Transcription

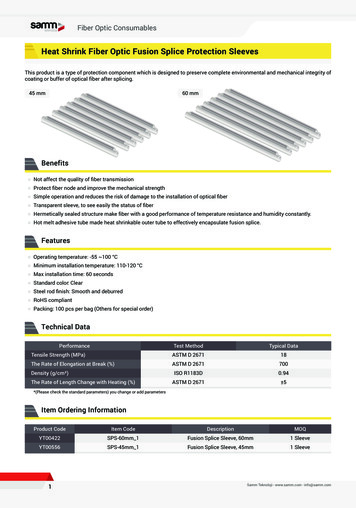

Fiber Optic ConsumablesHeat Shrink Fiber Optic Fusion Splice Protection SleevesThis product is a type of protection component which is designed to preserve complete environmental and mechanical integrity ofcoating or buffer of optical fiber after splicing.45 mm60 mmBenefitsNot affect the quality of fiber transmissionProtect fiber node and improve the mechanical strengthSimple operation and reduces the risk of damage to the installation of optical fiberTransparent sleeve, to see easily the status of fiberHermetically sealed structure make fiber with a good performance of temperature resistance and humidity constantly.Hot melt adhesive tube made heat shrinkable outer tube to effectively encapsulate fusion splice.FeaturesOperating temperature: ‐55 100 CMinimum installation temperature: 110-120 CMax installation time: 60 secondsStandard color: ClearSteel rod finish: Smooth and deburredRoHS compliantPacking: 100 pcs per bag (Others for special order)Technical DataTest MethodTypical DataTensile Strength (MPa)ASTM D 267118The Rate of Elongation at Break (%)ASTM D 2671700ISO R1183D0.94ASTM D 2671 5PerformanceDensity (g/cm²)The Rate of Length Change with Heating (%)*(Please check the standard parameters) you change or add parametersItem Ordering InformationProduct CodeItem CodeDescriptionMOQYT00422SPS-60mm 1Fusion Splice Sleeve, 60mm1 SleeveYT00556SPS-45mm 1Fusion Splice Sleeve, 45mm1 Sleeve1Samm Teknoloji - www.samm.com - info@samm.com

Fiber Optic ConsumablesPack Ordering InformationProduct CodeItem CodeDescriptionMOQMT12239SPS-60mm 100 Pc/BagFusion Splice Sleeve, 60mm 100 Pieces1 BagMT12240SPS-45mm 100 Pc/BagFusion Splice Sleeve, 45mm 100 Pieces1 BagDimensionsSplice ProtectorModelSteel RodFusion TubeLength ( L )Diameter ( D )Length ( Lr )Diameter ( Dr )Inner Diameter ( Dt )Length ( Lt )60 mm602.3 15511.36045 mm452.3 14011.345***All dimensions are in millimeters (mm)LrDrDtDL / LtLLength after recoveryLrRod lengthDDiameter after recoveryDtFusion tube inner diameterDrSteel rod diameterLtFusion tube lengthSamm Teknoloji - www.samm.com - info@samm.com2

Fiber Optic ConsumablesCleaner Pen SC/ST/FC & LCCleaner Pen is a type of fiber end-face cleaner with highperformance and efficiency. It is designed to clean both maleand female optical connectors especially in optical distributionframes. One time click makes the fiber end-face clean andminimizes fiber loss.Cleaner Pen ST/SC/FCOrder Code MT02715FeaturesClean 2.5mm ferrule/connector: FC, SC, ST (UPC,APC)Clean 1.25mm ferrule/connector: LC (UPC,APC)Over 800 cycles cleaningAnti-static, no secondary pollutionHigh clean efficiencyCleaner Pen LCOrder Code MT02716Construction1Lock ButtonOuter ShellNozzleTipGuide CapIndicatorUsage Instructions1Extend the nozzle when cleaning an adapter that is between plugged adapters.Standard ModeSC Adapter2Extended Nozzle ModeLC AdapterSC AdapterLC AdapterUse correct cleaner pen for connector type and insert the nozzle in a straight mannerSC Cleaner PenSC Connector3LC Cleaner PenLC ConnectorSamm Teknoloji - www.samm.com - info@samm.com

