Transcription

Engineering Analysis with SOLIDWORKS Simulation 20151

Engineering Analysis with SOLIDWORKS Simulation 2015Table of contentsAbout the AuthorError! Bookmark not defined.AcknowledgementsError! Bookmark not defined.Table of contents1Before You Start7Notes on hands-on exercises and functionality of SimulationPrerequisitesSelected terminology1: Introduction11What is Finite Element Analysis?Finite Element Analysis used by Design EngineersObjectives of FEA for Design EngineersWhat is SOLIDWORKS Simulation?Fundamental steps in an FEA projectErrors in FEAA closer look at finite elementsWhat is calculated in FEA?How to interpret FEA resultsUnits of measureUsing online helpLimitations of Static studiesl2: Static analysis of a plate37Using the SOLIDWORKS Simulation interfaceLinear static analysis with solid elementsControlling discretization error with the convergence processFinding reaction forcesPresenting FEA results in a desired format2

Engineering Analysis with SOLIDWORKS Simulation 20153: Static analysis of an L-bracketError! Bookmark not defined.Stress singularitiesDifferences between modeling errors and discretization errorsUsing mesh controlsAnalysis in different SOLIDWORKS configurationsNodal stresses, element stresses4: Static and frequency analyses of a pipe supportError! Bookmark not defined.Use of shell elementsFrequency analysisBearing load5: Static analysis of a linkError! Bookmark not defined.Symmetry boundary conditionsPreventing rigid body motionsLimitations of the small displacements theory6: Frequency analysis of a tuning fork and a plastic partError! Bookmark not defined.Frequency analysis with and without supportsRigid body modesThe role of supports in frequency analysisSymmetric and anti-symmetric modes7: Thermal analysis of a pipe connector and a heater Error! Bookmark not defined.Analogies between structural and thermal analysisSteady state thermal analysisAnalysis of temperature distribution and heat fluxThermal boundary conditionsThermal stressesVector plots8: Thermal analysis of a heat sinkError! Bookmark not defined.Analysis of an assemblyGlobal and local Contact conditionsSteady state thermal analysisTransient thermal analysisThermal resistance layerUse of section views in result plots3

Engineering Analysis with SOLIDWORKS Simulation 20159: Static analysis of a hangerError! Bookmark not defined.Global and local Contact conditionsHierarchy of Contact conditions10: Thermal stress analysis of a bi- metal loopError! Bookmark not defined.Thermal deformation and thermal stress analysisEliminating rigid body motionsConverting Sheet Metal bodies to Solid bobies"Parasolid" round tripSaving model in deformed shape11: Buckling analysis of I-beamError! Bookmark not defined.Buckling analysisBuckling load safety factorStress safety factor12: Static analysis of a bracket using adaptive solution methodsError! Bookmark notdefined.h-adaptive solution methodp-adaptive solution methodComparison between h-elements and p-elements13: Drop testError! Bookmark not defined.Drop test analysisStress wave propagationDirect time integration solution14: Selected nonlinear problemsError! Bookmark not defined.Large displacement analysisAnalysis with shell elementsMembrane effectsFollowing and non-following loadNonlinear material analysisResidual stress15: Mixed meshing problemError! Bookmark not defined.Using solid and shell elements in the same meshMixed mesh compatibilityManual and automatic finding of contact setsShell Manager4

Engineering Analysis with SOLIDWORKS Simulation 201516: Analysis of a weldment using beam elementsError! Bookmark not defined.Different levels of idealization implemented in finite elementsPreparation of a SOLIDWORKS model for analysis with beam elementsBeam elements and truss elementsAnalysis of results using beam elementsLimitations of analysis with beam elements17: Review of 2D problemsError! Bookmark not defined.5Classification of finite elements2D axi-symmetric element2D plane stress element2D plane strain element18: Vibration Analysis - Modal Time History and Harmonic Error! Bookmark notdefined.Modal Time History analysis (Time Response)Harmonic analysis (Frequency Response)Modal Superposition MethodDamping19: Analysis of random vibrationError! Bookmark not defined.1Random vibrationPower Spectral DensityRMS resultsPSD resultsModal excitation5

