Transcription

Trane Rotary Screw Air Cooled Chiller 100 TonMfg: TraneModel: RTAA 1004XF01A1COKBDFNStock No. DBPF255.5Serial No. U96D33776Trane Rotary Screw Air Cooled Chiller 100 Ton. Model RTAA 1004XF01A1COKBDFNS/N U96D33776.(2) Trane Compressors, Model CHHN050, 84 amp draw, 460 volt each.(10) Fans, 2-1/2 hp, 1.5 amp draw, 460 volt.Overall Dimensions 87 in. H x 207 in. L x 90 in. W.

Air-Cooled Series R Rotary Liquid ChillerModel RTAA70 to 125 TonsBuilt for the Industrial and Commercial MarketsAugust 2002RLC-PRC016-EN

Features andBenefits 2 2002 American Standard Inc. All rights reserved.You Designed by Customers .Like its chillers, Trane wants itsrelationships with customers to last.Trane is interested in maintaining longterm, loyal relationships. Thisperspective means the point in time thata customer purchases a chiller is thebeginning of a relationship, not the end.Your business is important, but yoursatisfaction is paramount.Trane’s RTAA 70-125 was designed withthe end user’s requirements in mind.Reliability, efficiency, sound, andphysical size were primary designconcerns in expanding the RTAA productline down to 70 tons. The result is areliable chiller that will help you achieveyour bottom line goals.RLC-PRC016-EN

ContentsFeatures and BenefitsThe standard ARI rating condition(54/44 F and 95 F) and IPLV are ARIcertified. All other ratings, including thefollowing, are outside the scope of thecertification program and are excluded: Glycol. 50 Hz. Remote evaporator models.RLC-PRC016-EN2Model Number Description13General Data14Selection Procedure15Application Considerations16Performance Adjustment Factors20Performance Data22Electrical Data29Jobsite Connections30Controls32Dimensional Data40Weights41Options42Typical Wiring Diagrams43Features Summary45Mechanical Specifications46Water Chiller Systems Business Unit3

Features andBenefitsImprovementsThe RTAA 70-125 offers the same highreliability of its larger predecessorcoupled with lowered sound levels,increased energy efficiency, and reducedphysical footprint, all due to its advanceddesign, low speed/direct drivecompressor and proven Series R performance.be at least 10% better than any productstandard for that product. In the case ofchillers, that product standard isASHRAE 90.1. Trane’s RTAA 70-125meets and exceeds the efficiencyrequirements of 90.1, with some unitsmeeting the “stretch goals” of ExecutiveOrder.Some of the major advantages of theModel RTAA 70-125 vs its largerpredecessor are: Higher energy efficiency Lower sound levels Smaller physical footprintThe Series R Model RTAA 70-125 is anindustrial grade design built for both theindustrial and commercial markets. It isideal for schools, hospitals, retailers,office buildings, Internet serviceproviders and industrials.ASHRAE Standard 90.1 and RTAA 70125 World Class Energy Efficiency The importance of energy efficiencycannot be understated. Fortunately,ASHRAE has created a guidelineemphasizing its importance.Nonetheless, energy is often dismissedas an operational cost over which theowner has little control. That perceptionresults in missed opportunities forenergy efficiency, reduced utility bills,and higher profits. Lower utility billsdirectly affect profitability. Every dollarsaved in energy goes directly to thebottom line. Trane’s RTAA 70-125 is oneway to maximize your profits.ASHRAE Standard 90.1 & ExecutiveOrder - New technology applied to thedesign, controls, and manufacturinghave created superior efficiency levels inthe RTAA 70-125 that are unmatched inthe industry. All Trane air-cooled chillersmeet the new efficiency levels mandatedby ASHRAE Standard 90.1. This newstandard requires higher efficienciesthan past technologies can deliver. TheUS Federal Government has adoptedstandard 90.1 and, in some cases,requires even higher efficiencies.Federal Executive Order mandatesenergy consuming devices procuredmust be in the top 25% of their class or4Risk. The US Federal Government hasadopted ASHRAE 90.1, and it’s expectedto be adopted domestically, if notglobally, in the future. Domesticacceptance has already begun. Makesure that your chillers as well as yourentire HVAC system complies, or youmay be caught retrofitting your projectwith new equipment and paying extradesign dollars if the code is adoptedduring construction.Precise Capacity Control. Trane’spatented unloading system allows thecompressor to modulate infinitely andexactly match building loads. At thesame time chilled water temperatureswill be maintained within /- 1/2ºF ofsetpoint, potentially eliminating the needfor external considerations to maintaintemperatures. Reciprocating and screwchillers with stepped capacity control dowell to maintain chilled watertemperatures within 2ºF of setpoint.Stepped control also results inovercooling or undercooling your spacebecause rarely does the capacity of themachine match the building load. Theresult can be 10% higher energy bills.Trane’s RTAA optimizes the part loadperformance of your machine for energyefficiency, precise temperature controlfor all modes of operation, and yourpersonal comfort regardless of changingconditions.RLC-PRC016-EN

