Transcription

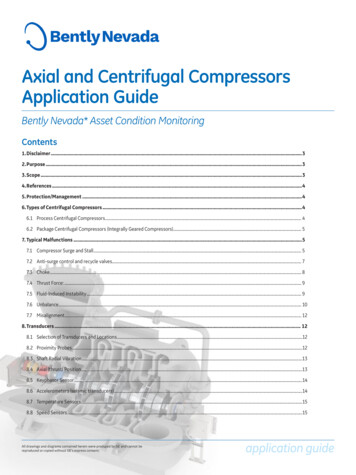

GE Oil GasAxial and Centrifugal CompressorsApplication GuideBently Nevada* Asset Condition MonitoringContents1. Disclaimer.32.Purpose.33. Scope.34. References.45. Protection/Management.46. Types of Centrifugal Compressors.46.1 Process Centrifugal Compressors. 46.2 Package Centrifugal Compressors (Integrally Geared Compressors). 57. Typical Malfunctions.57.1 Compressor Surge and Stall. 57.2 Anti-surge control and recycle valves. 77.3 Choke. 87.4 Thrust Force:. 97.5 Fluid-Induced Instability. 97.6 Unbalance. 107.7 Misalignment. 128. Transducers 128.1 Selection of Transducers and Locations 128.2 Proximity Probes 128.3 Shaft Radial Vibration 138.4 Axial (thrust) Position 138.5 Keyphasor Sensor 148.6 Accelerometers (seismic transducers) 148.7 Temperature Sensors 158.8 Speed Sensors 15All drawings and diagrams contained herein were produced by GE and cannot bereproduced or copied without GE’s express consent.application guide

application guide9. Bently Nevada 3500 Series Machinery Protecting System 159.1 3500 System Overview 159.2 System Copmonents Selection 169.2.1 Instrument Rack 169.2.2 Power Supplies 169.2.3 Trasnient Data Interface Module 179.3 Monitor Module Selection 169.3.1 Vibration Monitors 179.3.2 Keyphasor/Speed/Overspeed Monitors 189.3.3 Temperature Monitors 209.3.4 Relay Modules 209.3.5 Alarm Setpoints 219.6.6 Vibration Instrumentation diagram for Dual Flow Centrifugal Compressor 239.6.7 Vibration Instrumentation diagram for Axial Flow Compressor 249.6.8 Vibration Instrumentation diagram for Integrally Geared Compressor (3 or 4 stage) 2610. The Industrial Internet 2811. Management with System 1* Software 2811.1 Outline of System1 2811.2 Thermodynamic Performance 2911.3 Automated Machinery Diagnostic Functionality 2911.4 Centrifugal Compressor RulePak 3011.5 Axial Flow Compressor RulePak 3011.6 Integral Gear Compressor RulePak 3112. SmartSignal Integration 31APPENDIX 1 System 1 Software and Network Connectivity 32APPENDIX 2 Process Inputs for the RulePaks 34APPENDIX 3 OptiComp* BN 35APPENDIX 4 Data Required for Thermodynamic Performance 37APPENDIX 5 Discussion of 3500 Thrust Measurement and API 670 Compliance 38APPENDIX 6 Voting Truth Tables for Normal AND and True AND voting 402

application guide2 PurposeThe purpose of this document is to establish guidelines for theselection and installation of GE’s Bently Nevada transducersand protection and monitoring systems on axial and centrifugalcompressors with fluid film bearings – classified as criticalmachines. These recommendations apply to both new machinesand existing machine installations targeted for retrofit.3 ScopeThe American Petroleum Institute (API) 617 style compressors aretypically found in refinery and petrochemical applications.GE strongly recommends the continuous collection, trending andanalysis of the radial vibration, axial position, and temperaturedata using a machinery management system such as System 1*software. Use of these tools will enhance the ability to diagnoseproblems and analyze the performance of the compressors.Compressor asset management best practices indicate the use ofthe following items: Proper transducer suite Corresponding 3500 machine protection sys

4 application guide 4 References 1. API Standard 670 Fifth Edition, November 2014 2. API Standard 617 Eight Edition, Axial and Centrifugal Compressors and Expander-compressors for Petroleum,