Transcription

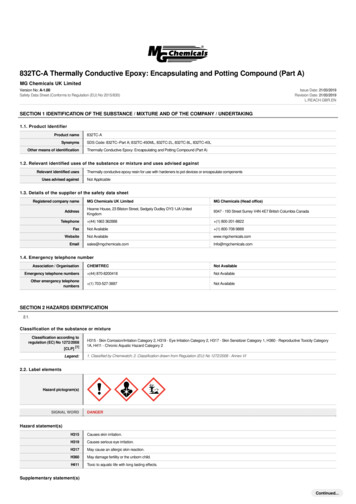

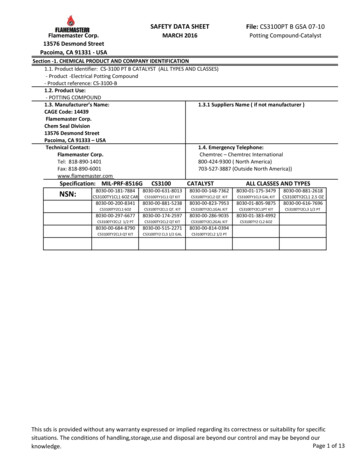

Potting & EncapsulatingPotting and encapsulating compounds are used to provide mechanical reinforcement to housed assemblies,to fill large voids, and to protect components from the effects of exposure to chemicals, moisture, mechanicalshock, and vibration. Sealing components with potting and encapsulating compounds prevents corrosion andensures long-term integrity of the device.Variables to consider when selecting a potting orencapsulating material include: Viscosity of uncured compound Dispensing requirements Device operating temperature Desired chemical resistance Desired thermal conductivity Desired flame retardance Hardness of cured product Overall costThere are a variety of potting and encapsulatingcompounds to choose from – epoxy, hot melt, silicone,and urethane. The thermal properties of epoxyand silicone systems make them ideally suited forapplications exposed to temperatures above 125 C. If asoft, flexible material is needed, particularly at lowtemperatures, then a urethane, silicone or hot meltmaterial may be used.What is the best product for my application?The following chart will work best when selecting apotting or encapsulating compound. This chart isintended to serve as a general guideline to help youdetermine which categories are best suited for yourapplication. The data presented represents typicalproperties for each product category; however,individual product properties may differ. It is suggestedthat, based on the information provided, you considerat least the two best product categories that meet yourapplication criteria. Individual product information canthen be found on the pages that follow to help younarrow your search.74This chart should not be used to specify products without specifictesting. It is recommended that you conduct on-part testing toensure product performance before specifying any adhesive.Loctite Adhesives and Sealants Product Specialists are available toassist you with new product designs, or to help you re- engineer anexisting application for improved performance and cost savings.They can also set up testing of your parts at the Henkel CustomerEngineering Center. For application assistance, call 1-800-LOCTITE(562- 8483) or visit www.loctite.com and select “Contact Loctite.” InCanada, please call 1-800-263-5043.

POTTING &ENCAPSULATINGSelector GuidePotting & Encapsulating Selector GuidePERFORMANCEC O N S I D E R AT I O N SPOTTING AND ENCAPSULATING COMPOUNDSHot MeltsPolyurethanesEpoxiesSiliconesBENEFITSFast, large gap fillingExcellent toughness/flexibilityWide range of formulationsExcellent temperature resistanceLIMITATIONSLow heat resistanceLiquid adhesivesensitive to moistureMixing requiredLow strengthTEMPERATURE RESISTANCE-65 C to 125 C-65 C to 125 C-65 C to 180 C-65 C to 200 CFLUID RESISTANCEPolar Solvents 1Good (Polyolefins, Polyamides)GoodVery GoodGoodGood RigidSoftFLEXIBILITYHighHighLowVery HighLowLowNon-Polar Solvents2TgPROCESSC O N S I D E R AT I O N SHighVery LowPOTTING AND ENCAPSULATING COMPOUNDSHot MeltsPolyurethanesEpoxiesSilicones1221Room Temperature(applied at elevated temperature)Room TemperatureRoom TemperatureUV/Room TemperatureAverage60 seconds1 to 3 hours1 to 3 hours30 secondsFastest10 to 20 seconds15 minutes15 minutes5 secondsNUMBER OF COMPONENTSCURE TEMPERATUREGEL TIMEFULL CURE TIME1 hour (or when cooled)24 hours24 hours24 hoursDEPTH OF CUREUnlimitedUnlimitedUnlimitedShallow ( 1.5")DISPENSING/CURINGEQUIPMENT REQUIRED?YesYesYesYesLIGHT CUREVERSIONS AVAILABLE?NoNoYesYes80-8176-7776-7980-81For more information oneach compound categoryrefer to pages 1 Examples of Polar Solvents: Water, Ethylene Glycol, IPA, Acetone.2 Examples of Non-Polar Solvents: Motor Oil, Gasoline, Toluene, n-Heptane, ATF.75

