Transcription

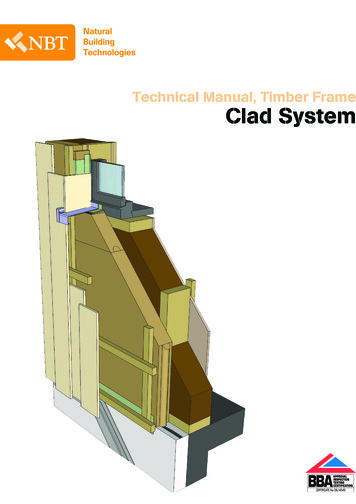

Series 45Frame K and LOpen CircuitAxial Piston PumpsService ManualDisplacement PistonPistonSwashplateTapered RollerBearingTapered RollerBearingShaft SealValve PlateCylinder Block Kit

Series 45 Frame K and L Open Circuit Axial Piston PumpsService ManualContentsINTRODUCTIONUsing this manual. 4Safety precautions. 4Unintended machine movement. 4Flammable cleaning solvents. 4Fluid under pressure. 4Personal safety. 4Symbols used in Sauer-Danfoss literature. 5General description. 6The system circuit. 7TECHNICALSPECIFICATIONSGeneral specifications. 8Type of mounting. 8Auxiliary mounting pad options. 8Control options. 8Port options. 8Direction of rotation. 8Installation position. 8Technical specifications. 8Hydraulic parameters. 9Inlet pressure. 9Pressure compensator valve setting. 9Case pressure. 9Hydraulic fluid . 9Fluid viscosity. 9Filtration . 9FEATURESDisplacement limiter.10Auxiliary mounting pads.10Input shafts.10Control options.11Operation.11Electric Proportional Controls.13Electric On/Off Controls.13 2001 Sauer-Danfoss. Sauer-Danfoss accepts no responsibility for possible errors in catalogs, brochures and other printed material. Sauer-Danfossreserves the right to alter its products without prior notice. This also applies to products already ordered provided that such alterations can be madewithout subsequent changes being necessary in specifications already agreed. All trademarks in this material are properties of their respective owners.Sauer-Danfoss and the Sauer-Danfoss logotype are trademarks of the Sauer-Danfoss Group. All rights reserved. Printed in U.S.A. (0402H)2520L0532 Rev AB October 2012

Series 45 Frame K and L Open Circuit Axial Piston PumpsService ManualContentsPRESSUREMEASUREMENTRequired tools.14Port locations and gauge installation.14INITIAL START-UPPROCEDURESGeneral.15Start-up procedure.15FLUID AND Excessive noise and / or vibration.17Actuator response is sluggish.17System operating hot.18Low pump output flow.18Pressure or flow instability.18System pressure not reaching PC setting.19High inlet vacuum.19ADJUSTMENTSPC control.20LS control.21MINOR REPAIRShaft seal replacement.22Auxiliary pads.23LS and PC Controls.24LS and PC Controls.25Electric Controls.26Servo Control Orifice.29Plug and fitting sizes and torques.30520L0532 Rev AB October 20123

Series 45 Frame K and L Open Circuit Axial Piston PumpsService ManualIntroductionUSING THIS MANUALThis manual includes information for the normal operation, maintenance, and serviceof the Series 45 frame K and L open circuit pumps. The manual includes a descriptionof the units and their individual components, troubleshooting information, adjustmentinstructions and minor repair procedures. Unit warranty obligations should not beaffected if maintenance, adjustment and minor repairs are performed according to theprocedures described in this manual.Many service and adjustment activities can be performed without removing the unitfrom the vehicle or machine. However, adequate access to the unit must be available,and the unit must be thoroughly cleaned before beginning maintenance, adjustment,or repair activities. Since dirt and contamination are the greatest enemies of any type ofhydraulic equipment, follow cleanliness requirements strictly. This is especially importantwhen changing the system filter and when removing hoses or plumbing.A worldwide network of Sauer-Danfoss Authorized Service Centers (ASCs) is availableshould major repairs be needed. Contact any Sauer-Danfoss ASC for details. A list of allASCs can be found in bulletin BLN-2-40527, or in brochure SAW (Ident. No. 698266), oryou can locate your nearest ASC using the distributor locator at www.sauer-danfoss.com.SAFETY PRECAUTIONSAlways consider safety precautions before beginning a service procedure. Protectyourself and others from injury. Take the following general precautions whenever servicinga hydraulic system.Unintended machine movement WARNINGUnintended movement of the machine or mechanism may cause injury to the technicianor bystanders. To protect against unintended movement, secure the machine or disable/ disconnect the mechanism while servicing.Flammable cleaning solvents WARNINGSome cleaning solvents are flammable. To avoid possible fire, do not use cleaningsolvents in an area where a source of ignition may be present.Fluid under pressure WARNINGEscaping hydraulic fluid under pressure can have sufficient force to penetrate your skincausing serious injury and/or infection. This fluid may also be hot enough to cause burns.Use caution when dealing with hydraulic fluid under pressure. Relieve pressure in thesystem before removing hoses, fittings, gauges, or components. Never use your handor any other body part to check for leaks in a pressurized line. Seek medical attentionimmediately if you are cut by hydraulic fluid.Personal safety WARNINGProtect yourself from injury. Use proper safety equipment, including safety glasses, at alltimes.4520L0532 Rev AB October 2012

Series 45 Frame K and L Open Circuit Axial Piston PumpsService ManualIntroductionSYMBOLS USED INSAUER-DANFOSSLITERATURE WARNING may result in injury Tip, helpful suggestion CAUTION may result in damage toproduct or property Lubricate with hydraulic fluid Reusable part Non-reusable part, use a new part Non-removable item Option – either part may exist Superseded – parts are notinterchangeable Apply grease / petroleum jelly Apply locking compound Inspect for wear or damage Clean area or part Be careful not to scratch or damage Note correct orientation Measurement required Mark orientation for reinstallation Flatness specification Torque specification Parallelism specification Press in – press fit External hex head Pull out with tool – press fit Internal hex head Cover splines with installationsleeve Torx head O-ring boss port Pressure measurement / gaugelocation or specificationThe symbols above can be found in the illustrations and text of this manual. They areintended to communicate helpful information at the point where it is most useful to thereader. In most instances, the appearance of the symbol itself denotes its meaning. Thelegend above is provided to define each symbol and explain its pu

x Joysticks and Control Handles x Microcontrollers and Software x Open Circuit Axial Piston Pumps x Orbital Motors x PLUS 1 GUIDE x Proportional Valves x Sensors x Steering x Transit Mixer Drives Memers of te Sauer-Danfoss roup: Comatrol www.comatrol.com Scwarmller-Inverter www.schwarzmueller-inverter.com Turolla www.turollaocg.com Hydro-Gear www.hydro-gear.com Sauer-Danfoss-Daiin www.sauer .