Transcription

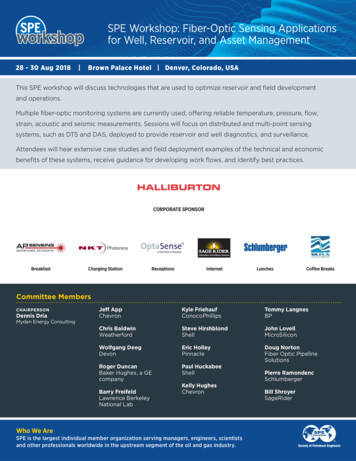

SPE Workshop: Fiber-Optic Sensing Applicationsfor Well, Reservoir, and Asset Management28 - 30 Aug 2018 Brown Palace Hotel Denver, Colorado, USAThis SPE workshop will discuss technologies that are used to optimize reservoir and field developmentand operations.Multiple fiber-optic monitoring systems are currently used, offering reliable temperature, pressure, flow,strain, acoustic and seismic measurements. Sessions will focus on distributed and multi-point sensingsystems, such as DTS and DAS, deployed to provide reservoir and well diagnostics, and surveillance.Attendees will hear extensive case studies and field deployment examples of the technical and economicbenefits of these systems, receive guidance for developing work flows, and identify best practices.CORPORATE SPONSOROptaSense a QinetiQ companyBreakfastCharging StationReceptionsInternetLunchesCoffee BreaksCommittee MembersCHAIRPERSONDennis DriaJeff AppChevronKyle FriehaufConocoPhillipsTommy LangnesBPChris BaldwinWeatherfordSteve HirshblondShellJohn LovellMicroSiliconWolfgang DeegDevonEric HolleyPinnacleDoug NortonFiber Optic PipelineSolutionsRoger DuncanBaker Hughes, a GEcompanyPaul HuckabeeShellMyden Energy ConsultingBarry FreifeldLawrence BerkeleyNational LabKelly HughesChevronWho We AreSPE is the largest individual member organization serving managers, engineers, scientistsand other professionals worldwide in the upstream segment of the oil and gas industry.Pierre RamondencSchlumbergerBill ShroyerSageRider

General InformationAccessibilityElectronic DevicesOur events and functions are accessible to all attendees withwheelchairs. If you require special arrangements, please contactour staff at the registration desk.As a courtesy to the speakers and your fellow registrants, pleaseturn off all electronic devices during presentations.Alcohol PolicyPlease wear your badge at all times. It is a courtesy to your fellowregistrants, speakers, and sponsors.SPE recognizes the legitimate serving of alcoholic beverages inthe process of conducting business and social activities. We alsorecognize that the use and consumption of alcohol carries withit the requirement for all attendees to consume those beveragesresponsibly.CommercialismIn remaining consistent with workshop objectives and SPEguidelines, commercialism in presentations will not be permitted.Company logos should be used only to indicate the affiliation ofthe presenter(s).Continuing Education UnitsAttendees will receive 2.0 CEUs. One CEU equals 10 contact hoursof participation. CEUs will be awarded through SPE ProfessionalDevelopment for participation and completion of an SPEworkshop. A permanent record of a participant’s involvement andawarding of CEUs will be maintained by SPE.DocumentationFollowing the workshop, a URL containing released copies of theworkshop presentations will be available to all attendees.Name BadgesPhotography and Recording PolicySPE reserves the exclusive rights to all video/audio recording orreproductions of the workshop.Unauthorized video/audio recording is expressly prohibited inthe session room(s) or poster area, whether by video, still ordigital camera, mobile phone, or any other means or form ofreproduction.Any person attending may be photographed or videotaped, and byyour attendance, you give permission to use your image in possiblefuture marketing publications including print, online, and video.Workshop FormatWorkshops maximize the exchange of ideas among attendeesand presenters through brief technical presentations followedby extended Q&A periods. Focused topics attract an informedaudience eager to discuss issues critical to advancing bothtechnology and best practices.Many of the presentations are in the form of case studies,highlighting engineering achievements and lessons learned. Inorder to stimulate frank discussion, no proceedings are publishedand members of the press are not invited to attend.Carina Sensing Systembreakthrough performance enabled by Constellation fibers»Seismic acquisitionData quality beyond that of geophones»GeophonesCarinaMicroseismic monitoringHigh sensitivity for lower microseismic event detection»Strain monitoringEarly crosswell strain monitoring»Proppant allocationFine resolution, wide dynamic rangefor treatment monitoring»Production allocationHigh sensitivity for dynamic production monitoring»Flow meteringNon-intrusive wellhead production monitoring»Subsea well monitoringOperating over long tie-back installationswww.silixa.comsales@silixa.comT: 44 (0) 20 8327 4210 / 1 832 772 3333

