Transcription

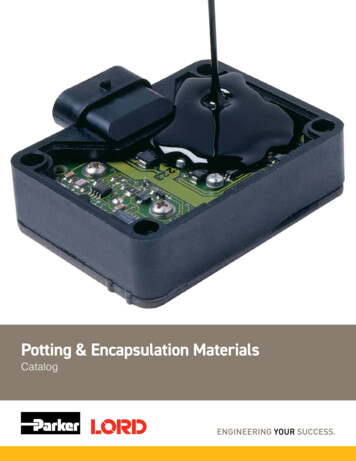

Potting & Encapsulation MaterialsCatalog

Design compromisenot an option?At Parker LORD, we have been developing custom potting andencapsulant solutions for more than 50 years. Whether utilizing epoxy,silicone or urethane polymer systems, we continue to deliver resultsfor demanding applications in a wide variety of industries includingautomotive, energy, medical, aerospace, telecommunications andindustrial electronics based on our customers’ design and specificationneeds.Our products offer diverse encapsulant application options including usein ignition coils, engine control modules, transmission control modules,sensors, power supplies, transformers and other critical electronicequipment.If you need help choosing one of our standard potting and encapsulantproducts or if you need a custom material to meet your needs, let ushelp you determine an appropriate solution for your application.Parker LORD partners with customers toleverage expertise in multiple chemistriesand diverse applications to developcustomized solutions.SILICONESEPOXIESURETHANESSilicones are one of the mostEpoxies provide strength, versatility,Urethanes are considered to be aversatile chemistries and offerdurability, adhesion, chemicalgreat alternative to silicones wheninherent flexibility spanning overresistance and high temperaturehigh temperature resistance is nota wide temperature range (-75 Ctolerance in adhesive, pottingrequired. For electronic packaging,to 200 C). Silicone products areand encapsulant applications.urethanes are known to work best inwidely known to protect fragileThese products can be formulatedlow-temperature applications. Theyelectronic components and modulesto fit a variety of applicationsprotect stress-sensitive electronicwhere flame and high temperatureand requirements thanks to thedevices and act as a barrier againstresistance and permanent flexibilitywide availability of raw materials.water. We offer low viscosity urethaneare top priorities. We offer addition-We offer a wide range of epoxyproducts ranging from soft gels tocured and condensation-curedproducts from extremely flexible tosemi-rigid casting materials thatsilicones, either filled or unfilled.highly-rigid casting materials, eitherare designed to fit various pottingfilled or unfilled, that are thermallyapplication needs.and/or electrically conductive andflame retardant.23

