Transcription

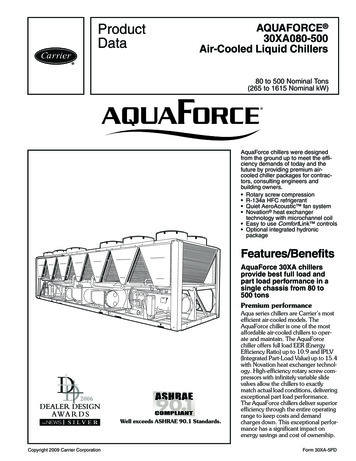

ProductDataAQUAFORCE 30XA080-500Air-Cooled Liquid Chillers80 to 500 Nominal Tons(265 to 1615 Nominal kW) AquaForce chillers were designedfrom the ground up to meet the efficiency demands of today and thefuture by providing premium aircooled chiller packages for contractors, consulting engineers andbuilding owners. Rotary screw compression R-134a HFC refrigerant Quiet AeroAcoustic fan system Novation heat exchangertechnology with microchannel coil Easy to use ComfortLink controls Optional integrated hydronicpackageFeatures/BenefitsAquaForce 30XA chillersprovide best full load andpart load performance in asingle chassis from 80 to500 tonsPremium performancea30-4024Well exceeds ASHRAE 90.1 Standards.Copyright 2009 Carrier CorporationAqua series chillers are Carrier’s mostefficient air-cooled models. TheAquaForce chiller is one of the mostaffordable air-cooled chillers to operate and maintain. The AquaForcechiller offers full load EER (EnergyEfficiency Ratio) up to 10.9 and IPLV(Integrated Part-Load Value) up to 15.4with Novation heat exchanger technology. High-efficiency rotary screw compressors with infinitely variable slidevalves allow the chillers to exactlymatch actual load conditions, deliveringexceptional part load performance.The AquaForce chillers deliver superiorefficiency through the entire operatingrange to keep costs and demandcharges down. This exceptional performance has a significant impact onenergy savings and cost of ownership.Form 30XA-5PD

Features/Benefits (cont)AquaForce chillers’ quietoperation make themideal for sound sensitiveapplicationsGreat performance is delivered in a lowsound unit that will be quiet enough forany application including hospitals,schools and other sites located inresidential neighborhoods. TheAquaForce chiller’s AeroAcoustic fanis almost twice as quiet per cfm as thecompetition. In part load operation,such as cooler weather or night timeduty, fewer fans operate. This results ineven quieter operation.Built in reliabilityAquaForce chillers were developedunder one of the most exactingqualification programs ever usedfor commercial chiller products.The compressors are virtuallymaintenance-free and protected byan auto-adaptive control that minimizes compressor wear. OperateAquaForce chillers year-round from–20 F (–29 C) to 125 F (52 C), with acombination of options and controlmethods. The following features arealso provided to help ensure reliableperformance:Multiple independent circuitsprovide redundancy and greaterreliability.Electronic expansion valve (EXV)allows for precise control through alloperating ranges.Highly efficient, reliablechilled water circuitAquaForce chillers provide a comprehensive chilled water circuit utilizing ahigh-efficiency shell-in-tube floodedcooler. Units are equipped with adrainable cooler.Table of contentsElectronic thermal-dispersionflow switch is included with the cooler. The switch is factory installed andtested and contains no moving partsfor high reliability.Environmentally soundRefrigerant R-134a enables the user tomake a responsible choice in helpingto preserve the environment. Refrigerant R-134a is an HFC refrigerant thatdoes not contain ozone-layer damaging chlorine. This refrigerant isunaffected by the Montreal Protocol. Itis a safe, non-toxic*, efficient and environmentally sound refrigerant.Easy installationA single chassis design provides aone-piece unit from 80 to 500 tons.The base rail is industrial-quality coldrolled steel for maximum structural integrity. The base rail is 1/4-in. withRTFP (round tube, plate fin) coils or7 ga with MCHX (microchannel) coils.The zinc-dipped galvanized