 bar / 14.5 psi.The lever automaticallyreturns to the middle position deadman position.Connect the controller tothe Lifting Bag with the inflation hose.Push nipple into twin-lockcoupling until it catches andtighten by hand (9).9Operating Low PressureLifting Bags with dualfitting controllerConnect the controller tothe Lifting Bag with theinflation hose.8310If the working pressureexceeds 0.5 bar / 7.25 psior 1 bar / 14.5 psi the safetyvalve opens.Open the handwheel (3) onthe Vetter pressure regulator.The max. tolerance foropening and closing thesafety valve may be 10 %. The manometer (8)shows the pressure in thebag.Pull back the lever (10) onthe controller to inflate theLifting Bag.Push the lever forwards todeflate the Lifting Bag and/or lower the load.Push nipple into twin-lockcoupling until it catches andtighten by hand (9).9Keep an eye on the manometer (8) and the load.Once the desired workingpressure for lifting force andheight is reached stopinflation by releasing thelever at a max. of 0.5 bar /16Place the bag in position.Close the ball valve (6) anddischarge device (7) on thehead of the safety valve.

Open the handwheel (3) onthe Vetter pressure regulator.Open the ball valve (6) toinflate the Lifting Bag andraise the load.766387Keep an eye on the internalpressures in the bag shownat the mano-meter (8) ofthe dual controller and theload. The safety valveprevents an overfilling of thebag.Depending on the type,position and behaviour ofthe load during lifting, theLifting Bags are filled either simultaneously andequally or gradually and / orindividually.Close the ball valve immediately in the event of a stopor fault, find the cause andremedy.Operating with othercompressed-air sourcesThe max. tolerance foropening and closing thesafety valve may be 10 %. The manometer (8)shows the pressure in thebag.Vetter adaptor sets areavailable for other compressed-air sources.Open the discharge deviceon the head of the safetyvalve (7) by turning anticlockwise to deflate theLifting Bag and / or lowerthe load.17181915162120 Compressed-air mains(15) Truck tyre inflator (16)WarningTyre inflation connector must be protectedby a safety valve. Truck air brakesystems (17)WarningSeal off control linewith the dummycoupling (18). Securetruck with wheelblocks.17

Vetter Low Pressure Lifting Bags 0.5 bar / 7.25 psiVetter Medium Pressure Lifting Bags 1 bar / 14.5 psiVetter Low Pressure Bags 0.5 bar / 7.25 psi Truck tyre valve (19).For inflation with anormal hand or footpump.Truck tyre valve connector (20). To take airfrom the spare tyre.2223 Building site compressor (21). Hand (22) or foot (23)pump with manometer.Reducing adaptors and airpumps are available fromthe manufacturer.If the maximum pressurefrom the compressed-airsupply exceeds 4 bar /58 psi a pressure reducermust be used and thepressure reduced toapprox. 2 bar / 29 psi.18Practical tipsYou should normally use atleast two bags of the samesize and design. Placeeach bag as close aspossible to the end of theload.Pull bag under the load witha working line or lowerbetween loads to beseparated. On account ofthe low bearing pressure[maximum 0.5 kg / cm2(7.25 psi) or 1.0 kg / cm2(14.5 psi)] substructuresare rarely required, even onsoft bases.Secure the load againstslipping during lifting bybracing or other suitablemeasures. Place LiftingBags completely underload wherever possible(though with at least 75% oftheir surface). The lower thecontact area between thelifting bag and load, thelower the lifting power.Place the side wall materialbetween the top andbottom of the bag beforeinserting under the load. Ifthe insertion height or areais inadequate for a properplacement of the liftingbags, Vetter Mini LiftingBags can usually be usedto quickly create thenecessary space.TroubleshootingIf a safety valve opensprematurely because aforeign body has penetrated the system, open thedischarge device at thehead of the safety valvefully by turning anticlockwise so that compressedair can escape. If this doesnot remove the foreignbody the top part of thevalve must be unscrewed.Unscrew in an anticlockwise direction using a pipewrench. Carefully removethe valve cone and removethe foreign body in front ofthe sealing plate. Screw thetop part of the valve backon tight and check forperfect operation. The preset pressure may not bechanged. If the lead orleaded plate on the top partof the valve is removed asafe function can no longerbe guaranteed - return thedevice to the manufacturer.