Can be usedwith multiplehardenersHardnessDielectricStrength,kV/mm (V/mil)ThermalConductivity,W/m·K16-24 hr@ 85 C65 Shore A17.1 (434)0.7High density, thermally conductiveprimerless silicone for encapsulatingsensitive electronic modules1:14 hr @ 65 C60 Shore A19.7 (500)0.8Two-component, thermally conductivesilicone for encapsulating densely packedpower units30,000100:0.512-16 hr@ 25 C; or4 hr @ 65 C60 Shore A23.6 (600)0.8Thermally conductive silicone with goodelectrical propertiesWhite32,000100:0.512-16 hr@ 25 C60 Shore A21.6 (550)1.0Two-component, thermally conductivesilicone with outstanding electricalpropertiesxRed20,000100:0.512-16 hr@ 25 C65 Shore A19.7 (500)1.0Two-component, low viscosity, thermallyconductive RTV silicone for applicationsrequiring low stress, rapid heat transfer, hightemperature and repairabilityxWhite30,000100:0.512-16 hr@ 25 C60 Shore A19.7 (500)1.0Two-component, thermally conductivesilicone with outstanding electricalpropertiesxRed15,0001:14 hr @ 85 C45 Shore A1.16High density, thermally conductive,primerless siliconexxRed56,0001:14 hr @ 85 C70 Shore A13.8 (350)0.8High density, thermally conductive,primerless siliconeSiliconexxLight Pink30,0001:124 hr @ 25 C;or 60 min@ 125 C50 Shore A7.4 (188)4.0Two-component, high thermallyconductive silicone for electrical/electronicencapsulating 24 hr @ 25 C;or 30 min@ 120 C60 Shore A8.7 (220)2.5Two-component, medium thermallyconductive silicone which can be cured atrelatively low temperatureCoolThermSC-104SiliconexxUL 94 V-0Gray7,0001:124 hr @ 25 C;or 10-15 min@ 100 C65 Shore A17.3 (440)0.8Two-component, thermally conductivesiliconeCoolThermSC-303SiliconexxUL 94 V-0,UL RTI 200 CGray6,0001:124 hr @ 25 C;or 10-15 min@ 100 C45 Shore A17.3 (440)0.9Two-component, thermally conductivesilicone for encapsulating applicationsrequiring high heat dissipationCoolThermSC-305SiliconexxUL 94 V-0,UL RTI 170 CGray4,0001:124 hr @ 25 C;or 10 min@ 100 C60 Shore A19.7 (500)0.7Two-component, thermally conductivesilicone for the protection of electrical/electronic applications where heatdissipation is criticalCoolThermSC-309SiliconexxUL 94 V-0,UL RTI 180 CGray3,6001:124 hr @ 25 C;or 10 min@ 120 C45 Shore A23.6 (600)1.0Two-component, thermally conductivesilicone for the protection of electrical/electronic applications where heatdissipation is criticalCoolThermSC-320SiliconexxUL 94 V-0,UL RTI 180 CLight Pink22,0001:124 hr @ 25 C;or 60 min@ 125 C54 Shore A7.9 (200)3.0Two-component, thermally conductivesilicone for the protection of electrical/electronic applications where heatdissipation is criticalCoolThermSC-6712 WHT/ 6730SiliconexxWhite7,00010:112 hr @ 25 C;or 2 hr @ 65 C35 Shore A19.7 (500)Two-component, solvent-free silicone forpotting and encapsulating densely packedcomponents and making flexible moldsCoolThermSC-6715 / 6730SiliconexxWhite12,00010:124 hr @ 25 C;or 2-4 hr@ 65 C35 Shore A19.7 (500)Two-component, solvent-free silicone forpotting and encapsulating densely packedcomponents and making flexible moldsCircalokTM6716 / 6733SiliconexBlack10,000100:2.512-16 hr@ 25 C45 Shore A19.7 (500)Solvent-free silicone for potting andencapsulating low- and high-voltageelectrical assembliesChemistryThermallyConductiveCoolTherm SC-6702SiliconexCoolThermSC- 6703SiliconeCoolThermSC-6708 WHT / 6731ComponentsUL RatingAppearanceViscosity,cP @ 25 CMix Ratio byWeightCureSchedulexUL 94 V-0Red30,0001:1xxUL 94 V-0Light Gray8,000SiliconexxxWhiteCoolThermSC-6709 / 6731SiliconexxxCoolThermSC-6710 RED / 6731SiliconexxCoolThermSC-6711 WHT / -6726SiliconeCoolThermSC-32441K2KUL 94 V-0Description5