Fiber Optic ConsumablesCleaner Pen MTP/MPOThe MPO Cleaner is a high-performance device designed forcleaning the ferrule end-faces of MPO & MTP connectors. Costeffective tool for cleaning fiber end-faces without the use ofalcohol .It saves time by effectively cleaning all fibers at once.The MPO connector cleaner is designed to clean both exposedjumper ends and connectors in adapters.FeaturesEffective on a variety of contaminates like dust and oilsCleans ferrule with or without guide pinsCleans MPO ferrule inside or outside an MTP/MPO adapterCleaner Pen MTP/MPOOrder Code MT02717Narrow design reaches tightly spaced MTP/MPO adaptersEasy one-handed operationUp to 600 cleaningsUsage Instructions1InsertionInsert the tip of the cleaner inside the adapter in a straightmanner until it reaches the ferrule surface.2MTP/MPO Connector with AdapterInsertClickingPush the cleaner forward to hear a “Click” that means theferrule surface and fiber end-faces have been wiped once.Repeat the click action 2 or 3 times for best results.As shown below dust and liquid can stick on fiber end-facesand cause distortion of signal. That is why cleaningMTP/MPO connectors is essential to have a good networkperformance.ClickMTP/MPO ConnectorMTP/MPO Connector without AdapterInsertClean Fiber End-faceClean Ferrule SurfaceClickDirty Fiber End-faceCleaner Pen AdapterDirty Ferrule SurfaceSamm Teknoloji - www.samm.com - info@samm.com4

Fiber Optic ConsumablesCleanSticks SC/ST/FC & LCThese CleanSticks are designed with two models, one forcleaning fiber optic SC, ST and FC connectors with 2.5mmdiameter and one for cleaning fiber optic LC connectors with1.25mm diameter.FeaturesEasy to use and very efficientDelivers a consistently high level of cleaning performanceEasy to clean ferrule end-faces inside the plug-in fiberoptic connectors and various adaptersLightweight and safe to useCompact and disposableSuitable for cleaning inside adapters for dust controlRecommended Cleaning Procedure1InsertionEnsure that stick is held straight when inserting into theCleanSticks SC/ST/FC 2.5mmOrder Code TT00177fiber optic connector ferrule.AdapterInsertSC CleanerLoading PressureApply sufficient pressure (600-700 g) to ensure the soft tipis reaching the fiber end-face and filling the ferrule.Load PressureRotate3RotationRotate the cleaning stick 4 to 5 times clockwise, whileCleanSticks LC 1.25mmOrder Code TT00176ensuring direct contact with ferrule end-face is maintained.Number of Possible Wipes- Maintenance (repair): 1 use.- Equipment construction: 4 uses (max).5Samm Teknoloji - www.samm.com - info@samm.com

Fiber Optic ConsumablesFiber Optic Cleaning WipesThese fiber optic cleaning wipes are specially designed paperused for cleaning laboratory equipment, camera lenses, fiberoptic connectors and delicate electronic items. They can cleanany surface without leaving any lint or dust that may block thesignal. Fiber optic cleaning wipes are ideal cleaning solution forlaboratories and manufacturing facilities.FeaturesHigh quality low lint wipeSoft and non-abrasiveExtremely absorbent280 wipes per boxApplicationsIdeal for laboratories and manufacturing facilitiesWet or dry cleaning for fiber optic connectorsFiber Optic Cleaning WipesOrder Code MT02625Fiber preparation before splicing or terminating connectorsCleaning of laboratory equipment and electronicsFiber Optic Cleaning CubeThe Fiber Optic Cleaning Cube can be used to clean fiber opticend faces quickly with good results. It can be used for wet ordry connector cleaning and splice preparation. Fiber OpticCleaning Cube has heavy-duty lint-free material that doesn'tshred or tear. It's tough enough for buffer gel removal yet softenough for end faces.FeaturesHigh quality low lint wipeSoft and non-abrasiveExtremely absorbent100 wipes per boxApplicationsDry clean first whenever possibleAvoid paper and cottonFiber Optic Cleaning CubeOrder Code MT08783If dry cleaning doesn't produce desired results, use aminimal amount of special solvent dispensed from penon a wipeAvoid isopropanol when cleaning end facesSamm Teknoloji - www.samm.com - info@samm.com6