Features andBenefitsExcellent ReliabilityA building environment is expected tobe comfortable. When it is, no one saysa word. If it’s not that’s a differentstory. The same is true with chillers. Noone ever talks about chillers, yet alonecompressors, until they fail, and tenetsare uncomfortable and productivity islost. Trane’s helical rotary compressorshave a first year reliability rate of over99%, which means our chillers stayrunning when you need them.Screw compressors were designed toreplace the inherent design flaws of areciprocating compressor. Trane’s helicalrotary compressor has successfullyachieved this goal, proven by the over99% reliability rating of our compressorin the first year of operation. A gooddesign like Trane’s should maintain thislevel of reliability for several years ofchiller operation. Not all screwcompressors maintain a high reliabilityand Trane is the only manufacturer thatwill publish a reliability number. Thepoint is to make sure that you are gettinga reliable screw chiller design so that youdon’t end up with the downtime and lostearnings that the industry is trying toRLC-PRC016-ENavoid by getting away fromreciprocating technology.a matter of time before you lose areciprocating compressor.Fewer moving parts. Trane’s helicalrotary compressors have only two majorrotating parts: the male and female rotor.A reciprocating compressor can havemore than 15 times that number ofcritical parts. Multiples of pistons,valves, crankshafts, and connecting rodsin a reciprocating unit all representdifferent failure paths for thecompressor. In fact, reciprocatingcompressors can easily have a failurerate four times that of a helical rotor.Combine this with two to threereciprocating compressors for eachhelical rotary compressor on chillers ofequal tonnage, and statistics tell you it’sRobust parts. Helical rotarycompressors are precisely machinedusing state of the art processes fromsolid metal bar stock. Tolerances aremaintained within a micron or less thana tenth of the diameter of a human hair.The resulting compressor is a robust yethighly sophisticated assembly capable ofingesting liquid refrigerant without riskof damage. Contrast this to areciprocating compressor, which can bedestroyed by a single slug of liquid.Series R Compressor Highlights Direct-drive, low speed for highefficiency and reliability. Simple design with only four movingparts, resulting in high reliability andlow maintenance. Field serviceable compressor for easymaintenance. Precise rotor tip clearance for optimalefficiency. Suction gas-cooled motor, resulting inlower operating temperatures forincreased motor life, and giving thecapability for: Five-minute start-to-start/two minutestop-to-start capability, which allowsfor closer water loop temperaturecontrol.5

Features andBenefitsRTAA 70-125 Chiller Highlights High Reliability, with over 99%compressor reliability rate in the firstyear of operation, and AdaptiveControls to keep the chiller on lineproducing cold water during adverseconditions. High Efficiency (all units exceedASHRAE 90.1 efficiency standard). Low sound levels. Small footprint, with smallest requiredapplication space (operating footprint)in the industry. Years of research, testing, andsuccessful applications. The Tranehelical rotary compressor has amassedthousands of hours of testing, much ofit at severe operating conditions. Notto mention the successful applicationof RTAA chillers for over 11 years, witha developed reputation as the industrystandard. Trouble free startup through factorytesting of compressor and completedchiller and factory installation of chilleraccessories. /- ½ F leaving water temperaturecontrol, resulting from PID feedforward controls, and linear loadmatching, also allowing for 10% flowrate change per minute whilemaintaining ½ F leaving watertemperature control.Trane helical rotary screw compressorcomponent parts versus reciprocatingcompressor components.6RLC-PRC016-EN

