Transcription

Streamlined ProductMigration ManagementTrueCommerce is the most complete way toconnect your business across the supply chain –so you can do business in every direction.More Connected.More Supported.More Prepared forWhat’s Next.

eBrief Streamlined Product Migration Management with TrueCommerce Datalliance VMIEXECUTIVE SUMMARYPROBLEM:When new products areintroduced to replace existingproducts, two problems can result:hhLost sales because of availabilityproblems, orhhReduced profitability because ofexcessive returnsSOLUTION:VMI establishes the collaborativerelationship and informationsharing processes to dramaticallyimprove the handling of productmigrations.TrueCommerce extends thecore VMI process with toolsdesigned specifically to supportnew product introduction andmigration.RESULT:TrueCommerce makes it mucheasier to ensure a smoothintroduction of new products that:hhMaximizes availability and saleshhMinimizes returnsINTRODUCTIONOne of the most challengingactivities suppliers and distributorsneed to manage together is the‘migration’ from an existing productto a replacement product. It takesa lot of coordination to perform themigration smoothly without eitherlosing sales due to stock-outs oradding cost due to obsolete productleft in inventory.TrueCommerce Datalliance VMIprovides a number of important toolsto help suppliers and their distributionpartners effectively manage theproduct migration process. By usingthese tools, both partners can bettercommunicate with each other duringthe transition so that the distributorhas the new product at the right timeto meet customer demand whileminimizing the need for returns orwrite-offs of the obsolete product.Note: In addition to ‘product migration’,this process is often referred to as‘product lifecycle management’, ‘productsupersession’, and other terms. We willuse those terms interchangeably in thispaper.WHY PRODUCTS CHANGEOn-going innovation drives theneed for product migration. Whennew products – often using newtechnologies, materials or designs– are launched, they may be clearlysuperior or lower cost than those theyreplace, making the older productsvery difficult to sell once they arelaunched.Some industrial products may alsobecome obsolete and unsellableafter a certain point in time becauseof regulatory changes or otherexternal forces. For instance,plumbing products were requiredto be ‘lead free’ as of January 4,2014 and both commercial andresidential lighting standards weresignificantly changed with the EnergyIndependence and Security Act of2007 (EISA 2007) obsoleting manytypes of bulbs and even fixturesbetween 2012 and 2014.2RESULTS OF POOR PRODUCTMIGRATION HANDLINGA number of negative things can happenwhen product migrations are not handledwell. A lot of hard work and expenditureon new product promotion can bewasted when customers find only the oldproduct at the distributor because thenew product was not shipped. Or worseyet, they find no product at all.On the other hand, if the old productis not sold down in preparation forintroduction of the new product, therecan be excessive old product left onthe shelves. Eventually, that inventorywill need to be either written off by thedistributor or returned to the supplier whoin turn may need to write it off.WHAT MAKES PRODUCTMIGRATIONS A CHALLENGEWhat causes poor handling of productmigrations? Essentially one thing – poorcommunication between the supplierand distributor. The distributor has no wayof knowing that a supplier is planning aproduct replacement until the suppliertells them. If that communication ismissed and the distributor is doing theirown replenishment ordering, they arelikely to keep ordering the old productuntil the supplier simply stops shipping it.Without shared visibility of thedistributor’s inventory and the supplier’snew product launch plans, it’s virtuallyimpossible to achieve a smooth phase-inof the new product.HOW A VMI RELATIONSHIPMAKES A BIG DIFFERENCESuppliers and distributors in a VMIrelationship have a tremendousadvantage when it comes to managingproduct migrations. First of all, VMIdoes a couple of fundamental thingsthat really help:hhVMI puts primary responsibility forproduct replenishment in the handsof the supplier. The supplier has theknowledge about the nature andtiming of the product changeover.They know exactly what product isbeing replaced and when the newproduct will be available to ship.www.datalliance.com

