Transcription

T H E R M A LTHERMOGRAVIMETRICANALYZERA N A L Y S I STGA 1000

Since 1957 LINSEIS Corporation has been delivering outstanding service, know how and leading innovative products in the field of thermalanalysis and thermo physical properties.Customer satisfaction, innovation, flexibilityand high quality are what LINSEIS represents.Thanks to these fundamentals, our companyenjoys an exceptional reputation among theleading scientific and industrial organizations.LINSEIS has been offering highly innovativebenchmark products for many years.The LINSEIS business unit of thermal analysisis involved in the complete range of thermoanalytical equipment for R&D as well as quality control. We support applications in sectorssuch as polymers, chemical industry, inorganicbuilding materials and environmental analytics.In addition, thermo physical properties of solids,liquids and melts can be analyzed.LINSEIS provides technological leadership. Wedevelop and manufacture thermo analytic andthermo physical testing equipment to the highest standards and precision. Due to our innovative drive and precision, we are a leading manufacturer of thermal Analysis equipment.The development of thermo analytical testingmachines requires significant research and ahigh degree of precision. LINSEIS Corp. investsin this research to the benefit of our customers.2Claus LinseisManaging Director

German engineeringInnovationThe strive for the best due diligence and ac-We want to deliver the latest and best tech-countability is part of our DNA. Our history is af-nology for our customers. LINSEIS continuesfected by German engineering and strict qualityto innovate and enhance our existing thermalcontrol.analyzers. Our goal is constantly develop newtechnologies to enable continued discovery inscience.3

GENERAL4

Thermogravimetry is a technique in which themass of the sample is monitored against time ortemperature while the temperature of the sample, in a specified atmosphere, is programmed.This technique serves the determination of material compositions. It is a common used analysis method in the chemical and pharmaceuticalindustry. Thermogravimetric analysis (TGA) isperformed on polymers, food, pharmaceuticalsas well as many other materials.Unsurpassed performanceL - DSC – Combined weight change and differential scanning calorimeterUnsurpassed sensitivity – sub microgram balance with thermostatic controlled measurement chamberBenchmark resolution – for detection of fastweight changesReliable Automation – up to 64 position autosamplerUltra Fast Heater – Ceramic heater with up to200 C/minTGA 1000The LINSEIS TGA 1000 is a robust and reliableTGA outperforming most competition high endmodels. The sub microgram balance offers highest sensitivity and resolution. The instrument isperfectly suited for academic teaching and dayto day laboratory quality control applications.5

SOFTWARE6

All LINSEIS thermo analytical instrumentsFeatures-Software:are PC controlled. Program capable of text editingThe individual softwaremodules exclusively run under Microsoft Data security in case of power failureWindows Thermocouple break protection operatingsystems.Thecom-plete software consists of 3 modules: temperature control, data acquisition and data Repetition measurements with minimumparameter inputevaluation. The 32 bit software incorpo- Evaluation of current measurementrates all essential features for measurement Curve comparison up to 32 curvespreparation, execution, and evaluation of a Storage and export of evaluationsThermogravimetric measurement. Thanks to Export and import of data ASCIIour specialists and application experts, LINSEIS Data export to MS Excelwas able to develop comprehensive easy to un- Multi-methods analysis (DSC TG, TMA, DIL,derstand user friendly application software.etc.) Zoom functionTG – Features: 1 and 2 derivation Mass Change as % and mg Programmable gas control Rate Controlled Mass Loss Statistical evaluation package Evaluation of Mass Loss Free scaling Residue Mass Evaluation Optional Kinetic and Lifetime Prediction Software packages7