Features andBenefitsOptimumEfficienciesSuperior Full Load EfficiencyGreat Part Load EfficiencyWith Trane Helical RotaryScrew Compressors andElectronic Expansion ValvePrecise Rotor Tip ClearancesHigher energy efficiency in a helicalrotary compressor is obtained byreducing the rotor tip clearances. Thisreduces the leakage between high andlow pressure cavities duringcompression. Precise rotor tip clearanceis achieved with the latest manufacturingand machining technology. Trane is thefirst helical rotary compressormanufacturer to electronically checkcompressor parts machining accuracy aspart of the standard production process.Optimized Compressor Parts ProfilesRotor and slide valves are uniquedesigns, optimized for the airconditioning application. The rotors aredesigned for the pressure ranges in theair conditioning application. The unloadervalve has a unique profile that resultedfrom computer performance modeling intypical part-load situations.Trane Helical Rotary Screw CompressorMeans Superior Part Load PerformanceThe air-cooled Series R chiller has greatpart-load performance. The combinationpatented unloading system on the“general purpose” compressor utilizesthe variable unloading valve for themajority of the unloading functionsimilar to that of the slide valve. The“general purpose” compressor alsouses a step unloader valve which is asingle unloading step to achieve theminimum unloading point of thecompressor. The result of both of thesedesigns is optimized part-loadperformance far superior to singlereciprocating compressors.Advanced Heat Transfer SurfacesCondenser and evaporator tubes use thelatest heat transfer technology forincreased efficiency.RLC-PRC016-EN7

Features andBenefitsElectronic Expansion ValveWhen coupled with Trane’s AdaptiveControl microprocessor, our electronicexpansion valve significantly improvespart-load performance of the Series R chiller by minimizing superheat in theevaporator and allowing the chiller torun at reduced condensingtemperatures. Chillers which useconventional TXV’s must run at higherhead pressures and consume morepower than necessary at part-loads.Additionally, the electronic expansionvalve and its controls allow much betterstability and control over dynamic loadand head changes. Under theseconditions a conventional TXV maynever achieve control stability andextended periods of TXV “hunting” andliquid slugging are common.PID Chilled Water SetpointControl Through Slide ValveModulationMaintain Chilled Water Supply Within 1/2 F of SetpointChillers that have step capacity controltypically can only maintain watertemperature to around 2 F. With theair-cooled Series R chiller, maintainingtemperature control has never been soaccurate.Reduce Compressor CyclingModulating capacity control offers bettercompressor reliability. Compressorcycling, typical of reciprocatingcompressors, will decrease compressorcomponent life. Parts like motors andvalves do not stand up well to excessivecompressor cycling.Capacity Control and Load MatchingInfinitely variable compressormodulation allows the compressorcapacity to exactly match the buildingcooling load. Reciprocating and screwchillers that rely on stepped capacitycontrol must run at a capacity equal to orgreater than the load. Much of thisexcess capacity is lost becauseovercooling goes toward building latentheat removal, causing the building to bedried beyond normal comfortrequirements. The result is an increase inchiller energy costs, particularly at thepart-load conditions at which the chilleroperates most of the time.Cutaway view of Trane’s electronic expansion valve.8RLC-PRC016-EN