ChemistryThermallyConductiveComponents1K2KCan be usedwith multiplehardenersUL RatingAppearanceViscosity,cP @ 25 CMix Ratio mm ermSC-6717 / 6731SiliconexRed15,100100:58-12 hr @ 25 C60 Shore A19.7 (500)Two-component, condensation curing,solvent-free silicone RTV for potting,encapsulating or coating applicationsCircalok6735SiliconexClear3,50010:14 hr @ 65 C40 Shore A17.7 (450)Clear, low viscosity, two-component siliconethat produces a clear, flexible elastomer thatadheres to most substrates without a primerCircalok6744SiliconexBlack2,7001:12 hr @ 25 C; or45 min @ 65 C55 Shore A17.7 (450)Low viscosity, flame retardant, roomtemperature curing siliconeThermosetTMSC-300MSiliconexClear1601:124 hr @ 25 CGel19.7 (500)Electronic-grade silicone gel encapsulantThermosetSC-316SiliconexWhite2001:11 hr @ 25 CGel19.7 (500)Electronic-grade silicone gel 5 min@ 125 C; or30-60 min@ 150 C40 Shore OOOne-component, rapid cure siliconedesigned for use as an encapsulant orcoating to protect electronic devicesThermosetSC-319SiliconeBlack1,0002 hr @ 25 C70 Shore OOTwo-component, room temperature curingsilicone encapsulantxx1:1Circalok6756AdhesionPromoter SiliconexClear or Red160-90 min@ 25 CPrimer for bonding RTV silicones to metaland glassLORD P-1291AdhesionPromoter SiliconexClear or Red530-60 min@ 25 CElectronic-grade primer for bonding tincatalyzed RTV silicone to most metals andglassLORDP-1292AdhesionPromoter SiliconexBlue530-60 min@ 25 CElectronic-grade primer for bondingplatinum-catalyzed RTV silicone to mostmetals and glassDark Gray8,000 @ 60 C1:1Staged Cure:2 hr each @120 C, 150 C,180 C & 210 C90 Shore D15.4 (390)3.3Two-component, electrically insulatingepoxy encapsulant with very high thermalconductivity, low thermal expansion andhigh-temperature stabilityUL 94 V-0Black22,500100:17.524 hr @ 25 C;or 2 hr @ 65 C90 Shore D19.7 (500)1.1Thermally conductive, low shrinkage, twocomponent epoxyUL 94 V-0Black14,200100:5.512-16 hr@ 25 C85 Shore D19.3 (490)0.6Thermally conductive adhesive and pottingcompoundUL 94 V-0Black12,0001:124 hr @ 25 C;or 2 hr @ 65 C75 Shore D18.7 (475)1.0Low viscosity, flame retardant, roomtemperature curing epoxyBlack or Green25,000100:7.124 hr @ 25 C;or 2 hr @ 65 C92 Shore D 15.7 ( 400)1.1Two-component epoxy for thesemiconductor industryBlack10,000100:724 hr @ 25 C90 Shore D16.9 (430)1.5Filled, thermally conductive epoxy for usewith various hardenersCoolThermEP-3500EpoxyxxCoolThermEP-6006 HS /6011EpoxyxxCoolThermEP-6007 BLK/ / 6252EpoxyxxxCoolThermEP-340 / 70EpoxyxxxCoolThermEP-301 AD / 6010EpoxyxxBlack or White10,350100:5.324 hr @ 25 C;or 2 hr @ 65 C87 Shore D19.7 (500)1.3Thermally conductive casting epoxyCoolThermEP-343EpoxyxxBlack55100:3.92 hr @ 65 Cfollowed by4 hr @ 135 C90 Shore D59 (1,500)1.1Two-component, thermally conductive,dielectric epoxy coatingCoolThermEP-6150EpoxyxxWhite145,00030 min@ 121 C; or10 min@ 177 C90 Shore D17.7 (450)0.6One-component, thixotropic epoxy forassembling electronic components anddevicesThermosetEP-937EpoxyxBlack47,90018-28 min@ 120 C; or6-12 min@ 150 C88-94 Shore D6xUL 94 HB (onlywith ThermosetHardener No. 70)One-component, fast curing epoxy7

