Transcription

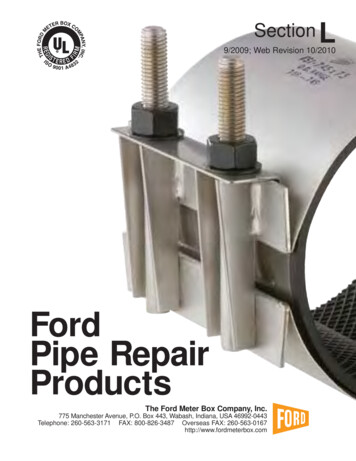

Section L9/2009; Web Revision 10/2010FordPipe RepairProductsThe Ford Meter Box Company, Inc.775 Manchester Avenue, P.O. Box 443, Wabash, Indiana, USA 46992-0443Telephone: 260-563-3171 FAX: 800-826-3487 Overseas FAX: 260-563-0167http://www.fordmeterbox.com

ContentsHydrostatic Test Pressures – Average . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4Installation Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5All Stainless Steel Style FS1 Quality Circle Repair Clamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6All Stainless Steel Style FS2 Quality Circle Repair Clamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7All Stainless Steel Style FS3 Quality Circle Repair Clamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7Fordflex Style F1 Quality Circle Repair Clamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8Fordflex Style F2 Quality Circle Repair Clamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9Fordflex Style F3 Quality Circle Repair Clamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9Ford Style FSC Snap Clamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10Ford Style FSC Wrap Clamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10Ford All Stainless Steel Style FLSC Snap Clamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11Ford All Stainless Steel Style FLSC Wrap Clamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11Ford Style FCC Repair Clamps for Solvent Weld PVC Couplings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12Ford Style FIBC Repair Clamps for Integral Bell Solvent Weld PVC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12Ford Style FBC Bell Joint Leak Clamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13Bolt Extension Kit for Bell Joint Leak Clamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13O.D. Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16F1F2F2WF3FS1FS2FS3FSCFLSCFCCFBCFIBC TYPE OF CLAMPSingle Band Stainless Steel Clamp with Ductile Iron LugsDouble Band Stainless Steel Clamp with Ductile Iron LugsSpecial Range Double Band Stainless Steel Clamp with Ductile Iron LugsTriple Band Stainless Steel Clamp with Ductile Iron LugsSingle Band All Stainless Steel ClampDouble Band All Stainless Steel ClampTriple Band All Stainless Steel ClampSnap ClampAll Stainless Steel Snap ClampRepair Clamp for Coupling Solvent Weld PVCBell Joint Leak ClampRepair Clamp for Integral Bell Solvent Weld PVCCLAMP LENGTH(Lengths are not required on styles FBC, FCCand FIBC)3 3" (FSC, FSC-R and FLSC only)6 6" (FSC, FSC-R and FLSC)75 7-1/2"9 9" (FSC, FSC-R and FLSC only)10 10"12 12" (FSC, FSC-R and FLSC only)125 12-1/2"15 15"20 20"24 24"30 30"FS1-939-15-CC4O.D. SIZEFor most clamp styles,the O.D. size numberindicates the top end ofthe range.Use listed Catalog H OPTIONAL FEATURES3/4" AWWA Tapped Thread1" AWWA Tapped Thread1-1/4" AWWA Tapped Thread1-1/2" AWWA Tapped Thread2" AWWA Tapped ThreadConductivity StripsEPDM Rubber Gasket for Repair ClampE-Coated Lugs (F1, F2, F3, FCC and FIBC)3/4" Iron Pipe Tapped Thread1" Iron Pipe Tapped Thread1-1/4" Iron Pipe Tapped Thread1-1/2" Iron Pipe Tapped Thread2" Iron Pipe Tapped ThreadBuna-N Rubber Gasket for Repair ClampWrap Clamp, features a 360 gasketStainless Steel Nuts & Bolts (for ductile lug clamps)