Monday, August 27, 20181730–1900Welcome ReceptionOnyx RoomTuesday, August 28, 20180700–0800Registration Check-in and BreakfastGrand Ballroom Foyer0800–0810Chairperson’s Welcome0810–0845Keynote Presentation:Future Directions in Fiber-Optic Sensing From Quantum-Based Data Acquisitionto Advanced Machine LearningAlan Cohen, U.S. Department of Energy0845–1015Session 1: Seismic ImagingSession Chairs: Barry Freifeld, Lawrence BerkeleyNational LabSteve Hirshblond, Shell Presentation 1: Distributed Acoustic Sensing Measurements forReservoir Characterization in the Anadarko BasinReal-timeAll the TimeDan Kahn, Devon Energy Presentation 2: DAS VSP from the Containment and MonitoringInstitute Field Research Station in Newell County, Alberta,CanadaHeather Hardeman, Fotech Solutions Presentation 3: Permanent Reservoir Monitoring using DAS VSPand Surface Orbital Vibrators: Field Trials from the CO2CRCOtway ProjectBarry Freifeld, Lawrence Berkeley National Lab1015–1045Fiber Optic ServicesDAS & DTSAcquisition and InterpretationCoffee BreakGrand Ballroom Foyer1045–1215Session 2: Emerging and EnablingTechnologiesSession Chairs: John Lovell, MicroSiliconWolfgang Deeg, Devon Presentation 1: Point Heating and Optical Fiber Monitoring forFlow Movement InvestigationFrank Selker, SelkerMetrics Presentation 2: Evaluation of Distributed and EngineeredAcoustic Sensors for Multiphase Flow Measurements includingPhase Allocation Using a Machine Learning TechniqueGarth Naldrett, Silixa Presentation 3: Enhancing the Temperature Performanceof DTS Measurements when using a Combined DTS/DASConfigurationGareth Lees, AP Sensingsageriderinc. com

1215–13151445-1500LunchCoffee Break5280 SuiteGrand Ballroom Foyer1315-14451500–1700Session 3: Completion and Stimulation DesignOptimizationSession 4: Stimulation DiagnosticsSession Chairs: Chris Baldwin, WeatherfordEric Holley, Halliburton Presentation 1: Combination of Distributed Sensing and PointFlow Measurements: What is the Value?Pierre Ramondenc, SchlumbergerSession Chairs: Paul Huckabee, ShellPierre Ramondenc, Schlumberger Presentation 1: New Near-Wellbore Hydraulic FractureGeometry Insights from the Integration of FiberOptics and Downhole Pressure Gauge DataGustavo Uguesto, Shell Presentation 2: Development of a Completion Model for theMonitoring of EOR in Wells with Heavy and Extra Heavy Crudein the Largest Deposit in Latin AmericaGerardo Peña, Rosneft Presentation 2: Fiber Optics in Completions: Real Time StageOptimizationPrice Stark, Pinnacle, a Halliburton Company Presentation 3: A Frac Monitoring Case Study in the Montney Presentation 3: Successful Applications using Real-Time FiberOptic Technology in KuwaitSam Gorgi, Pinnacle, a Halliburton CompanyCarson Laing, OptaSense Presentation 4: Completions Optimization Utilizing MultipleWells Fiber Optics Data with Intervention Type FiberJennifer Charbonneau, Oasis Petroleum1700–1830Networking ReceptionBrown Palace ClubWELL & RESERVOIR MONITORINGDistributedTemperature Sensing (DTS) Superior reliability and ruggedness Outdoor, rack mount & portable Outstanding worldwide support Singlemode and multimodeLeading the Way with Passion.www.apsensing.comDistributedAcoustic Sensing (DAS) Upstream, midstream and downstream Leading performance Hydraulic fracture monitoring In-well flow profiling of productionand injection wellsAmerica’s Sales Office: 214 471-3460