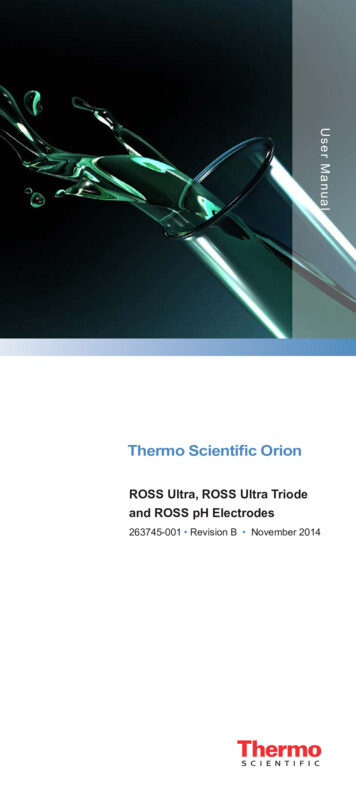

UNIQUE FEATURESMeasurement systemThe platinum measuring system enables precise TGA measurements. The unique L-Calc DSCsensor attachment permits differential scanningcalorimeter signals.OptionsThe following options are available for the TGA:GC, MS or FTIR coupling for evolved gas analysis (EGA) Turbo-molecular pump: for measurements under highest vacuum and cleanest gasatmospheres and a vapor generator.Gas dosing systemThe TGA 1000 (optional feature) incorporates anautomatic gas dosing system (MFC Mass FlowController) containing two gas channels. Theflow rate of the two gases is software controlled.AtmosphereThe balance design enables measurements under inert, oxidative, reducing and vacuum conditions. Corrosive conditions can be analyzedwith proper precautions. The system is capableof adapting residual gas analysis systems usingan optional heated capillary.8

HeaterSampleMeasuringsystem9

SPECIFICATIONSTGA 1000DesignTop-loadingTemperature range(10 C) RT up to 1100 CHeat and Cooling rates0.001 up to 250 C/minSample massmax. 5gResolution0.1µgGas atmospereInert, ocid, red., vaccumVacuumup to 10E-2mbarGas Dosingbuilt-in MFC block with 3 gases(one Purge gas and two reactive gases)Cool down speed 12min (1100 C - 100 C)Sample CarriersTGASample robot42 positionsCruciblePt, Al2O3, Au, Al, Ag etc. others on requestEGA CouplingsOptional FTIR and/or MS or GC-MSInterfaceUSB10

APPLICATIONSVitriol of copper3.002.0-21.0-40.0-6-1.0-2.0-3.0-12-4.0DTA Signal (smoothed) [µV]-8-10dM-rel [%]-14-16-18-20-22-24-26-28DTA Signal smoothed [CUSO-1]Mass change-14.08%0.01.02.0Mass change-14.30%4.0-6.0-7.05.0-8.0-9.06.0-10.0Mass d) [%/min]2Inorganic salts first set their crystal water free. Vitriol of Copperheated with 10 C/min. resultsin a first TG stage, which corresponds to 4H2O. TG and DTAshow that the curve is madeup of two separate steps, oneclosely behind the other. Ataround 250 C the most stronglybound water ature (smoothed) [ C]200220240260280300Dehydration of raw gypsum5.0045-240-435-143.53.02.01.5251.00.520DTA Signal(1.Deriv .) [GIPS1B1]0.015-0.5-1.0235.3 C-2.48µV/ C10-1.5DTA Signal [GIPS1B1]5-2.0-16-2.5199.5 C-0.25µV/ C0-18-3.0210.0 C-15.8%-5-20DTA Signal(1.Deriv .) [µV/ C]-124.02.5DTA Signal (smoothed) [µV]dM-rel [%]-104.530-6-8dM-rel[GIPS1B1]The dehydrate is raw gypsum.There are two molecules of water attached to a single CaSO4molecule. By heating up to app.160 C the semi hydrate gypsumis built. 1,5 molecules of water are released; so two CaSO4molecules are sharing a singlewater molecule. By heating tohigher temperatures (400 C)the anhydrate is built. This isthe socalled „dead burned gypsum“, also known as alabaster.In this state no water at all is attached to the CaSO4 molecules.-3.5368.0 0220240260280300320340360380400Temperature (smoothed) [ C]11