Typical Problems Solved WithFord Repair ClampsCracks or full breaks inasbestos-cement and cast iron pipePinholes in pittedcast iron and steel pipeHoles in asbestos-cement, cast iron,steel and plastic pipeSplits in asbestos-cement,cast iron, steel and plastic pipePipe ends with slight separationRepair leaking tap with a tappedrepair clamp.Fish mouthed gasket inasbestos-cement pipe couplingRemove coupling and replace itwith a Fordflex ClamporBroken asbestos-cement pipe couplingHydrostatic Test Pressures – Average550Test Pressure - PSI500450400Style F2350300250200Style F115010023456789101112131415Outside Diameter of Pipe - InchesConditions of Test Test Pipe: asbestos-cement, cast iron or steel Two pieces of test pipe with average space of 1/8" between ends, coupled together with 7-1/2" wideFordflex Clamp 5/8" bolts (clamps up through 4.73" O.D.) tightened to a torque of 30-35 ft. lbs., 5/8" bolts (clamps over 4.73O.D.) to 70-80 ft. lbs., and 3/4" bolts to 90-100 ft. lbs.Ford offers more than 10,000 products that are Classified by Underwriters Laboratories Inc. to ANSI/NSF Standard 61. Toverify if a product is classified to this Standard, contact the Ford Meter Box Customer Service Department at 260-563-3171or go to /1FRAME/index.htm to view our compliant product listings.The UL marking will be on the box label to indicate that the product is classified to the ANSI/NSF Standard 61. Ford MeterBox meets your needs for products that are proven and reliable.L-3

Ford Quality Circle Repair ClampsThe Ford Styles FS1, FS2 and FS3 All Stainless Steel RepairClamp combines the corrosion-resistant characteristics ofstainless steel and the sealing capabilities of rubber toprovide a strong, dependable and versatile repair clamp.The All Stainless design is lightweight and easy to handleunder adverse conditions associated with almost every mainbreak. The fixed bolt position provides uniform bolt controland fewer parts to fall into the trench. The sliding lifter baris retained on the bolts by the heavy hex nuts and facilitatesthe installation by serving as a handle to hold while installingthe clamp.18-8 TYPE 304 STAINLESSSTEEL BAND18-8 TYPE 304 STAINLESS STEELNUTS AND BOLTS.NUT THREADS ARE COATED.Ford Styles F1, F2 and F3 Repair Clamps provide a simpleand economical method of repairing holes or breaks in watermains, particularly where corrosion is not a factor. Fordclamps offer heavy-duty lug construction for maximum strengthand a drop-in bolt design that does not require bolt removalwhen installing the clamp. There are never any loose parts tolose in the ditch.Ford Repair Clamps come in a wide variety of styles and covera wide range of pipe diameters; other fine features of FordRepair Clamps are shown below.LOW ALLOY BOLTSAND HEAVY HEX NUTS18-8 TYPE 304 STAINLESSSTEEL BAND18-8 TYPE304 HEAVYGAUGESTAINLESSSTEELSIDEBARSGRIDDED VIRGIN SBRGASKET ASTM D2000OPTIONAL BUNA-NOR EPDM18-8 TYPE 304 HEAVY GAUGESTAINLESS STEEL ARMORSHOP COATED DUCTILEIRON LUGS(OPTIONAL E-COAT)18-8 TYPE 304HEAVY GAUGESTAINLESS STEELARMORGRIDDEDVIRGIN SBRGASKETASTM D2000OPTIONALBUNA-NOR EPDMSpecifications:Specifications:Band:18-8 Type 304 Stainless Steel.Band:18-8 Type 304 Stainless Steel.Bolts andHeavy HexNuts:18-8 Type 304 Stainless Steel. Nut threads arecoated to prevent galling. Bolts are permanentlyattached to the clamp sidebar by means of aMetal Inert Gas (MIG) weld.18-8 Type 304 heavy gauge Stainless Steel, MIGwelded to clamp sidebar.Bolts andHeavy HexNuts:Low alloy per ASTM A242 and AWWA C111.Lugs:Sidebars:18-8 Type 304 heavy gauge Stainless SteelTungsten Inert Gas (TIG) welded to form a strong,permanent fusion with the repair clamp band.Lifter Bar:18-8 Type 304 heavy gauge Stainless Steel. Lipcurve holds bolts in position while tightening andserves as a bearing surface for nuts andNylatron GS self lubricating washers.Gasket:Gridded virgin Styrene Butadene Rubber (SBR)compounded for water service, ASTM D2000.Gasket ends are tapered for a dependable seal.SBR is suitable for temperatures of 150 Fconstant, 180 F intermittent. An optional Buna-N,nitrile gasket is recommended for 220 F constantand/or 240 F intermittent.Armor:1/4 hard 18-8 Type 304 heavy gauge StainlessSteel vulcanized and recessed into the gasket toensure uniform compression against the pipe.Passivated:All clamps are fully passivated by means of achemical technique which restores the corrosionresistant characteristics of the stainless steel.Options: Conductivity Strips Buna-N Gasket(suitable for natural gas applications) EPDM GasketL-4Lugs:Ductile iron ASTM A536. Lugs can be temporarilyremoved to assist installation in tight spaces.Gasket:Gridded virgin Styrene Butadene Rubber (SBR)compounded for water service ASTM D2000.Gasket ends are tapered for a dependable seal.SBR is suitable for temperatures of 150 Fconstant, 180 F intermittent. An optional Buna-N,nitrile gasket is recommended for 220 F constantand/or 240 F intermittent.Armor:1/4 hard 18-8 Type 304 heavy gauge StainlessSteel vulcanized and recessed in the gasket toensure uniform compression against the pipe.Finish:Shop Coat.Options: Stainless Steel Nuts and bolts Conductivity Strips Buna-N Gasket(suitable for natural gas applications) EPDM Gasket E-Coated LugsANSI/NSF Standard 61see page L-3

