Transcription

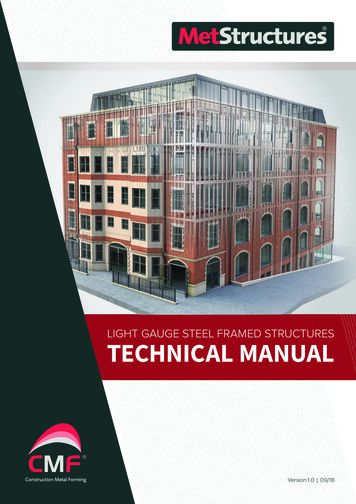

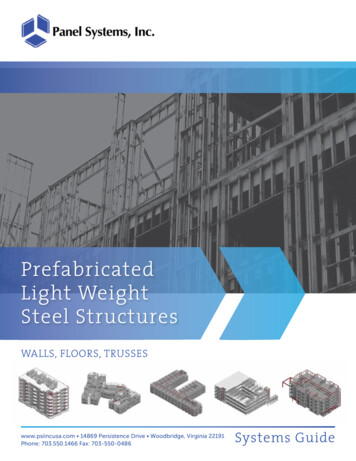

Prefabricated L ight Weight S teel StructuresWALLS, FLOORS, TRUSSESwww.psiincusa.com 14869 Persistence Drive Woodbridge, Virginia 22191Phone: 703.550.1466 Fax: 703-550-0486Systems Guide

Introduction to PSICompany OverviewEstablished in 1979, Panel Systems, Inc. provides the ultimate in Load Bearing, Light Gauge, Panelized Structures. Our In-HouseEngineering, Fabrication, Delivery, and Installation Departments optimizes cost, efficiency, quality and speed while our ultimate goal is tomeet our commitments, do what’s best for the job and provide an excellent product.Our Design Teams Light Gauge experience stems from the on-set of the product as a Structural Component. We provide full specialtyengineering services for our structures in accordance with the generally accepted rules governing the relationships between the StructuralEngineer of Record (SER) and the Specialty Engineer.We are eager to participate in the early design phase to assist in selecting the most economical structural system for the project.Our WallsTypically, PSI includes all (Cold-Formed Metal) Exterior Walls, Interior Load Bearing Walls as well as all Shear Walls and Shear Wall “hardware.”This normally encompasses all work described under CSI Specification Section 05400. In addition, Structural Steel components such as HSSposts, distribution plates and/or corridor beams are often included in this wall “package.”PSI panels are factory-fabricated with all GMAW (Mig) welded connections, performed by Welders who have been Qualified in accordancewith American Welding Society guidelines for the specific equipment and materials employed.We utilize the state-of-the-art “Vertex BD Framer for Light Gauge Steel Program” for our design/material procurement,quality control and labeling procedures for each individual panel. Distributed by Argos Systems, Vertex BD is a highlycustomizable BIM application continuously employed by PSI since 1999. Batts Insulation is factory-installed in exterior wall headers/boxed assemblies that otherwise would be inaccessible after fabrication.Typically, we exclude wall insulation, interior drywall and all finishes from our bid. Structural (non gauge-metal) Steel is also excluded, exceptfor members which can readily be integrated into the wall panel installation.DESIGN2FABRICATIONINSTALLATIONPanel Systems Inc. www.psiincusa.com 14869 Persistence Drive Woodbridge, Virginia 22191 phone: 703-550-1466 Fax: 703-550-0486

