Transcription

2015.11.04.Construction of Steel structuresIstván Vidovszky PhDhistoric overview2round 800 B.C.the general use of iron16th-19th centurywrought iron / cast iron (in Europe)round 1870 A.D.the first production of modern steellate 19th centurymulti-storey iron structure buildingsearly 20th centurythe application of tower and mobile cranes in constructionVidovszky – BUTE/BME-Faculty of Architecture – Department of Construction Technology and Management9/11/20121

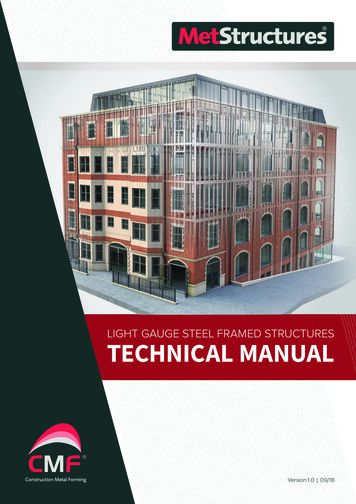

2015.11.04.material3cast iron: iron-carbon alloy with 2,1-3,6 wt% carbon content (used for cast buildingelements)wrought iron: in consequence of the fabricating process inhomogeneous iron-carbonalloy (likely to found in 19th century buildings)modern steel: homogenous iron-carbon alloy with 0,002-2 wt% carbon contentVidovszky – BUTE/BME-Faculty of Architecture – Department of Construction Technology and Management9/11/2012steel structures4main categorieshall structureshigh (multi-storey) buildingsVidovszky – BUTE/BME-Faculty of Architecture – Department of Construction Technology and Management9/11/20122

2015.11.04.steel hall structures – static models5structures with I/H-girdersstructures with truss-girdersVidovszky – BUTE/BME-Faculty of Architecture – Department of Construction Technology and Managementbasic characteristics-prefabricated structural elements-in situ assembled frame structures-welded or mounted joints-relative rapid construction processVidovszky – BUTE/BME-Faculty of Architecture – Department of Construction Technology and Management9/11/201269/11/20123

2015.11.04.preparatory work phases71.Design of the building2.Preparation of element consignation3.Planning the transport route4.Planning the site arrangement5.Selection of the temporary structures ofthe assembly6.Planning the lifting sequence of theelements and the temporary bracingVidovszky – BUTE/BME-Faculty of Architecture – Department of Construction Technology and Management9/11/2012hierarchy of the structure8FCEA. columns/pillarsB. girderC.roof joistsBD. wall studsE.bracingsF.front frameFDEVidovszky – BUTE/BME-Faculty of Architecture – Department of Construction Technology and ManagementA9/11/20124

2015.11.04.element consignationIDFigure (drawing)9Geometry (mm)Weight (kg)Amount1. P-001a4000x500x30030022. P-001b5000x500x30035023. G-0016000x500x3004203 Vidovszky – BUTE/BME-Faculty of Architecture – Department of Construction Technology and Management9/11/2012application of element consignation10What is the weight of the heaviest element?What are the dimensions of the largest/longest element?What is the total amount of the elements?Vidovszky – BUTE/BME-Faculty of Architecture – Department of Construction Technology and Management9/11/20125

2015.11.04.work sequence of the assembly1.set up the site (layout)2.foundation3.installation of the temporary structures4.transportation5.lifting process6.preparation of the structural joints7.bracing8.corrosion protection9.disassemble temporary structuresVidovszky – BUTE/BME-Faculty of Architecture – Department of Construction Technology and Management1. Transportation - site logistic119/11/201212Organizational questions: Do structural elements have to be stored on the side?(Avoid if possible!) Is it possible to lift the elements directly from the trailerto their final place or a part of the structure have to beassembled on the ground before lifting? How can the shipments enter and leave the site? (Driveroutes in case of a long-vehicle) What is to be considered as main equipment?Vidovszky – BUTE/BME-Faculty of Architecture – Department of Construction Technology and Management9/11/20126

2015.11.04.1. Transportation - site logistic13?Vidovszky – BUTE/BME-Faculty of Architecture – Department of Construction Technology and Management1. Transportation - tracks, trailers9/11/201214Organizational questions: How long trailer is required? What is the required load capacity of the trailer? What is the maximum vertical extension of the shipment? Is route permission required?Vidovszky – BUTE/BME-Faculty of Architecture – Department of Construction Technology and Management9/11/20127

2015.11.04.2. Site layout15Site set up (layout):I.preparatory (row) set up – before the foundation is placedII.fine set up – mark the exact place of the pillars on the foundation padsVidovszky – BUTE/BME-Faculty of Architecture – Department of Construction Technology and Management3. Site layout, foundation9/11/201216Usual foundation types:A.prefab reinforced concrete padfoundationB.prefab concrete pad foundationC.monolithic concrete padfoundationD.composite cases (e.g. monolithicconcrete pad prefab reinforcedconcrete elementsVidovszky – BUTE/BME-Faculty of Architecture – Department of Construction Technology and Management9/11/20128

2015.11.04.4. installing temporary structuresVidovszky – BUTE/BME-Faculty of Architecture – Department of Construction Technology and Management5. lifting179/11/201218tower crane:accustomed application:above 3 floorsVidovszky – BUTE/BME-Faculty of Architecture – Department of Construction Technology and Management9/11/20129