Installation GuideFord Style F Quality Circle Repair Clampsand Ford Style FS All Stainless Steel Quality Circle Repair ClampsThe successful application of a repair clamp depends heavily on the installer.We suggest the following guidelines as routine practice.1. CHECK DIAMETER OF PIPE TO MAKE CERTAIN YOU ARE USING THE CORRECT SIZE CLAMP.2. Scrape pipe to remove as much dirt and corrosion as possible so surface is smooth.3. Make certain the gasket is free of foreign material and that nothing becomes lodged between thegasket and the pipe. Lubricate the pipe and/or gasket with soapy water to achieve maximum results.4. Avoid loose fitting wrenches and wrenches that are too short to achieve proper torque of nuts. A torque wrenchis recommended.5. Although threads are coated to prevent galling between bolt and nut, keep threads free of foreign material to facilitate tightening.6. Tighten all sections of a multi-section clamp evenly to the recommended torque.7. ALWAYS RECHECK TORQUE AND PRESSURE TEST FOR LEAKS BEFORE BACKFILLING.8. Backfill and compact carefully around clamp according to pipe manufacturer’s instructions.Caution: Repair clamps are not designed to restrain axial pipe movement. Make sure proper restraint is applied when necessary.Installing an F1 Repair ClampBack off nuts to end of bolts, butDO NOT remove them. Separateclamp and position on the pipewith the bolt lug section on top.Hook the middle bolt into thereceiver lug and tighten the nutuntil the bolt is secure.ROTATE THE CLAMP in thedirection of the arrow approximately 1/4 turn to ensure propergasket positioning.Squeeze the two lug sectionstogether. Tighten the bolts evenlywith incremental torque settings, upto the recommended torque.RECOMMENDED TORQUEClamp TopApprox.Bolt DiameterRangeTorqueThru 5.62"5/8"30 / 35 ft. lbs.6.35" & Above5/8"75 ft. lbs.Installing an FS1 All Stainless Steel Repair ClampBack off nuts to end of bolts, butDO NOT remove them. Separateclamp and wrap it around the pipeby holding the lifter bar and boltsabove the pipe and sliding thereceiver section under the pipe.Bring the lifter bar and receiversection together at a convenientposition on top of the pipe.Slide the lifter bar up the receiverlugs and snap into place. Spinone of the nuts hand tight.Tighten all nuts evenly withincremental torque settings, upto the recommended torque.For a proper installation Ford recommends that bolts be tightened to the following torque values;for 1/2" bolts - 50-60 Ft. Lbs., 5/8" bolts (clamps up through 4.73" O.D.) - 30-35 Ft. Lbs.,5/8" bolts (clamps over 4.73" O.D.) - 70-80 Ft. Lbs., and 3/4" bolts - 90-100 Ft. Lbs.L-5