POTTING &ENCAPSULATINGEpoxies & PolyurethanesEpoxies& PolyurethanesThere are a variety of Loctite potting and encapsulating compounds to choose from – epoxy, hot melt,polyurethane, and silicone. Loctite potting and encapsulating compounds are designed to protect electricalcomponents from the effects of exposure to chemicals, moisture, thermal shock, mechanical shock, andvibration. Sealing components with Loctite potting and encapsulating compounds prevents corrosion andensures long-term integrity of electrical devices.EPOXIES & POLYURETHANESLoctite Hysol potting and encapsulating compounds are two-partepoxy and polyurethane systems formulated to offer a wide range ofperformance characteristics matched to specific application requirements.Any epoxy resin can be combined with any epoxy hardener to create amixed system. The same applies to the polyurethane resins and hardeners.LOCTITE HYSOL EPOXIESHARDENERSRESINSPackageItemPRODUCTNumber Type & SizePackageWeightKeyFeatures3140 39944 1 gallon pail39945* 5 gallon pail12 lbs.65 lb.GeneralPurpose3141 3994739948*1 gallon pail5 gallon pail12 lbs.63 lbs.HighTemperature3142 3995039951*1 gallon pail5 gallon pail16 lbs.65 lbs.ThermallyConductive3145 4051240511*1 gallon pail5 gallon pail13 lbs.65 lbs.FlameRetardant3160 39958*5 gallon pail40 lbs.GlossySurface Finish3162 3996039962*1 quart can5 gallon pail1.8 lbs.36 lbs.Fast Cure3163 399643996539966*1 quart can1 gallon pail5 gallon pail1.7 lbs.7 lbs.38 lbs.ExcellentAdhesion3164 3996939970*1 gallon pail5 gallon pail7 lbs.40 lbs.GeneralPurpose3165V3939539973*1 quart can1 gallon pail1.7 lbs.7 lbs.LowShrinkageHARDENERSRESINSL O C T I T E H Y S O L P O LY U R E T H A N E SPRODUCTItemPackageNumber Type & SizeKeyFeatures3173 399843998539986*1 quart can1 gallon pail5 gallon pail2.5 lbs.10 lbs.50 lbs.GeneralPurpose3182 3999539996*39997*1 gallon pail5 gallon pail55 gallon pail12 lbs.62 lbs.625 lbs.Fast Cure3183 3999839999*1 gallon pail5 gallon pail7.5 lbs.37 lbs.GeneralPurpose3184 3939839397*1 gallon pail5 gallon pail12 lbs.625 lbs.FlameRetardant* Made-to-order items.76PackageWeightDISPENSING OPTIONSLoctite Mix Nozzles areplastic, disposable nozzlesthat attach directly to Loctite dispensers. They are designedto automatically mix adhesiveas it travels through thestatic - mix nozzle.For all available nozzles,accessories, and packagesizes, please visitwww.equipment.loctite.com.Item Numbers: 98430, 98344, 98456,98457, 98458, 98459, 98460, 98461,98467, 98469, 98470, 98473, 98474,98476, 98477, 98478, 989516, and 989518