If this ices up because of aexcess atmospherichumidity in connection withlow temperatures use anormal defroster (such asis used for car locks).Maintenance andservicingMinor damage such ascracks, cuts or puncturescan be repaired by the userwith the enclosed repair kitas follows:a) Select a patch which isapprox. 5 cm largerthan the damage on allsides.b) Mark patch on bag.c) Roughen up the surfaceof the bag and one sideof the patch.d) Apply a thin layer ofspecial adhesive on theroughened up surfaceof the bag and thepatch.e) Leave special adhesiveapprox. 20 minutes todry until no longer tacky.*f) Press patch firmly ontoprepared area of thebag and rub.g) Leave bag at least 48hours in deflated state.The bag should be testedby a safety expert after therepair.Recurrent testsTests for lifting bags arebased on the PressureVessel Legislation and DIN14152 Part 1*. The testscontained herein are to becarried out as specified.Lifting bags with a maximum working pressure of0.5 bar / 7.25 psi do nothave to be tested by asafety expert but can betested by a qualified tester.Vetter Lifting Bags 0.5 bar /7.25 psi are subjected to aconstructional and pressure test as well as anapproval test in accordancewith § 9 of the PressureVessel Legislation by awork’s tester.Performance of testsTests on delivery by userDuring this test in accordance with DIN 14 152 Part1, Item 5.2* the deviceshould be checked by theuser’s qualified tester toensure that all parts havebeen delivered and thatnone are damaged. Thebags are to be inflated up to0.2 times the permissibleworking pressure, i.e. to 0.1bar / 1.5 psi. The qualifiedtester should then performa visual check.Recurrent testsThe lifting bag systemshould be checked afterevery use, though at thelatest after one year, toensure that all parts arecomplete and none aredamaged. If all parts arecomplete and present thelifting bag should be inflated to 0.5 times themaximum working pressure of 0.5 bar / 7.25 psi,i.e. 0.25 bar / 4 psi, andthen washed with lukewarm soapy water. Checkfor cracks, wear, cuts orPressure Vessel Legislation and DIN 14152 Part 1 are only valid in Germany.19

Vetter Low Pressure Lifting Bags 0.5 bar / 7.25 psiVetter Medium Pressure Lifting Bags 1 bar / 14.5 psiVetter Low Pressure Bags 0.5 bar / 7.25 psiother damage. Lifting bagsare made of neoprenecoated fabric. However, airdiffuses through neoprene(completely safe duringwork with the bag). Duringtests for leaks with leakfinder spray and warmsoapy water this effectappears as a fine-porefoaming. This is typical forthe material and should notbe rated as a leak. Only ifair escapes profusely ormore than 10 % is lost after1 hour should the bag berepaired or returned to themanufacturer. Otherwiseinflate the bag to themaximum working pressure of 0.5 bar / 7.25 psi 10 %. At 0.55 bar / 8 psithe safety valve on thecontroller should be fullyopen, the pressure insidethe bag may not rise anyfurther.If the safety valve does notopen fully, stop the test andremedy the fault in themanner explained under“Troubleshooting”. Once thefault has been remedi-edrepeat this part of the test.20In accordance with thePressure Vessel Legislationand DIN, the user isresponsible for the correctperformance of the recurrent tests.We recommend that awritten record be kept ofthe test and results.Vetter offers courses totrain qualified testers.

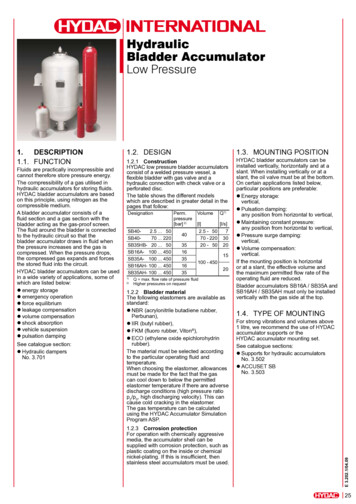

Table of recurrent testsTimeIntervalType of testTester*Basis*Before initialcommissioningAcceptance inspectionin manufacturer’s worksWork’s testerPressure Vessel Legislation § 9After receiptby the userCheck on deliveryQualified testerDIN 14 152, Part 1, Item 5.2After everyuseVisual and functionalinspectionQualified testerDIN 14 152, Part 1, Item 5.3.2AnnuallyVisual and functionalinspectionQualified testerDIN 14 152, Part 1, Item 5.3.3After repairsTest on specialoccasionsQualified testerPressure Vessel Legislation § 11*Pressure Vessel Legislation and DIN 14152 Part 1 are only valid in Germany.21

