Transcription

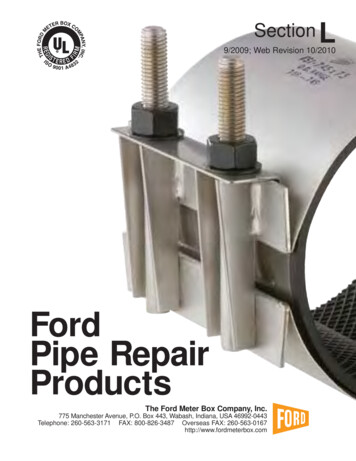

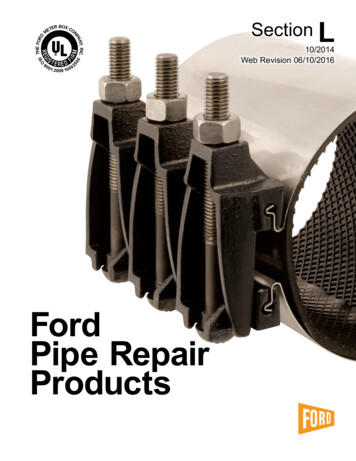

O9001:50IS5THE FORDNY, INC.PAMBOX CTEROME2 0 0 8 10 002FordPipe RepairProductsSection L10/2014Web Revision 06/10/2016

ContentsTypical Problems Solved with Ford Repair Clamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3Hydrostatic Test Pressures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3Specifications for FS Repair Clamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4Specifications for F Repair Clamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5All Stainless Steel FS1 Repair Clamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6All Stainless Steel FS2 Repair Clamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7All Stainless Steel FS3 Repair Clamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7All Stainless Steel FSP1 Repair Clamps for HDPE Pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8All Stainless Steel FSP2 Repair Clamps for HDPE Pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9All Stainless Steel FSP3 Repair Clamps for HDPE Pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9All Stainless Steel FLS1 Drop-In Bolt Design Repair Clamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10All Stainless Steel FLS2 Drop-In Bolt Design Repair Clamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11All Stainless Steel FLS3 Drop-In Bolt Design Repair Clamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11Fordflex F1 Repair Clamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12Fordflex F2 Repair Clamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13Fordflex F3 Repair Clamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13Fordflex FP1 Repair Clamps for HDPE Pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14Fordflex FP2 Repair Clamps for HDPE Pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15Fordflex FP3 Repair Clamps for HDPE Pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15FSC Snap Clamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16FSC Wrap Clamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16FSC Dual-Armor Wrap Clamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17All Stainless Steel FLSC Snap Clamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17All Stainless Steel FLSC Wrap Clamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18All Stainless Steel FLSC Dual-Armor Wrap Clamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18FSC1 Wrap Clamps and Dual-Armor Wrap Clamps with Finger Lugs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19FCC Repair Clamps for Solvent Weld PVC Couplings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20FIBC Repair Clamps for Integral Bell Solvent Weld PVC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20FBC Bell Joint Leak Clamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21Bolt Extension Kit for Bell Joint Leak Clamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21FACC Abandoned Corp Caps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22Application Information for HDPE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23O.D. Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . SP2FSP3FACCFSCFLSCFCCFBCFIBC TYPE OF ClampSingle Band Stainless Steel Clamp with Ductile Iron LugsDouble Band Stainless Steel Clamp with Ductile Iron LugsSpecial Range Double Band Stainless Steel Clamp with Ductile Iron LugsTriple Band Stainless Steel Clamp with Ductile Iron LugsSingle Band Stainless Steel Repair Clamps with Drop-In BoltsDouble Band Stainless Steel Repair Clamps with Drop-In BoltsTriple Band Stainless Steel Repair Clamps with Drop-In BoltsSingle Band Stainless Steel Clamp with Ductile Iron Lugs for HDPE PipeDouble Band Stainless Steel Clamp with Ductile Iron Lugs for HDPE PipeTriple Band Stainless Steel Clamp with Ductile Iron Lugs for HDPE PipeSingle Band All Stainless Steel ClampDouble Band All Stainless Steel ClampTriple Band All Stainless Steel ClampWrap Clamp with Finger LugsSingle Band All Stainless Steel Clamp for HDPE PipeDouble Band All Stainless Steel Clamp for HDPE PipeTriple Band All Stainless Steel Clamp for HDPE PipeAbandoned Corp CapSnap or Wrap ClampAll Stainless Steel Snap or Wrap ClampRepair Clamp for Coupling Solvent Weld PVCBell Joint Leak ClampRepair Clamp for Integral Bell Solvent Weld PVCclamp length(Lengths are not required on styles FACC, FBC, FCCand FIBC)3 3" (FSC(1), FSC-R(2) and FLSC only)6 6" (FSC(1), FSC-R(2) and FLSC)75 7-1/2"9 9" (FSC and FLSC only)10 10"12 12" (FSC and FLSC only)125 12-1/2"15 15"20 20"24 24" (FS Style)25 25" (F Style)30 30"35 35" (F Style)36 36" (FS Style)FS1-939-15-CC4O.D. SizeFor most clamp styles, theO.D. size number indicatesthe top end of the range.Use listed catalog sizes.HBL-2optional featuresIP5 1-1/4" Iron Pipe Tapped ThreadLong Starter Bolt3/4" AWWA Tapped ThreadIP6 1-1/2" Iron Pipe Tapped Thread1" AWWA Tapped ThreadIP7 2" Iron Pipe Tapped Thread1-1/4" AWWA Tapped ThreadN Buna-N Rubber Gasket1-1/2" AWWA Tapped ThreadOS1 1" offset gasket for overlapping clamps2" AWWA Tapped Threadfor extended lengthsConductivity StripsQ 316 Stainless Steel (FS style)EPDM Rubber GasketR Wrap Clamp, features a 360 gasketE-Coated Lugs(for FSC style clamp)(F1, F2, F3, FCC and FIBC)R2 Dual-Armor Wrap Clamp with EPDM Handlebolt (F1, F2, FP1gasket (less dimples)and FP2)SH Stainless Steel Nuts & Bolts 3/4" Iron Pipe Tapped Thread(for ductile lug clamps) 1" Iron Pipe Tapped ThreadA CC3 CC4 CC5 CC6 CC7 CS EPDM E3 IP3IP4