mES-21EpoxyCoolThermEP-6008 BLK / yxCircalok6022EpoxyCoolThermEP-6028 / 6029EpoxyThermoset300 / 70EpoxyxLORD600 / lThermEP-636EpoxyThermosetEP-20 / 70EpoxyxThermosetES-40 / 70EpoxyxThermosetES-100EpoxyThermosetES-115Can be usedwith multiplehardenersUL RatingViscosity,cP @ 25 CBlack35,000Black6,800BlackMix Ratio mm (V/mil)ThermalConductivity,W/m·KDescription60 min@ 125 C88 Shore D100:712 hr @ 25 C;or 2 hr @ 65 C85 Shore D17.7 (450)0.3Filled, low viscosity, general purpose pottingand encapsulating epoxy2,60010:12-4 hr @ 65 C90 Shore D19.7 (500)0.7Two-component epoxyGray200,000100:8524 hr @ 25 C;or 2 hr @ 65 C85 Shore D15.7 (400)Two-component, room temperature curingepoxy with long working life, good peelstrength and adhesion to metals, plastics,fiberglass and woodxYellow50,000100:8724 hr @ 25 C67 Shore D17.7 (450)Two-component, room temperature curingepoxy with good peel strength and adhesionto metals, plastics, fiberglass and woodxBlue15,0001:13-4 hr @ 100 C90 Shore D17.7 (450)xBlack2,000100:1524 hr @ 25 C88 Shore D15 (380)xClear Amber550100:3024 hr @ 25 C82 Shore DUnfilled, moderate viscosity epoxy for usewith various hardenersxGrayThixotropicPaste1:124 hr @ 25 C;5 min @ 121 C82 Shore DEpoxy used in varying mix ratios to provideoptimum propertiesxBlack12,0001:12-3 hr @ 95 C86 Shore DTwo-component, heat curing epoxy withexcellent thermal shock resistancexGray50,000100:116-24 hr @ 5065 C followedby 2 hr each @95 C, 150 C &205 C95 Shore DxBlack550100:3024 hr @ 25 C82 Shore DBlack, unfilled, moderate viscosity epoxy foruse with various hardenersxWhite550100:3024 hr @ 25 C82 Shore DUnfilled, moderate viscosity epoxy for usewith various hardenersxBlack1,2001:13-4 hr @ 80 C70 Shore OO15.7 (400)Two-component epoxy for encapsulatingintricate electronic components inautomotive, marine and heavy industrialapplicationsEpoxyxTan85,0001:12.5 hr @ 85 Cplus 1.5 hr@ 125 C90 Shore D 25 ( 635)Two-component epoxy for high voltage,automotive ignition coilsThermosetES-121 LV/ EP-809EpoxyxBlack6,000100:292.5 hr @ 90 Cfollowed by2.5 hr @ 140 C 90 Shore D30 (762)Two-component epoxy for high voltage,automotive ignition coilsThermosetMP 110-10EpoxyxBlack75,0001:1 by Volume2 hr @ 25 Cplus 1 hr@ 80 C45 Shore A 15.7 ( 400)Unfilled epoxy with good thermal shockperformance and excellent chemicalresistanceThermosetHardener No. 18EpoxyxAmber50100:14(with 600 Resin)24 hr @ 25 C(with 600 Resin)88 Shore D(with 600 Resin)Room temperature hardenerThermosetHardener No. 25EpoxyxAmber5,0001:1(with 600 Resin)24 hr @ 25 C(with 600 Resin)80 Shore D(with 600 Resin)High surface gloss, fast setting, moistureinsensitive hardenerThermosetHardener No. 37EpoxyxAmber40,0001:1(with 600 Resin)24 hr @ 25 C;or 5 min@ 93 C(with 600 Resin)84 Shore D(with 600 Resin)Hardener that produces epoxies withimproved flexibility and impact strengthThermosetHardener No. 65EpoxyxTan50100:40(with 600 Resin)24 hr @ 25 C(with 600 Resin)85 Shore D(with 600 Resin)High surface gloss, long working life,moisture insensitive hardener8xAppearancexxxUL 94 V-0One-component, fast curing epoxycontaining a fluorescent dye for detectionunder UV light18.3 (464)0.45Filled, two-component epoxy for pottinghigh voltage transformers, especially forhigh temperature devicesFilled, thermal shock resistant epoxy for usewith various hardeners0.7Ultra-high temperature resistantencapsulating epoxy9