POTTING &ENCAPSULATINGLOCTITE HYSOL EPOXY KITSPRODUCTItem Number293242932529326E-60NC Package Type & Size50 ml dual cartridge200 ml dual cartridge400 ml dual cartridgeCOLORWORKLIFEHARDNESS (SHORE)AGENCY APPROVALSKEY FEATURESBlack60 minutes85CFIAElectrically non-corrosive,low viscosityEpoxies& PolyurethanesL O C T I T E H Y S O L P O LY U R E T H A N E S Y S T E M S3173 /3182 3173 /3183 3173 /3184 50WORKING TIME73 F (23 C) 7 minutes @ 300 g20 to 40 minutes @ 105 g150 minutes @ 300 gGEL TIME73 F (23 C)14 minutes @ 300 g40 to 70 minutes @ 105 g150 minutes @ 300 gNormal 73 F (23 C)90 minutes24 hours24 hoursAlternate 185 F (85 C)30 minutes1 to 3 hours1 to 3 hoursBy Weight(Resin:Hardener)13:8730:7015:85By Volume(Resin:Hardener)1:5.21:31:4.8ResinDark BrownClear BrownClear BrownHardenerBlackOpaque BlackOpaque WhiteMixedBlackOpaque BlackOpaque 51.061.40Hardness, Shore A757080Hardness, Shore 00N/AN/AN/ATg ( C)-10-16-15CTE above Tg (m/mm C)128 x 10e-6190x 10e-6151 x 10e - 60.1 kHz4.685.924.511.0 kHz4.024.364.2910.0 kHz3.763.653.94100.0 kHz3.633.313.560.1 kHz0.130.220.021.00 kHz0.070.170.0410.0 kHz0.040.100.06100.0 kHz0.020.050.07Insulation Resistance (ohms)2.5x10e 131.1x10e 111.1x10e 12Volume Resistivity (ohms/cm)1.5x10e 156.83x 10e 126.61x 10e 13Dielectric Strength (Volts/mil)370375370Flammability RatingN/AN/A94V-Ø at 3 8"UL File No. E106917N/AN/A94V-2 at 1 4"SYSTEM CHARACTERISTICSVISCOSITY (cP)CURE CYCLETYPICALUNCUREDPROPERTIESMIX CTOR77

POTTING &ENCAPSULATINGSYSTEMCHARACTERISTICSTYPICAL UNCURED PROPERTIESEpoxies& PolyurethanesVISCOSITY(cP)TYPICAL CUREDPROPERTIES3140 /3160 3140 /3162 3140 /3163 3140 /3164 3140 /3165 3141 /3160 3141 /3162 3141 /3163 3141 /3164 3141 /3165 013,0005 min.@ 200 g30 to 45 min.@ 200 g10 min.@ 400 g35 to 40 min.@ 200 g73 F (25 C)80 to 100 min. 5 to 10 min. 80 to 100 min. 10 to 15 min. 1 to 1.5 hrs.@ 200 g@ 100 g@ 200 g@ 400 g@ 400 g1.5 to 2 hrs.@ 400 gGEL TIME73 F (25 C)2.5 to 3 hrs. 10 to 15 min. 2.5 to 3 hrs. 25 to 35 min.@ 200 g@ 105 g@ 200 g@ 400 g2.5 to 3.5 hrs. 10 to 15 min. 60 to 80 min. 20 to 25 min. 65 to 75 min.@ 400 g@ 200 g@ 200 g@ 200 g@ 200 g2 to 3 hrs.@ 400 gNormal73 F (25 C)24 hours16 hours24 hours16 hours24 hrs./77 F 4 hrs./200 F24 hours24 hours24 hours24 hours24 hrs./77 F 4 hrs./200 FAlternate150 F (60 C)2 hours1 hour2 hours2 hoursN/A4 hours2 hours2 hours2 41.461.401.401.40Hardness, Shore D80808070858590808585Tg ( C)273520276743753831104CTE above Tg(mm/mm x10e-6135x10e-6138x10e-6111x10e-6115x10e-5CTE below Tg(mm/mm 1 kHz4.434.254.614.24.874.303.913.584.114.281.0 kHz4.374.204.3744.834.223.883.523.974.1810.0 kHz4.314.164.203.84.754.143.843.463.874.06100.0 kHz4.244.104.053.74.644.033.793.393.773.920.1 kHz0.0080.0100.0400.080.0030.010.010.010.020.011.0 0 .0 ECYCLEBy Weight(R:H)MIXRATIOBy L ELECTRICAL PROPERTIESLOCTITE 3141 HYSOL EPOXY SYSTEMWORKINGTIMECOLOR78LOCTITE 3140 HYSOL EPOXY SYSTEMDISSIPATIONFACTORInsulation Resistance(ohms)1.14x10e 13 2.67x10e 13 1.61x10e 12 7.5x10e 111 5.19x10e 13 5.72x10e 13 4.09x10e 13 1.23x10e 14 4.57x10e 13 2.15x10e 13Volume Resistivity(ohms/cm)6.03x10e 14 2.53x10e 15 1.02x10e 14 1.5x10e 14 2.69x10e 15 4.03x10e 15 2.61x10e 15 7.41x10e 15 2.98x10e 15 1.37x10e 15Dielectric lammability RatingUL File No. E106917N/AN/AN/AUL 94B@ 1/16"N/AN/AN/AN/AN/AN/AInsulation SystemUL File No. E106917N/AN/AN/AUL 1446N/AN/AN/AN/AN/AN/A