Our WallsSubmittalsWe employ a two-part submittal process.First, an overall engineering submittal is made, includingDesign Criteria and calculations in an 8 ½ x 11 format,as well as Large Scale Plans, Sections & Details.Second, we prepare all the individual panel elevationsand site layout plans which are submitted for recordfollowing approval of the Engineering Submittal.LATERAL BRACING DESIGNThe SER defines load paths in the structure, in accordance with the “AISI Code ofStandard Practice,” PSI will then design each Shear Wall accordingly. It is assumed thatthe SER will designate an adequate quantity of Shear Wall locations to allow the use ofLight Gauge Straps for the Typical conditions. (PSI is capable of integrating StructuralSteel Posts and/or “K-Frames” at select conditions).BRIDGING-BRACINGHorizontal Bracing in the Panels is designed to incorporate the latest AISIrequirements including diagonal members to “brace the bracing.” Our standard HorizontalBridging technique, (for studs up to 6”) thick, is to thread 16 ga. Cold Rolled Channel(CRC), through “punch-outs”and weld the flanges to the studs.BLAST RESISTANCE & PROGRESSIVE COLLAPSEPanelized Light Gauge Framing lends itself well to these new structural requirements forGovernment Buildings. Enhanced Jambs, Sills, Headers and Slab Connections aroundopenings, help meet blast design requirements.Proper bottom-chord bracing and reinforcing fabric in concrete decks afford the necessarystrength to resist upward blast pressures. Continuous HSS distribution plates, rebar, andvertical straps provide the horizontal and vertical ties required to prevent progressive collapse.LEEDS ConsiderationsCold-Formed Metal Framing is a 100% Recyclable product. Under Leed-NC standards, TotalPoints Available are 69, with Platinum Certification requiring a minimum of 52 points. Localmanufacturing plants and low product weight minimize the “carbon footprint” of shipping.Fabrication, Delivery & InstallationPSI manufactures and installs its own Wall Panels. Field Welders are trained and Qualifiedper AWS Standards. We utilize a custom designed Quality Control program for everypanel. We have the experience and equipment to guarantee on-time Deliveries andInstallation in accordance with the strictest Safety & Scheduling standards.Panel Systems Inc. www.psiincusa.com 14869 Persistence Drive Woodbridge, Virginia 22191 phone: 703-550-1466 Fax: 703-550-04863

PSI System “A”3” Composite Metal DeckSystem “A” consists of load-bearing structural stud (braced) walls witha 3 inch deep, 18 gauge metal deck acting as a permanent form toreceive a composite concrete slab. Key to the system is the alignmentof the vertical studs (@ 24”oc), with the corresponding flutes of thefloor deck, thus eliminating the need for load-distribution plates atthe top of the stud walls.Given the span characteristics of the 18 gauge metal deck, this systemis especially suited for multi-story hotels, dormitories and apartmentswith stacked bearing walls up to 14 feet apart.ADVANTAGES: Speed (No Shoring 14’ Span) Cost (Non Proprietary Pricing) Quantity of Walls Included Floor-to-Floor HeightCONSIDERATIONS: Relatively Short Span Open Deck Flutes Bulkheads for HVACTypical DetailsEND/BEARING WALLINTERIOR/BEARING WALLSIDE WALL/ ELEVATION1. 3” Composite Deck2. Pour-Stop (16 Ga. Typ.)3. 3 5/8, 4” or 6” Studs @ 24” o.c.4. Wire mesh reinforcing5. Line of Drywall6. Head of Wall Fireproofing as required7. Load Bearing Framing beyond8. 5 1/2” to 7 1/2” Slab thickness9. RebarFIRE PROTECTION - WALLS:Load-Bearing Wall UL ratings are achieved through the use of layers of5/8” Firecode sheathing on each side; (one layer 1 hr/UL #U-425).FIRE PROTECTION - FLOOR:UL ratings for the Composite Deck system range from 1 hour to 3 hoursper UL #D913, and are achieved without protection of the deck by anadditional fire-rated ceiling assembly.UL DESIGN # D913RestrainedConcreteAssembly Rating Hr(Type)1Normal Weight1-1/2Normal Weight2Normal Weight1Lightweight2Lightweight2LightweightConcrete UnitWeight pcf------107-113107-113107-120ConcreteThkns In.3-1/244-1/22-1/23-1/43-1/2FIREPROOFING OF FLUTESULsystemFirestopping S-00401 hr.gypsum wallSteelfluted deckXHBN.HWS-00402 hr.gypsum wallSteelfluted deckHourlyrating12REF: IBM FIRENAM "REF: PCSI4Panel Systems Inc. www.psiincusa.com 14869 Persistence Drive Woodbridge, Virginia 22191 phone: 703-550-1466 Fax: 703-550-0486