Features andBenefitsTrouble-Free Installation,Start-Up and OperationAdaptive Control MicroprocessorThe RTAA 70-125 chiller offers advancedmicroprocessor control and features theAdaptive Control microprocessor. Sowhat is the Adaptive Controlmicroprocessor? Adaptive Controlmeans the Unit Control Module (UCM)directly senses the control variables thatgovern operation of the chiller: motorcurrent draw, evaporator temperature,condenser temperature, etc.When any of the variables approaches alimit condition where the unit may bedamaged or shut down on a safety, theUCM takes corrective action to avoidRLC-PRC016-ENshutdown and keep the chiller operating.It does this through combined actions ofcompressor slide valve modulation,electronic expansion valve modulationand fan staging. Additionally, the UCMoptimizes total unit power consumptionduring normal operating conditions. Noother chiller control system in themarketplace duplicates thisperformance.The End Of Most Nuisance Trip-OutsAnd Unnecessary Service Calls?Unnecessary service calls and unhappytenants are reduced. Only when theUCM has exhausted the correctiveactions it can take and the unit is stillviolating an operating limit will the unitshut down. CONTROLS ON OTHERCHILLERS TYPICALLY SHUT DOWN THECHILLER, QUITE PROBABLY JUSTWHEN IT IS NEEDED THE MOST.For example:A typical five-year-old chiller with dirtycoils might trip-out on high pressurecutout on a 100 F day in August. A hotday is just when comfort cooling isneeded the most. In contrast, the aircooled Series R chiller with an AdaptiveControl microprocessor will stage fanson, modulate electronic expansion valve,and modulate slide valve as itapproaches a high pressure cutout.Thereby KEEPING THE CHILLER ONLINE JUST WHEN YOU NEED IT THEMOST.9

Features andBenefitsClose Spacing Of ChillerThe air-cooled Series R chiller has thetightest recommended side clearance inthe industry, four feet, but that is not all.In situations where equipment must beinstalled with less clearance thanrecommended, such as frequentlyoccurs in retrofit and rooftopapplications, restricted air flow iscommon. Conventional chillers may notwork at all. However, the air-cooledSeries R chiller with Adaptive Control microprocessor will simply make asmuch chilled water as it can given theactual installed conditions, stay on lineduring any unforeseen abnormalconditions, and optimize itsperformance. Consult your Trane salesengineer for more details.Factory Testing Means Trouble-FreeStart-UpAll air-cooled Series R chillers are givena complete functional test at the factory.This computer-based test programcompletely checks the sensors, wiring,electrical components, microprocessorfunction, communication capability,expansion valve performance and fans.In addition, each compressor is runtested to verify capacity and powerconsumption. The end result of this testprogram is that the chiller arrives at thejobsite fully tested and ready to go towork.Factory Installed And Tested Controls/Options Speed InstallationAll Series R chiller options, includingcontrol power transformer, starterdisconnect, low ambient control,ambient temperature sensor, lowambient lockout, communicationinterface and ice making controls arefactory installed and tested. Somemanufacturers send options in pieces tobe field installed. With Trane, thecustomer saves on installation expenseand has assurance that ALL chillercontrols/options have been tested andwill function as expected.Lower Service ExpenseNuisance service calls are avoided.When there is a real problem that mustbe corrected, the UCM’s extensivediagnostics help assure that the problemis quickly identified. Down time andservice expense are minimized. And withthe ability to communicate with theTrane Integrated Comfort system or aremote display panel, service problemscan be identified and diagnosed remoteto the installation.10RLC-PRC016-EN

Features andBenefitsSuperior ControlUnit Control Module FeaturesUnit Control ModuleTrane’s Adaptive Control microprocessor control system enhancesthe air-cooled Series R chiller byproviding the very latest chiller controltechnology.Equal Compressor SequencingTrane maximizes both compressor andmotor life by equalizing both the numberof starts and the operating hours. TheUCM will start the compressor with theleast number of starts and turn off thecompressor with the most operatinghours. Conventional “auto” lead-lagcontrol will equalize starts, but runninghours will typically be unequal.Equalizing both starts and running hourswill provide equal compressor wear.State-of-the-Art EquipmentThe 70 to 125 ton air-cooled chillers offerthe exclusive Trane Adaptive Controllogic with the Clear Language Display(UCM). The Clear Language Display hasvarious functions that allow the operatorto read unit information and adjustsetpoints. The Clear Language Displaypanel has 16 keys, the readout screen is atwo-line, 40 character liquid crystal with abacklight. The backlight allows theoperator to read the display in low-lightconditions.Internal “Built-In” Chiller FlowProtectionThe UCM automatically detects a nowaterflow condition. An external flowswitch is not required, which lowerscosts versus typical chillers. Built-in flowprotection also eliminates nuisance flowswitch problems.Remote Clear Language Display Panelfor 70 to 125-ton air-cooled chillers.RLC-PRC016-EN11