Ford All Stainless Steel Quality CircleRepair ClampsANSI/NSF Standard 61see page L-3Style FS1 (single section)Operating Range .40" (4" and larger)To order: Specify Catalog Number x Length of clamp desired.Example: FS1-724 x 12.5 would be a one-section clamp for pipe with an O.D. ofbetween 6.84 and 7.24, and the length of the clamp would be 12.5".Options Include: Buna-N Gasket - add “-N” to Catalog NumberEPDM Gasket - add “-EPDM” to Catalog NumberConductivity Strips - add “-CS” to Catalog NumberNote: Sizes and lengths not listed (including metric) are available upon request.Contact the Ford Meter Box Customer Service Department for information.FORD ALL STAINLESS STEEL QUALITY CIRCLE REPAIR CLAMPS - STYLE FS1 (SINGLE SECTION) - OPERATING RANGE .40" (4" AND LARGER)NOM. PIPEPIPE O.D.CATALOGLENGTH AND APPROXIMATE SHIPPING WEIGHT 2.25FS1-225xLength4 Lbs.4 Lbs.5 Lbs.5 ngth3"- FS1-967xLength9.70-10.10FS1-1010xLength10.60-11.04 FS1-1104xLength10"11.04-11.44 FS1-1144xLengthN/A1114162428324211.34-11.74 FS1-1174xLength11.75-12.15 FS1-1215xLength12.00-12.40 FS1-1240xLength12.60-13.02 FS1-1302xLength13.10-13.50 FS1-1350xLength12"N/A1316182730364813.40-13.80 FS1-1380xLength13.70-14.10 FS1-1410xLength14.00-14.40 FS1-1440xLengthNUMBER OF STUDS2233-4*4679*12.5" long clamps in the 10" and 12" Nominal Pipe Size have 4 studs. br / br / br / br / br / br / br / br / br / br / br / br / br / br / br / br / br / br / br / br / br / br / br / br / br / br / br / br / br / br / br / br / br / br / br / br / br / br / br / br / br / br / Tapped Repair ClampsTapped Repair ClampsTapping CodesCC (AWWA) THREADCODEMIN. CLAMP 1/4"CC53.705.241-1/2"CC64.255.242"CC74.735.57IP THREADCODEMIN. CLAMP T TAPS for corporation stops are available on Ford Stainless Steel Clamps. The Minimum Clamp Size for each tap type and size is listed inthe Tapping Code table above. The tapped outlet is 18-8 Type 304 stainless steel and is “fused” to the clamp band by a fully passivated TIG weld.To Order: 1. Select the proper code from table to match desired size and type of thread.2. Add code to catalog number of repair clamp.Example: The number for an FS1-724-12.5 with a 3/4" CC tap is FS1-724-125-CC3.Note: Tapped Repair Clamps are non-returnable.L-6