Vetter Low Pressure Lifting Bags 0.5 bar / 7.25 psiVetter Medium Pressure Lifting Bags 1 bar / 14.5 psiVetter Low Pressure Bags 0.5 bar / 7.25 psiTechnical dataVetter Low Pressure Lifting Bags 0.5 bar / 7.25 psiModelVSL 12VSL 7VSL 5VSL Product No.: complete set111 00 000112 00 000113 00 000114 00 000Product No.: individual bag111 01 000112 01 000113 01 000114 01 000Lifting power(2 bags 1 set)kN (to)US-tons113 (11.3)12.565 (6.5)7.245 (4.5)529 (2.9)3.2Lifting 76306124Max. alowablebarworking pressure psi0.57.250.57.250.57.250.57.25Air req. for2 bagslitrescu.ft.37291321209438162939313.14Nominal content1 baglitrescu.ft.124344403142729.61314.6Test n , 2 bagswith valisekglbs.4497255520441431Weightcomplete setkglbs.5812839863475286222

Vetter Medium Pressure Lifting Bags 1.0 bar / 14.5 psifor export onlyModelVSM 24VSM 14VSM 10VSM 6Type1/2301/1301/901/60Product No.: complete set311 00 000312 00 000313 00 000314 00 000Product No.: inidividual bag311 01 000312 01 000313 01 000314 01 000Lifting power(2 bags 1 set)kN (to)US-tons226 (22.6)25130 (13.0)14.390 (9.0)9.958 (5.8)6.4Lifting 76306124Max. allowablebarworking pressure psi1.014.51.014.51.014.51.014.5Air req. for2 bags,litrescu.ft.497217516125710883852419Nominal content, litres1 bagcu.ft.124344403142729.61314.6Test n , 2 bagswith valisekglbs.4599265721461533Weight,complete setkglbs.59130408835772964DIN-code**Pressure Vessel Legislation and DIN 14152 Part 1 are only valid in Germany.23

Vetter Low Pressure Lifting Bags 0.5 bar / 7.25 psiVetter Medium Pressure Lifting Bags 1 bar / 14.5 psiVetter Low Pressure Bags 0.5 bar / 7.25 psiVetter Low Pressure Bags 0.5 bar / 7.25 psi *Type / ModelLH10LH30LH10 SLH20 SArt.-No.11801000118020001180300011804000Lifting capacity kN22.4061.9010.8222.32Lifting capacity kg2240619010822232Nominal capacity kN11.2030.9510.8222.32Nominal capacity kg1120309510822232Lifting height cm36.5604565Nominal stroke cm18304565Size cm65 x 69125 x 9950 x 4570 x 65Nominal content, litres64284121369Air requirementat 0.5 bar, litres96426182554Weight kg2.05.03.58.0Working pressure bar0.50.50.50.5Test pressure bar0.650.650.650.65Bursting pressure bar1.5 - 5.61.5 - 5.61.5 - 5.61.5 - 5.6Insertion height cm2244*24not available in USA

EC Declaration of Conformity in theintendment of the EC Machine Directive89 / 392 / EECLH30 SLH50 0726590659090 x 70110 x 93526115278917289.511.00.50.50.650.651.5 - 5.61.5 - 5.644WeManfred Vetter GmbH & Comp.Blatzheimer Strasse 10-12D-53909 Zülpichhereby declare that the lifting bags(0/12; I/6; II/4; III/3; 1/230; 1/130; 1/90; 1/60)for raising and lowering loadsSerial No.:Design:(see ratings plate, to be completed by customer)comply with the following pertinent regulations intheir standard design:Machine Directive 89 / 392 / EECas amended by Directives 91 / 368 / EEC,93 / 44 / EEC, 94 / 68 / EEC.Harmonised standards employed:EN 292 Part 1 / 2National standards and technical specificationsemployed:Pressure Vessel LegislationInternal measures ensure that the standardlifting bags always comply with the requirements of the latest EC Directives and applicable standards.Zülpich, October 27, 199525

Vetter Low Pressure Lifting Bags 0.5 bar / 7.25 psi Vetter Medium Pressure Lifting Bags 1 bar / 14.5 psi Vetter Low Pressure Bags 0.5 bar / 7.25 psi 14 . compressed-air sources Vetter adaptor sets are available for other com-pressed-air sources. Compressed-air mains (15) File Size: 297KB