Features andBenefitsEasy Chiller System LoggingThe UCM displays data required to logthe chiller system. The followinginformation is available either asstandard or as an option with the AirCooled Series R Chiller microprocessor: Entering and leaving chilled watertemperatures Ambient air temperature Evaporator and condenser refrigeranttemperatures and pressures Compressor suction temperature Percent RLA for each compressor Percent line voltage Compressor starts and running hours Active setpoints:chilled water setpointcurrent limit setpointice termination setpointlow ambient lockout setpoint Over 90 diagnostic and operatingconditions Part failure diagnostics:water temperature sensorsrefrigerant temperature sensorscompressor contactorsRemote Display PanelTrane air-cooled Series R 70-125 tonchillers are available with a twisted pairconnection to an optional remote displaypanel. Chiller operation can be controlledsimilarly to the control interface on thechiller itself. Through a twisted pair ofwires the unit can be turned on or off,change the chilled water setpoint, anddisplay over 90 operating and diagnosticconditions. The remote display panel canbe mounted indoors so access to chillerinformation is just steps away,eliminating any need to go outdoors oron the roof.Easy Interface To The BuildingManagement SystemControlling the air-cooled Series R chiller with building managementsystems is state-of-the-art yet simple.Chiller inputs include: Chiller enable/disable Circuit enable/disable Chilled water setpoint Current limit setpoint Ice making enableChiller outputs include: Compressor running indication Alarm indication (CKt 1/CKt2) Maximum capacityTrane Chiller Plant Manager/ICSThe Tracer Chiller Plant ManagerBuilding Management Systemprovides building automation andenergy management functionsthrough stand- alone control. TheChiller Plant Manager is capable ofmonitoring and controlling your entirechiller plant system.Application software available: Time-of-day scheduling Duty cycle Demand limiting Chiller sequencing Process control language Boolean processing Zone control Reports and logs Custom messages Run time and maintenance Trend log Totalizing PID control loopsAnd of course, Trane’s Chiller PlantManager Panel can be used on astand- alone basis or tied into acomplete building automationsystem.The clear language display for chillersizes of 70-125 tons has the ability tocontrol multiple units. In a multiple unitconfiguration, the Remote ClearLanguage Display Panel has thecapability to communicate with up tofour units. Each unit requires a separatecommunication link with the RemoteDisplay Panel.12RLC-PRC016-EN

Model NumberDescriptionModel Nomenclature Digit Number1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 1770-125 TonsDigits 1,2 — Unit ModelRT Rotary ChillerDigit 3 — Unit TypeA Air CooledDigit 4 — Development SequenceA First SequenceDigit 5, 6 & 7 — Nominal Capacity070 70 tons080 80 tons090 90 tons100 100 tons110 110 tons125 125 tonsDigit 8 — Unit VoltageA 200/60/3C 230/60/3D 380/60/34 460/60/35 575/60/3S SpecialDigit 9 — Compressor Starter TypeY Y-Delta Closed TransitionX X-Line (Across the Line)S SpecialDigit 10, 11 — Design Sequence** Factory InputDigit 12 — Evaporator Leaving Temperature1 Standard 40 to 65 F2 Low 0 to 39 F3 Ice-Making 20 to 65 FS SpecialRLC-PRC016-ENDigit 13 — Condenser Coil Fin MaterialA AluminumS Special2 Copper Fins4 CompleteCoatDigit 14 — Agency Listing0 No Agency Listing3 C/UL ListingDigit 15 — Control InterfaceC Deluxe without CommunicationD Deluxe with CommunicationDigit 16 — Chilled Water Reset0 No Chilled Water Reset1 Based on Return Water Temperature2 Based on Outside Air TemperatureDigit 17 — Miscellaneous Factory InstalledOptionsA Architectural Louvered PanelsB Control Power TransformerC Convenience OutletD Low Ambient Lockout SensorF Mech. Disconnect SwitchG Low Ambient OperationK Coil ProtectionM Access GuardP Circuit Breaker (Single Point Power)Z Circuit Breaker (Dual Point Power)Field Installed OptionsQ Spring IsolatorsN Neoprene IsolatorsR Remote Display Panel3 5 Year Compressor Warranty8 Architectural Louvered Panels9 Coil Protection0 Access GuardJ Remote EvaporatorH Sound Attenuator13