Typical Problems Solved WithFord Repair ClampsCracks or full breaks inasbestos-cement and iron pipePinholes in pittediron and steel pipeSplits in asbestos-cement,iron, steel and plastic pipeHoles in asbestos-cement, iron,steel and plastic pipePipe ends of the same diameterwith slight separationRepair leaking tap with a tappedrepair clamp.Fish mouthed gasket inasbestos-cement pipe couplingRemove coupling and replace itwith a clamporBroken asbestos-cement pipe couplingHydrostatic Test Pressures – Average550Test Pressure - PSI500450400Style F2350300250200Style F115010023456789101112131415Outside Diameter of Pipe - InchesConditions of Test Test Pipe: asbestos-cement, cast iron or steel Two pieces of test pipe with average space of 1/8" between ends, coupled together with 7-1/2" wide clamp 5/8" bolts (clamps up through 4.73" O.D.) tightened to a torque of 30-35 ft. lbs., 5/8" bolts (clamps over 4.73"O.D.) to 70-80 ft. lbs., and 3/4" bolts to 90-100 ft. lbs.Standards and Classifications:The Ford F, FS and FLS Series clamps are listed by Underwriters Laboratories as satisfying the requirements of NSF61.The 2" - 12" sizes of the F and FS clamps satisfy AWWA C230.l-3