Engineering Analysis with SOLIDWORKS Simulation 201520: Miscellaneous topicsError! Bookmark not defined.1Mesh qualitySolvers and solvers optionsDisplaying mesh in result plotsAutomatic reportsE drawingsNon uniform loadsFrequency analysis with pre-stressInterference fit analysisRigid connectorPin connectorBolt connectorRemote load/massWeld connectorBearing connectorCyclic symmetryStrongly nonlinear problemSubmodelingTerminology issues in the Finite Element Analysis21: Implementation of FEA into the design process Error! Bookmark not defined.5Verification and Validation of FEA resultsFEA driven design processFEA project managementFEA project checkpointsFEA reports22: Glossary of termsError! Bookmark not defined.323: Resources available to FEA usersError! Bookmark not defined.124: List of exercisesError! Bookmark not defined.76

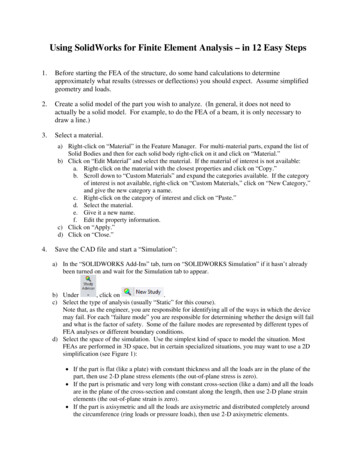

Engineering Analysis with SOLIDWORKS Simulation 2015Before You StartNotes on hands-on exercises and functionality of SimulationThis book goes beyond a standard software manual because its unique approachconcurrently introduces you to SOLIDWORKS Simulation software and thefundamentals of Finite Element Analysis (FEA) through hands-on exercises. Werecommend that you study the exercises in the order presented in the book. As you gothrough the exercises, you will notice that explanations and steps described in detail inearlier exercises are not repeated in later chapters. Each subsequent exercise assumesfamiliarity with software functions discussed in previous exercises and builds on theskills, experience, and understanding gained from previously presented problems.Exceptions to the above are chapters 21, 22, 23, 24 which do not include hands-onexercises.Exercises in this book require different levels of SOLIDWORKS Simulationfunctionality and this depends on which Simulation product is used. TheSOLIDWORKS Simulation Product Matrix document is available n/simulation-matrices.htmThis book deals with structural analysis using SOLIDWORKS Simulation.Therefore, Motion analysis won’t be covered. SimulationXpress is a simplifiedversion of SOLIDWORKS Simulation and will not be covered either.All exercises in this book use SOLIDWORKS models, which can be downloadedfrom www.SDCpublications.com. These exercises do not contain any Simulationstudies; you are expected to create all studies, results plots, and graphs yourself. Theonly exceptions are exercises in chapter 4 (MISALIGNMENT), 20 and 21 whichcome with Simulation studies fully or partially defined. All problems presented herehave been solved with SOLIDWORKS Simulation Premium running on Windows7 in a 64 bit operating environment.We encourage you to explore each exercise beyond its description by investigatingother options, other menu choices, and other ways to present results. You will soondiscover that the same simple logic applies to all functions in SOLIDWORKSSimulation.7

Engineering Analysis with SOLIDWORKS Simulation 2015“Engineering Analysis with SOLIDWORKS Simulation” is an introductory text. Thefocus is more on understanding Finite Element Analysis than presenting all softwarecapabilities. This book is not intended to replace software manuals. Therefore, not allSimulation capabilities will be covered, especially those of fatigue, design studies,optimization, advanced nonlinear thermal and dynamic analyses.Readers of "Engineering Analysis with SOLIDWORKS Simulation" may wish toreview the book “Thermal Analysis with SOLIDWORKS Simulation” (Figure 23-1)and “Vibration Analysis with SOLIDWORKS” (Figure 23-2), both published by theSDC Publications. These books are not introductory texts; they are designed for userswho are familiar with topics presented in “Engineering Analysis with SOLIDWORKSSimulation”.The knowledge acquired by the readers of "Engineering Analysis withSOLIDWORKS Simulation" will not be software specific. The same concepts, toolsand methods will apply to any FEA software.PrerequisitesThe following prerequisites are recommended: An understanding of Statics, Kinematics and DynamicsAn understanding of Mechanics of MaterialsAn understanding of Heat TransferAn understanding of Mechanical VibrationsExperience with parametric, feature based solid modeling using SOLIDWORKSFamiliarity with the Windows Operating System8