frame (withSermaGuard coated screws) providesthe best protection on the market forcorrosion resistance. With such a structurally sound base, no perimeter baserail is needed.ComfortLinkTM controls forease of useThe ComfortLink controls communicate in easy to understand English,making it as easy as possible to monitor and control each AquaForce chillerwhile accurately maintaining fluidtemperatures. ComfortLink controlsare available with French, Portugueseand Spanish as a standard configuration option. Carrier 30 Series chillers’ComfortLink controls provide features such as chilled water temperaturereset, demand limiting, compressorwear minimization and protection,temperature and pressure displays andPageFeatures/Benefits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3Model Number Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4ARI Capacity Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5Physical Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-19Options and Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20-22Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23-49Selection Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50,51Performance Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52-59Typical Piping and Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60-62Electrical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63-75Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75-77Control and Power Wiring Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . 78Application Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79-85Guide Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86-912diagnostic functions. These controlsresult in higher chiller reliability, simplified training and more productive service calls with correspondingly loweroperational and maintenance costs.Two user interface options areavailable, the Touch Pilot display andthe Navigator module. The TouchPilot display is an easy to use touchscreen display that provides simplenavigation for configuration and control of AquaForce units.Carrier's exclusive handheld Navigator display provides convenience andpowerful information in the palm ofyour hand. The Navigator display helpstechnicians to quickly diagnose problems and even prevent them fromoccurring. All AquaForce units areready to be used with Carrier ComfortNetwork (CCN) devices.Novation heat exchangertechnologyThe Novation heat exchanger designwith microchannel (MCHX) condensercoil is a robust, cost effective alternative to traditional coil design. Thesecoils are offered coated or uncoated tomatch coil protection to site conditions. The Carrier Electronic Catalog(E-Cat) can be used to determinewhether or not corrosion protection isrecommended for particular applications in coastal/marine environments.Following the input of the requesteddata, the E-Cat program output will advise the appropriate coil to be used.Other factors described in "SelectionGuide: Environmental Corrosion Protection, Novation Heat Exchanger withMicrochannel Coil Technology" catalognumber 04-581042-01 must also beconsidered to determine if corrosionprotection is required.Microchannel coils are sturdier thanother coil types, making them easier toclean without causing damage to thecoil.Due to the compact all aluminumdesign, microchannel coils will reduceoverall unit operating weight by 6 to7%. The streamlined MCHX coil design reduces refrigerant charge by upto 30%.The coil is designed with rubber isolation around the powder painted coilframe to eliminate galvanic coupleswhich can cause corrosion due to dissimilar metals.*Under ASHRAE Standard 34-1992, R-134a isclassified as an A1refrigerant.