Ford All Stainless Steel Quality CircleRepair ClampsANSI/NSF Standard 61see page L-3Style FS2 (double section)Operating Range .80"To order: Specify Catalog Number x Length of clamp desired.Example: FS2-764 x 10 would be a two-section clamp for pipe withan O.D. of between 6.84 and 7.64, and the length of the clamp wouldbe 10".Options Include: Buna-N Gasket - add “-N” to Catalog NumberEPDM Gasket - add “-EPDM” to Catalog NumberConductivity Strips (FS2-979 and larger) add “-CS” to Catalog NumberNote: Sizes and lengths not listed (including metric) are available upon request. Contact the Ford Meter Box Customer ServiceDepartment for information.Ford All Stainless Steel Quality Circle Repair Clamps - Style FS2 (double section) Operating Range .80"NOM. PIPESIZEPIPE O.D.CATALOGLENGTH AND APPROXIMATE SHIPPING WEIGHT 2-524xLength4"11 Lbs. 14 Lbs. 18 Lbs. 26 Lbs. 32 Lbs. 38 ngth10.70-11.50 FS2-1150xLength10"11.04-11.84 FS2-1184xLengthN/A18233241505411.60-12.40 FS2-1240xLength12.70-13.50 FS2-1350xLength12"13.14-13.94 FS2-1394xLengthN/A19253444545713.65-14.45 FS2-1445xLength14"15.07-15.82 FS2-1582xLengthN/A20273647586316"17.15-17.90 FS2-1790xLengthN/A222938506266NUMBER OF STUDS466-8*8121418* 12.5" long clamps in the 10" thru 16" Nominal Pipe Size have 8 studs. br / br / br / br / br / br / br / br / br / br / br / br / br / br / Style FS3 (triple section)Operating Range 1.20"To order: Specify Catalog Number x Length of clamp desired.Example: FS3-1920 x 24 would be a three-section clamp for pipe withan O.D. between 18.00 and 19.20, and the length of the clamp wouldbe 24".Options Include: Buna-N Gasket - add “-N” to Catalog NumberEPDM Gasket - add “-EPDM” to Catalog NumberConductivity Strips - add “-CS” to Catalog NumberNote: Sizes and lengths not listed (including metric) are available uponrequest. Contact the Ford Meter Box Customer Service Departmentfor information.Ford All Stainless Steel Quality Circle Repair Clamps - Style FS3 (triple section) Operating Range 1.20"NOM. PIPESIZE16"18"20"24"PIPE O.D.CATALOGRANGENUMBER17.10-18.30 FS3-1830xLength18.00-19.20 FS3-1920xLength19.50-20.70 FS3-2070xLength21.60-22.80 FS3-2280xLength25.80-27.00 FS3-2700xLengthNUMBER OF STUDS br / LENGTH12.5"31 Lbs. br / APPROXIMATE SHIPPING WEIGHT LBS.15"20"24"30"40 Lbs. 52 Lbs. 64 Lbs. 77 7

Ford Quality Circle Repair ClampsStyle F1 (single section)Operating Range .40" (4" and larger)ANSI/NSF Standard 61see page L-3To order: Specify Catalog Number x Length of clamp desired.Example: F1-724 x 12.5 would be a one-section clamp for pipe with an O.D. ofbetween 6.84 and 7.24, and the length of the clamp would be 12.5".Options Include: Buna-N Gasket - add “-N” to Catalog NumberEPDM Gasket - add “-EPDM” to Catalog NumberConductivity Strips - add “-CS” to Catalog NumberBlue Fluorocarbon Coated Nuts and Bolts - add “-BBN” to Catalog NumberType 304 Stainless Steel Bolts & Nuts - add “-SH” to Catalog NumberE-Coated Lugs - add “-E3” to Catalog NumberNote: Sizes and lengths not listed (including metric) are available upon request. Contact the Ford MeterBox Customer Service Department for information.Ford Quality Circle Repair Clamps Style F1 (single section) Operating Range .40" (4" and larger)NOM. PIPESIZE1"2"2-1/4"-2-1/2"PIPE 3.5013.40-13.8013.70-14.1014.00-14.40 br / 3" br / br / br / br / br / br / br / br / br / 467182329354670 br / br / br / br / br / 12"14 br / br / 10"12 br / br / 8"10 br / br / br / 6"8 br / br / br / 4"LENGTH AND APPROXIMATE SHIPPING WEIGHT LBS.7.5"10"12.5"15"20"30"7 Lbs. 9 Lbs. 12 Lbs. 14 Lbs.N/AN/A791214N/AN/A7101214N/AN/A7101214N/AN/A br / br / br / 0xLengthF1-1440xLength br / br / br / br / br / br / br / br / br / br / br / br / Tapped Repair ClampsTapped Repair ClampsTapping CodesCC (AWWA) THREADCODEMIN. CLAMP SIZEF1F2 5.601-1/2"CC64.255.602"CC74.735.60SIZEIP THREADCODEMIN. CLAMP SIZEF1F2 5.601-1/2"IP63.705.602"IP74.255.60SIZEOUTLET TAPS for corporation stops are available on Ford Stainless Steel Clamps. The Minimum Clamp Size for each tap type and size is listed inthe Tapping Code table above. The tapped outlet is 18-8 Type 304 stainless steel and is “fused” to the clamp band by a fully passivated TIG weld.To Order: 1. Select the proper code from table to match desired size and type of thread.2. Add code to catalog number of repair clamp.Example: The number for an F1-724-12.5 with a 3/4" CC tap is F1-724-125-CC3.Note: Tapped Repair Clamps are non-returnable.L-8