General DataTable G-1 — General Data RTAA — 70-125 TonSizeCompressorQuantityNominal Size (1)EvaporatorWater StorageMin. FlowMax. 9844/443/312.7/12.7CondenserQty of CoilsCoil Length(In)Coil Height(In)Fins/Ft.Number of RowsCondenser FansQuantity (1)Diameter(In)Total Airflow(CFM)Nominal RPMTip Speed(Ft/Min)Motor HP (Ea)Min Starting/Oper Ambient (2)Std Unit(Deg F)Low Ambient(Deg F)General UnitRefrigerantNo. of IndependentRefrigerant Circuits% Min. Load (3)Refrigerant Charge (1)(Lb)(Kg)Oil Charge (1)(Gallons)(Liters)1. Data containing information on two circuits shown as follows: ckt 1/ckt2.2. Minimum start-up/operating ambient based on a 5 mph wind across the condenser.3. Percent minimum load is for total machine at 50 F ambient and 44 F LWT, not each individual circuit.14RLC-PRC016-EN

SelectionProcedureThe chiller capacity tables, P-1 throughP-12, cover the most frequentlyencountered leaving watertemperatures. The tables reflect a 10 F(6 C) temperature drop through theevaporator. For temperature drops otherthan 10 F (6 C), refer to Table F-1, andapply the appropriate Performance DataAdjustment Factors. For chilled brineselections, refer to Figures F-2 and 3 forEthylene and Propylene GlycolAdjustment Factors.To select a Trane air-cooled Series R chiller, the following information isrequired:1. Design load in tons of refrigeration2. Design chilled water temperature drop3. Design leaving chilled watertemperature4. Design ambient temperatureEvaporator flow rates can be determinedby using the following formulas:GPM Tons x 24Temperature Drop (Degrees F)OR L/S kW (Capacity) x .239Temperature Drop (Degrees C)NOTE: Flow rates must fall within thelimits specified in Table G-1 (for GPM orfor l/s).RLC-PRC016-ENSelection ExampleFor example:Given:Corrected Capacity Capacity(unadjusted) x Glycol Flow RateAdjustment FactorRequired System Load 115 TonsLeaving Chilled Water Temperature(LCWT) 44 F Chilled WaterTemperature Drop 10 F DesignAmbient Temperature 95 FEvaporator Fouling Factor 0.00011. To calculate the required chilled waterflow rate we use the formula givenbelow:GPM 115 Tons x 24 276 GPM10 F2. From Table P-6 (RTAA PerformanceData), an RTAA 125 at the givenconditions will produce 120.1 tonswith a compressor power input of136.3 kW and a unit EER of 9.8.3. To determine the evaporator pressuredrop we use the flow rate (GPM) andthe evaporator water pressure dropcurves, Figure F-1. Entering the curveat 276 GPM, the pressure drop for anominal 125 ton evaporator is 18 feet.5. The final unit selection is: QTY (1) RTAA 125 Cooling Capacity 120.1 tons Entering/Leaving Chilled WaterTemperatures 54/44 F Chilled Water Flow Rate 276 GPM Evaporator Water Pressure Drop 18feet Compressor Power Input 136.3 kW Unit EER 9.8Minimum Leaving Chilled WaterTemperature SetpointThe minimum leaving chilled watertemperature setpoint for water is 40 F.For those applications requiring lowersetpoints, a glycol solution must be used.Contact the local Trane sales engineer foradditional information.4. For selection of chilled brine units orapplications where the altitude issignificantly greater than sea level orthe temperature drop is different than10 F, the performance adjustmentfactors from Tables F-1, F-2, and/or F-3should be applied at this point.15