a30-4456TOUCH PILOT DISPLAYa30-4458OPTIONAL PUMP PACKAGE30-562SMOOTH ROTARY COMPRESSORTWIN-SCREW DESIGNComfortLinka30-3926MODEAlarmRunStatusService TestTemperaturesPressuresSetpointsStatusLOW-NOISE AEROACOUSTIC essESCAlarmENTERTUBESa30-3924FINSOPTIONAL NAVIGATOR DISPLAYAEROACOUSTIC FAN vs. PROPELLER FANSOUND POWER [dB(A)]90858075706560PENETRATES 10801600240040001/3 OCTAVE BAND CENTER FREQUENCY (Hz)AEROACOUSTIC FAN63008000a30-3162PROPELLER FANAEROACOUSTIC FAN VS PROPELLER FANa30-4457MICROCHANNELSNOVATION HEAT EXCHANGER TECHNOLOGYWITH MICROCHANNEL CONDENSER COILS3

Model number nomenclaturePackaging/Security Options0 – Coil Face Shipping Protection (CFSP), Skid1 – CFSP, Skid, Top Crate, Bag3 – CFSP, Coil Trim Panels4 – CFSP, Skid, Coil Trim Panels5 – CFSP, Skid, Top Crate, Bag, Coil Trim Panels7 – CFSP, Coil Trim Panels, Upper and Lower Grilles8 – CFSP, Skid, Coil Trim Panels, Upper and Lower Grilles9 – CFSP, Skid, Top Crate, Bag, Coil Trim Panels, Upper and Lower GrillesC – CFSP, Trim Panels, Upper and Lower Grilles, Upper Hail GuardsD – CFSP, Skid, Coil Trim Panels, Upper and Lower Grilles, Upper Hail GuardsF – CFSP, Skid, Top Crate, Bag, Trim Panels, Upper and Lower Grilles,Upper Hail GuardsL – CFSP30XA – AquaForce Air-Cooled ChillerDesign SeriesUnit Sizes080 140 240090 160 260100 180 280110 200 300120 220 325350400450500Voltage1 – 575-3-602 – 380-3-604 – 230-3-606 – 460-3-607 – 200-3-60Controls/Communication Options- – Navigator Display0 – Navigator Display, EMM1 – Navigator Display, Service Option2 – Navigator Display, EMM, Service Option3 – Touch Pilot Display4 – Touch Pilot Display, EMM5 – Touch Pilot Display, Service Option6 – Touch Pilot Display, EMM, Service Option7 – Navigator Display, BACnet Translator8 – Navigator Display, BACnet Translator, EMM9 – Navigator Display, BACnet Translator, Service OptionB – Navigator Display, BACnet Translator, EMM, Service OptionC – Touch Pilot Display, BACnet TranslatorD – Touch Pilot Display, BACnet Translator, EMMF – Touch Pilot Display, BACnet Translator, Service OptionG – Touch Pilot Display, BACnet Translator, EMM, Service OptionH – Navigator Display, LON TranslatorJ – Navigator Display, LON Translator, EMMK – Navigator Display, LON Translator, Service OptionL – Navigator Display, LON Translator, EMM, Service OptionM – Touch Pilot Display, LON TranslatorN – Touch Pilot Display, LON Translator, EMMP – Touch Pilot Display, LON Translator, Service OptionQ – Touch Pilot Display, LON Translator, EMM, Service OptionCondenser Coil/Ambient/Low Sound Options- – Aluminum Fin/Copper Tube, High Ambient Temperature0 – Copper Fin/Copper Tube, High Ambient Temperature1 – Aluminum Pre-Coat Fin/Copper Tube, High Ambient Temperature2 – Aluminum E-Coat Fin/Copper Tube, High Ambient Temperature3 – Copper E-Coat Fin/Copper Tube, High Ambient Temperature4 – Novation Heat Exchanger (MCHX), High AmbientTemperature5 – MCHX E-Coat, High Ambient Temperature6 – Aluminum Fin/Copper Tube, High Ambient Temperature,Low Sound7 – Copper Fin/Copper Tube, High Ambient Temperature, Low Sound8 – Aluminum Pre-Coat Fin/Copper Tube, High Ambient Temperature,Low Sound9 – Aluminum E-Coat Fin/Copper Tube, High Ambient Temperature,Low SoundB – Copper E-Coat Fin/Copper Tube, High Ambient Temperature,Low SoundC – MCHX, High Ambient Temperature, Low SoundD – MCHX E-Coat, High Ambient Temperature, Low SoundF – Aluminum Fin/Copper Tube, Standard Ambient Temperature,Low SoundG – Copper Fin/Copper Tube, Standard Ambient Temperature,Low SoundH – Aluminum Pre-Coat Fin/Copper Tube, Standard AmbientTemperature, Low SoundJ – Aluminum E-Coated Fin/Copper Tube, Standard AmbientTemperature, Low SoundK – Copper E-Coat Fin/Copper Tube, Standard Ambient Temperature,Low SoundL – MCHX, Standard Ambient Temperature, Low SoundM – MCHX E-Coat, Standard Ambient Temperature, Low SoundN – Aluminum Fin/Copper Tube, Standard Ambient TemperatureP – Copper Fin/Copper Tube, Standard Ambient TemperatureQ – Aluminum Pre-Coat Fin/Copper Tube, Standard AmbientTemperatureR – Aluminum E-Coat Fin/Copper Tube, Standard AmbientTemperatureS – Copper E-Coat Fin/Copper Tube, Standard Ambient TemperatureT – MCHX, Standard Ambient TemperatureV – MCHX E-Coat, Standard Ambient TemperatureElectrical Options- – Single Point Power, XL, Terminal Block, No Control Transformer0 – Single Point Power, Wye-Delta, Terminal Block, No Control Transformer3 – Dual Point Power, XL, Terminal Block, No Control Transformer4 – Dual Point Power, Wye-Delta, Terminal Block, No Control Transformer7 – Single Point Power, XL, Disconnect, No Control Transformer8 – Single Point Power, Wye-Delta, Disconnect, No Control TransformerC – Dual Point Power, XL, Disconnect, No Control TransformerD – Dual Point Power, Wye-Delta, Disconnect, No Control TransformerH – Single Point Power, XL, Terminal Block, Control TransformerJ – Single Point Power, Wye-Delta, Terminal Block, Control TransformerM – Dual Point Power, XL, Terminal Block, Control TransformerN – Dual Point Power, Wye-Delta, Terminal Block, Control TransformerR – Single Point Power, XL, Disconnect, Control TransformerS – Single Point Power, Wye-Delta, Disconnect, Control TransformerW – Dual Point Power, XL, Disconnect, Control TransformerX – Dual Point Power, Wye-Delta, Disconnect, Control TransformerRefrigeration Circuit Options- – None0 – Suction Line Insulation1 – Suction Service Valves2 – Low Ambient Temperature Head Pressure Control3 – Suction Line Insulation, Suction Service Valves4 – Suction Line Insulation, Low Ambient Temperature Head Pressure Control5 – Suction Service Valves, Low Ambient Temperature Head Pressure Control6 – Suction Line Insulation, Suction Service Valves, Low Ambient TemperatureHead Pressure Control7 – Minimum Load Control8 – Suction Line Insulation, Minimum Load Control9 – Suction Service Valves, Minimum Load ControlB – Low Ambient Temperature