Transcription

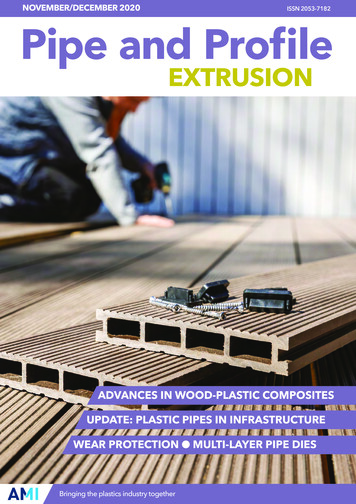

EOMENGINEERING OPERATION& MAINTENANCEP2 ClampedPlastic PumpWhere Innovation FlowsWIL-10150-E-10

ContentsSection 1: Precautions - Read First!4Section 2: Wilden Pump Designation System5Section 3: How It Works —Pump & Air Distribution System6Section 4: Dimensional Drawings7P2 Pla st ic7Section 5: Performance8P2 Pla st ic R ubb er - F i tte d8P2 Pla st ic T PE - F it te d8P2 Pla st ic R edu ced - S tro k e PT F E - F i tte d9P2 Pla st ic F u ll- Str ok e PT F E - F itt ed9Su ct ion - Li ft Cur ve s10Section 6: Suggested Installation, Operation,11Maintenance and TroubleshootingSection 7: Disassembly / Reassembly14Pu mp Di sa ss emb ly14Ai r Va lve / Ce nte r Se ct ion D isa ss emb ly18Rea ss emb ly H in ts & T i ps18Gas ke t Ki t I ns tal la tio n21Section 8: Exploded View and Parts List20P2 Pla st ic F u ll - Stro ke D i aphra gm - Fi tte d .22P2 Pla st ic R edu ced - Str ok e D ia phra gm - Fi tte d .24Section 9: Elastomer OptionsWIL-10150-E-10262Wilden

CopyrightCopyright 2018 PSG , a Dover Company. All rights reserved.PSG reserves the right to modify the information and illustrations in this document without prior notice. Theproduct described in this document is furnished under a license agreement or nondisclosure agreement. Nopart of this document may be reproduced, stored in a retrieval system, or transmitted in any form or anymeans electronic or mechanical, including photocopying and recording, without the written permission of PSG,a Dover Company, except as described by the terms of those agreements.This is a non-contractual document. 01-2019.TrademarksPSG and the PSG logo are registered trademarks of PSG. Wilden is a registered trademark of PSGCalifornia LLC. Pro-Flo SHIFT and Pro-Flo are registered trademarks of PSG California LLC. Wil-Flex is atrademark of PSG California LLC. Saniflex is a trademark of PSG California LLC.All trademarks, names, logos and service marks (collectively "trademarks") in this document are registeredand unregistered trademarks of their respective owners. Nothing contained in this document should beconstrued as granting any license or right to use any trademark without the prior written permission of thetrademark owner.WarrantyEach and every product manufactured by Wilden is built to meet the highest standards of quality. Every pumpis functionally tested to insure integrity of operation. Wilden warrants that pumps, accessories and partsmanufactured or supplied by it to be free from defects in material and workmanship for a period of five (5)years from date of installation or six (6) years from date of manufacture, whichever comes first.For more information, and to register your Wilden pump for warranty, please en