2015.11.04.5. lifting19mobile crane: optimal in case of relative low building height and huge vertical extensionVidovszky – BUTE/BME-Faculty of Architecture – Department of Construction Technology and Management5. lifting9/11/201220lifting columns/pillars1.lifting the elements2.place the elements onto foundation3.mounting at the joints with screws or wedges4.setting temporary bracingVidovszky – BUTE/BME-Faculty of Architecture – Department of Construction Technology and Management9/11/201210

2015.11.04.5. lifting21lifting (truss) girders1.lifting the elements2.placement of the elements onto their final place3.mounting with screws or welding at the joints4.assemble bracingVidovszky – BUTE/BME-Faculty of Architecture – Department of Construction Technology and Management5. preparing structural joints weldingmounting (with screw) temporaryfinalVidovszky – BUTE/BME-Faculty of Architecture – Department of Construction Technology and Management9/11/2012229/11/201211

2015.11.04.6. bracing work sequnce23 rod (for pressure and tension) or cable (for tension only) K, V or X shape in the predefined places7123456work sequenceVidovszky – BUTE/BME-Faculty of Architecture – Department of Construction Technology and Management7. corrosion prevention9/11/201224painting of the surface with a painting system:primer fire protection layer cover paintingVidovszky – BUTE/BME-Faculty of Architecture – Department of Construction Technology and Management9/11/201212

2015.11.04.8. disassemble of temporary structures25remove scaffolding / temporary bracingsVidovszky – BUTE/BME-Faculty of Architecture – Department of Construction Technology and Managementequipments9/11/201226cranes:moblie cranetower cranelifting tools:spreader beamswire rope slingsrigging tools:lifting toungeeye boltshaklesclipshooksclampsVidovszky – BUTE/BME-Faculty of Architecture – Department of Construction Technology and Management9/11/201213

2015.11.04.selection of mobile crane27Vidovszky – BUTE/BME-Faculty of Architecture – Department of Construction Technology and Managementselection of mobile crane9/11/201228relevant parameters:1.Lifting heights the level of the final location of the element the height of the highest element the height of the equipment (lifting and rigging tools) 1m2.Lifting weight the weight of the heaviest element to liftVidovszky – BUTE/BME-Faculty of Architecture – Department of Construction Technology and Management9/11/201214

2015.11.04.selection of mobile crane2935tVidovszky – BUTE/BME-Faculty of Architecture – Department of Construction Technology and Managementselection of mobile crane9/11/201230160tVidovszky – BUTE/BME-Faculty of Architecture – Department of Construction Technology and Management9/11/201215

2015.11.04.equipments31temporary structures:rolling scaffoldinglifting platformsVidovszky – BUTE/BME-Faculty of Architecture – Department of Construction Technology and Managementtools9/11/201232hand tools: snips, hand seamer, hammer, screw driver, measuring wrench,hand swagger, wire rope cutterpower tools: screw gun, cordless drill, electric shear, angle grinderVidovszky – BUTE/BME-Faculty of Architecture – Department of Construction Technology and Management9/11/201216

2015.11.04.examples33Airport, Suttgart, GermanyVidovszky – BUTE/BME-Faculty of Architecture – Department of Construction Technology and Managementexamples9/11/201234Calgary, CanadaVidovszky – BUTE/BME-Faculty of Architecture – Department of Construction Technology and Management9/11/201217

2015.11.04.examples35Beijing National Stadium, Peking, ChinaVidovszky – BUTE/BME-Faculty of Architecture – Department of Construction Technology and Managementexamples9/11/201236Oriente, Lisbonne, PortugalVidovszky – BUTE/BME-Faculty of Architecture – Department of Construction Technology and Management9/11/201218

2015.11.04.examples37Divatcsarnok, Budapest, HungaryVidovszky – BUTE/BME-Faculty of Architecture – Department of Construction Technology and Managementexamples9/11/201238Street decoration, Calgary, CanadaVidovszky – BUTE/BME-Faculty of Architecture – Department of Construction Technology and Management9/11/201219

2015.11.04.special examples39Vidovszky – BUTE/BME-Faculty of Architecture – Department of Construction Technology and Management9/11/2012Thank you for your attention!Vidovszky – BUTE/BME-Faculty of Architecture – Department of Construction Technology and Management9/11/201220

2015.11.04.References4[1] Klujber Róbert: Acélszerkezetek építéstechnológiája. 2009 (Presentation)[2] Lepel Adrienn: Acélszerkezetű csarnokok szerelése. 2010 (Presentation)[3]A Builder’s Guide to Steel Frame Construction.http://www.steelframing.org/PDF/SFA Framing Guide final%202.pdf 2011.09.12[4]http://en.wikipedia.org/wiki/Crane %28machine%29 2011.09.12[5]http://www.hoistquip.co.uk 2011.09.13[6]http://www.bairstow.com 2011.09.13Vidovszky – BUTE/BME-Faculty of Architecture – Department of Construction Technology and Management9/11/201221

Construction of Steel structures István VidovszkyPhD historic overview Vidovszky –BUTE/BME-Faculty of Architecture –Department of Construction Technology and Management 9/11/2012 2 round 800 B.C. the general use of iron 16th-19th century wrought iron / cast iron (in Europe) round 1870 A.D. the first production of modern steel late 19th century multi-storey iron structure buildings early .