Head Pressure Control, Minimum Load ControlC – Suction Line Insulation, Suction Service Valves, Minimum Load ControlD – Suction Line Insulation, Low Ambient Temperature Head PressureControl, Minimum Load ControlF – Suction Service Valves, Low Ambient Temperature Head PressureControl, Minimum Load ControlG – Suction Line Insulation, Suction Service Valves, Low Ambient TemperatureHead Pressure Control, Minimum Load ControlHydronic Pump Package Options- – None1 – Single Pump, 5 HP2 – Single Pump, 7.5 HP3 – Single Pump, 10 HP4 – Single Pump, 15 HP7 – Dual Pump, 5 HP8 – Dual Pump, 7.5 HPB – Dual Pump, 10 HPC – Dual Pump, 15 HPCooler/Brine Options0 – Integral Cooler with Heater3 – Integral Cooler with Heater, Minus One Pass5 – Integral Cooler with Heater, Plus One Pass7 – Integral Cooler with Heater, Full End ScreenH – Integral Cooler with Heater, Plus One Pass, BrineK – Integral Cooler with Heater, Minus One Pass, Full End ScreenM – Integral Cooler with Heater, Plus One Pass, Full End ScreenV – Integral Cooler with Heater, Plus One Pass, Brine, Full End ScreenCFSPEMMLONXL————LEGENDCoil Face Shipping ProtectionEnergy Management ModuleLocal Operating NetworkAcross-the-Line StarterQuality AssuranceCertified to ISO 9001:20004a30-4757

ARI* capacity ratings (English and SI)UNITS WITH AL/CU CONDENSER 01.2326.3347.1374.8449.4509.3549.2FULL LOADIPLVCOOLER FLOW RATECOOLER PRESSURE DROPEERCOPEERCOPGPML/sft 139.346.152.930.534.339.040.144.431.029.936.0UNITS WITH MCHX CONDENSER 23.3344.8372.7444.1505.5544.8FULL LOADIPLVCOOLER FLOW RATECOOLER PRESSURE DROPEERCOPEERCOPGPML/sft NDAluminumCoefficient of PerformanceCopperEnergy Efficiency RatioIntegrated Part Load ValueMicrochannel Heat Exchanger*Air Conditioning and Refrigeration Institute (U.S.A.).NOTES:1. Rated in accordance with ARI Standard 550/590 at standard ratingconditions.2. Standard rating conditions are as follows:Cooler Conditions:Leaving water temperature: 44 F (6.7 C)Entering water temperature: 54 F (12.2 C)Fouling Factor:0.00010 hr x sq ft F/Btu (0.000018 m2 x C/W)Condenser Conditions:Entering air temperature:95 F (35 C)5

Physical data30XA080-500 — ENGLISHUNIT 30XAOPERATING WEIGHT (lb)*Al-Cu Condenser CoilsCu-Cu Condenser CoilsMCHX Condenser CoilsREFRIGERANT TYPERefrigerant Charge (lb) Ckt A/Ckt B/Ckt CRefrigerant Charge (lb) Ckt A/Ckt B/Ckt C (MCHX)COMPRESSORSQuantitySpeed (rpm)(Qty) Compressor Model Number Ckt A(Qty) Compressor Model Number Ckt B(Qty) Compressor Model Number Ckt COil Charge (gal), Ckt A/Ckt B/Ckt CMinimum Capacity Step 225/—161/161/—270/225/—170/161/—R-134a, EXV Controlled emi-Hermetic Twin Rotary Screws2222223500(1) 06TS-137† (1) 06TS-137 (1) 06TS-155 (1) 06TS-186 (1) 06TS-186 (1) 06TT-266 (1) 06TT-301 (1) 06TT-266 (1) 06TT-301 (1) 06TT-356(1) 06TS-137† (1) 06TS-137 (1) 06TS-155 (1) 06TS-155 (1) 06TS-186 (1) 06TS-155 (1) 06TS-186 (1) 06TT-266 (1) 06TT-301 (1) 5/—6.25/5.5/—6.25/6.25/— 6.25/6.25/— 