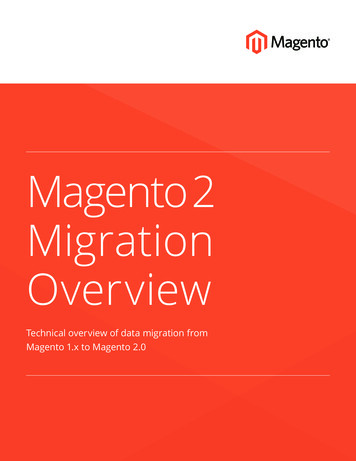

eBrief Streamlined Product Migration Management with TrueCommerce Datalliance VMIhhVMI gives the supplier’s VMI plannerclear visibility of inventory anddemand for the old product at eachdistributor.This combination gives the supplier’sVMI planner far more ability to adjustreplenishment of the old product fora smooth sell-down while initiatingshipment of the new product in timeto be available in the right quantity asthe old product runs out.CHALLENGES THAT REMAINVMI helps greatly in the managementof the product migration process. But,like many inventory managementprocesses, the devil is in the details.The VMI planner may have hundredsor even thousands of SKUs to manage.A dozen or more of those might be intransition at any given time. That’s a lotto keep track of each day - especiallyif the supplier is managing a largenumber of distributor locations.And in some cases, such as replacementparts for equipment or machinery,there may be a long series of partsupersessions that spans many years.For parts that only sell infrequently,the current part at replenishment timemay actually be multiple iterations fromwhat was previously stocked by a givendistributor.HOW TRUECOMMERCEDATALLIANCE GOES BEYONDSTANDARD VMITrueCommerce Datalliance VMIgives the supplier a combinationof tools to help the VMI plannersmoothly manage the productmigration process. Those tools makeit easy for the VMI Planner to knowwhat products are in the process ofmigration; where the transition stands;what item to ship at any point in time;and what to communicate to thedistributor during each phase of themigration. Specifically, those tools are:hhAn item status indicator withvalues of ‘active’, ‘inactive’, ‘obsolete’,‘replaced’, ‘recalled’, or ‘do not stock’.Only ‘active’ items are automaticallyreplenished.www.datalliance.comhhTwo alternative ways to indicate thereplacement situationhhFor simple cases: thereplacement item for an itembeing replaced.hhFor more complex cases, amaster item with a family ofmultiple actual items, showing thesequence of supersession andthe currently shipping item.hhThe obsolescence date for olditem – this date impacts how longreturns may be allowed based onpolicy – e.g. ‘n’ days after obsoletedate.hhA Product life cycle indicator setby the supplier with user-definedvalues that tell the VMI plannermore specifically what they shouldbe communicating to the distributorabout a particular item at variouspoints in its life cycle. For instance:values could be something like‘New’, ‘Phasing In’, ‘New andAvailable’, ‘Mature’, ‘Phasing Out’,‘Retired’. The values are usuallytaken from the supplier’s businesssystem so the meanings are alreadywell recognized.TrueCommerce Datalliance VMI does anumber of things with this informationto help the VMI Planner manageproduct migrations. These are:hhAlert the VMI Planner any timean inactive item shows up with asuggested replenishment so theycan make a conscious decision ofwhich item to send. The system canoptionally be set to automaticallyremove inactive items from an orderif desired.hhAlert the VMI Planner based onthe Product Lifecycle Indicator.This alert tells the VMI Plannerwhat conversation they shouldbe having with the distributor.For instance, if the indicator issomething like ‘phasing out’, theplanner may want to give thedistributor notice that the itemwill only be available to returnfor ‘n’ more weeks based on theobsolete date and policy.3

eBrief Streamlined Product Migration Management with TrueCommerce Datalliance VMITrueCommerceMANAGING PRODUCT MIGRATION WITHTRUECOMMERCE DATALLIANCE VMI AT A GLANCEDatalliance VMIcombination of tools tohelp the VMI plannerPhasePlanninggives the supplier asmoothly managethe product migrationprocess. Those toolsmake it easy for theTrueCommerce Datalliance VMIReporting to identify scope ofmigrationSupplier can effectively planrequired effort and timeframeCustomer Care knowledge ofboth supplier and distributorsystem capabilitiesSupplier can request assistanceto plan the most efficient,effective migration processAlerts when old product issuggested for replenishmentPrevent shipment of old productonce phase-out beginsAlerts at key stages of eachproduct’s lifecycleVMI planner knows what tocommunicate to distributor –e.g. migration beginning; newproduct now shipping; returnsallowed until specific date, etc.Automatic exclusion of olditem on distributor’s stock-inreportPrevent old item replenishmentbeing inadvertently triggeredCopy or summation of historyfrom old item(s) to new itemProperly plan replenishmentquantities for new itemCombining of ‘net quantityavailable’ for old and new itemsSmooth, cost-effective ‘selldown’ of old item whilebeginning shipment of new itemSuggested returns reportAutomate returns per policy ifexcess residual inventory occursExclusion from suggestedreturns reportAutomate prevention of returnsafter allowed periodin the process ofExecutionVMI Planner to knowwhat products aremigration; where thetransition stands; whatitem to ship at anyto communicate to thedistributor during eachphase of the migration.4Completionpoint in time; and whatBenefitswww.datalliance.com