PSI System “B”Dovetail DeckSystem “B” consists of load-bearing structural stud (braced)walls with a 2” inch deep, Dovetail formed metal deck acting as apermanent form to receive a composite concrete slab. Thissystem affords long spans, typically 16 to 20 feet, with continuousbearing, eliminating the need for load distribution members.The longer spans allow more flexibility in locating loadbearing walls, suitable for almost any type of multi-story residential construction.CONSIDERATIONS:ADVANTAGES: Shoring/Re-shoring Long Spansrequirements. Thin Slabs (less concrete) Negative reinforcing Standard Wallsteel.Fireproofing techniquesTypical DetailsSIDE WALL1. 2” DOVETAIL DECK2. POUR-STOP (16 GA. TYP.)3. 3 5/8, 4” OR 6” STUDS4. WIRE MESH REINFORCING5. REBARINTERIOR/BEARING WALLEND/BEARING WALLFIRE PROTECTION - FLOOR:UL ratings for the Dovetail composite deck systemrange from 1 hour to 3 hours per UL #D904, andare achieved without protection of the deck by anadditional fire-rated ceiling assembly.FIRE RESISTANCELINKS:SOUND TRANSMISSIONRestrainedRatings (Hr.)Total DepthNormal-weight ConcreteTotal DepthLight-weight Concrete1 Hr.4”NA2 Hr.5.25”4.5”3 Hr.6.75”5.25”Dovetail Deck6” Total Depthnormal weightconcrete58Grade ISTC (min)Grade IISTC (min)5552Grade IIISTC aldek.com48Panel Systems Inc. www.psiincusa.com 14869 Persistence Drive Woodbridge, Virginia 22191 phone: 703-550-1466 Fax: 703-550-04865

PSI System “C”Composite JoistsSystem “C” consists of load-bearing structural stud (braced) wallssupporting a composite floor system consisting of bar joists at 48” oc.,which receive a steel deck fastened with Shear screws that provide averifiable composite lock between the joists and a 3 1/2” (standard)concrete slab. The floor system is manufactured by Vulcraft underthe trade name Ecospan This system provides great economy atspans of 20 to 35 feet and permits the most floor plan flexibility,without shoring or formwork.ADVANTAGES: Long Spans Fewer Bearing Walls Plenum Space for Mechanicals Joists manufactured locallyfor LEED calculations. Standard Concrete-over-Deckinstallation techniques. No down-time for othertrades once concrete is poured.CONSIDERATIONS: Distribution Platemay be required Floor-to-Floor heightgreater than withComposite Deck.LINKS:www.ecospan-usa.comTypical DetailsEND/BEARING WALLINTERIOR/BEARING WALLSIDE WALL/ELEVATION1. 1” 26 GA. (TYP.) FORM DECK2. POUR-STOP3. 3 5/8”, 4” OR 6” STUDS (TYP.)4. WELDED WIRE FABRIC REINF.5. ECOSPAN STEEL JOIST (2 1/2” MIN. BRG.)6. SHEARFLEX SHEAR CONNECTOR7. E-CLOSURE CONCRETE STOP8. 7/8” FURRING CHANNEL AT 24” o.c.9. 5/8” GYPSUM BOARD10. COMPOSITE DECK AT CORRIDORFIRE PROTECTION - FLOOR:SOUND TRANSMISSIONThe Ecospan Composite Floor System is listed byUnderwriters Laboratories Inc. with multiple Fire Ratings (1 hr. to 3hrs.) for Acoustical and Gypsum ceilingapplications. The most common UL code encounteredin construction utilizing the Ecospan CompositeFloor System is UL Code G5616Flooring Materials/ThicknessBare ConcreteCarpet1. 6 PCF PAd (0.4”)2. 100% Pet polyester carpet (0.438”)Ceramic Tile1. Loose-laid cork (0.235”)2. Thinset mortar3. Glazed ceramic tile (0.3”)IIC26,30*STC77575154*N/A57Panel Systems Inc. www.psiincusa.com 14869 Persistence Drive Woodbridge, Virginia 22191 phone: 703-550-1466 Fax: 703-550-0486