Wednesday, August 29, 20180700–0800BreakfastGrand Ballroom Foyer0800–0930Session 5: New TechnologiesSession Chairs: Tommy Langnes, BPBill Shroyer, SageRider Presentation 1: Real-time Cement Displacement and Long-termZonal Isolation Monitoring using Distributed Fiber Optic SensorsQian Wu, The University of Texas at Austin Presentation 2: Fiber Optic Resistivity SensingGlenn Wilson, Halliburton Presentation 3: Downhole Distributed Fiber Optic ProductionLogging ToolGarth Naldrett, Silixa0930–1000Coffee BreakGrand Ballroom Foyer1000–1200Session 6: Fiber DeploymentSession Chairs: Bill Shroyer, SageRiderDoug Norton, Fiber Optic Pipeline Solutions Presentation 1: Best Practices of 10 Years of Using DistributedMeasurements as Part of Coiled Tubing InterventionsPierre Ramondenc, Schlumberger Presentation 2: A New and Cost-Effective Approach to FiberOptic Well InterventionsTad Bostick, Well-SENSE Presentation 3: Mapping the Orientation of Downhole SensingCables and Control Lines Using a Hybrid Distributed andEngineered Acoustic Sensing SystemMahmoud Farhadiroushan, Silixa Presentation 4: Conveyance-Agnostic DAS Seismic TomographyGlenn Wilson, Halliburton1200–1300Lunch5280 Suite1300–1430Session 7: Data Management, Visualization,Big Data, and Data FusionSession Chairs: Steve Hirshblond, ShellKelly Hughes, Chevron Presentation 1: Fiber Optics Data and Cloud TechnologiesKanwal Gupta, Chevron Presentation 2: Sparse Representation of Distributed AcousticSensorMatt McDonald, Fotech Solutions Presentation 3: Digital Transformation of Wells and ReservoirSurveillance Using Distributed Fibre OpticsTommy Langnes, BP

1430–1500Thursday, 30 August, 2018Coffee BreakGrand Ballroom Foyer0700–08001500–1700Grand Ballroom FoyerBreakfastSession 8: Production and Injection Profiling/Flow Monitoring0800–0930Session Chairs: Jeff App, ChevronKyle Friehauf, ConocoPhillipsSession 9: Integrity, Flow Assurance, andPipeline Monitoring Presentation 1: A Comparison of Different DAS Technologiesfor Production Flow AnalysisSession Chairs: Doug Norton, Fiber Optic Pipeline SolutionsRoger Duncan, Baker Hughes, a GE company Presentation 1: Value of Strain Sensing in the Belridge FieldFrode Hveding, Saudi Aramco Presentation 2: Downhole Sand Ingress Detection Using FibreOptic Distributed Acoustic SensorsTommy Langnes, BP Presentation 3: Calibration of Double-Ended DTS SystemGe Jin, ConocoPhillips Presentation 4: Distributed Fiber Optic MeasurementsCombined with Production Logging Tool Data StrengthensFluid Flow Interpretation in WellsYosmar Gonzalez, SchlumbergerMatt Cannon, Shell Presentation 2: The Applicability of Distributed AcousticSensing for the Application of Pipeline Integrity MonitoringStuart Large, Fotech Solutions Presentation 3: Tubing Leak Detection using Distributed FibreOptic Acoustic SensorsTommy Langnes, BP Presentation 4: Putting Theory Into Practice: Field Trial ofDFOS on a PipelineDavid Norman, ExxonMobil Upstream Research0930–1000Coffee BreakGrand Ballroom FoyerWellWatcher BriteBlueMULTIMODE DTS FIBERBP optimizes drainage of more than100 million barrels of secondary oil.WellWatcher BriteBlue* multimode DTS fiber provided continuous temperature profiles of individual reservoir zones,which enabled the effects of depletion to be monitored over time. As a result, BP adjusted its strategy for water injectionand oil drainage—facilitating the drainage of more than 100 million barrels of secondary oil and also eliminating the needto run production logging tools.Find out more atslb.com/wellwatcher*MarMark oof SchMarSScchlumbum ergeumbrgeerr. 201801 SSchlSchchlh umumbeumbmbeergermrgerrgergerggeer. 18-CO-4218-C8-CO-42O-44204O046004624622