3142 /3163 3142 /3164 3142 /3165 3145 /3160 3145 /3162 3145 /3163 3145 /3164 3145 /3165 9013,355WORKINGTIME77 F (25 C)1.5 to 2 hrs.@ 400 g5 to 10 min.@ 200 g2 hrs.@ 400 g25 min.@ 400 g80 min.@ 400 gGEL TIME77 F (25 C)3.5 to 4 hrs.@ 400 g5 to 30 min.@ 200 g 3 hrs.@ 400 g50 min.@ 400 g2.5 hrs.@ 400 g6 to 8 hrs.@ 200 g35 to 45 min.@ 200 g6 to 7 hrs.@ 200 g75 to 90 min.@ 200 g5 hrs.@ 200 gNormal77 F (25 C)24 hours24 hours48 hours24 hours24 hrs./77 F 4 hrs./200 F24 hours24 hours24 hours24 hours24 hrs./77 F 2 hrs./200 FAlternate150 F (66 C)4 hours2 hrs.4 hrs.2 hrs.4 hrs./ 200 F2 hours2 hours4 hours2 hours4 hrs./ 200 F100:10.7100:9100:10.9100:14.3100:4.1100:15100 :13100:15.5100:20100: 91.58Hardness, Shore D90909085908084807588Tg ( C)26423029842842383253CTE above Tg(mm/mm 1.22x10e-6128x10e-6130x10e-6122x10e-6111x10e-6CTE below Tg(mm/mm -6Watts/Meter 410.1 kHz5.774.875.285.515.654.083.814.274.194.431.0 kHz5.694.835.205.355.574.283.854.364.464.4510.0 kHz5.624.785.125.215.464.153.744.114.224.28100.0 kHz5.524.725.025.065.3443.633.903.994.110.1 0 0.0 0.0 PICAL UNCURED PROPERTIESCURECYCLEBy Weight(R:H)MIXRATIOBy ANTDISSIPATIONFACTOREpoxies& Polyurethanes3142 /3162 SPECIFICGRAVITYTYPICAL CUREDPROPERTIESLOCTITE 3145 HYSOL EPOXY SYSTEM3142 /3160 VISCOSITY(cP)TYPICAL ELECTRICAL PROPERTIESLOCTITE 3142 HYSOL EPOXY SYSTEMPOTTING &ENCAPSULATINGSYSTEMCHARACTERISTICS2.5 to 4 hrs. 15 to 30 min. 3 to 3.5 hrs. 35 to 45 min. 2.5 to 3 hrs.@ 200 g@ 200 g@ 200 g@ 200 g@ 400 gInsulation Resistance(ohms)4.61x10e 13 5.31x10e 13 3.65x10e 13 2.75x10e 12 4.09x10e 13Not TestedNot TestedNot TestedNot TestedNot TestedVolume Resistivity(ohms/cm)3.00x10e 15 3.47x10e 15 2.55x10e 15 1.65x10e 14 2.61x10e 151.10e 148.4e 142.1e 142.5e 137.3e 14Dielectric lammability RatingUL File No. E106917N/AN/AN/AN/AN/AN/AUL 94V-0@ 1/8"N/AN/AUL 94V-0@ 1/8"79

POTTING &ENCAPSULATINGHot Melts& SiliconesHot Melts & SiliconesHOT MELT ADHESIVESIn addition to structural bonding, Loctite Hysol hot melt adhesivesare also well suited for fast, deep potting applications requiring largegap fills in a high speed manufacturing environment.LOCTITE 1942 HYSOL HOT MELT ADHESIVELOCTITE 7901 HYSOL HOT MELT ADHESIVEGeneral PurposeMedium setting, general purposehot melt adhesive. Excellentadhesion to wood and many plastics.PolyamideLow viscosity polyamideused extensively for pottingand encapsulating.SILICONE POTTING COMPOUNDSLoctite silicones are single - component, tough protective potting andencapsulating compounds that seal components against moisture,solvents, and environmental conditions. Loctite Nuva - Sil productscure in as little as 30 seconds to depths of 0.150" when exposed to UVlight or visible light, while Loctite RTV silicones cure in 24 hours atroom temperature when exposed to atmospheric moisture.LOCTITE 5031 NUVA -SIL SILICONE POTTING COMPOUNDLOCTITE 5040 RTVSILICONE POTTING COMPOUNDHigh Adhesion / Visible LightA low viscosity, self - leveling,UV or visible light curing siliconefor high speed deep potting,coating and sealing applications.Provides high adhesion fordifficult- to - bond substrates.A non- corrosive, self - leveling RTVsilicone for shallow potting, sealingand coating of devices, especially formilitary and industrial applications.DISPENSING OPTIONSLoctite Meter Mix 3000 Dispense Systems – Programmable Shot Sizeare versatile dispensing systems for two -part adhesive chemistries andincorporates a variety of feed system options. Available in fixed orvariable ratio, these systems offer programmable shot sizeand integrated PLC controls with convenienttouch screen capability. For available valves,spare parts, accessories and dispense tips,please visit www.equipment.loctite.com.Item Numbers: Fixed: 988908, Variable: 988909Dimensions: 20" H x 15" W x 28" DWeight: 75 to 100 lbs.Package Types & Sizes: Cans, pails, drums, totes80