Fiber Optic ConsumablesOptical Connector CleanerThis fiber optic cleaning cassette is compatible with manyconnectors like FC, SC, ST, LC, and MU. It can eliminatecontaminants such as oil, dust and dirt particulates that causefiber loss and may cause permanent damage to fiberconnectors. The optical connector cleaning cassette has a tapeof anti-static microfiber cleaning fabric that dose one wipe witheach click, and the cleaning cassette can clean up to 500connectors.FeaturesDesigned so that all operators can consistently achievehigh quality cleaning without alcohol or other solvents.Palm-sized and lightweight. Easy and safe to use whetherin the engineering lab, on the production line, or in the field.Cleaning tape is replaceable and cost effective.One cleaning tape can be used for over 500 wipes.Has excellent anti-static properties to avoid reattachmentof dust to the ferrule after cleaning.Spare Cleaning TapeThis cleaning tape reel is used with the optical connectorcleaner cassette. It can eliminate contaminants such as oil,dust and dirt particulates that cause fiber loss and may causepermanent damage to fiber connectors. The tape is made ofanti-static microfiber cleaning fabric that dose one wipe witheach click and the cleaning tape can last up to 500 cleans.Polishing Pads 127mmPolishing film are used for polishing optical fibers to insure theminimum rate of insertion loss and they are 127mm (5”). Fiberpolishing pads can have a surface made of diamond, siliconcarbide, silicone dioxide or glass. Some of them are usedmanually and some are used with polishing machines. Everytype of polishing pad has a different roughness like 1μm, 9μm,30μm or licone Carbide30μmXF5DSilicone DioxideFinalPR5X-500Silica Gel70,75,80,85,90 ShoreSamm Teknoloji - www.samm.com - info@samm.com

Fiber Optic ConsumablesIBC Cleaning PensCleaner Pen is a type of fiber end-face cleaner with highperformance and efficiency. One click is enough to make thefiber end-face clean and minimize fiber loss. Cleaner Pen isanti-static and has 525 cleaning operation capacity. Each typeof pen is designed to clean a different type of connectors.SCFeatures525 cleaning engagements per unitAnti-static system produces pristine end face andLCminimizes contaminant attractionCleans cable assembly in hand as well as behind panelsNon-fraying cloth designSimple push to clean actionPush Style Port CleanerM16CompatibilityCleanerCleaned Connectors and AdaptersSizeSCSC, FC, ST, D4, E20002.5mmLCLC, MU1.25 mmM16MIL DTL 389991.6 mmM20SMPTE 304M / MIL / COTS2.0 mmM20Harsh Environment ConnectorsH125ARINC 800, ODC series, LuxCis series,MXL38999, MIL PRF 64266 [NGCON],1.25 mmNeutrik opticalCONH125Connector Ferrule Cleaning WireConnector Ferrule Cleaning Wire provides an easy way to savea fiber optic connector when an optical fiber breaks inside theferrule during connectorization. Connector Ferrule CleaningWire also enables you to remove broken optical fiber from barefiber adapters. It is also useful the 102μm diameter wire in thefiber optic connectorization process to apply fiber optic epoxyto protruding fiber at the connector ferrule. Sticky colored tabsare included, providing you with an easy way to hold the thinwire during use. Connector Ferrule Cleaning Wire is sold incontainers with 8 pieces of 7,5 cm piano wire per container.Samm Teknoloji - www.samm.com - info@samm.com8

Standard color: Clear Steel rod finish: Smooth and deburred RoHS compliant . Order Code MT02625 Fiber Optic Cleaning Cube Order Code MT08783. Fiber Optic Consumables 7 Samm Teknoloji - www.samm.com - info@samm.com Optical Connector Cleaner This fiber optic cleaning cassette is compatible with many

![Fiber Optic - Perimeter Intrusion Detection System [Fopids]](/img/57/foss-presentation.jpg)