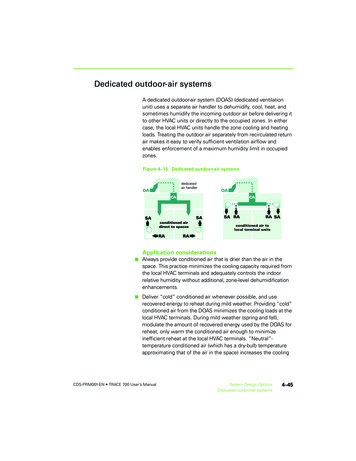

ApplicationConsiderationsApplication ConsiderationsCertain application constraints should beconsidered when sizing, selecting andinstalling Trane air-cooled Series R chillers. Unit and system reliability isoften dependent upon properly andcompletely complying with theseconsiderations. Where the applicationvaries from the guidelines presented, itshould be reviewed with your localTrane sales engineer.Unit SizingUnit capacities are listed in theperformance data section. Intentionallyoversizing a unit to assure adequatecapacity is not recommended. Erraticsystem operation and excessivecompressor cycling are often a directresult of an oversized chiller. In addition,an oversized unit is usually moreexpensive to purchase, install, andoperate. If oversizing is desired, considerusing two units.Unit Placement1. Setting The UnitA base or foundation is not required ifthe selected unit location is level and thebase is strong enough to support theunit’s operating weight as listed in TablesW-1 and W-2.2. Isolation and Sound EmissionThe most effective form of isolation is tolocate the unit away from any soundsensitive area. Structurally transmittedsound can be reduced byELASTOMERIC vibration eliminators.Spring isolators have proven to be oflittle benefit on air-cooled Series R chiller installations and are notrecommended. An acoustical engineershould always be consulted in criticalsound applications.Coil starvation occurs when free airflowto (or from) the condenser is restricted.For maximum isolation effect, waterlines and electrical conduit should alsobe isolated. Wall sleeves and rubberisolated piping hangers can be used toreduce the sound transmitted throughwater piping. To reduce the soundtransmitted through electrical conduit,use flexible electrical conduit.Both warm air recirculation and coilstarvation cause reductions in unitefficiency and capacity because of thehigher head pressures associated withthem. The air-cooled Series R chilleroffers an advantage over competitiveequipment in these situations.Performance is minimally affected inmany restricted air flow situations due toits unique condensing coil geometry.Also, through its advanced AdaptiveControl microprocessor logic, thechiller will attempt to stay on-line wherecompetitive chillers would usually shutdown.State and local codes on soundemissions should always be considered.Since the environment in which a soundsource is located affects sound pressure,unit placement must be carefullyevaluated. Sound power levels for Traneair-cooled Series R chillers are availableon request.3. ServicingAdequate clearance for evaporator andcompressor servicing should beprovided. Recommended minimumspace envelopes for servicing arelocated in the dimensional data sectionand can serve as a guideline forproviding adequate clearance. Theminimum space envelopes also allowfor control panel swing and routinemaintenance requirements. Local coderequirements may take precedence.4. Unit Locationa. GeneralUnobstructed flow of condenser air isessential to maintain chiller capacity andoperating efficiency. When determiningunit placement, careful considerationmust be given to assuring a sufficientflow of air across the condenser heattransfer surface. Two detrimentalconditions are possible and must beavoided if optimum performance is to beachieved: warm air recirculation and coilstarvation.Trane’s unique Adaptive Controlmicroprocessor has the ability tounderstand the operating environmentof the chiller and adapt to it by firstoptimizing its performance and second,staying on lin

Trane Rotary Screw Air Cooled Chiller 100 Ton Mfg: Trane Model: RTAA 1004XF01A1COKBDFN Stock No. DBPF255.5 Serial No. U96D33776 Trane Rotary Screw Air Cooled Chiller 100 Ton. Model RTAA 1004XF01A1COKBDFN S/N U96D33776. (2) Trane Compressors, Model CHHN050, 84 amp draw, 460