Ford Quality Circle Repair ClampsStyle F2 (double section) / Operating Range .80"ANSI/NSF Standard 61see page L-3NOM. PIPESIZE4"4" Special6"8"10"To Order: Specify Catalog Number x Length of clamp desired.Example: F2-1445 x 20 would be a two-section clamp for pipe with an O.D. of between 13.65 and 14.45, and thelength of the clamp would be 20".Options Include: Buna-N Gasket - add “-N” to Catalog NumberEPDM Gasket - add “-EPDM” to Catalog NumberConductivity Strips (F2-979 and larger) - add “-CS” to Catalog NumberBlue Fluorocarbon Coated Nuts and Bolts - add “-BBN” to Catalog NumberType 304 Stainless Steel Bolts & Nuts - add “-SH” to Catalog NumberE-Coated Lugs - add “-E3” to Catalog NumberNote: Sizes and lengths not listed (including metric) are available upon request. Contact the Ford MeterBox CustomerDepartmentfor F2information.Ford QualityServiceCircle RepairClamps Style(double section) / Operating Range .80"LENGTH AND APPROXIMATE SHIPPING WEIGHT LBS.PIPE 84xLength11.60-12.40F2-1240xLength11.04-12.24 4.34 N/A5576110NUMBER OF BOLTS6810121624 br / br / br / br / br / br / br / br / br / br / br / 10" Special12"12" SpecialRange br / br / br / br / br / br / br / Style F3 (triple section) / Operating Range 1.20"To order: Specify Catalog Number x Length of clamp desired.Example: F3-2680 x 30 would be a three-section clamp for pipe with an O.D. ofbetween 25.60 and 26.80, and the length of the clamp would be 30".Options Include: Buna-N Gasket - add “-N” to Catalog NumberEPDM Gasket - add “-EPDM” to Catalog NumberConductivity Strips - add “-CS” to Catalog NumberType 304 Stainless Steel Bolts & Nuts - add “-SH” to Catalog NumberE-Coated Lugs - add “-E3” to Catalog NumberNote: Sizes and lengths not listed (including metric) are available upon request.Contactthe Ford Meter Box Customer Service Department for information.Ford Quality Circle Repair Clamps Style F3 (triple section) / Operating Range 1.20"NOM. PIPESIZERangePIPE BER OF BOLTSLENGTH AND APPROXIMATE SHIPPING WEIGHT LBS.10"15"20"30"102 Lbs.148 Lbs.185 Lbs.268 8311116020228711316320429012182436L-9