Section 1Precautions - Read First!TEMPERATURE LIMITS:AcetalBuna-NGeolast NeopreneNordel EPDMNylonPFAPolypropylenePolyurethanePVDFSaniflex SIPD PTFE with EPDMbackedSIPD PTFE with NeoprenebackedPTFE1FKMWil-Flex –29 C to 82 C–12 C to 82 C–40 C to 82 C–18 C to 93 C–51 C to 138 C–18 C to 93 C–7 C to 107 C0 C to 79 C–12 C to 66 C–12 C to 107 C–29 C to 104 C4 C to 137 C–20 F to 180 F10 F to 180 F–40 F to 180 F0 F to 200 F–60 F to 280 F0 F to 200 F45 F to 225 F32 F to 175 F10 F to 150 F10 F to 225 F–20 F to 220 F40 F to 280 F4 C to 93 C40 F to 200 F4 C to 104 C–40 C to 177 C–40 C to 107 C40 F to 220 F–40 F to 350 F–40 F to 225 FCAUTION: Before any maintenance or repair isattempted, the compressed air line to the pump shouldbe disconnected and all air pressure allowed to bleedfrom pump. Disconnect all intake, discharge and airlines. Drain the pump by turning it upside down andallowing any fluid to flow into a suitable container).CAUTION: Blow out air line for 10 to 20 secondsbefore attaching to pump to make sure all pipe linedebris is clear . Use an in-line air filter.A 5µ (micron) air filter is recommended.NOTE: Tighten clamp bands and retainers prior toinstallation. Fittings may loosen during transportation.NOTE: When installing PTFE diaphragms, it isimportant to tighten outer pistons simultaneously(turning in opposite directions) to ensure tight fit.NOTE : Before starting disassembly, mark a line fromeach liquid chamber to its corresponding air chamber.This line will assist in proper alignment duringreassembly.4 C to 149 C (40 F to 300 F) - 13 mm (1/2”) and 25 mm (1”)models only.1NOTE: Not all materials are available for all models. Refer to Section 2 formaterial options for your pump.CAUTION: Verify the chemical compatibility of theprocess and cleaning fluid to the pump’s componentmaterials in the Chemical Resistance Guide.CAUTION: When choosing pump materials, be sure tocheck the temperature limits for all wetted components.Example: FKM has a maximum limit of 177 C (350 F) butpolypropylene has a maximum limit of only 79 C (175 F).CAUTION: When removing the end cap usingcompressed air, the air valve end cap may come outwith considerable force. Hand protection such as apadded glove or rag should be used to capture theend cap.CAUTION: Maximum temperature limits are based uponmechanical stress only. Certain chemicals will significantlyreduce maximum safe operating temperatures. Consultengineering guide for chemical compatibility and temperaturelimits.CAUTION: P2 PTFE-fitted pumps come standardfrom the factory with expanded PTFE gaskets.(See Gasket Kit Installation.)CAUTION: Always wear safety glasses when operatingpump. If diaphragm rupture occurs, material being pumpedmay be forced out air exhaust.CAUTION: Do not over-tighten the air inlet reducerbushing. Too much torque on the reducer bushingmay damage the air valve muffler plate. Do notexceed 0.9 Nm (8.0 in-lb).WARNING: Prevent static sparking — If static sparkingoccurs, fire or explosion could result. Pump, valves, andcontainers must be properly grounded when handlingflammable fluids and whenever discharge of staticelectricity is a hazard.NOTE: When reinstalling the outer pistons, apply two(2) drops of Loctite 246 to the shaft internal threadsbefore the diaphragm assembly.CAUTION: Do not exceed 8 .6 bar (125 psig) airsupply pressure.CAUTION: P2 pumps are made of virgin plastic and are notUV-stabilized. Direct sunlight for prolonged periods can causedeterioration of plastics.WIL-10150-E-104Wilden