43525143525143525143525143CONDENSER FANSFan Speed (rpm) Standard/High Ambient**No. Blades.Diameter (in.)No. Fans (Ckt A/Ckt B/Ckt C)Total Airflow (cfm) 850 rpmTotal Airflow (cfm) 1140 ,400—850/—9.304/4/—74,400—Shrouded Axial Type, Vertical 093,000——124,000124,000CONDENSER COILSNo. Coils (Ckt A/Ckt B/Ckt C)Total Face Area (sq et Fluid Volume (gal.)Maximum Refrigerant Pressure (psig)Maximum Water Side Pressure Without Pumps (psig)Maximum Water Side Pressure With Pumps (psig)WATER CONNECTIONSDrain (NPT, in.)Standard, Inlet and Outlet, Victaulic (in.)Number of PassesMinus 1 Pass, Inlet and Outlet, Victaulic (in.)Number of PassesPlus 1 Pass, Inlet and Outlet, Victaulic (in.)Number of PassesHYDRONIC MODULE (Optional)PumpCHASSIS DIMENSIONS (ft-in.)LengthWidthHeightUNIT 30XAOPERATING WEIGHT (lb)*Al-Cu Condenser CoilsCu-Cu Condenser CoilsMCHX Condenser CoilsREFRIGERANT TYPERefrigerant Charge (lb) Ckt A/Ckt B/Ckt CRefrigerant Charge (lb) Ckt A/Ckt B/Ckt C (MCHX)COMPRESSORSQuantitySpeed (rpm)(Qty) Compressor Model Number Ckt A(Qty) Compressor Model Number Ckt B(Qty) Compressor Model Number Ckt COil Charge (gal), Ckt A/Ckt B/Ckt CMinimum Capacity Step (%)StandardOptionalCOOLERNet Fluid Volume (gal.)Maximum Refrigerant Pressure (psig)Maximum Water Side Pressure Without Pumps (psig)Maximum Water Side Pressure With Pumps (psig)WATER CONNECTIONSDrain (NPT, in.)Standard, Inlet and Outlet, Victaulic (in.)Number of PassesMinus 1 Pass, Inlet and Outlet, Victaulic (in.)Number of PassesPlus 1 Pass, Inlet and Outlet, Victaulic (in.)Number of PassesCONDENSER FANSFan Speed (rpm) Standard/High Ambient**No. Blades.Diameter (in.)No. Fans (Ckt A/Ckt B/Ckt C)Total Airflow (cfm) 850 rpmTotal Airflow (cfm) 1140 rpmCONDENSER COILSNo. Coils (Ckt A/Ckt B/Ckt C)Total Face Area (sq uminumElectronic Expansion ValveMicrochannel Heat ExchangerNot �305Flooded, Shell and Tube 6/4/—234Pump(s) with pressure/temperature taps and combination valve.Single or Dual, 3600 a, EXV Controlled 5/415236/170/227415/270/415243/177/227222333(1) 06TT-356(1) 06TT-356N/A6.75/6.75/—(1) 06TU-483(1) 06TT-301N/A7.5/6.75/—(1) 06TU-483(1) 06TT-356N/A7.5/6.75/—Semi-Hermetic Twin Rotary Screws2223500(1) 06TU-554(1) 06TU-483(1) 06TU-554(1) 06TT-356(1) 06TU-483(1) �(1) 06TT-356(1) 06TT-356(1) 06TU-4836.75/6.75/7.5(1) 06TU-554(1) 06TT-266(1) 06TU-5547.5/6.25/7.5(1) 06TU-554(1) 06TT-356(1) 5.0220300—83.0220300—12715101510Flooded, Shell and Tube /7/—3756/6/84698/6/85168/6/8516HYDRONIC MODULE (Optional)PumpCHASSIS DIMENSIONS (ft-in.)LengthWidthHeight1510Shrouded Axial Type, Vertical 535-439-343-27-43/47-67/16*Operating weight includes 2 pumps on models 30XA090-160. No pumps are available on 30XA080 or30XA180-500. All weights include coil trim panels. See pages 8-19 for mounting weights for units without pumps and units with single pump packages.†30XA080 unit does not have an economizer.**The high ambient temperature option is not available on 30XA080-120 units.