SpecificationsFord All Stainless Steel Repair ClampsThe Ford FS Style All Stainless Steel Repair Clamp combines the corrosion-resistant characteristics of stainless steel andthe sealing capabilities of rubber to provide a strong, dependable and versatile repair clamp.The all stainless design is lightweight and easy to handle under adverse conditions associated with almost every main break.The fixed position of the studs provides uniform control and fewer parts to fall into the trench. The sliding lifter bar is retained onthe studs by the heavy hex nuts and facilitates the installation by serving as a handle while installing the clamp. Bi-directionallytapered lugs allow the lifter bar to easily slide into locking position on the sidebar.18-8 Type 304 Stainless Steel Band18-8 Type 304 Stainless SteelNuts and STUDS.nut threads are coated.ANSI/NSF Standard 61see page L-318-8 Type 304 heavy gaugeStainless Steel Sidebarsand lifter barsGridded virgin SBR gasket ASTM D2000Optional Buna-N or epdm1/4 HARD heavy gauge Stainless Steel ArmorSpecifications:Band:18-8 Type 304 stainless steel.Studs and Heavy 18-8 Type 304 stainless steel. Coated nut threads to prevent galling. Studs are permanently attached toHex Nuts:the clamp sidebar by means of a Metal Inert Gas (MIG) weld.Lugs:18-8 Type 304 heavy gauge stainless steel, MIG welded to clamp sidebar. Lugs are rounded and tapered foreasy installation.Sidebars:18-8 Type 304 heavy gauge stainless steel Tungsten Inert Gas (TIG) welded to form astrong, permanent fusion with the repair clamp band.Lifter Bar:18-8 Type 304 heavy gauge stainless steel. Lip curve holds bolts in position whiletightening and serves as a bearing surface for stainless steel nuts and washers.Gasket:Gridded virgin Styrene Butadiene Rubber (SBR) compounded for water service, ASTM D2000. Gasket endsare tapered for a dependable seal. SBR is suitable for temperatures of 150 F continuous, 180 F intermittent.An optional Buna-N, nitrile gasket is recommended for 220 F continuous and/or 240 F intermittent.Armor:1/4 hard heavy gauge stainless steel vulcanized and recessed into the gasket to ensure uniform compressionagainst the pipe.Passivated:All clamps are fully passivated by means of a chemical technique which restores the corrosion resistantcharacteristics of the stainless steel.OptionsInclude: BellevilleWashers foruse on HDPE:Belleville washers, also referred to as spring washers, promote consistant force on the gasket as the pipediameter expands and contracts. The Belleville washers are made of 17-7 PH stainless steel. Dependingon the pipe size and recommended installation torque, Belleville washers are used singularly, or in a stackto allow for more expansion/contraction of the pipe.Conductivity stripsBuna-N gasket (suitable for natural gas applications)EPDM gasket316 stainless steel1" offset gasket for overlapping clamps for extended lengths1 Washer StackL-42 Washer Stack3 Washer Stack4 Washer Stack

SpecificationsFord Repair ClampsThe Ford F Style Repair Clamps provide a simple and economical method of repairing holes or breaks in water mains, particularlywhere corrosion is not a factor. Ford clamps offer heavy-duty lug construction for maximum strength and a drop-in bolt design thatdoes not require bolt removal when installing the clamp. There are never any loose parts to lose in the ditch.Ford Repair Clamps come in a wide variety of styles and cover a wide range of pipe diameters; other features of Ford RepairClamps are shown below.18-8 Type 304 Stainless Steel BandOptional: Handlebolt shop coated ductile iron lugs(Optional Epoxy applied by thee-coat process)1/4 HARD heavy gaugeStainless Steel ArmorFord F1 REPAIR CLAMP SHOWNWITH OPTIONAL HANDLEBOLT ANSI/NSF Standard 61see page L-3Gridded virgin SBR gasket ASTM D2000Optional Buna-N or epdmLow Alloy Bolts and Heavy Hex NutsSpecifications:Band:18-8 Type 304 stainless steel.Bolts and Heavy Low alloy per ASTM A242 and AWWA C111.Hex Nuts:Lugs:Ductile iron ASTM A536. Lugs can be temporarily removed to assist installation in tight spaces.Gasket:Gridded virgin Styrene Butadiene Rubber (SBR) compounded for water service ASTM D2000. Gasket endsare tapered for a dependable seal. SBR is suitable for temperatures of 150 F continuous, 180 F intermittent.An optional Buna-N, nitrile gasket is recommended for 220 F continuous and/or 240 F intermittent.Armor:1/4 hard heavy gauge stainless steel vulcanized and recessed in the gasket to ensure uniform compressionagainst the pipe.Finish:Shop coat.OptionsInclude: Handlebolt - Includes an integrally attached handle at the end of the starter boltproviding leverage for easy installation when pulling the clamp together. Stainless steel nuts and bolts Conductivity strips Buna-N gasket (suitable for natural gas applications) EPDM gasket E-Coated lugs Starter bolt 1" offset gasket for overlapping clamps for extended lengthsBellevilleWashers foruse on HDPE:Belleville washers, also referred to as spring washers, promote consistant force on the gasket as the pipediameter expands and contracts. The Belleville washers are made of 17-7 PH stainless steel. Dependingon the pipe size and recommended installation torque, Belleville washers are used singularly, or in a stackto allow for more expansion/contraction of the pipe.1 Washer Stack2 Washer Stack3 Washer StackHandlebolt in action4 Washer Stackl-5