Section 2WILDEN PUMP DESIGNATION SYSTEMP2 PLASTICLEGENDP2/ X X X X X / XXX / XX / X XX /MODEL25 mm (1") PumpMaximum Flow Rate:140 lpm (37 gpm)XXXXO-RINGSVALVE SEAT SPECIALTY CODEVALVE BALLS(if applicable)DIAPHRAGMSAIR VALVECENTER SECTIONOUTER PISTONWETTED PATHMATERIAL CODESMODELP2 PRO-FLO WETTED PATHK PVDFP POLYPROPLYENEOUTER PISTONK PVDFP POLYPROPLYENECENTER SECTIONLL ACETALPP POLYPROPYLENEAIR VALVEP POLYPROPYLENEL ACETALSPECIALTY ard II 110VWil-Gard II sensor wires ONLYWil-Gard II 220VPFA coated hardware,Wil-Gard II sensor wires ONLYP2 plasticP2 plastic, PFA coated hardwareP2 plastic, DIN flangeP2 plastic, PFA coated hardware, DIN flangeP2 plastic, Wil-Gard II sensor wires ONLYP2, PFA coated hardware,Wil-Gard II sensor wires BNS BUNA-N (Red Dot)EPS EPDM (Blue Dot)FSS SANIFLEX [Hytrel (Cream)]NES NEOPRENE (Green Dot)PUS POLYURETHANE (Clear)TEU PTFE W/EPDMBACK-UP (White)TNU PTFE W/NEOPRENEBACK-UP (White)TSU PTFE W/SANIFLEX BACKUP (White)VTS FKM (White Dot)WFS WIL-FLEX [Santoprene (Three Black Dots)]TSS FULL-STROKE PTFEW/SANIFLEX BACKUPTWS FULL-STROKE PTFEW/WIL-FLEX BACKUPP2 plastic, Wil-Gard II 110VP2 plastic, PFA coated hardware,Wil-Gard II 110VP2 plastic, Wil-Gard II 220V, DIN flangeP2 plastic, PFA coated hardware, Wil-Gard II 220V, DIN flangeP2 plastic, Wil-Gard II 220VP2 plastic, SS outer pistonsPFA coated hardwareSplit manifoldSplit manifold, PFA coated hardware056305640603060806600661VALVE BALLSBN BUNA-N (Red Dot)EP EPDM (Blue Dot)FS SANIFLEX [Hytrel (Cream)]NE NEOPRENE (Green Dot)PU POLYURETHANE (Brown)TF PTFE (White)VT FKM (White Dot)WF WIL-FLEX [Santoprene (Three Black Dots)]VALVE SEATSK PVDFP POLYPROPYLENEVALVE SEAT O-RINGBN BUNA-NPU POLYURETHANE (Brown)TV PTFE ENCAP. FKMWF WIL-FLEX [Santoprene ]Split manifold, discharge ONLYSplit manifold, inlet ONLYPFA coated hardware, Wil-Gard II 110VPFA coated hardware, Wil-Gard II 220VSplit manifold, Wil-Gard II 110VSplit manifold, PFA coated hardware,Wil-Gard II 110VNOTE: Most Elastomeric materials use colored dots for identification.NOTE: Not all models are available with all material options.Hytrel is a registered trademark of DuPont Dow Elastomers.WIL-10150-E-105Wilden

Section 3HOW IT WORKS — PUMPThe Wilden diaphragm pump is an air-operated, placement, self-priming pump. These drawings show the flow patternthrough the pump upon its initial stroke. It is assumed the pump has no fluid in it prior to its initial stroke.FIGURE 1 The air valve directs pressurizedair to the back side of diaphragm A. Thecompressed air is applied directly to theliquid column separated by elastomericdiaphragms. The diaphragm acts as aseparation membrane between thecompressed air and liquid, balancing theload and removing mechanical stress fromthe diaphragm. The compressed air movesthe diaphragm away from the center blockof the pump. The opposite diaphragm ispulled in by the shaft connected to thepressurized diaphragm. Diaphragm B is onits suction stroke; air behind the diaphragmhas been forced out to the atmospherethrough the exhaust port of the pump. Themovement of diaphragm B toward thecenter block of the pump creates a vacuumwithin chamber B. Atmospheric pressureforces fluid into the inlet manifold forcingthe inlet valve ball off its seat. Liquid is freeto move past the inlet valve ball and fill theliquid chamber (see shaded area).FIGURE 2 When the pressurizeddiaphragm, diaphragm A, reaches the limitof its discharge stroke, the air valveredirects pressurized air to the back side ofdiaphragm B. The pressurized air forcesdiaphragm B away from the center blockwhile pulling diaphragm A to the centerblock. Diaphragm B is now on its dischargestroke. Diaphragm B forces the inlet valveball onto its seat due to the hydraulic forcesdeveloped in the liquid chamber and manifold of the pump. These same hydraulicforces lift the discharge valve ball off itsseat, while the opposite discharge valveball is forced onto its seat, forcing fluid toflow through the pump discharge. Themovement of diaphragm A toward thecenter block of the pump creates a vacuumwithin liquid chamber A. Atmosphericpressure forces fluid into the inlet manifoldof the pump. The inlet valve ball is forcedoff its seat allowing the fluid being pumpedto fill the liquid chamber.FIGURE 3 At completion of the stroke,the air valve again redirects air to theback side of diaphragm A, which startsdiaphragm B on its exhaust stroke. As thepump reaches its original starting point,each diaphragm has gone through oneexhaust and one discharge stroke. Thisconstitutes one complete pumping cycle.The pump may take several cycles tocompletely prime depending on theconditions of the application.HOW IT WORKS — AIR DISTRIBUTION SYSTEMThe Pro-Flo patented air distribution system incorporates twomoving parts: the air valve spool and the pilot spool. The heartof the system is the air valve spool and air valve. This valvedesign incorporates an unbalanced spool. The smaller end ofthe spool is pressurized continuously, while the large end isalternately pressurized then exhausted to move the spool. Thespool directs pressurized air to one air chamber whileexhausting the other. The air causes the main shaft/diaphragmassembly to shift to one side — discharging liquid on that sideand pulling liquid in on the other side. When the shaft reachesthe end of its stroke, the inner piston actuates the pilot spool,which pressurizes and exhausts the large end of the air valvespool. The repositioning of the air valve spool routes the air tothe other air chamber.WIL-10150-E-106Wilden