ChemistryThermallyConductiveComponents1K2KCan be usedwith multiplehardenersUL RatingAppearanceViscosity,cP @ 25 CMix Ratio mm setHardener No. 66EpoxyxAmber12,000100:50(with 600 Resin)24 hr @ 25 C(with 600 Resin)85 Shore D(with 600 Resin)General purpose hardener well-suited for avariety of applicationsThermosetHardener No. 67EpoxyxClear30100:24(with 600 Resin)2 hr @ 100 C(with 600 Resin)92 Shore D(with 600 Resin)Long working life, heat curing hardener withhigh TgThermosetHardener No. 70EpoxyxTan30100:30(with 600 Resin)24 hr @ 25 C(with 600 Resin)82 Shore D(with 600 Resin)High impact strength hardenerThermosetHardener No. 71EpoxyxLight Amber1251:1(with 600 Resin)24 hr @ 25 C(with 600 Resin)60 Shore D(with 600 Resin)Semi-rigid, low exotherm hardenerThermosetHardener No. 72EpoxyxBlack7,0001:1(with 300 Resin)24 hr @ 25 C(with 300 Resin)65 Shore D(with 300 Resin)Clear, Straw Yellow3.5LORDAP-134AdhesionPromoter- Epoxy orUrethaneCoolThermUR-288UrethanexxUL 94-HBBlack4,900100:2024 hr @ 25 C or6 hr @ 60 C90 Shore ACoolThermUR-388UrethanexxUL 94 V-0Black6,000100:2024 hr @ 25 C or6 hr @ 60 C90 Shore ACoolThermUR-388 FSTUrethanexxUL 94 V-0Black6,000100:2030 min @ 25 k6403UrethanexAmber or 12UrethanexThermosetUR-325Urethanex10x14.6 (370)(with 300 Resin)Filled, room temperature curing hardenerwith low exotherm and semi-rigidencapsulation1-2 hr @ 25 CMoisture-cure primer for epoxy orpolyurethane0.4Two-component, room temperature curing,flame retardant urethane potting compound15.0 (388)0.7Two-component, flame retardant, semiflexible urethane for encapsulating andcasting applications88 Shore A15.0 (388)0.7Two-component, flame retardant, semiflexible urethane for encapsulating andcasting applications24 hr @ 25 C;or 2 hr @ 70 C45 Shore D16 (406.4)0.7Two-component, flame retardant, semiflexible urethane for encapsulating andcasting applications22:1030-45 min@ 25 C80 Shore A23.6 (600)General purpose, encapsulating urethanefor applications requiring a fast cure,mechanical shock resistant system1,500100:924 hr @ 25 C;or 3 hr @ 75 C25 Shore A13.5 (344)Two-component, room temperature curingurethane encapsulating compoundClear1,500100:552:1 by volume24 hr @ 25 C;or 2 hr @ 85 C50 Shore OO 11.8 ( 300)Microelectronic grade, clear, low modulusurethane encapsulating gelBlack4,0004:124 hr @ 25 C60 Shore A25.6 (650)Two-component, room temperature curing,urethane encapsulating compound11

Parker LORDEngineered Materials Group111 LORD DriveCary, NC 27511-7923USAphone 1 877 ASK LORD (275 5673)www.lord.comValues stated in this technical data sheet represent typical values as not all tests are run on each lot of material produced. For formalized product specifications for specific product end uses, contact the Customer Support Center.Information provided herein is based upon tests believed to be reliable. In as much as Parker LORD has no control over the manner in which others may use this information, it does not guarantee the results to be obtained. In addition, ParkerLORD does not guarantee the performance of the product or the results obtained from the use of the product or this information where the product has been repackaged by any third party, including but not limited to any product end-user.Nor does the company make any express or implied warranty of merchantability or fitness for a particular purpose concerning the effects or results of such use.WARNING — USER RESPONSIBILITY. FAILURE OR IMPROPER SELECTION OR IMPROPER USE OF THE PRODUCTS DESCRIBED HEREIN OR RELATED ITEMS CAN CAUSE DEATH, PERSONAL INJURY AND PROPERTY DAMAGE.This document and other information from Parker-Hannifin Corporation, its subsidiaries and authorized distributors provide product or system options for further investigation by users having technical expertise.The user, through its own analysis and testing, is solely responsible for making the final selection of the system and components and assuring that all performance, endurance, maintenance, safety and warning requirements of theapplication are met. The user must analyze all aspects of the application, follow applicable industry standards, and follow the information concerning the product in the current product catalog and in any other materials provided from Parkeror its subsidiaries or authorized distributors.To the extent that Parker or its subsidiaries or authorized distributors provide component or system options based upon data or specifications provided by the user, the user is responsible for determining that such data and specificationsare suitable and sufficient for all applications and reasonably foreseeable uses of the components or systems. 2022 Parker HannifinInformation and specifications subject to change without notice and without liability therefore.Trademarks used herein are the property of their respective owners.ODPC300202/22 Rev.11

85 Shore D 19.3 (490) 0.6 Thermally conductive adhesive and potting compound CoolTherm EP-6035 or 2 hr @ 65 C 75 Shore D 18.7 (475) 1.0 Low viscosity, flame retardant, room temperature curing epoxy CoolTherm EP-6037/ 6252 or 2 hr @ 65 C 92 Shore D 15.7 ( 400) 1.1 Two-component epoxy for the semiconductor industry CoolTherm EP-340 / 70