30XA080-500 — SIUNIT 30XA0800901001101201401601802002203 4813 8093 2814 5174 9554 2554 6205 0584 3564 6845 1224 4174 7505 1874 4805 7886 3355 4545 8986 4455 5596 1646 8215 7606 2206 8765 8116 6807 3916 .1/73.0/—222222(1) 06TS-137†(1) 06TS-137†N/A20.8/20.8/—(1) 06TS-137(1) 06TS-137N/A20.8/20.8/—(1) 06TS-155(1) 06TS-155N/A20.8/20.8/—Semi-Hermetic Twin Rotary Screws22258.3(1) 06TS-186 (1) 06TS-186 (1) 06TT-266 (1) 06TT-301(1) 06TS-155 (1) 06TS-186 (1) 06TS-155 (1) 06TS-186N/AN/AN/AN/A20.8/20.8/— 20.8/20.8/—23.7/20.8/— 23.7/23.7/—(1) 06TT-266(1) 06TT-266N/A23.7/23.7/—(1) 06TT-301(1) 06TT-301N/A23.7/23.7/—(1) 06TT-356(1) .8119.21516.8128.71516.8140.11516.82 0682 0682 0682 0682 0682 0682 0682 0682 0682 068—1 0341 0341 0341 0341 0341 63CONDENSER FANSFan Speed (r/s) Standard/High Ambient**No. Blades.Diameter (mm)No. Fans (Ckt A/Ckt B/Ckt C)Total Airflow (L/s) 14.2 r/sTotal Airflow (L/s) 19.0 r/s14.2/—9.7623/3/—26 335—14.2/—9.7624/4/—35 113—14.2/—9.7624/4/—35 113—Shrouded Axial Type, Vertical 7629.7629.7624/4/—4/4/—6/4/—6/4/—35 11335 11343 89143 891——58 52258 52214.2/19.09.7626/6/—52 66970 22614.2/19.09.7626/6/—52 66970 22614.2/19.09.7627/6/—57 05976 078CONDENSER COILSNo. Coils (Ckt A/Ckt B/Ckt C)Total Face Area (sq /—267/6/—28OPERATING WEIGHT (kg)*Al-Cu Condenser CoilsCu-Cu Condenser CoilsMCHX Condenser CoilsREFRIGERANT TYPERefrigerant Charge (kg) Ckt A/Ckt B/Ckt CRefrigerant Charge (kg) Ckt A/Ckt B/Ckt C (MCHX)COMPRESSORSQuantitySpeed (r/s)(Qty) Compressor Model Number Ckt A(Qty) Compressor Model Number Ckt B(Qty) Compressor Model Number Ckt COil Charge (liters), Ckt A/Ckt B/Ckt CMinimum Capacity Step (%)StandardOptionalCOOLERNet Fluid Volume (liters)Maximum Refrigerant Pressure (kPa)Maximum Water Side Pressure WithoutPumps (kPa)Maximum Water Side Pressure With PumpsWATER CONNECTIONSDrain (NPT, in.)Standard, Inlet and Outlet, Victaulic (in.)Number of PassesMinus 1 Pass, Inlet and Outlet, Victaulic (in.)Number of PassesPlus 1 Pass, Inlet and Outlet, Victaulic (in.)Number of PassesHYDRONIC MODULE (Optional)PumpCHASSIS DIMENSIONS (mm)LengthWidthHeightUNIT 30XAOPERATING WEIGHT (kg)*Al-Cu Condenser CoilsCu-Cu Condenser CoilsMCHX Condenser CoilsREFRIGERANT TYPERefrigerant Charge (kg) Ckt A/Ckt B/Ckt CRefrigerant Charge (kg) Ckt A/Ckt B/Ckt C (MCHX)COMPRESSORSQuantitySpeed (r/s)(Qty) Compressor Model Number Ckt A(Qty) Compressor Model Number Ckt B(Qty) Compressor Model Number Ckt COil Charge (liter), Ckt A/Ckt B/Ckt CMinimum Capacity Step (%)StandardOptionalCOOLERNet Fluid Volume (liters)Maximum Refrigerant Pressure (kPa)Maximum Water Side Pressure WithoutPumps (kPa)Maximum Water Side Pressure With PumpsWATER CONNECTIONSDrain (NPT, in.)Standard, Inlet and Outlet, Victaulic (in.)Number of PassesMinus 1 Pass, Inlet and Outlet, Victaulic (in.)Number of PassesPlus 1 Pass, Inlet and Outlet, Victaulic (in.)Number of PassesCONDENSER FANSFan Speed (r/s) Standard/High Ambient**No. Blades.Diameter (mm)No. Fans (Ckt A/Ckt B/Ckt C)Total Airflow (L/s) 14.2 r/sTotal Airflow (L/s) 19.0 r/sCONDENSER COILSNo. Coils (Ckt A/Ckt B/Ckt C)Total Face Area (sq inumElectronic Expansion ValveMicro-Channel Heat ExchangerNot Applicable21510117Flooded, Shell and Tube 2Pump(s) with pressure/temperature taps and combination valve. Single or Dual, 58.3 r/s3 6064 8005 994N/A7 1888 382225523002402602803003253504004505006 7537 4646 3047 6448 4657 1307 7218 5427 2027 8768 7517 3228 5439 5287 9238 6369 6218 01011 14912 24310 45012 06613 26911 29512 19913 40211 416R-134a, EXV Controlled System122.5/122.5/— 170.1/99.8/— 170.1/122.5/— 188.3/122.5/— 170.1/170.1/— 188.3/170.1/— 122.5/122.5/170.1 188.3/102/188.3 188.3/188.3/122.577.3/76.4/— 112.3/75.0/— 109.1/77.3/— 111.4/77.3/— 109.1/109.1/— 111.4/109.1/— 77.3/77.3/97.7 107.3/77.3/103.2 110.5/80.5/103.5Semi-Hermetic Twin Rotary Screws223500(1) 06TU-554 (1) 06TU-483 (1) 06TU-554(1) 06TT-356 (1) 06TU-483 (1) .4/—222(1) 06TT-356(1) 06TT-356N/A25.6/25.6/—(1) 06TU-483(1) 06TT-301N/A28.4/25.6/—(1) 06TU-483(1) 9.01516.8166.61516.8183.61516.82 0682 0682 0682 0682 18314.2/19.09.7627/6/—57 05976 07814.2/19.09.7629/6/—65 83787 78214.2/19.09.7629/7/—70 22693 6347/6/—289/6/—339/7/—358HYDRONIC MODULE (Optional)PumpCHASSIS DIMENSIONS (mm)LengthWidthHeightR-134a, EXV Controlled System61/61/—61/61/—92/55/—45.4/45.4/— 43.4/43.4/—62.1/43.6/—2333(1) 06TT-356(1) 06TT-356(1) 06TU-48325.6/25.6/28.4(1) 06TU-554(1) 06TT-266(1) 06TU-55428.4/23.7/28.4(1) 06TU-554(1) 06TT-356(1) 314.21516.82 0682 0682 0682 6/887 782117 04314.2/19.09.7628/6/896 561128 74714.2/19.09.7628/6/896 561128 7476/6/8448/6/8488/6/84815101410Flooded, Shell and Tube Type191.2202.11516.81516.8Shrouded Axial Type, Vertical 210/6/—9/9/—9/9/—70 22679 00479 00493 63493 634105 33910/6/—359/9/—399/9/—39N/A8 3829 57610 7702 2552 30011 96413 158*Operating weight includes 2 pumps on models 30XA090-160. No pumps are available on 30XA080 or30XA180-500. All weights include coil trim panels. See pages 8-19 for mounting weights for units without pumps and units with single pump packages.†30XA080 unit does not have an economizer.**The high ambient temperature option is not available on 30XA080-120 units.7

Physical data (cont)UNIT MOUNTING WEIGHTSUNITS WITHOUT PUMPS AND WITH MCHX CONDENSER COILS — ENGLISH30XAUNIT SIZE08030XAUNIT SIZE09010011012030XAUNIT SIZE14016030XAUNIT SIZE18020030XAUNIT SIZE22024026028030030XAUNIT SIZE32535030XAUNIT SIZE400450500MOUNTING WEIGHT (lb)MCHX CONDENSER COILSABCDTotal19471673167019437234MOUNTING WEIGHT (lb) MCHX CONDENSER 78098120381224834812392136798100620751229848312722

tion option. Carrier 30 Series chillers' ComfortLink controls provide fea-tures such as chille d water temperature reset, demand limiting, compressor wear minimization and protection, temperature and pressure displays and diagnostic functions. These controls result in higher chiller reliability, simpli-fied training and more productive ser-