Transcription

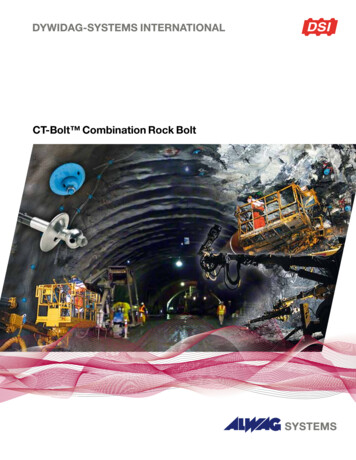

CT-Bolt Combination Rock Bolt

2

ContentsIntroduction. 3Fields of Application. 4Main Advantages. 4System Description. 4System Components. 5Specifications. 5Installation Procedure. 6Technical Features. 6Further References. 6IntroductionThe CT-BoltTM is an unique combinationrock bolt system. It offers the combinedadvantages of an immediate pointanchorage and subsequently a fullygrouted rock bolt. A two-step installationprocedure allows fast installation andimmediate anchorage, separate andindependent grouting provides flexibilityin regard to working cycles.Due to the controlled grouting procedureand different bar coatings available, theCT-BoltTM is a reliable ground controlsystem for underground applications.The working ability of the CT-BoltTMhas been proven throughout variousunderground construction projects;the system has become a standard intoday’s state-of-the-art ground controlprocedures.3

Fields of Application Systematic permanent reinforcementof underground excavations Ground support for areas with limitedor no access during operationallifetimeMain Advantages Efficient, practically proven, andreliable rock reinforcement system Combination of an immediate pointanchorage and a fully grouted rockbolt Immediate load-bearing capacity afterinstallation by the mechanical anchor Fast installation and flexible postgrouting behind the working face Double corrosion protection dueto a polyethylene sleeve and groutcoverage Easy adjustment of the corrosionprotection level to customer demands Semi-automated or manual installationprocedureSystem Description Combination rock bolt Immediate point anchorage byactivation of an expansion shell anchor Post-grouting assembly featuresdouble corrosion protection4 Permanent roadways and excavations Hydropower and underground oil orgas storage caverns Sub-sea and sewer tunnels

System ComponentsPolyethylene sleeveCorrugated, with inner centralizersDome-shaped grouting adapterWith grouting hole and welded-on sleeveNutExpansion shellRebar rock boltCold rolled threads on both sides for mountingexpansion shell and nutPlateIncl. bore for grout dischargeSpecificationsCharacteristic Value / TypeUnitCT-M20CT-M22Outer rebar diameterThread designationCharacteristic yield load 1)Characteristic ultimate load 1)Borehole diameter range 2)Delivery lengths 4 - 511.5 - 6.01) After grouting2) Expansion shells for larger borehole diameters available upon request3) Delivery lengths up to 8.0 m are available upon request5

Installation ProcedureBorehole drilling Drilling of a borehole: Ø 44-51 mm Recommended borehole length: about100 mm longer than the bolt lengthBolt installation Insertion of the assembled CT-Bolt into the pre-drilled boreholeFlexible bolt grouting Preparation of cement grout accordingthe given specifications Pressing the bolt plate firmly againstthe excavation surface Connection of an injection adapter tothe grouting adapter of the CT-Bolt Activation of the expansion anchorby pre-stressing of the anchor nutprovides immediate point anchorage Primary grout flow inside the sleevetowards the bolt’s toe (expansionshell) - complete grout coverage of therebar Typical required torque: 200-300 Nm Secondary grout flow outside thesleeve until the grouting medium flowsout at the bore for grout discharge atthe hemispherical bolt plateFurther References Load indicators and rock bolt testingequipment available upon requestTechnical FeaturesCombination rock bolt Active reinforcement by pre-stressingof the expansion anchor Allowance of a certain amount ofelastic deformation of the rebarinduced by displacements of the rockmass Flexible grouting behind the workingface allows an optimum adoption ofthe CT-Bolt to given ground andoperating conditions Optimum alignment and assurance ofcomplete grout coverage of the rockbolt by the polyethylene sleeveUnique choice of the corrosionprotection level Protection of the components of theCT-Bolt according to given levels ofcorrosive environments Bolts are available black, hot dipgalvanised, or with a specialCombi Coat (combination of hotdip galvanizing, zinc phosphate, andpowder coating) Indicated lifetimes for load-bearingcomponents of the fully-groutedCT-Bolt by accelerated corrosiontests performed by Vik Ørsta AS from50 (black type) to 150 (Combi Coat type) years6

7

AustriaEMEADYWIDAG-Systems International GmbHAlfred-Wagner-Strasse 14061 Pasching/Linz, AustriaPhone 43-7229-610 49 0Fax 43-7229-610 49 80E-mail raliabelgiumBosnia and herzegovinaBrazilCanadaNorth AmericaDSI Underground Systems Inc.9786 S Prosperity RoadWest Jordan, UT 84081, USAPhone 1-801-973 7169Fax 1-801-973 7172E-mail d.comChileColombiaC o s t a R i caCroatiaCzech republicDenmarkSouth AmericaDSI Chile Industrial Ltda.Las Encinas #1387, Valle GrandeLampa, Santiago de Chile, ChilePhone 56-2-596 96 20Fax 56-2-596 96 69E-mail gyptestoniaFinlandFranceGermanyGreeceGU A TEM A L AAPAC/ASEANDYWIDAG-Systems International Pty. Ltd.25 Pacific HighwayBennetts Green, NSW 2290, AustraliaPhone 61-2-49 48 90 99Fax 61-2-49 48 99 56E-mail UR A SHong KongIndonesiaItalyJapanKoreaLebanonLuxembourgMa l a y s i aMexicoNetherlandsNorwayOmanPa n a m aPa r a g u a yPeruPOL A NDPortugalQatarSa u d i A r a b i asingaporeS o u t h A f r i caSpainSwedenSwitzerlandTa i w a nThailand„ALWAG“ (AM 952/79), „AT“ (AM 6138/2003),„AT-SYSTEM” (AM 6139/2003),„DYWI “ (4197869), „LSC“ (AM 4326/2008),„OMEGA-BOLT “ (3258282),„POWER SET“ (AM 6163/2002), and„TUBESPILE“ (AM 4328/2008) are registeredtrademarks of DYWIDAG-Systems International GmbH.„Combi Coat “ and „CT-BoltTM“ are trademarks ofVik Ørsta AS. DYWIDAG-Systems International GmbHis a partner of Vik Ørsta AS.TurkeyUnited Arab EmiratesUnited kingdomUruguayUS AVenezuela04314-1/08.12-web hePlease note:This brochure serves basic informationpurposes only. Technical data and information provided herein shall be considerednon-binding and may be subject to changewithout notice. We do not assume anyliabilityfor losses or damages attributed to the useof this technical data and any improperuse of our products. Should you requirefurther information on particular products,please do not hesitate to contact us.

the CT-Bolt to given ground and operating conditions Optimum alignment and assurance of complete grout coverage of the rock bolt by the polyethylene sleeve Installation Procedure Borehole drilling Drilling of a borehole: Ø 44-51 mm Recommended borehole length: about 100 mm longer than the bolt length Bolt installation