Engineering Analysis with SOLIDWORKS Simulation 2015Selected terminologyThe mouse pointer plays a very important role in executing various commands andproviding user feedback. The mouse pointer is used to execute commands, selectgeometry, and invoke pop-up menus. We use Windows terminology when referring tomouse-pointer -clickSelf-explanatoryClick-insideClick the left mouse button. Wait a second, andthen click the left mouse button inside the pop-upmenu or text box. Use this technique to modify thenames of items in SOLIDWORKS SimulationManager.Drag and dropUse the mouse to point to an object. Press andhold the left mouse button down. Move the mousepointer to a new location. Release the left mousebutton.Right-clickClick the right mouse button. A pop-up menu isdisplayed. Use the left mouse button to select adesired menu command.All SOLIDWORKS file names appear in CAPITAL letters, even though the actualfile names may use a combination of capital and small letters. Selected menu itemsand SOLIDWORKS Simulation commands appear in bold. SOLIDWORKSconfigurations, SOLIDWORKS Simulation folders, icon names and study namesappear in italics except in captions and comments to illustrations. SOLIDWORKSand Simulation also appear in bold font. Bold font may also be used to draw reader'sattention to particular term.9

Engineering Analysis with SOLIDWORKS Simulation 201510

Engineering Analysis with SOLIDWORKS Simulation 20151: IntroductionWhat is Finite Element Analysis?Finite Element Analysis, commonly called FEA, is a method of numerical analysis.FEA is used for solving problems in many engineering disciplines such as machinedesign, acoustics, electromagnetism, soil mechanics, fluid dynamics, and many others.In mathematical terms, FEA is a numerical technique used for solving field problemsdescribed by a set of partial differential equations.In mechanical engineering, FEA is widely used for solving structural, vibration, andthermal problems. However, FEA is not the only available tool of numerical analysis.Other numerical methods include the Finite Difference Method, the BoundaryElement Method, and the Finite Volume Method to mention just a few. However, dueto its versatility and numerical efficiency, FEA has come to dominate the engineeringanalysis software market, while other methods have been relegated to nicheapplications. When implemented into modern commercial software, both FEA theoryand numerical problem formulation become completely transparent to users.Finite Element Analysis used by Design EngineersFEA is a powerful engineering analysis tool useful in solving many problems rangingfrom very simple to very complex. Design engineers use FEA during the productdevelopment process to analyze the design-in-progress. Time constraints and limitedavailability of product data call for many simplifications of computer models. On theother hand, specialized analysts implement FEA to solve very complex problems,such as vehicle crash dynamics, hydro forming, and air bag deployment.This book focuses on how design engineers use FEA, implemented inSOLIDWORKS Simulation, as a design tool. Therefore, we highlight the mostessential characteristics of FEA as performed by design engineers as opposed to thosetypical for FEA performed by analysts.FEA for Design Engineers: Another design toolFor design engineers, FEA is one of many design tools that are used in the designprocess and include CAD, prototypes, spreadsheets, catalogs, hand calculations, textbooks, etc.11

Engineering Analysis with SOLIDWORKS Simulation 2015FEA for Design Engineers: Based on CAD modelsModern design is conducted using CAD, so a CAD model is the startingpoint for analysis. Since CAD models are used for describing geometric informationfor FEA, it is essential to understand how to prepare CAD geometry in order toproduce correct FEA results, and how a CAD modelis different from an FEA model. This will be discussed in later chapters.FEA for Design Engineers: Concurrent with the design processSince FEA is a design tool, it should be used concurrently with the design process. Itshould drive the design process rather than follow it.Limitations of FEA for Design EngineersAn obvious question arises: would it be better to have a dedicated specialist performFEA and let design engineers do what they do best – design new products? Theanswer depends on the size of the business, type of products, company organizationand culture, and many other tangible and intangible factors. A general consensus isthat design engineers should handle relatively simple types of analysis, but do itquickly and of course reliably. Analyses that are very complex and time consumingcannot be executed concurrently with the design process, and are usually betterhandled either by a dedicated analyst or contracted out to specialized consultants.12

Engineering Analysis with SOLIDWORKS Simulation 2015Objectives of FEA for Design EngineersThe ultimate objective of using FEA as a design tool is to changethe design process from repetitive cycles of “design, prototype, test” intoa streamlined process where prototypes are not used as design tools andare only needed for final design validation. With the use of FEA, design iterations ar

Engineering Analysis with SOLIDWORKS Simulation 2015 7 Before You Start Notes on hands-on exercises and functionality of Simulation This book goes beyond a standard software manual because its unique approach concurrently introduces you to SOLIDWORKS Simulation software and the fundamentals of Finite Element Analysis (FEA) through hands-on exercises. We recommend that you File Size: 717KBPage Count: 37