Ford All Stainless Steel Repair ClampsStyle FS1 (single section)Operating Range .40" (5.14" and larger)MEETSAWWAC230To order: Specify Catalog Number x Length of clamp desired.ANSI/NSF Standard 61see page L-3Example: FS1-724-12.5 would be a single section clamp for pipe with an O.D.of between 6.84 and 7.24, and the length of the clamp would be 12.5".Options Include: Buna-N Gasket - add “-N” to catalog numberEPDM Gasket - add “-EPDM” to catalog numberConductivity Strips - add “-CS” to catalog number316 Stainless Steel - add “-Q” to catalog numberNote: Sizes and lengths not listed (including metric) are available upon request.Contact the Ford Meter Box Customer Service Department for information.Nom. PipeSizePipe O.D.CatalogLength and Approximate Shipping Weight -215-Length4 Lbs.4 Lbs.5 Lbs.5 th3.96-4.25FS1-425-Length3"- gth10.60-11.04 FS1-1104-Length10"11.04-11.44 FS1-1144-LengthN/A11141624283211.34-11.74 FS1-1174-Length11.75-12.15 FS1-1215-Length12.00-12.40 FS1-1240-Length12.60-13.02 FS1-1302-Length13.10-13.50 FS1-1350-Length12"N/A13161827303613.40-13.80 FS1-1380-Length13.70-14.10 FS1-1410-Length14.00-14.40 FS1-1440-LengthNumber of Studs2233-4*467*12.5" long clamps in the 10" and 12" nominal pipe size have 4 studs.Tapped Repair Clamps br / br / br / br / br / br / br / br / br / br / br / br / br / br / br / br / br / br / br / br / br / br / br / br / br / br / 30"N/AN/AN/AN/A212730 br / br / br / br / br / br / br / br / br / br / br / br / br / br / br / br / br / br / Tapped Repair Clamps42489Tapping CodesCC (AWWA) ThreadIP ThreadMin.Min.CodeCodeClamp Size SizeClamp SizeSizeNumberNumberFS1 FS2FS1 FS23/4" CC3 2.63 5.24 3/4"IP3 2.63 5.241"CC4 2.63 5.24 1"IP4 2.63 5.241-1/4" *CC5 3.70 5.24 1-1/4" *IP5 3.70 5.241-1/2" CC6 4.25 5.24 1-1/2" IP6 3.70 5.242"CC7 4.73 5.57 2"IP7 4.25 5.57* Contact factory for availabilityOutlet taps for corporation stops are available on Ford All Stainless Steel Clamps. The minimum clamp size for each tap type and size is listedin the tapping code table above. The tapped outlet is 18-8 Type 304 stainless steel and is “fused” to the clamp band by a fully passivated TIG weld.To Order: 1. Select the proper code from table to match desired size and type of thread.2. Add code to catalog number of repair clamp.Example: The number for an FS1-724-12.5 with a 3/4" CC tap is FS1-724-125-CC3.L-6Note: Tapped repair clamps are non-returnable.