Decomposition of CaC2O4 H2OThe evolved gases from thedecomposition of calcium oxalate has been fed into the massspectrometer with a heatedcapillary. The ion currents formass numbers 18 (water), 28(carbon monoxide) and 44 (carbon dioxide) have been imported into the graph.Time [min]035-1520-2015dM-rel [%]DTA-Signal [µV]25-4020253035404550556065707580859095Mass change-12.13%dM-rel[Ca-Ox-1]2630-10-3515Mass change-18.69%2422979.8 C-61.0%18Mass change-30.05%10DTA-Signal[Ca-Ox-1]516140Ion Current 18[Ca-Ox]12-510-108-45-156-50-20-55-6020Ion Current 18 [E-12A]-5-3010280-2554Ion Current 28[Ca-Ox]-252Ion Current 44[Ca-Ox]-3001002000300400500600700Temperature (smoothed) [ C]8009001000Cement25dM-rel[B 10-1]200.04Mass change-0.26%0.02Mass change-0.17%15-0.210-0.4-0.02Mass change-1.83%50-0.6-1.2-1.4-1.6751.7 C463.0 C-2.0-0.12DTA Signal [B .36-750100200300400500600Temperature (smoothed) [ C]12-0.06-0.10-15-45-1.8-0.04-0.08-10DTA Signal [mV]dM-rel [%]-0.8811.1 C145.0 C-5-1.00.007008009001000dM-rel(derived) [%/min]0.0The main parts of cement aretri calcium silicate, di calciumsilicate and tri calcium aluminates. Hydrates slowly form after mixing cement with water.The absorbed water evaporatesfirst. Hydrates of the calciumsilicate decompose at 570 C.The hydroxides of calcium, magnesium and aluminum follow.Subsequently, CO2 splits offfrom calcium carbonate.

Decomposition of rubber1000dM-rel[Rubber 2]09505.0Mass change -9.27%4.5DTA Signal[Rubber 2]9004.0-58503.5-108003.0Dehydration750Mass change-35.99%-157002.5-201.5550500450dM-rel [%]Temperature [ C]6001.0-250.5-300.0-0.5-35400350-40300-1.0Mass change-14.33%Temperature [Rubber 2]-1.5-2.0-45250-2.5Release of volatile parts200-50-3.0150-3.5-5510050-4.0Burn out of organic parts-600DTA Signal(1.Deriv.) [µV/ C]2.0650Atmosphere: N2051015202530-4.5Atmosphere: O2354045In the first step of weight loss,the dehydration of the sample takes place. The amountof water was 9.27%. In the second reaction step, the volatilecomponents are released bypyrolysis under N2 atmosphere.The amount of these components is 35.99%. For the thirdreaction step, the atmosphereis changed to O2 – all organiccomponents are burned out.The loss in weight is 14.33%.The remaining rest of 40.41%are inorganic components likeashes, slake or fillers.-5.0505560Time [min]Aspirin0-20-50-600.0DTA-Signal (smoothed) [Asp-1]-1.0-2.0-4-3.0-6-4.0-8-5.0-10Mass ass change-3.46% Mrel [%]-40DTA-Signal (smoothed) [µV]-21.0Mass change -1.12% DehydrationDTA Signal(1.Deriv.) [µV/ C]2 Endo Exo 4-10-30 Mrel[Asp-1]6Mass change-28.03%0At the beginning of the heatingprocess some adsorbed wateris released, resulting in a weightloss of around 1%. At 140 C themelting point of the Aspirin isreached, resulting in an exothermic reaction, measured onthe DTA trace. At 160 C the decomposition of the melted drugtakes place in several stages.Since the decomposition products are volatile a weight lossof just about 80% occurs.143.5 C 0520Temperature (smoothed) [ C]13

LINSEIS GmbH GermanyLINSEIS Inc. USAVielitzerstr. 43109 North Gold Drive95100 SelbRobbinsville, NJ 08691Tel.: ( 49) 9287 880 0Tel.: ( 1) 609 223 2070E-mail: info@linseis.deE-mail: info@linseis.deLINSEIS ChinaLINSEIS FranceKaige Scientific Park 2653 Hunan Road1 Route de Trévoux201315 Shanghai69250 Neuville/SaoneTel.: ( 86) 21 5055 0642Tel.: ( 33) 6.24.72.33.31Tel.: ( 86) 10 6223 7812E-mail: contact@ribori-instrumentation.comE-mail: info@linseis.deLINSEIS Polandul. Dabrowskiego 105-800 PruszkówTel.: ( 48) 692 773 795E-mail: info@linseis.dewww.linseis.comProducts: DIL, TG, STA, DSC, HDSC, DTA, TMA, MS/FTIR, In-Situ EGA, Laser Flash, Seebeck Effect, Thin Film Analyzer, Hall-EffectServices: Service Lab, Calibration Service02/20

10 SPECIFICATIONS TGA 1000 Design Top-loading Temperature range (10 C) RT up to 1100 C Heat and Cooling rates 0.001 up to 250 C/min Sample mass max. 5g Resolution 0.1µg Gas atmospere Inert, ocid, red., vaccum Vacuum up to 10E-2mbar Gas Dosing built-in MFC block with 3 gases (one Purge gas and two reactive gases)