DIMENSIONAL DRAWINGP2 PlasticDIMENSIONSITEMMETRIC (mm)STANDARD .84.55.40.4STUSTUWIL-10150-E-107DIN84 DIA.114 DIA.15 DIA.ANSI79 DIA.109 DIA.15 DIA.3.3 DIA.4.5 DIA.0.6 DIA.3.1 DIA.4.3 DIA.0.6 DIA.Wilden

Section 5PERFORMANCEP2 PLASTICRUBBER-FITTEDShip Weight . Polypropylene 8 kg (18 lb)PVDF 10 kg (23 lb)Air Inlet . 6 mm (1/4")Inlet. .25 mm (1")Outlet . 25 mm (1")Suction Lift . 5.5 m Dry (18.0')8.8 m Wet (29.0')Disp. Per Stroke1 . 0.31 L (0.082 gal)Max. Flow Rate . 140 lpm (37 gpm)Max. Size Solids . 3.2 mm (1/8")1Displacement per stroke was calculatedat 4.8 bar (70 psig) air inlet pressure againsta 2 bar (30 psig) head pressure.Example: To pump 68 lpm (18 gpm)against a discharge pressure head of2.7 bar (40 psig) requires 4.1 bar (60 psig)and 21.9 Nm3/h (13 scfm) air consumption.(See dot on chart.)Caution: Do not exceed 8.6 bar (125 psig)air supply pressure.Flow rates indicated on chart were determined by pumping water.For optimum life and performance, pumps should be specified so that dailyoperation parameters will fall in the center of the pump's performance curve.P2 PLASTICTPE-FITTEDShip Weight . Polypropylene 8 kg (18 lb)PVDF 10 kg (23 lb)Air Inlet . 6 mm (1/4")Inlet. .25 mm (1")Outlet . 25 mm (1")Suction Lift . 5.5 m Dry (18.0')8.8 m Wet (29.0')Disp. Per Stroke1 . 0.39 L (0.104 gal)Max. Flow Rate . 140 lpm (37 gpm)Max. Size Solids . 3.2 mm (1/8")1Displacement per stroke was calculatedat 4.8 bar (70 psig) a

WIL-10150-E-10 6 Wilden The Wilden diaphragm pump is an air-operated, placement, self-priming pump. These drawings show the flow pattern through the pump upon its initial stroke. It is assumed the pump has no fluid in it prior to its initial stroke. FIGURE 1 The air valve directs pressurized air to the back side of diaphragm A. The compressed air is applied directly to the liquid column .