Ford All Stainless Steel Repair ClampsANSI/NSF Standard 61see page L-3MEETSAWWAC230Style FS2 (double section)Operating Range .80" (4"-12")To order: Specify Catalog Number x Length of clamp desired.Example: FS2-764-10 would be a double section clamp for pipe withan O.D. of between 6.84 and 7.64, and the length of the clamp wouldbe 10".Options Include: Buna-N Gasket - add “-N” to catalog numberEPDM Gasket - add “-EPDM” to catalog numberConductivity Strips (FS2-979 and larger) add “-CS” to catalog number316 Stainless Steel - add “-Q” to catalog numberNote: Sizes and lengths not listed (including metric) are available uponrequest. Contact the Ford Meter Box Customer Service Departmentfor information.Nom. PipeSize4"6"8"Pipe O.D.CatalogLength and Approximate Shipping Weight 2-524-Length11 Lbs. 14 Lbs. 18 Lbs. 26 Lbs. 32 Lbs. 38 10.70-11.50 FS2-1150-Length11.04-11.84 FS2-1184-LengthN/A18233241505411.60-12.40 FS2-1240-Length12.70-13.50 FS2-1350-Length13.14-13.94 FS2-1394-LengthN/A19253444545713.65-14.45 FS2-1445-Length15.07-15.82 FS2-1582-LengthN/A20273647586317.15-17.90 FS2-1790-LengthN/A222938506266Number of Studs466-8*8121418 br / br / br / br / br / br / br / br / 10"12"14"16" br / br / br / br / br / br / * 12.5" long clamps in the 10" thru 16" nominal pipe size have 8 studs.Style FS3 (triple section)Operating Range 1.20"To order: Specify Catalog Number x Length of clamp desired.Example: FS3-1920-24 would be a triple section clamp for pipe withan O.D. between 18.00 and 19.20, and the length of the clamp wouldbe 24".Options Include: Buna-N Gasket - add “-N” to catalog numberEPDM Gasket - add “-EPDM” to catalog numberConductivity Strips - add “-CS” to catalog number316 Stainless Steel - add “-Q” to catalog numberNote: Sizes and lengths not listed (including metric) are available uponrequest. Contact the Ford Meter Box Customer Service Departmentfor information.Ford All Stainless Steel Quality Circle Repair Clamps - Style FS3 (triple section) Operating Range 1.20" br / Nom. PipeSize16"18"20"24"30"Pipe O.D.CatalogRangeNumber17.10-18.30 FS3-1830-Length18.00-19.20 FS3-1920-Length19.50-20.70 FS3-2070-Length21.60-22.80 FS3-2280-Length25.80-27.00 FS3-2700-Length29.62-30.82 FS3-3082-Length31.70-32.90 FS3-3290-LengthNumber of Studs br / Length and Approximate Shipping Weight Lbs.12.5"15"20"24"30"31 Lbs. 40 Lbs. 52 Lbs. 64 Lbs.77 182127l-7

Ford All Stainless Steel Repair ClampsFor HDPE PipeANSI/NSF Standard 61see page L-3Style FSP1 for HDPE Pipe (single section)To order: Specify Catalog Number x Length of clamp desired.Example: FSP1-690-12.5 would be a single section clamp for pipe with an O.D.of 6.90, and the length of the clamp would be 12.5".Options Include:Buna-N Gasket - add “-N” to catalog numberEPDM Gasket - add “-EPDM” to catalog numberConductivity Strips - add “-CS” to catalog number316 Stainless Steel - add “-Q” to catalog numberBelleville Washers: Belleville washers are used to allow for expansion andcontraction of HDPE pipe. Belleville washers are madeof 17-7 PH stainless steel.For HDPE application information see page L-22.Nom. PipeSizePipe O.D.CatalogLength and Approximate Shipping Weight Lbs.6"7.5"10"12.5"15"20"24"RangeNumber2.38 FSP1-238-Length4 Lbs.4 Lbs.5 Lbs.5 Lbs.N/A2"N/AN/A2.50 FSP1-250-Length445572-1/4"x2-1/2"2.88 FSP1-288-Length45568N/AN/A3.50 FSP1-350-Length3"45569N/AN/A3.80 FSP1-380-Length4.50 FSP1-450-Length4"56781014164.80 FSP1-480-Length6.63 FSP1-663-Length6"N/A79101417216.90 FSP1-690-Length8.63 FSP1-863-Length8"N/A810111519249.05 FSP1-905-Length10.75 FSP1-1075-Length10"N/A11141624283211.10 FSP1-1110-Length12.75 FSP1-1275-Length12"N/A13161827303613.20 FSP1-1320-LengthNumber of Studs2233-4*467*12.5" long clamps in the 10" and 12" nominal pipe size have 4 studs.30"N/AN/AN/A21273042489Tapped Repair ClampsTapped Repair ClampsTapping CodesCC (AWWA) ThreadIP ThreadMin.Min.CodeCodeClamp SizeClamp SizeSizeSizeNumberNumberFSP1 FSP2FSP1 FSP23/4"CC32.63 5.24 3/4"IP32.635.241"CC42.63 5.241"IP42.635.241-1/4" *CC53.70 5.24 1-1/4" *IP53.705.241-1/2"CC64.25 5.24 1-1/2"IP63.705.242"CC74.73 5.572"IP74.255.57* Contact factory for availabilityOutlet taps for corporation stops are available on Ford All Stainless Steel Clamps. The minimum clamp size for each tap type and size is listedin the tapping code table above. The tapped outlet is 18-8 Type 304 stainless steel and is “fused” to the clamp band by a fully passivated TIG weld.To Order: 1. Select the proper code from table to match desired size and type of thread.2. Add code to catalog number of repair clamp.Example: The number for an FSP1-663-12.5 with a 3/4" CC tap is FSP1-663-125-CC3.Note: Tapped repair clamps are non-returnable.L-8