Loctite Hysol Bulk Hot MeltSystem ApplicatorsLoctite Hysol Bulk-34 System is a compact andItem Numbers: 98145, 98146, 98147, 98148, and 98149For similar equipment, please see ourLoctite Equipment Sourcebook, LT-3669 orvisit us at www.equipment.loctite.com.Item Number: 98135Voltage: 230Standard Tank Capacity: 34 lbs. (15.4 kg)System Power Consumption: 6600 WattsAGENCYAPPROVALS7901 Hysol HARDNESS(SHORE A)7811 Hysol % ELONGATION TEMPERATURERESISTANCE7809FR Hysol OPEN TIME3651 Hysol TENSILE STRENGTH(PSI)3650 Hysol VISCOSITY (cP)AT DISPENSETEMPERATURE1942 Hysol COLORLoctite Hysol Hot Melt AdhesivesProperties ChartTan5,00025030seconds142 F500N/AFDACFR175,105Light Beige2,90030560 to 80 seconds176 F4387N/A26.4 lb. squaresBeige10,00033480 to 100 seconds266 F79055N/A5 lb. sample bag pelletsSuperstick 10" 13 oz. sample bagPolyshot 13 oz. bagAmber7,00036335seconds240 F37385UL Classifiedfor U.S.8333783339833405 lb. sample bag pelletsPolyshot 13 oz. sample bagPolyshot 25 lb. pailAmber6,40040035seconds266 F1,200N/AN/A833418334283343833445 lb. sample bag pellets40 lb. carton pelletsPolyshot 13 oz. sample bagPolyshot 25 lb. pailAmber75026035seconds300 F8084N/AItemNumberPackage Type & 3276832775 lb. sample bag pellets40 lb. carton pelletsMaxistick 7 oz. sample bagMaxistick 35 lb. cartonPT stick 36 lb. cartonMinistick 35 lb. cartonSuperstick 10" 5 oz. sample bagSuperstick 10" 25 lb. bagSuperstick 4" 25 lb. cartonPolyshot 12 oz. sample bagPolyshot 35 lb. Carton313023129722 lb. pellets44 lb. pellets31303833888339083391Hot Melts& SiliconesHenkel offers accurate and convenientstyles of dispense applicators.For available valves, spareparts and applicators,please visitwww.equipment.loctite.com.efficient bulk hot melt unit capable of manual orautomatic product delivered up to 75 lbs. / hr. ThisCE certified unit has three independent temperaturecontrols for the tank, hosing and dispense valves thatwill provide an effective extrusion or spray applicationfor a wide range of hot melt adhesives. For availablevalves, spare parts, accessories and dispense tips,please visit www.equipment.loctite.com.PRODUCTPOTTING &ENCAPSULATINGDISPENSING OPTIONSLoctite Silicone Potting CompoundsProperties ChartPRODUCTItemNumberPackageType & SizeCURE SCHEDULE(CURE /ALT. CURE)VISCOSITY(cP)GEL TIMEHARDNESSAGENCYAPPROVALS5031 Nuva-Sil 4008640087300 ml cartridge40 lb. pailUV/visible light/moisture60 seconds @ 40 mW/cm 25,500Seconds34 shore AN/A5040 40405404044040785 g tube300 ml cartridge40 lb. pailMoisture24 hours @ 25 C35,000 3 hours(skin over)30 shore AMIL-A-46146B1741218074300 ml cartridge40 lb. pailUV/moisture60 seconds @ 40 mW/cm 25,500Seconds34 shore AUL Classifiedfor U.S.5091 Nuva-Sil 81

potting or encapsulating compound. This chart is intended to serve as a general guideline to help you determine which categories are best suited for your application. The data presented represents typical properties for each product category; however, individual product properties may differ. It is suggested