Ford Snap ClampsStyle FSCFor Economical Repair of Water Pipe LeaksFord Snap Clamps offer a handy and economical way to repair pinholes and other smallleaks that do not require a full gasket seal. A heavy gridded gasket design and “cushionlugs” make them ideal for older pitted pipe that has worn thin over the years.To order: Specify Catalog Number by Length of desired clamp. For example, aFSC-190x6 would be a 6" long clamp for 1-1/2" Standard Steel pipe.Shell:18-8 Type 304 Stainless SteelLugs:Ductile Iron per ASTM A536, electrodeposited zinc finishGaskets: Buna-N with heavy grid design extended lug-to-lugBolts:AISI C1018 steel, 3/8" and/or 7/16" electrodeposited zinc with Di-chromate sealFord Snap Clamps Style FSC For Economical Repair of Water Pipe LeaksNOM. H AND APPROXIMATE SHIPPING WEIGHT LBS.3"CTN. QTY.6"CTN. QTY.9"CTN. QTY.54 Lbs.251.08 .97.48.08.8CTN. QTY.22211111111Ford Wrap ClampsSpecial Style FSC Clamp with Full-Wrap GasketFord Wrap Clamps offer the same leak repair features of the Snap Clamp with the extraassurance of 360 gasket coverage. Specific sizes are available for I.P.S. steel or copper.To order: Specify Catalog Number. Example: an FSC-190-6R would be a 6" longclamp for 1-1/2" Standard Steel pipe.Shell:18-8 Type 304 Stainless SteelLugs:Ductile Iron per ASTM A536, electrodeposited zinc finishGasket:Buna-N rubber with gridded armored gasket for 360 coverageBolts:AISI C1018 steel, 3/8" and/or 7/16" electrodeposited zinc with Di-chromate sealFord Wrap Clamps Special Style FSC Clamp with Full-Wrap GasketNOM. PIPESIZE1/2"3/4"1"1-1/4"1-1/2"2"To order:L-10PIPE3" LONG CLAMP (1 BOLT)6" LONG CLAMP (2 BOLTS)CATALOG NUMBER APPROX. WT. LBS. CTN. QTY. CATALOG NUMBER APPROX. WT. LBS. CTN. 38-3RFSC-238-6R2.38Specify Catalog Number. Example: an FSC-190-6R would be a 6" long clamp for 1-1/2" Standard Steel pipe. br / br / br / br / br / br /

Ford All Stainless Steel Snap ClampsStyle FLSCFord All Stainless Steel Snap Clamps offer a handy way to repair pinholes and othersmall leaks that do not require a full gasket seal. A heavy gridded gasket design and“cushion lugs” make them ideal for older pitted pipe that has worn thin over the years.The All Stainless Steel Snap Clamp offers the same conveniences and performance ofthe traditional Snap Clamp with the added security of stainless steel lugs and bolts.To order: Specify Catalog Number by Length of desired clamp. For example, aFLSC-190x6 would be a 6" long clamp for 1-1/2" Standard Steel pipe.Shell:18-8 Type 304 Stainless SteelLugs:18-8 Type 304 Stainless SteelGaskets: Buna-N with heavy grid design extended lug-to-lugBolts:18-8 Type 304 Stainless SteelFord All Stainless Steel Snap Clamps Style FLSCNOM. 863xLengthLENGTH AND APPROXIMATE SHIPPING WEIGHT LBS.6"CTN. QTY.9"CTN. QTY.12"3"CTN. QTY.54 Lbs.251.08 26.617.9CTN. QTY.22211111111Ford All Stainless Steel Wrap ClampsStyle FLSC Clamp with Full-Wrap GasketFord Wrap Clamps offer the same Leak Repair features of the Snap Clamp with the extraassurance of 360 gasket coverage. Specific sizes are available for I.P.S. steel or copper.The All Stainless Steel Wrap Clamp offers the same conveniences and performance of thetraditional Wrap Clamp with the added security of stainless steel lugs and bolts.To order: Specify Catalog Number. Example: an FLSC-190-6R would be a 6" longclamp for 1-1/2" Standard Steel pipe.Shell:18-8 Type 304 Stainless SteelLugs:18-8 Type 304 Stainless SteelGasket:Buna-N rubber with g

Pipe Repair Products The Ford Meter Box Company, Inc. 775 Manchester Avenue, P.O. Box 443, Wabash, Indiana, USA 46992-0443 . Test Pipe: asbestos-cement, cast iron or steel Two pieces of test pipe with average space of 1/8" between ends, coupled together with 7-1/2" wide