Transcription

PRECASTCONCRETEUNDERGROUNDUTILITY VAULTS

OUTLINE PurposePrecast AdvantagePurpose of Utility VaultsUses of Utility VaultsApplicable StandardsStructural DesignMaterialsProductionInstallationNPCA Plant Certification

PURPOSE Provide current and accuratetechnical information as it relates tothe design, production andinstallation of precast concrete utilityvaults.

PRECAST ADVANTAGE Available nationwideEnvironmentally friendlyNon-combustibleLong life span and durabilityDelivered and set by manufacturerLess maintenance than CMUEasily designed to withstand traffic or aircraft loadingMassFaster installation – large structures easily designedProduced in a controlled environmentCost effective

PURPOSE Provide easy accessto equipment formaintenance. Provide structurallysound enclosure. Provide a secureenclosure for costlyequipment.

PURPOSE of UTILITY VAULT Protect vital underground connections and controlsfor utility distribution.

APPLICATION

APPLICATION

APPLICATION

APPLICATION

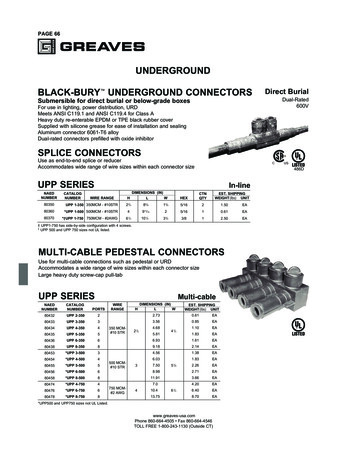

USES of UTILITY VAULTS Communications Electricity Gas Steam

APPLICABLE STANDARDS ASTM C 857 Practice for Minimum Structural Design Loadingfor Underground Precast Concrete UtilityStructures ASTM C 858 Specification for Underground Precast ConcreteUtility Structures ASTM C 891 Practice for Installation of Underground PrecastConcrete Utility Structures

APPLICABLE STANDARDS ASTM C 1037 Practice for Inspection ofUnderground PrecastConcrete Utility Structures

APPLICABLE STANDARDS ACI 318 Building Code Requirements for StructuralConcrete AASHTO Specification for Highway Bridges Project Specific Requirements

REFERENCES NPCA BestPractices Manual –Precast ConcreteUtility VaultManufacturing

REFERENCES NPCA QualityControl Manualfor Precast Plants Local Codes andRegulations

STRUCTURAL DESIGN Loading Conditions Surface surchargeConcentrated wheel loadsLateral loadsPresumptive soil bearing capacityBuoyant forcesConnections and penetrationsPoint loadsLive loadsDead loads

STRUCTURAL DESIGN Concrete Thickness Sufficient to meet minimum reinforcement cover andwithstand design loading conditions. Concrete Mix Design Concrete Compressive Strength – Minimum 4,000 psistrength at 28 days. w/c .45 (water/cementitious ratio). Quality materials using well-graded aggregates. Air entrained in accordance with ACI 318. Reinforcement Reinforcement design by structural calculations as requiredby code or as proven by testing.

MATERIALS CementThe majority of cementused in the manufacturedconcrete products industryis governed by ASTM C 150“Standard Specification forPortland Cement.”

MATERIALS AggregatesWell-graded, sound,nonporous aggregateconforming to ASTMC 33, “StandardSpecification forConcrete Aggregates,”is essential in theproduction of highquality precastconcrete.

MATERIALS WaterWater for mixing high-qualityprecast concrete shall meetASTM C1602, “StandardSpecification for Mixing WaterUsed in the Production ofHydraulic Cement Concrete.”

MATERIALS Admixtures & SupplementaryCementitious Materials (SCMs)Admixtures and SCMs allow the manufacturer to finetune and enhance the properties of the concrete mix. Air entraining admixtures per ASTM C 260 improvefreeze-thaw properties while SCMs per ASTM C595and C618 have impacts upon the water content andcan lead to significant improvements in the physicalproperties of the concrete. Today, precast concrete is thehigh-tech material of choice.

MATERIALS Reinforcement Reinforcement of concreteis required and must beprovided and designed tomeet structural loading andhandling conditions of thestructure.

MATERIALS Reinforcement Reinforcement types canvary from WWM toconventional rebar tofibers – all reinforcementmust comply withapplicable standards.

PRODUCTION Pre-pour Inspection Trained and qualified plant personnel performinspection before each pour to verify formcleanliness, proper amount of release agent, andreinforcing steel placement and configuration. Post-pour Inspection As an essential part of the production process, thepost-pour inspection verifies product conformanceto project specifications.

PRODUCTION Final Inspection Validation of Quality

INSTALLATION Proper installation is absolutelycritical for maintaining the inherentquality of plant-manufacturedconcrete utility structures, andconsiderations include: Proper connections Planning for site conditions Excavation and bedding

INSTALLATION Vault placement Proper sealing methods Installation of access risers and entry Penetrations Backfilling procedures

NPCA PLANT CERTIFICATION Quality ControlManual to ensure theproduction of qualityprecast products Plant Inspectionsconducted by thirdparty consultants

is governed by ASTM C 150 “Standard Specification for Portland Cement.” MATERIALS Aggregates Well-graded, sound, nonporous aggregate conforming to ASTM C 33, “Standard Specification for Concrete Aggregates,” is essential in the production of high-quality precast concrete. MATERIALS Water Water for mixing high-quality precast concrete shall meet ASTM C1602, “Standard .