1000–1130Session 10: Consortia ReviewSession Chairs: Eric Holley, HalliburtonWolfgang Deeg, DevonBrief overviews from the various organizations that are involvedwith formulating standards and protocols for the industry willbe provided. A focus on current and planned activities for eachorganization will also be discussed. Presentation 1: Energistics – Energy StandardsRoss Philo, Energistics Presentation 2: FOSA – Fiber Optic Sensing AssociationMike Hines, OFSIs yourWell Done? Presentation 3: SEAFOMChris Baldwin, WeatherfordPOSTER PRESENTATIONSDisplayed Wednesday and Thursday during coffee breaksNovel Methods for Interpretation of In-WellTemperature MeasurementsKhafiz Muradov, Heriot-Watt UniversitySubsurface Flow Profiling for Hydraulic Fracturing withDownhole Fiber Optic Distributed Temperature SensingBurton Mendonca, Pamban Energy SystemsNotes:LIOS WELL.DONEReliable temperatureand strain sensingDistributed Temperature Sensing with reĂůͲƟŵĞ ƌĞƐŽůƵƟŽŶ ďĞƩĞƌ ƚŚĂŶ Ϭ͘ϬϴΣ ĂŶĚ ĨĂƐƚ ŵĞĂƐƵƌĞŵĞŶƚƐ ŽǀĞƌ ůŽŶŐ ĚŝƐƚĂŶĐĞƐ ƵƉ ƚŽ ϳϬ Ŭŵ͘Distributed Strain Sensing ĨŽƌ ƌĞĂůͲƟŵĞ ƐŚĞĂƌŝŶŐ ĂŶĚ ĚĞĨŽƌŵĂƟŽŶ ŵŽŶŝƚŽƌŝŶŐ͘ ůů ŝŶ ŵĂŝŶƚĞŶĂŶĐĞͲĨƌĞĞ ŝŶĚƵƐƚƌŝĂů ƵŶŝƚƐ ĚĞƐŝŐŶĞĚ ĨŽƌ ŚĂƌƐŚ ĞŶǀŝƌŽŶŵĞŶƚƐ͘

LEVEL 1 CAPABILITYINTEGRATEDSENSOR LevelDIAGNOSTICS 2 Capability(ISD)(if applicable)6CurveFracture StageSpacingWell Spacing5ingWell PlacementAsset OptimizationarnMontneyCalibrated raelPermianProduction Analysis3erBarnettccAEagle FordCalibrated FractureModeling21Sensor AcquisitionProject SetupISD Accelerates the Asset Learning Curve by Combining theWorld’s Leading Frac Company with our Industry Leading DiagnosticsSolve the most fiscally critical challenges:» Real-time decision making on the job site» Solve your well and fracture spacing challenges» Make intelligent data driven decisions guided by expertsSales of Halliburton products and services will be in accord solely with the terms and conditionscontained in the contract between Halliburton and the customer that is applicable to the sale.H012523 6/18 2018 Halliburton. All Rights Reserved.halliburton.com/pinnacle

Sensing for the Application of Pipeline Integrity Monitoring Stuart Large, Fotech Solutions Presentation 3: Tubing Leak Detection using Distributed Fibre Optic Acoustic Sensors Tommy Langnes, BP Presentation 4: Putting Theory Into Practice: Field Trial of DFOS on a Pipeline David Norman, ExxonMobil Upstream Research 0930-1000

![Fiber Optic - Perimeter Intrusion Detection System [Fopids]](/img/57/foss-presentation.jpg)