Ford All Stainless Steel Repair ClampsFor HDPE PipeANSI/NSF Standard 61see page L-3Style FSP2 for HDPE Pipe (double section)To order: Specify Catalog Number x Length of clamp desired.Example: FSP2-690-10 would be a double section clamp for pipe withan O.D. of 6.90, and the length of the clamp would be 10".Options Include:Buna-N Gasket - add “-N” to catalog numberEPDM Gasket - add “-EPDM” to catalog numberConductivity Strips (FSP2-1075 and larger) add “-CS” to catalog number316 Stainless Steel - add “-Q” to catalog numberBelleville Washers: Belleville washers are used to allow forexpansion and contraction of HDPE pipe.Belleville washers are made of 17-7 PHstainless steel.For HDPE application information see page L-22.Nom. PipeSize4"6"8"10"Pipe O.D.CatalogLength and Approximate Shipping Weight 0-Length11 Lbs. 14 Lbs. 18 Lbs. 26 Lbs. 32 Lbs. 38 h17.40FSP2-1740-LengthN/A222938506266Number of Studs466-8*8121418 br / br / br / br / br / br / br / br / br / br / 12"14" br / br / br / br / br / br / br / 16"* 12.5" long clamps in the 10" thru 16" nominal pipe size have 8 studs.Style FSP3 for HDPE Pipe (triple section)To order: Specify Catalog Number x Length of clamp desired.Example: FSP3-1950-24 would be a triple section clamp for pipe withan O.D. of 19.50, and the length of the clamp would be 24".Options Include:Buna-N Gasket - add “-N” to catalog numberEPDM Gasket - add “-EPDM” to catalog numberConductivity Strips - add “-CS” to catalog number316 Stainless Steel - add “-Q” to catalog numberBelleville Washers: Belleville washers are used to allow forexpansion and contraction of HDPE pipe.Belleville washers are made of 17-7 PHstainless steel.For HDPE application information see page L-22.Nom. PipeSize16"18"20"24"30"Pipe .00FSP3-3000-Length32.00FSP3-3200-LengthNumber of Studs br / br / br / br / br / br / Length and Approximate Shipping Weight Lbs.12.5"15"20"24"30"31 Lbs. 40 Lbs. 52 Lbs. 64 Lbs.77 182127l-9

Ford All Stainless Steel Repair ClampsDrop-In Bolt DesignStyle FLS1 (single section)Operating Range .40" (5.14" and larger)ANSI/NSF Standard 61see page L-3To order: Specify Catalog Number x Length of clamp desired.Example: FLS1-724-12.5 would be a single section clamp for pipe with an O.D.of between 6.84 and 7.24, and the length of the clamp would be 12.5".Options Include: Buna-N Gasket - add “-N” to catalog numberEPDM Gasket - add “-EPDM” to catalog numberConductivity Strips - add “-CS” to catalog numberNote: Sizes and lengths not listed (including metric) are available upon request.Contact the Ford Meter Box Customer Service Department for information.Nom. PipeSizeStyle FLS1 Drop-In BoltPipe O.D.CatalogLength and 225-Length4 Lbs. 4 Lbs. 5 Lbs. 5 gth3.96-4.25FLS1-425-Length3"- 67FLS1-967-Le

Broken asbestos-cement pipe coupling Repair leaking tap with a tapped repair clamp . Fish mouthed gasket in asbestos-cement pipe coupling Remove coupling and replace it . Test Pipe: asbestos-cement, cast iron or steel Two pieces of test pipe with average space of 1/8" between ends, coupled together with 7-1/2" wide clamp