PSI System “D”Cold Formed JoistsSystem “D” comprises load-bearing structural stud (braced) walls witha light gauge “C-Joist” Floor framing assembly topped with (either)poured gypsum-cement on metal deck, or reinforced interlocking3/4” thick Structural Cement Panels fastened directly to the joists.This system eliminates all concrete on the elevated decks, whileproviding a two hour rated floor assembly (poured gyp) with onlyone layer of Firecode Gypsum Board. It is suitable for all medium( 20 ft.) span applications.ADVANTAGES Installation Plenum space Fire Ratings No Concrete Prefab FloorsCONSIDERATIONS: Floor-to-Floor Height No Floor DiaphragmTypical Details1.2.3.4.5.6.7.8.9.9 1/4” (MIN) 16 GAUGE JOISTS @ 24” o.c.WEB STIFFENER3 5/8, 4” OR 6” WALL STUDS9/16” 22 GA. GALV. METAL DECK1 9/16” POURED GYPSUM TOPPING3 1/2” FR GLASS FIBER INSULATION1/2” 25 GA. RESIL. CHANNELS @ 12” o.c.5/8” FC GYPSUM BOARD3/4” STRUCTURAL CEMENT PANELEND/BEARING WALLW/ POURED GYPSUMSOUND TRANSMISSIONFIRE RESISTANCEMaterialsHR RATINGPoured GypOne layer 5/8” FC Gyp Bd.Structural Cement PanelsOne layer 5/8” FC Gyp Bd.Two layers 5/8” FC Gyp. Bd.212INTERIOR BEARING WALLW/ POURED GYPSUMUL #Flooring Materials STC IICG-563G-574G-559Ceramic Tile & mat 58 46(Poured Gyp)G-556G-557SIDE NON-BEARING WALLW/CEMENT arpet & Pad 56 65(Poured Gyp)Carpet & Pad 52 67Structural Cement PanelPanel Systems Inc. www.psiincusa.com 14869 Persistence Drive Woodbridge, Virginia 22191 phone: 703-550-1466 Fax: 703-550-04867

PSI System “E”Precast Concrete PlankSystem “E” consists of load-bearing structural stud (braced)walls with precast plank of various thicknesses. The plankcan have a structural toping applied before the next level ofbearing walls is set, or non-structural gypsum concrete levelingcan be applied after the structure is complete. Six inch studsare used at the exterior bearing wall while eight inch studs areused at interior walls to provide adequate bearing length forthe plank. Stud spacing can be 16 or 24 inches oc dependingon the requirements of sheathing.Given the span characteristics of plank bearing walls can bespaced up to 30 feet apart. This system is especially suited forsuite type hotels were plenum spaces or highly finished ceilingsare not required.Typical Details1. POUR STOP2. GROUT FOR STUD BEARING3. GROUT PLANK VOIDS4. DEFLECTION TRACK5. BEARING STUDS6. INFILL FRAMINGADVANTAGES OVER WOODTrussesNON-COMBUSTIBLEINSECT AND ROT RESISTANTDIMENSIONALLY STABLE.INSPECTION FRIENDLYCURVED CHORD OPTIONPanel System TrussesPanel Systems originated cold-formed steel trussdesign and fabrication in the DC MetropolitanRegion. Starting with “C-Stud” trusses, and nowthe TrusSteel system utilizing Alpine software.With higher relative stiffness than competitiveproducts, TrusSteel requires less horizontal bracingand is easier and safer to handle, resulting in lessdamage to the trusses during unloading, hoistingand installation. When necessary, Tube Steel (HSS)Girder trusses may be integrated into the design.8FIRE RATED ASSEMBLIESUL FileNumberDesign AssemblyNumber DescriptionBXUV.P525P525TrusSteel RoofTrusses-1, 1-1/2 and 2Hour Assemblies witha SINGLE layer ofgypsum wallboard(steel roof deck).BXUV.P526P526TrusSteel Roof Trusses-1Hour Assembly witha SINGLE layer ofgypsum wallboard(plywood as roof deck).LEEDS CHARACTERISTICSMR 4.1 (1 POINT)MR 4.2 (1 POINT)MR 3.1

which receive a steel deck fastened with Shear screws that provide a verifiable composite lock between the joists and a 3 1/2” (standard) concrete slab. The floor system is manufactured by Vulcraft under the trade name Ecospan This system provides great economy at spans of 20 to 35 feet and permits the most floor plan flexibility, without shoring or formwork. ADVANTAGES: Long Spans .