eBrief Streamlined Product Migration Management with TrueCommerce Datalliance VMIhhExclude an item from theDistributor Suggested StockingReport based on the value of theProduct Life Cycle Indicator. Thisperiodic report tells the distributorwhat items should have shelfspace allocated to them. Once anitem reaches an end-of-life status,it is automatically removed fromthis report to prevent additionalinventory being pushed into thesupply chain.Once the supplier and distributormake the decision to beginreplenishing only the new item, thesupplier can work with TrueCommerceDatalliance Customer Care toimplement this in one of two ways:hhImmediately switch to the newitem. This is done by copyingthe demand history from the olditem to the new item to drivereplenishment.hhInitiate ‘sell-down’ of the old itemwhile beginning replenishmentwith the new item. This is doneby combining the ‘Net QuantityAvailable’ (NQA) of the two items.This way the new item is shippedwhen replenishment is needed,but the proper combined quantityof both items is maintained untilthe old item is sold down to zero.When using the master itemcapability, demand history and NQAare combined for all items in thefamily and applied to the currentlyshipping item.Once the migration is complete,TrueCommerce Datalliance VMI helpsmanage any returns of the old productbased on the agreed upon policy.Specifically, it will:hhAllow or not allow the item to bereturned on the Suggested ReturnsReport based on the ProductLifecycle Indicator. As long as thevalue indicates that returns are stillallowed, the item will be treatednormally and will show suggestedreturns if distributor stock is inexcess. When that value indicatesthat returns are no longer allowedbut the distributor still has stock,the item will show on the reportas having excess, but as ‘rejected’based on policy.IN STOCK ISWHAT’S INSTOREwww.datalliance.com5

eBrief Streamlined Product Migration Management with TrueCommerce Datalliance VMITRUECOMMERCEDATALLIANCE VMIAUTOMATED RETURNSPROCESSINGAnother innovative capabilityprovided by TrueCommerceDatalliance VMI is automatedreturns processing. VMI greatlyreduces the need for returns, butthey can never be fully eliminated.With TrueCommerce DatallianceVMI you can at least make theprocess dramatically easier tomanage.Request the ‘Returns Automation’solution brief to learn how it savesboth suppliers and distributors atremendous amount of time, effortand cost.OTHER WAYS TRUECOMMERCEDATALLIANCE CAN HELPThe TrueCommerce DatallianceCustomer Care team is veryexperienced at planning for andmanaging product migrations, and ishappy to provide additional assistanceto planners throughout the process.For instance, they can produce reportsthat cover all distributor locationswhere a particular item is currentlybeing stocked in order to give theplanner a better idea of the scope ofthe migration before it begins. Andbased on knowledge of both thesupplier’s system and the distributorsystems, Customer Care will often helpthe planner identify the best approachto managing the migration. Then, asstated earlier, they can help handlethe ‘copy history’ and ‘combined NQA’process described above.As with all aspects of the VMI process,TrueCommerce Datalliance CustomerCare is an integral part of the overallTrueCommerce Datalliance VMI solution.RESULT: SMOOTH, PROFITABLEMIGRATIONShhNo migration steps ‘fall throughthe cracks’ because TrueCommerceDatalliance VMI is continuallymonitoring the situation and alertingthe VMI planner to any actions thatshould be taken.hhThe need for returns is minimizedbecause of the well-coordinatedmigration. Just as importantly,any items that are candidates forreturn are clearly communicated soboth parties avoid surprises whenthe window for allowed returns isreached.SUMMARY – ADDINGCONSIDERABLE VALUE TO THESUPPLY CHAINProduct migrations are a fact of life inall markets. Without VMI, an efficientand profitable management ofmigrations can be extremely difficult.By providing simple, yet powerfultools to guide VMI Planners throughthe entire process, TrueCommerceDatalliance VMI makes productmigration smooth, efficient, free ofsurprises, and profitable for both thesupplier and distributor.Using these TrueCommerceDatalliance VMI system capabilitiesand Customer Care services to driveprecise, timely communication, severalimportant benefits are achieved:hhThe supplier and distributor workclosely together on the timing ofthe product migration to introducethe new product at exactly the righttime, manage the residual inventory,and maintain high service levelsthroughout the process.ABOUT TRUECOMMERCETrueCommerce is the most completeway to integrate your businessacross the supply chain, integratingeverything from EDI to inventorymanagement, to fulfillment, to digitalstorefronts and marketplaces, to yourbusiness system and to whatevercomes next. That’s why thousands ofcompanies across various industriesrely on us.TrueCommerce.Do business in every direction.THE TRUECOMMERCE DATALLIANCE TEAM IS HERE TO HELP!If you have any questions regarding TrueCommerce Datalliance and VMI, or howit applies to your business, our passionate, focused team is here for you.Call us today at 513.791.7272www.datalliance.com Copyright 2019 True Commerce, Inc. All rights reserved. Reproduction in whole or in part without permission is prohibited, andinformation contained herein is subject to change without notice. TrueCommerce is a registered trademark of True Commerce, Inc.All other trademarks are property of their respective owners.

HOW A VMI RELATIONSHIP MAKES A BIG DIFFERENCE Suppliers and distributors in a VMI relationship have a tremendous advantage when it comes to managing product migrations. First of all, VMI does a couple of fundamental things that really help: h VMI puts primary responsibility for product replenishment in the hands of the supplier. The supplier .