Transcription

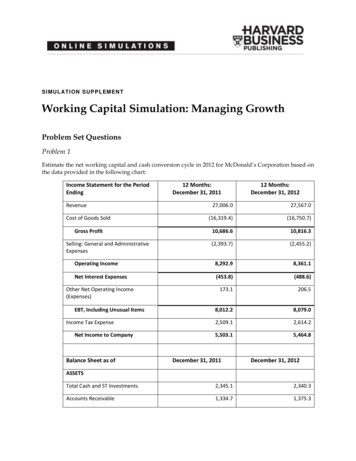

SOLIDWORKS Simulation – Avoiding SingularitiesWhat is a Singularity?A singularity is a function’s divergence into infinity. SOLIDWORKS Simulation occasionally producesstress (or heat flux) singularities.How do they occur? Mathematically, the solver uses matrices to represent the elastic field(displacements of the elements). When a highly localized load is applied, the gradients of thedisplacement vectors begin to diverge, causing the roots of the matrices to go to infinity. For asimplified explanation, see the stress equation below. Stress goes to infinity due to force applied ina very small area.𝜎 𝐹𝐴𝑜Where do they occur? Singularities are usually seen at points, edges, or reentrant corners.Reentrant corners are interior corners, with angles pointing into the part. The high stressconcentrations are usually seen near 90 degree corners, but can potentially occur for any angleless than 180 degrees.Why don’t they occur in real life? Think of the common case of singularities created on interiorcorners. In software, that corner is perfectly sharp. In real life, there will always be a slight bend.Also, the part may deform slightly,or “slip”, and allow the faces of“Adjust your legend’s color settings to grey out above thethe corner to slide against eachmaterial’s yield point. This prevents singularities fromother. The slight bend andovershadowing other important stress results!”additional friction allow for aconverging stress.-Joe Engineer, Know It All, GoEngineerIs it a Singularity?There are two methods to determine whether a stress concentration is a singularity.Method for SOLIDWORKS 2016 and earlier:First, apply sensors in high stress locations. Secondly, activate trend tracker to monitor thosesensors. Third, use increasingly fine mesh controls in the high stress regions. As mesh finenessincreases in the high stress fields, the stress sensors will either converge or diverge, viewable inyour trend tracker graph.888.688.3234 GOENGINEER.COM

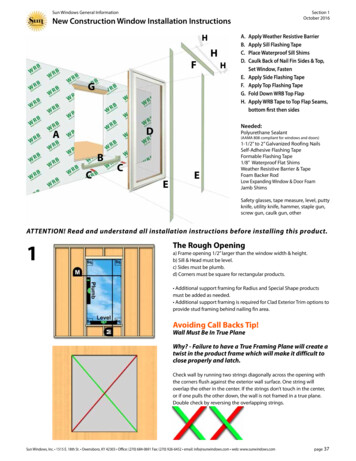

Have you not used Trend Tracker before? It is explained at the end of this tion/?open video 9003#prettyPhotoMethod for SOLIDWORKS 2017 and later:Create a Stress Hot Spot Diagnostics graph. This plot shows the variation of von Mises stresses.Areas with high, rapidly changing von Mises stresses, indicative of a singularity, will be highlightedin grey.Want to see how to create these hot spot plots? Watch our What’s New in 2017 video here:http://gou.teachable.com/How to Avoid?You now understand singularities and have determined you have a singularity in your part. If youwant to fix it, you must adjust your part or adjust the settings in your study.Adjust GeometryLocate reentrant corners where singularities most commonly occur. Since the force transfer tryingto go through that edge is causing the singularity, provide a larger surface area in order todistribute the loads. Fillets or chamfers are commonly used. The pictures below demonstrate thisconcept.Figure 1. Re-entrant corner vs. FilletDon’t let the fear of singularities prevent you from defeaturing your models. Remember,sometimes fillets are useful, but they always cause a finer mesh and longer calculation times.If non-filleted re-entrant corners are unavoidable in your part, design nearby support to preventcrack growth. This support must dissipate the load over a larger surface area before allowing theload to affect the reentrant corner.888.688.3234 GOENGINEER.COM

Adjust FixturesA fixture applied at a point or edge can cause a singularity. To understand why, consider a simplecantilever beam problem. The force being applied on one end of the beam must be counteractedby the fixed end. If the element along the edge of the beam is forced to remain rigid whilesimultaneously counteracting the force, a singularity is created. In this situation, applying thefixture to the face rather than the edge will prevent divergence.If fixing the face is not applicable, include the component from the assembly that is creating thefixture. A fraction of the component may also be used as long as it is large enough to allow forcomplete load transfer. Only replace components with fixtures if the component is much stifferthan the study’s part, or if the fixtures are far removed from important results.Figure 2. Fixture on edge.Realize that some connectors act as fixtures too. Check if your connector is assuming infinitestiffness by accessing the Solidworks Help menu. If so, adjust your connectors or include themodeled part in the study. The assembly shown below is connected by a tight-fit bolt connector.The tight fit allows the shank to deform, but the nut is still infinitely stiff. The actual bolt needs tobe modeled.Figure 3. Singularity due to Connector.Adjust loads888.688.3234 GOENGINEER.COM

Don’t apply force or a heat source at points or small edges. This causes a sharp inflection point inthe data input into the deflection equations, which leads to the singularity. If a thin loading area isrequired, create split lines and apply force to the area between them, as in the picture below. Thiswill allow convergence.Figure 4. Load on area.Adjust MeshWeak singularities may form at the interface of two bonded materials in a thermal study. This isdue to the more rigid nature of a bonded element. If necessary, provide a thermal resistance alongthe interface—this will detract from the implied “perfect” bond.In nonlinear studies where parts are yielding, a single element’s calculations may collapse if it istoo different relative to its neighbors. Fix this by either reducing the aspect ratio in the standardglobal mesh or applying a mesh control.How can I ignore the singularity?If you have confirmed the singularity, you know it is due to idealization, or the stress is farremoved from the important areas of the model, it is allowable to ignore it.If you are concerned about the stress near the singularity, use an Energy Norm Error plot.Singularities and high stress change areas will produce high energy norm errors.1. Refine your mesh in these areas until you have reduced the error region.2. Create sensors very near the error region.3. Confirm those sensors are converging on a stress result.More practically, the stress results near the error region will likely realistically represent the stressin the singularity regions.888.688.3234 GOENGINEER.COM

Figure 4. Singularity within Energy Norm Error plot.SummarySingularities are idealization errors that you can avoid by understanding the assumptions made withinthe software. First confirm singularities using a hot spots plot, or a trend tracker graph withincreasingly finer mesh. Then adjust your geometry, connections, fixtures, loads, or mesh dependingon the location of the singularity. If that does not help, use the Energy Norm Error plot and refinedmesh to determine what results can be trusted.888.688.3234 GOENGINEER.COM

SOLIDWORKS Simulation occasionally produces stress (or heat flux) singularities. How do they occur? Mathematically, the solver uses matrices to represent the elastic field (displacements of the elements). When a highly localized load is applied, the gradients of the displacement vectors begin to diverge, causing the roots of the matrices to go to infinity. For a simplified explanation, see the .